CARVIN®DIAMOND SERIES OVAL POOL | USER MANUAL

4

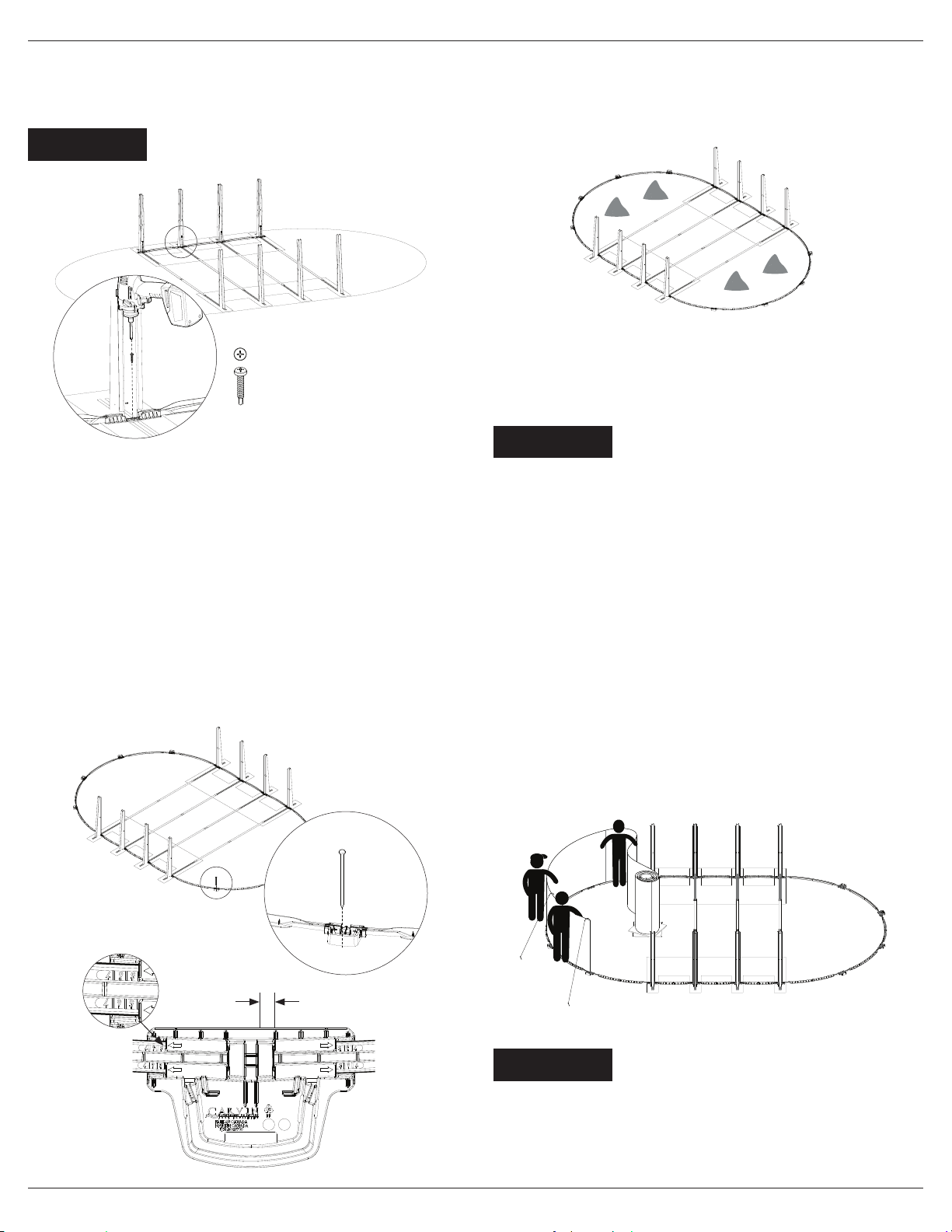

INSTALLATION

Before starting the installation of your pool, make sure you have all the necessary

tools listed below. Check the contents of each of the boxes containing the parts of

the pool and make sure everything is there before starting your installation. All parts

included in the boxes are important and should all be installed. If parts are left out

from the installation, this could cause serious failure of the pool structure. Once the

installation of a swimming pool is started, it should be completed as soon as

possible.

