SAFETY

Symbol in This Manual

ft.

This symbol indicates where applicable cautionary or

other information

is

to

be

found.

Power Source

This equipment operates from a power source

that

does

not apply more than

250

V rms between the supply con-

ductors or between either supply conductor

and

ground. A

protective ground connection by

way

of

the grounding con-

ductor in the power cord

is

essential for safe operation.

Grounding the Product

This equipment is grounded through the grounding conduc-

tor

of

the power cord. To avoid electrical shock, plug the

power cord into a properly wired receptacle before connec-

ting

to

the equipment input or output terminals.

Use

the Proper Power Cord

Use

only the power cord

and

connector specified for your

product.

Use

the Proper Fuse

To avoid fire hazard, use a fuse

of

the correct type.

Do

not Operate in Explosive Atmospheres

To avoid explosion, do not operate this product

in

an

ex

-

plosive atmosphere.

Do not Remove Cover or

Panel

To avoid personal injury, do not remove the cover

or

panel.

Refer servicing

to

qualified personnel.

Voltage Conversion

If

the power source

is

not applied

to

your product, contact

your dealer. To avoid electrical shock, do not perform the

voltage conversion.

CONTENTS

SAFETY

........................................................

2 TRACE ROTATION COMPENSATION

......................

19

FEATURES

.....................................................

3

DC

VOLTAGE MEASUREMENTS

............................

19

MEASUREMENTS

OF

THE

VOLTAGE

SPECIFICATIONS............................................

4

BETWEEN

TWO POINTS

ON

A WAVEFORM

...........

20

PREPARATION

FOR

USE

...........

............

............

