3

variety of functions available, circuit diagrams, operating se-

quences, and function descriptions are contained in separate

Application Data publications. Refer to the specific control

publication for details.

CCN Control Arrangement — The CCN control

packages must be used in combination with a thermostat. Ther-

mostats are not included in the CCN package.

4160: Constant volume dual duct

4170: 35N only, variable volume dual duct, constant minimum

cooling (requires cold deck inlet and total flow probe)

4175: 35N only, variable volume dual duct, cooling close-off

during heating (requires hot deck inlet and total flow probe)

4180: 35N only, constant ventilation dual duct, Cooling only

(requires cold deck inlet and total flow probe)

4190: Variable air volume (VAV) with Demand Control Venti-

lation (DCV) requires separate CO2sensor

Analog Electronic Control Arrangement — Con-

trol package is pressure independent and includes a standard

linear airflow sensor in both the hot and cold inlets for variable

air volume control, 24-volt transformer, control enclosures,

and a wall thermostat to match the control type.

Variable volume control:

2400 — Heating and cooling control, hot and cold inlet sensor

location (35L,N)

2440 — Heating and cooling control, hot inlet and discharge

airflow sensing (35N only)

2470 — Heating and cooling control, cold inlet and discharge

airflow sensing (35N only)

Direct Digital Electronic Control Arrangement

(Field Supplied) — Control packages are field supplied

for factory mounting, unless otherwise noted. All DDC control

arrangements include a standard linear inlet flow sensor,

24-volt transformer and control enclosure.

Contact Carrier for details about mounting field-supplied

controls.

Pneumatic Control Arrangement — All control pack-

ages are pressure independent and include standard linear

airflow sensors in both the hot and cold inlets for variable air

volume control or an airflow sensor in one inlet and the unit

discharge for constant volume control arrangements. Thermo-

stats will either be direct acting (DA) or reverse acting (RA),

and damper position will be identified as normally open (NO)

or normally closed (NC).