If a part is missing or defective, please contact your CARVIN®retailer were your

purchase was made.

TOOLS

• Shovel

• Water hose

• Hammer

• Rubber mallet

• Soil Compactor (manual or mechanic)

• Pliers

• Vacuum cleaner

• Gardening rake

• Measuring tape

• Drill, ratchet or adjustable wrench

• Screwdriver bit #3 Phillips or Robertson

• Hexagonal socket 7/16”

• Wheelbarrow

• Punch 3/16” diameter

• Stepladder

• Vinyl covered hook, rope and tent pegs

• Hexagonal Socket ¾’’

• Hex Key ¾’’

• Linear level/transit level

• Tape measure

• Pump

• Filter

• Skimmer

• Water return

REQUIRED MATERIAL

• Duct tape 2”

• Nails or rods 8” (number of uprights +1)

• Wall stabilizing hooks (number of uprights)

• Sand or finest rock dust or both (see below quantities)

• Stones (3/4” minimum) or river stones

• Patio slab (equal to the # of uprights) (optional)

• Prefabricated cove sections (optional)

• Under liner pool carpet

• Plywood sheet ½”, (2x) 3’x3’

• Cardboard 16”x9“

• Wooden plank 2”x4” of length equal to the radius of the pool

• Straight plank

• Patio blocks 16x8x2’’

