BLADE GUARD SYSTEM

The lower blade guard, attached to your

saw, is there for your protection and safety.

It should never be altered for any reason. If it

becomes damaged or begins to return slowly

or sluggishly, do not operate your saw until

the damage has been repaired or replaced.

Always leave the guard in its correct operation

position when using the saw.

When sawing through a work piece, the lower

blade guard does not cover the blade on the

underside of the work piece. Since the blade

is exposed on the underside of the work piece.

Always keep your hands and fingers away

from the cutting area. Any part of your body

coming in contact with the moving blade will

result in serious injury.

Never use this saw when the guard is not op-

erating properly. The guard should be checked

for correct operation before each use. If you

drop your saw, check lower blade guard and

bumper for damage at all depth setting before

using. NOTE: The guard is operating properly

when it moves freely and then steadily returns

to the closed position if the lower blade guard

does not close freely for no reason, take it

to your nearest authorized Repair Center for

service before using it.

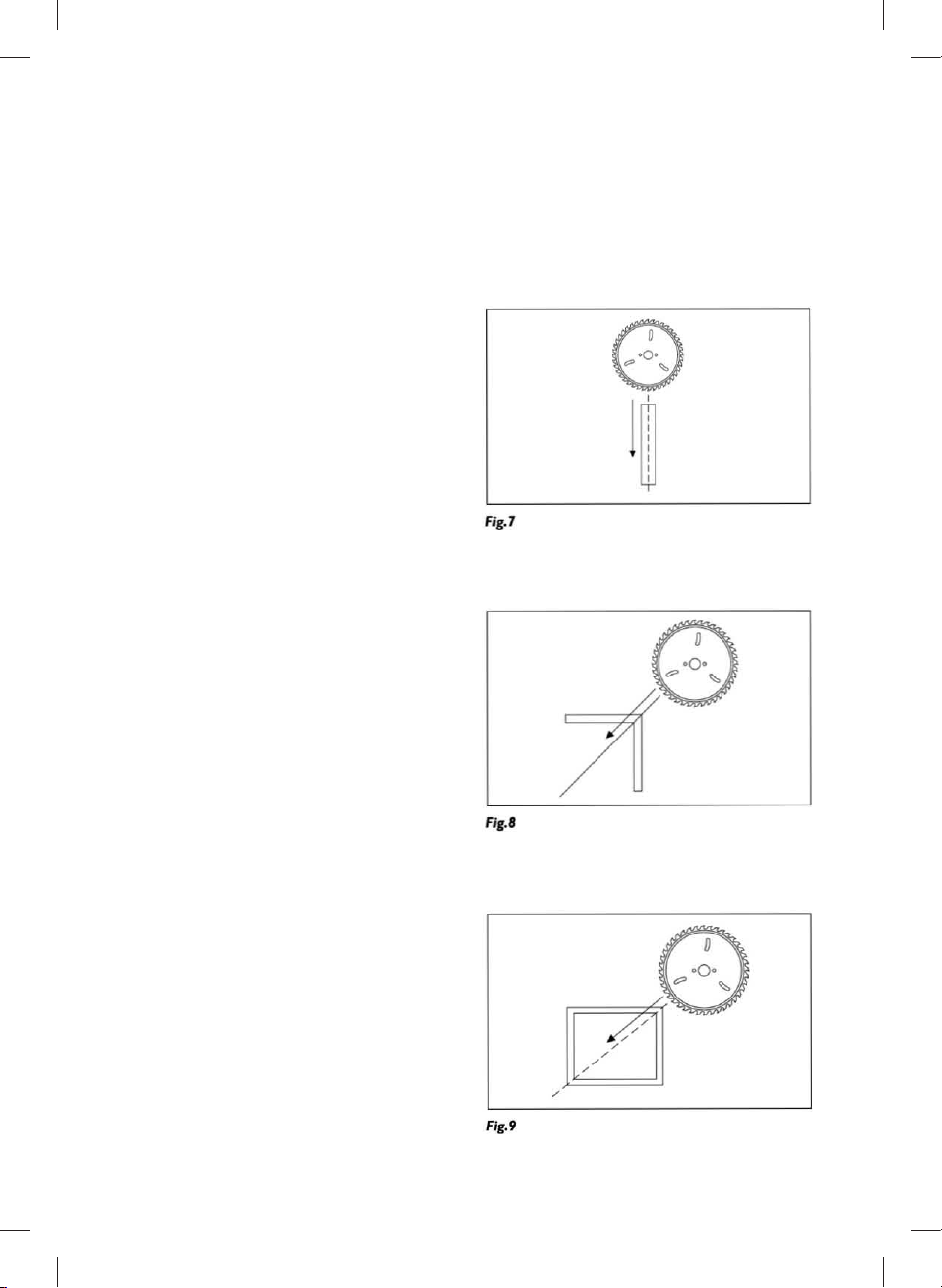

STARTING A CUT

1. Always use your saw correctly.

2. Always support the work piece near the cut.

3. Always support the work piece so the cut

will be on your side.

4. Always clamp the work piece so it will not

move during the cut. Before starting a cut,

draw a guideline along the desired line of

cut. Then place the front edge of the saw

blades on that part of the work piece that is

solidly supported.

5. Never place the saw on the part of the work

piece that will fall off when the cut is made.

6. Always keep the cord away from the cutting

area. Always place the cord so it does not

hang up on the work piece when making

a cut.

Always maintain control of the saw to make

sawing safer and easier. Loss of control of

the saw could cause an accident resulting

in possible serious injury.

If the cord hangs up on the work piece

during a cut, release the trigger switch

immediately. Unplug the saw and move the

cord to prevent it from hanging up again.

Using the saw with a damaged cord could

result in shocking. Have it replaced before

using the saw again.

7. Slide the on/off switch to start the saw. Al-

ways let the blades reach full speed before

you begin to cut into the work piece.

If the blades come in contact with the work

piece before they reach full speed, it could

cause the saw to kickback towards you,

resulting in serious injury.

8. When making a cut, always use a steady,

even pressure. Forcing the saw causes

rough cuts and could shorten the life of the

saw or cause kickback.

When sawing through a work piece, the

lower blade guard does not cover the

blades. The blades are exposed on the

underside of the work piece; always keep

your hands and fingers away from the cut-

ting area. Any part of your body coming in

contact with the moving blade will result in

serious injury.

Whenever you lift your saw from the work

piece, the blade is exposed on the under

side of the saw until the lower blade guard

closes. Always MAKE SURE that the lower

blade guard is closed before setting the

saw down on work surface.

9. Always use the lubricating device (includ-

ed) when cutting aluminum, copper, stain-

less steel & cast iron materials because

they have a tendency to smear and adhere

to the blades.

FEED SPEED

Feed speed is how quickly you push the saw

blades through the material being cut. The

correct feed speed is totally determined by

the hardness and the thickness of the material

being cut.

Only feed the blades down approximately 3/8”,

then start cutting.

1. If feed speed is too slow

2. The blades will only press down on the

material rather than cutting it.

3. The blade edge glides and wears down the

material.

4. This will cause a poor cut and will cause

excessive wear on the blades

5. If the feed speed is too fast

6. There is a definite risk that the cut might

split. The splinter will get bigger and bigger

eventually break risking serious personal