General Information 0A-3

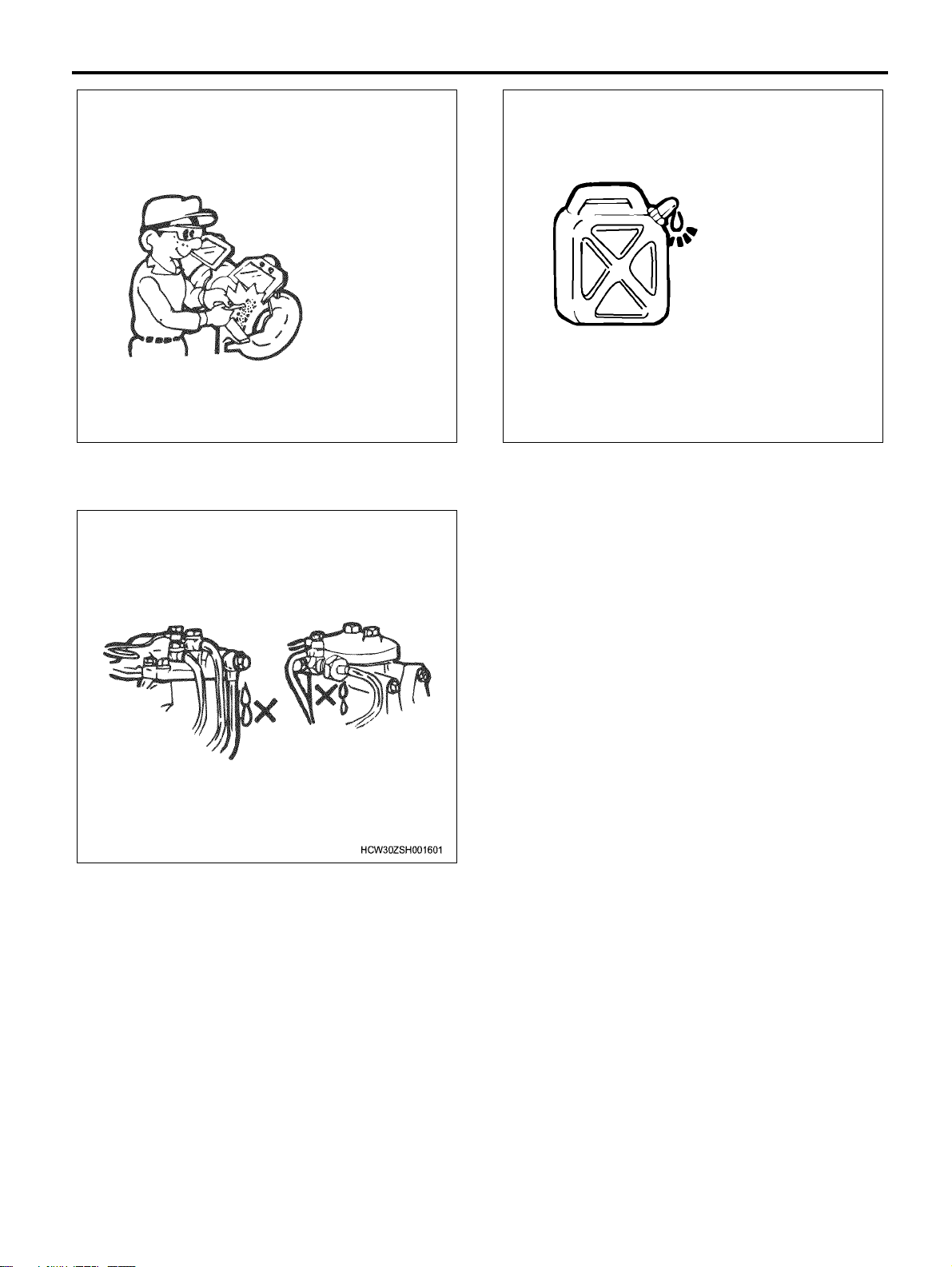

8. Always check that there are no fuel leaks when

performing maintenance work on the fuel system.

(It may cause a fire.)

9. Pay close attention to the risk of ignition if you are

handling parts that carry a high voltage.

Furthermore, any oil or fat spilt onto rubber parts

must be wiped off immediately, as it will cause

deterioration of the rubber.

Replacement parts and part numbers.

1. Always replace packing, oil seals, o-rings, caulking

lock nuts, folding lock plates, split pins and other

such parts with brand new parts.

2. The parts numbers contained in this manual may

not represent the supply condition of the parts, and

the part numbers may be changed due to

revisions. Therefore, parts should always be

checked against a parts catalogue before use.

Liquid gasket

1. Each time you disassemble parts that use liquid

gasket, completely remove the old gasket residue

from each of the parts and matching sections using

a scraper, then clean each of the parts to

completely remove oil, water, and dirt etc. from the

various surfaces. Using the specified type of liquid

gasket, apply new liquid gasket to each of the

surfaces before reassembling the parts.

2. In order to make it easier to clean liquid gasket

surfaces, apply gasket remover liquid (Pando-

391D made by Three Bond Co., Ltd.) and leave

the part to stand for approximately 10 minutes,

after which the old liquid gasket residue will be

easier to remove.

However, this should not be used on resin

components or painted components.

3. Please take care not to apply too much or too little

liquid gasket.

Also, you should always re-apply the liquid gasket

upon itself when you start and finish application.

4. Make sure that there are no gaps when re-

installing the liquid gasket parts to each other. If

there are gaps between the two parts, re-apply the

liquid gasket. Some parts, especially the oil pan,

use the same size studs as a guide to eliminate the

need for knock pin positioning etc.

5. Re-install these parts within 7 minutes of applying

the liquid gasket.

Find manuals at https://best-manuals.com