• CARVIN®pool parts

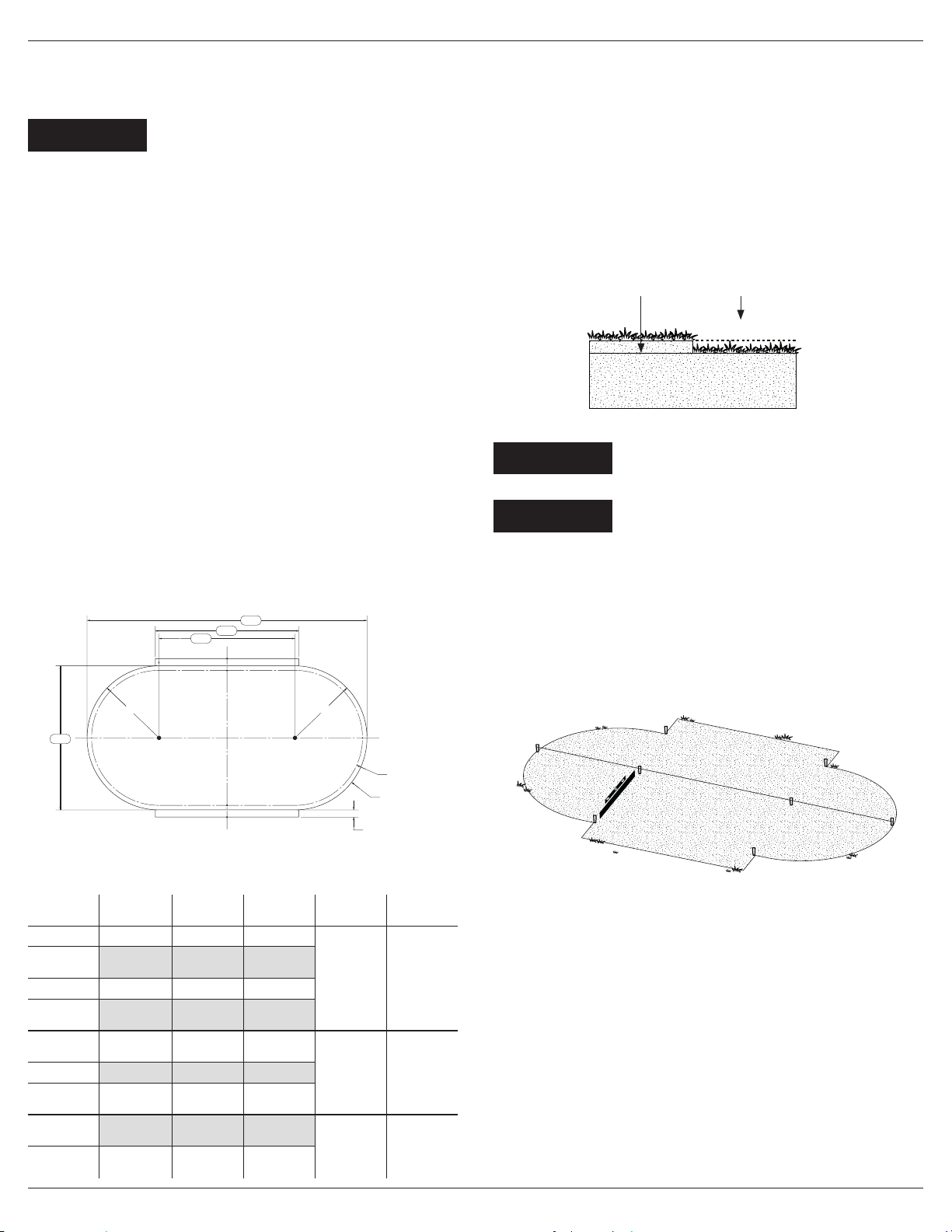

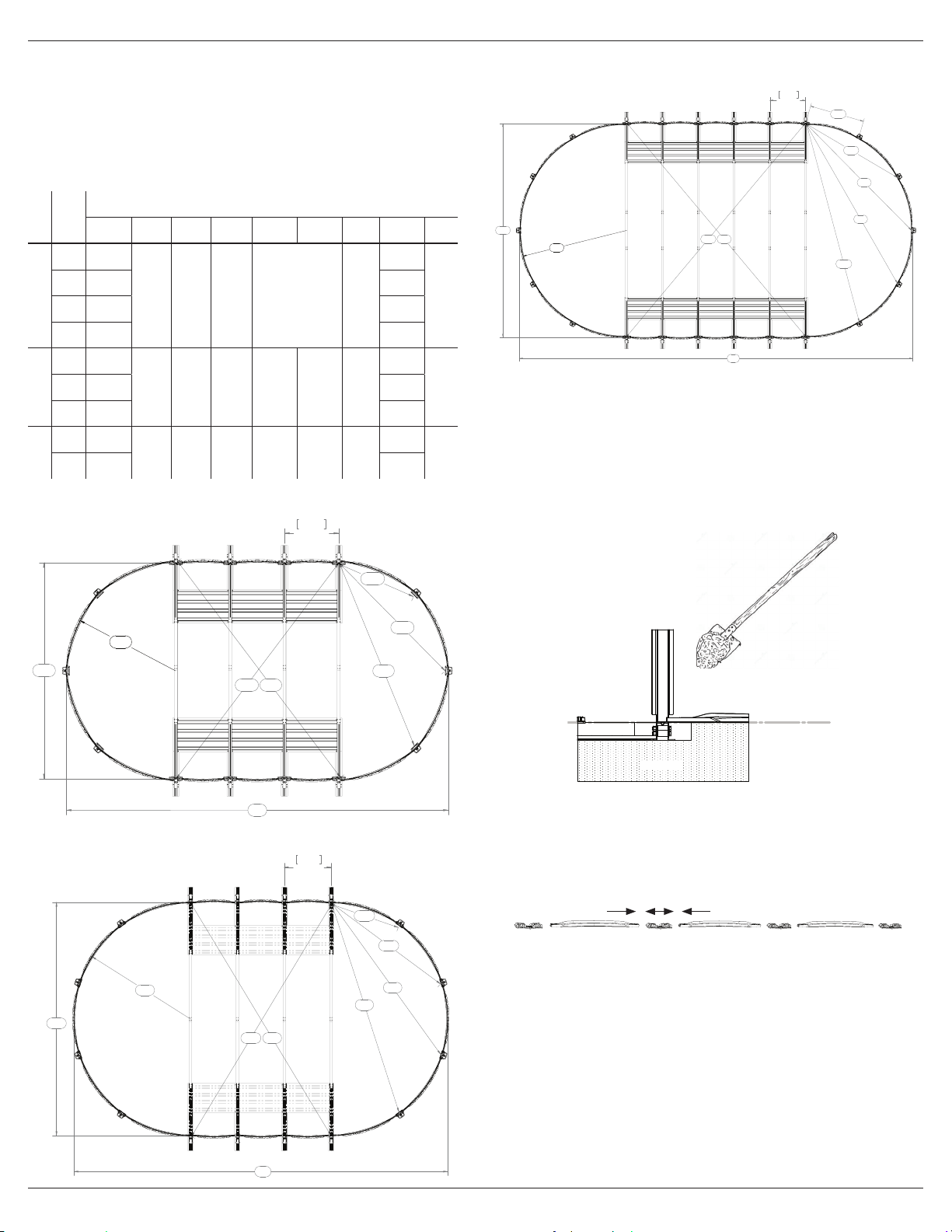

INFORMATIONS REQUIRED FOR SWIMMING POOL INSTALLATION

POOL SIZE

12’x 15’x 18’x

15’ 18’ 21’ 24’ 21’ 24’ 30’ 33’ 39’

POOL OVERAL

FINISHED WIDTH* 13’2’’ 13’2’’ 13’2’’ 13’2’’ 16’2’’ 16’2’’ 16’2’’ 19’2’’ 19’2’’

POOL OVERAL

FINISHED LENGHT 16’ 19’ 22’ 25’ 21’6’’ 24’6’’ 30’6’’ 34’2’’ 40’2’’

FOUNDATION

DETAILS REFER TO PAGE XX

CONCRETE PATIO

BLACKS 8X16X2’’ 4681068121216

SAND REQUIRED

(TONS) 2.5 3 3 3 3.5 3.5 4 5 5.5

* Refer to Installation overall dimensions to be sure of burried structure dimensions will fit.

The Warranty of the Product will be canceled if all instal-

lation requirements and guidelines are not respected.

WARNING

POOL LOCATION

We highly recommend you hire a certified installer recommended by your retailer

to install your pool. If you decide to install your pool yourself, we recommend it be

done by at least 3 people.

The installation must comply with the codes of the

authority having jurisdiction and may require permits

for building, plumbing electrical, zoning etc. Check local

municipal laws and rules before starting your installa-

tion, this could influence the location of your pool.

WARNING

One of the most important steps is to choose the ideal location for your pool.

This will determine the life expectancy of your pool.

• The ground must have a good drainage and be solid, have a positive slope

(keeping the water away from pool base), should not be on a hollow ground since

this will result in a build up of water, this could jeopardize your foundation and

damage your pool.

•The ground must be free of rocks, pebbles, tree roots, bamboo and cattails.

•Never install your pool in a place where chemicals have been spread, this could

damage the liner and rust the wall.

•Never install your pool on a concrete floor, asphalt, tarpaper, grass, wood, gravel