6 ELIMINATION

OF

UNDESIRED

SIGNAL

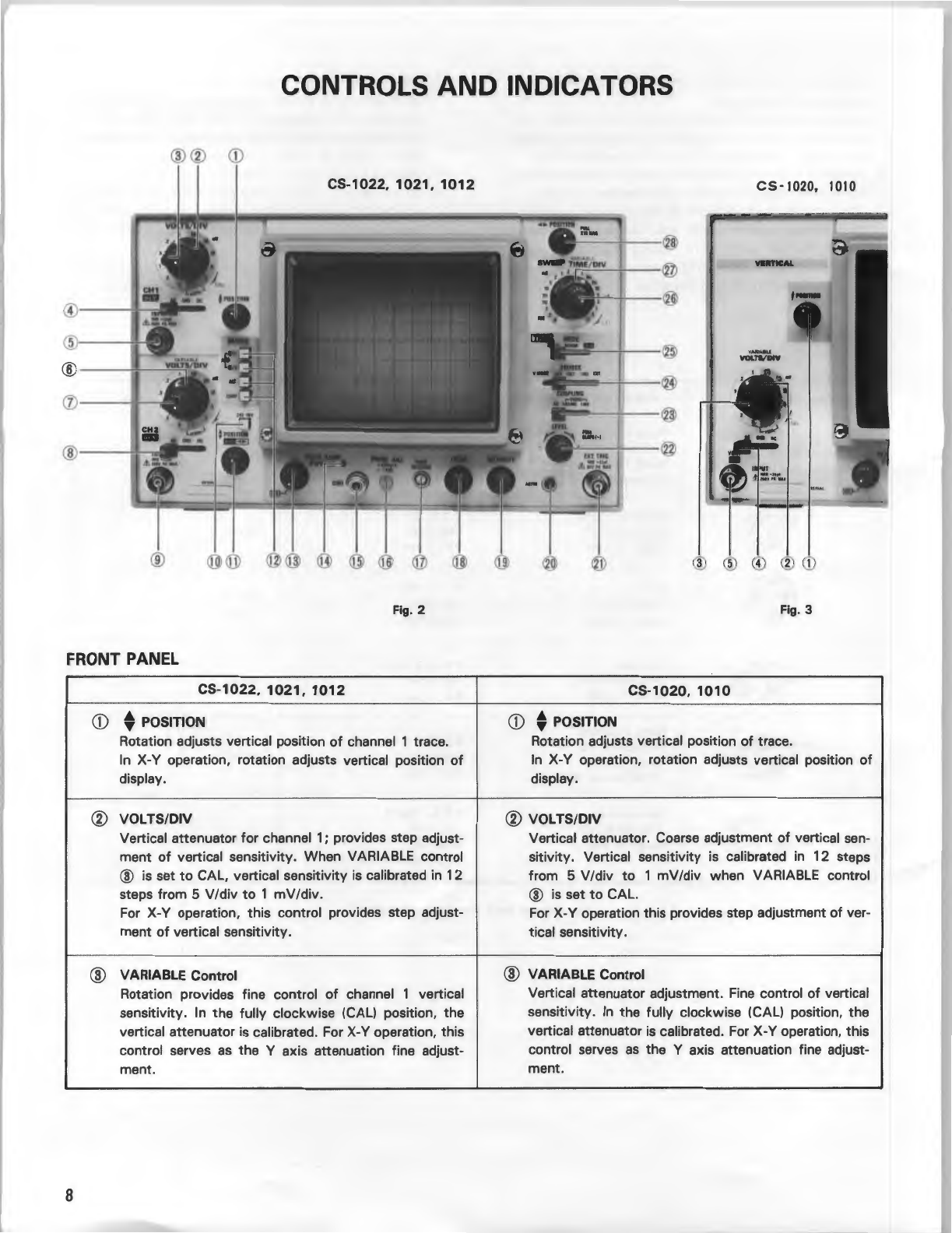

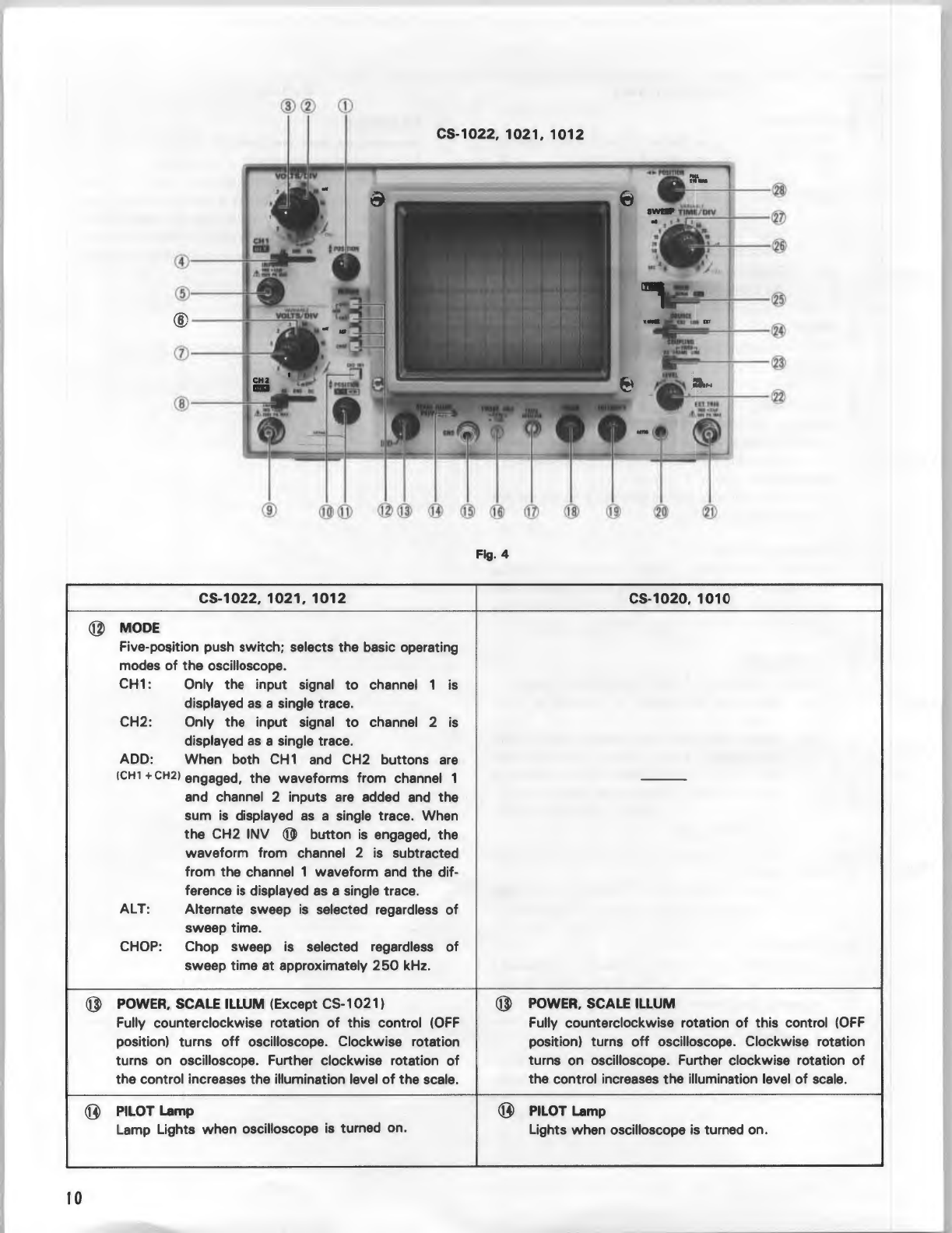

CONTROLS AND INDICATORS .......................... 8 COMPONENTS

.................................................

20

FRONT

PANEL....................................................

8 TIME MEASUREMENTS

........................................

21

REAR

PANEL

......................................................

14

FREQUENCY

MEASUREMENTS

.............................

21

OPERATION

...................................................

14

PULSE

WIDTH MEASUREMENTS ....

........................

22

PULSE

RISE

TIME AND FALLTIME

INITIAL STARTING

PROCEDURE

............................

15

MEASUREMENTS

..............

....

.........

...................

22

(1) NORMAL

SWEEP

DISPLAY OPERATION

................

15

TIME

DIFFERENCE

MEASUREMENTS

......................

23

(2) MAGNIFIED

SWEEP

OPERATION

..........................

18

PHASE

DIFFERENCE

MEASUREMENTS

...................

24

(3) X-V OPERATION

...............................................

18

RELATIVE MEASUREMENTS

.................................

24

(4) VIDEO SIGNAL OBSERVATION

............................

18

APPLICATION

OF

X-V OPERATION

.........................

27

APPLICATION

................................................

19

ACCESSORIES

...............................................

29

PROBE

COMPENSATION

........................

.

.............

19

Note: This instruction manual

is

described for five models.

Refer

to

item applied

to

your product.

2