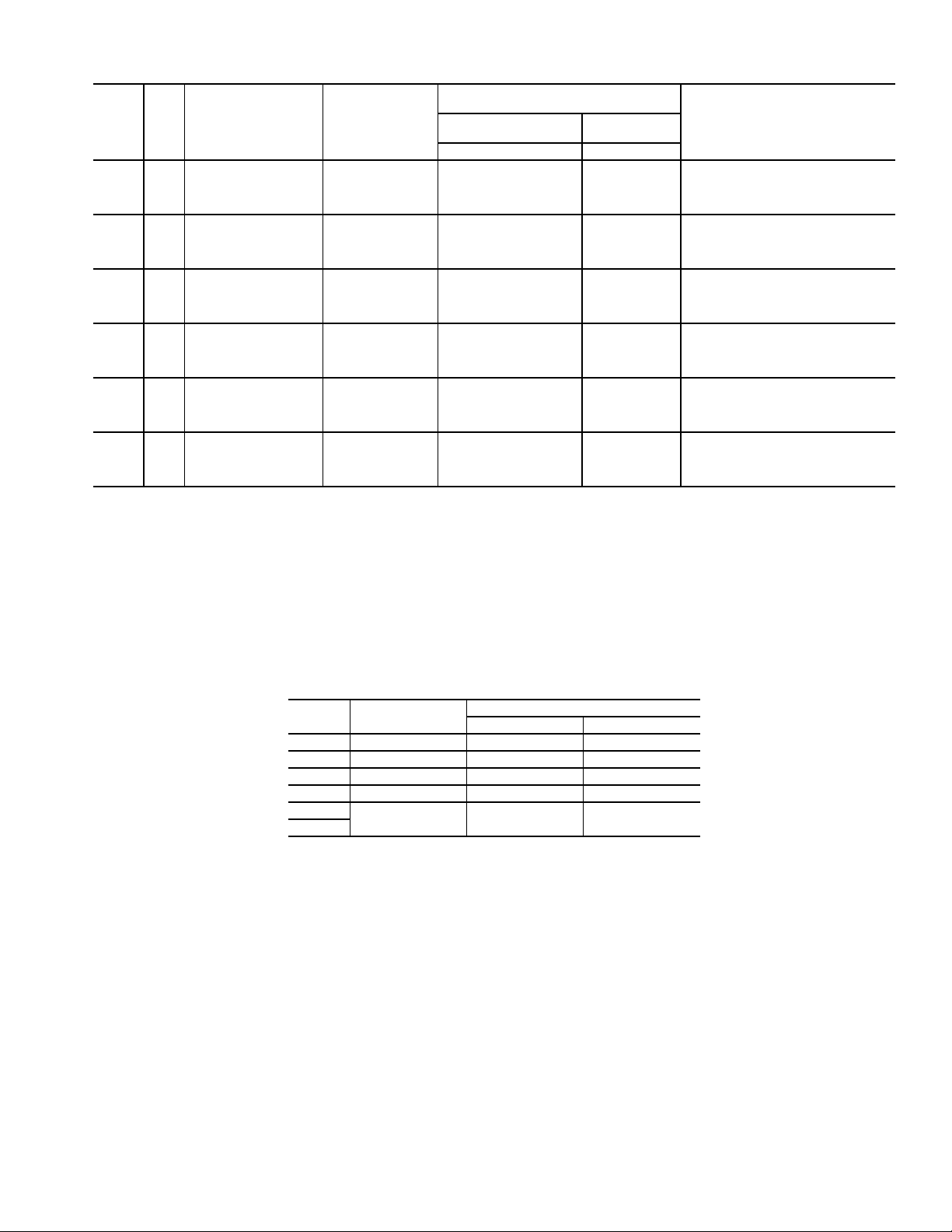

Variable air volume control with inlet air sensing (all units):

1500 — Multi-function controller, DA-NC cold inlet, NC

hot inlet

1501 — Multi-function controller, DA-NC cold inlet, NO

hot inlet

1502 — Multi-function controller, DA-NO cold inlet, NO

hot inlet

1503 — Multi-function controller, DA-NO cold inlet, NC

hot inlet

1504 — Multi-function controller, RA-NC cold inlet, NC

hot inlet

1505 — Multi-function controller, RA-NC cold inlet, NO

hot inlet

1506 — Multi-function controller, RA-NO cold inlet, NO

hot inlet

1507 — Multi-function controller, RA-NO cold inlet, NC

hot inlet

Constant volume control with hot inlet and discharge air

sensing (35N Units):

1508 — Multi-function controller, DA-NC cold inlet, NC

hot inlet

1509 — Multi-function controller, DA-NC cold inlet, NO

hot inlet

1510 — Multi-function controller, DA-NO cold inlet, NO

hot inlet

1511 — Multi-function controller, DA-NO cold inlet, NC

hot inlet

1512 — Multi-function controller, RA-NC cold inlet, NC

hot inlet

1513 — Multi-function controller, RA-NC cold inlet, NO

hot inlet

1514 — Multi-function controller, RA-NO cold inlet, NO

hot inlet

1515 — Multi-function controller, RA-NO cold inlet, NC

hot inlet

Constant volume control with cold inlet and discharge air

sensing (35N units):

1516 — Multi-function controller, DA-NC cold inlet, NC

hot inlet

1517 — Multi-function controller, DA-NC cold inlet, NO

hot inlet

1518 — Multi-function controller, DA-NO cold inlet, NO

hot inlet

1519 — Multi-function controller, DA-NO cold inlet, NC

hot inlet

1520 — Multi-function controller, RA-NC cold inlet, NC

hot inlet

1521 — Multi-function controller, RA-NC cold inlet, NO

hot inlet

1522 — Multi-function controller, RA-NO cold inlet, NO

hot inlet

1523 — Multi-function controller, RA-NO cold inlet, NC

hot inlet

A multi-function controller is capable of providing DA-NO,

DA-NC, RA-NC or RA-NO functions (all units).

No Control

0000: 35L,N box only

D000: 35L,N box with control box only

D001: 35L,N box with control box and transformer

INSTALLATION

Step 1 — Install Volume Control Box

1. Move unit to installation area. Remove unit from ship-

ping package. Do not handle by controls or damper

extension rod.

2. The unit has factory-installed brackets.

3. Suspend units from building structure with straps, rods,

or hanger wires. Secure the unit and level it in each direc-

tion.

Step 2 — Make Duct Connections

1. Install supply ductwork on each of the unit inlet collar.

Check that air-supply duct connections are airtight and

follow all accepted medium-pressure duct installation

procedures. (Refer to Tables 3-5 for pressure data.)

2. Install the discharge ducts. Fully open all balancing

dampers.

A straight length of inlet duct is not required before the unit

inlet. Ninety-degree elbows or tight radius flexible duct imme-

diately upstream of inlet collar should be avoided.