or clay.

•Position your pool far from trees, electric lines or cables, buildings (house, garage,

etc.). Swimmers could use them for diving and could get seriously injured.

•Never install your pool above buried electrical lines or above a septic tank.

•The pool shall be located a minimum distance of 6ft (1.83 m) from any electrical

receptacle. All 125 volt, 15 and 20 ampere receptacles located within 20’ (6.0 m)

of the pool shall be protected by a ground fault circuit interrupter (GFCI).

The 20’ (6 m) distance is measured via the shortest straight line distance the

supply cord would follow without piercing a floor, wall, ceiling, doorway, window,

or other permanent barrier.

•Do not cover the rail and the bottom of the wall with mulch. The mulch retains

moisture and could help rust the metal wall.

•The use of any material other than specified for the installation of this pool could

void the warranty.

IMPORTANT TO CONSIDER BEFORE INSTALLING

1. Follow the installation steps thoroughly without omitting anything. It can result in

serious accidents.

2. Your pool must be level: Your foundation base should have a maximum of ½’’ of

slope. The slope of the floor from the shallow wall towards the deep area shall

not exceed 1’ in 7’ (1: 7, 305 mm: 2134 mm) to the point of the first slope

change. The slope of the floor from the point of the first slope change towards the

deepest point shall not exceed 1’ in 3’ (1: 3), (305 mm: 914 mm). The slope

adjcent to the shallow area shall have a maximum slope of 1’ in 3’ (1: 3,

305 mm: 914 mm) and the slope adjacent to the side walls shall have a maximum

slope of 1’ in 1’ (1: 1, 305 mm: 305 mm). The point of the first slope change

shall be defined as the point at which the shallow area slope exceeds 1’ in 7’

(1: 7, 305 mm: 2134 mm) and be at least 6’ (1829 mm) from the shallow end wall

of the pool.

