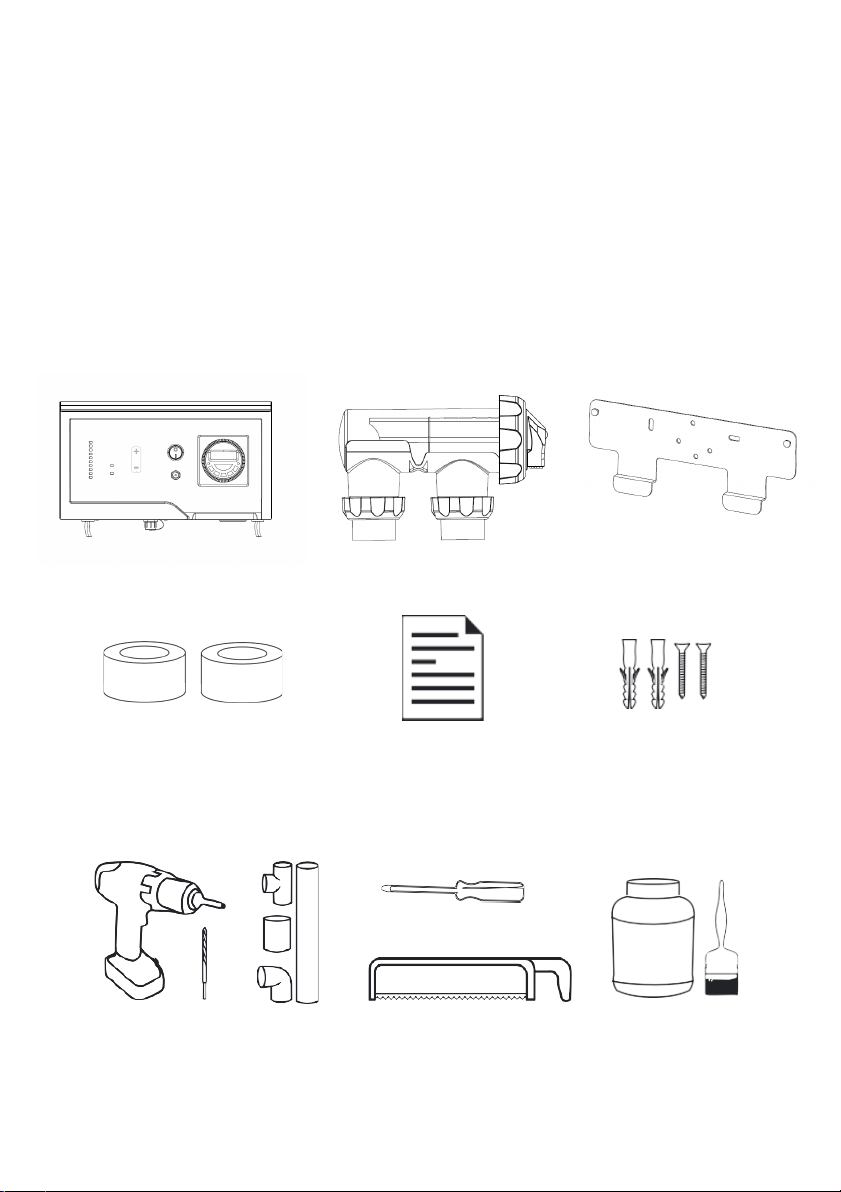

3. POOL

6

PREPARATION

Before operating your XR Series Salt Chlorinator, please read the following:

Check your salt levels in your pool before starting your unit.

Salt levels and mineral levels should ideally be 3000-4000ppm (3500ppm ideal) and 1200ppm -

1800ppm (1500ppm ideal) for XR25LS and XR35LS Freshwater/Ultra-Low Salt models. No more

than 4500ppm for regular models and 2500ppm for Low Salt models. To achieve this salt level

with minerals, you may need to add 20-30% more product to the pool water. Contact your

local pool Professional for further assistance.

Salt levels above 6000ppm may overload the unit and cause excessive heat and void your

warranty. We recommend you lower the output by 10% for every 500ppm over 4500ppm. You

could also drain your pool water to achieve the optimum output. You will save more in

electricity saving than the costs of the water loss.

For all new pool installations please seek advice from your pool builder or your local pool

Professional before adding salt, as some new surfaces request no salt to be added when initially

completed.

NEVER ADD SALT/MINERALS DIRECTLY TO THE SKIMMER BOX. This high concentration of either salt

or minerals will pass through your filtration, pump and other pool equipment.

Handy Tips:

The colder the water the lower your output but this does not mean you need more salt. There

will always be less chlorine demand in colder water.

We recommend adding 3.5kg of pool salt per 1000 litres of pool water, a 50,000lt new pool needs

approximately 175kg of salt. For the FRESHWATER/ULTRA-LOW SALT SYSTEM Models: XR25LS and

XR35LS, we recommend 1.5kg per 1000 litres of pool water.

The unit can operate on mineral/magnesium chloride salts, and you should allow an extra 20-

30% of the product to achieve the correct salt level for these types of salts.

Salt should always be added to the shallow end of the pool and allowed to dissolve. Do not let

the salt settle on the floor of the pool as it may cause damage to the surface. Use your pool

brush to mix the salt into the water.

Running the pump will mix the water and help the salt to dissolve.

Only run the pump in the first 8-12 hours (ensure the cell is switched off) to allow the salt to dissolve.

If you press the Increase Button (+) until all 10 LEDs are ON, then wait 5 seconds and if all 10 LEDs

remain ON then you have enough salt. DO NOT ADD ANY MORE SALT. If only 9 are ON, then

your salt is at 90% of the required level.