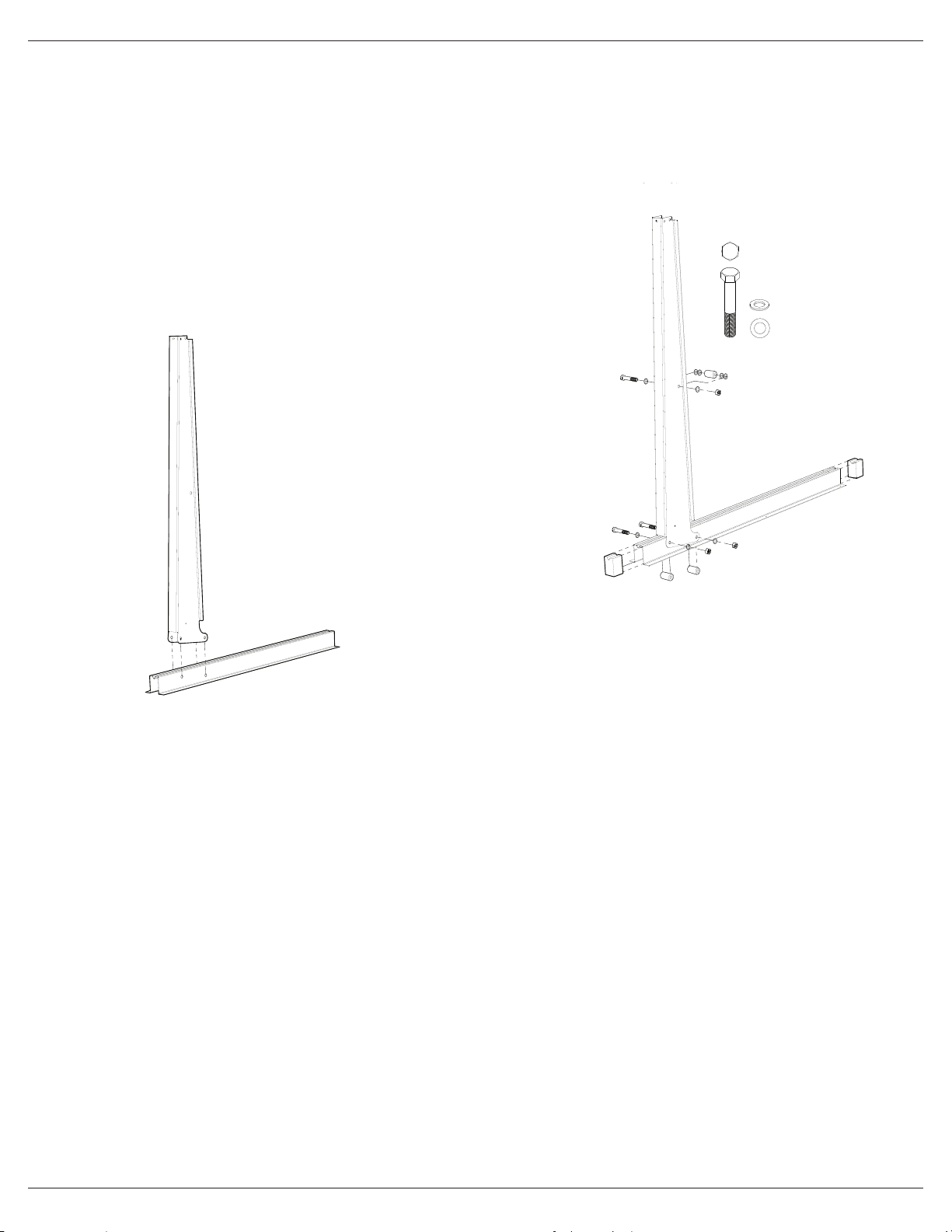

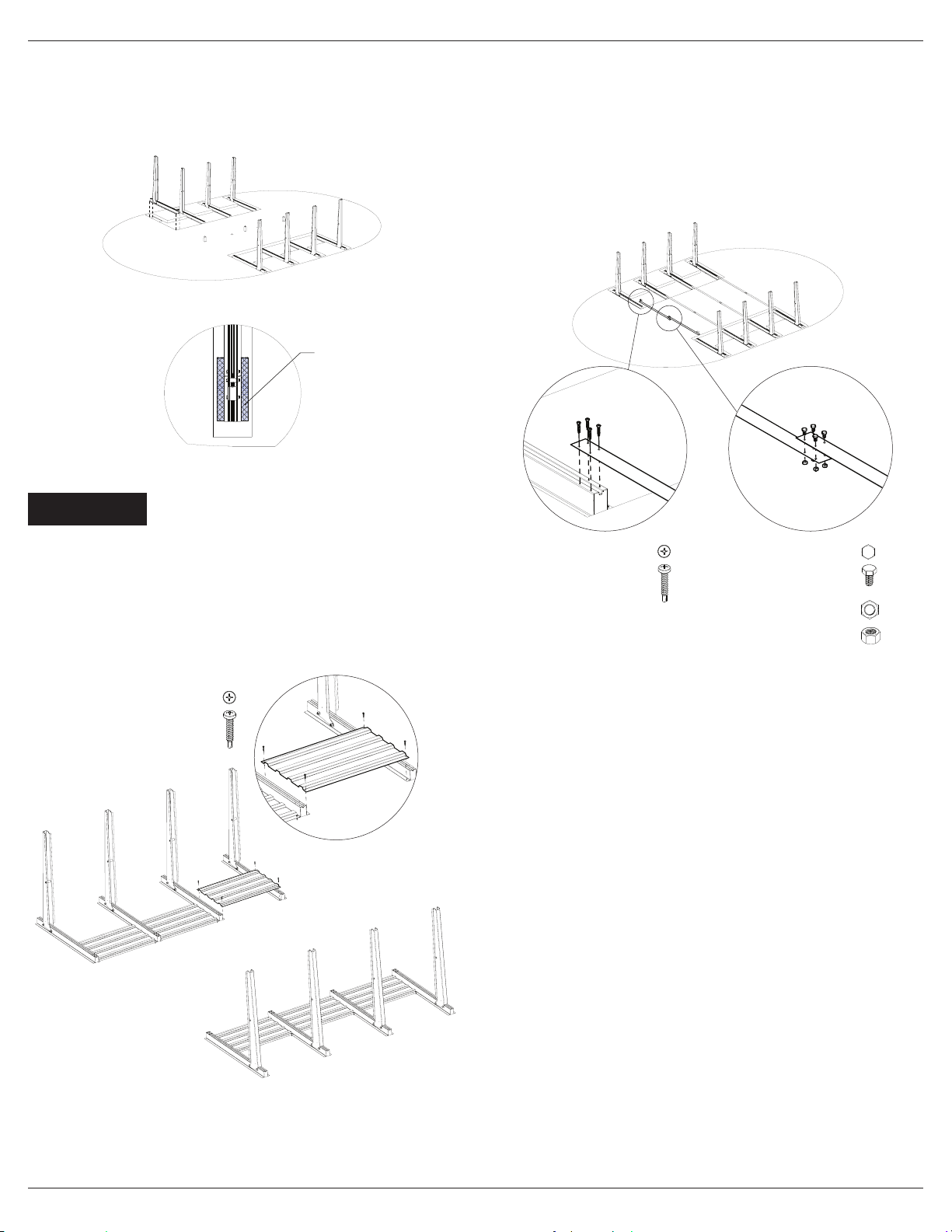

3. When closing the wall, follow the instructions in our manual using the 2 wall

brackets and all provided hardware (all holes must contain a screw).

4. The prefabricated cove sections should be well compacted. A lack of thoroughness

can result in the liner getting jammed under the rails and perforate. the ground

could deform, making the pool sink in or even burst.

5. The pool was not designed to be buried (inground). The weight of the soil will

crush the wall inside the pool.

6. No installation should be done on unstable ground, ground with a drainage

problem, ground with movement or instability and at least 10 meters from a tree.

The manufacturer of your Product has no responsibility for any omission of the

installation steps contained in this manual or a non-compliant installation.