3,

MowerBladeBolts:

Beforeoperatingthemowerforthe

firsttime,checktheboltsholdingthe

blades.THEYMUSTBETIGHT.After

thefirst8 hoursoperating,checkthem

again.Wheneverthebladesarere-

moved,itisa goodpracticetoinstall

newlockwashersunderthebolts,and

againchecktightnessafternext8 hours

operation,

4.

EngineMaintenance:

Completetractorandenginemain-

tenanceinstructionsareoutlinedon

page12and13ofyourtractorOpe-

rator'sManual,Whenmowing,give

particularattentiontotheareaswhich

areaffectedbygrassaccumulation.

Checkandbrushofftheengineair

intakescreenandheatexchangerfins

DAILY.Alsocheckandcleanthe

engineaircleanerelementdailyas

explainedonpage21ofyourtractor

manual.Ifmowingunderparticularly

dryordusyconditionsa "Precleaner,"

partnumberK0237421,isavailable

throughyourJ I CaseDealerwhich

fitsovertheregularelement.See

Figure6,Thisprecleanercanbe

washedoutwithsoapandwaterasnec-

essarywhichwillextendthelifeofthe

dryelementfurnishedwiththetractor.

Figure6.

5.

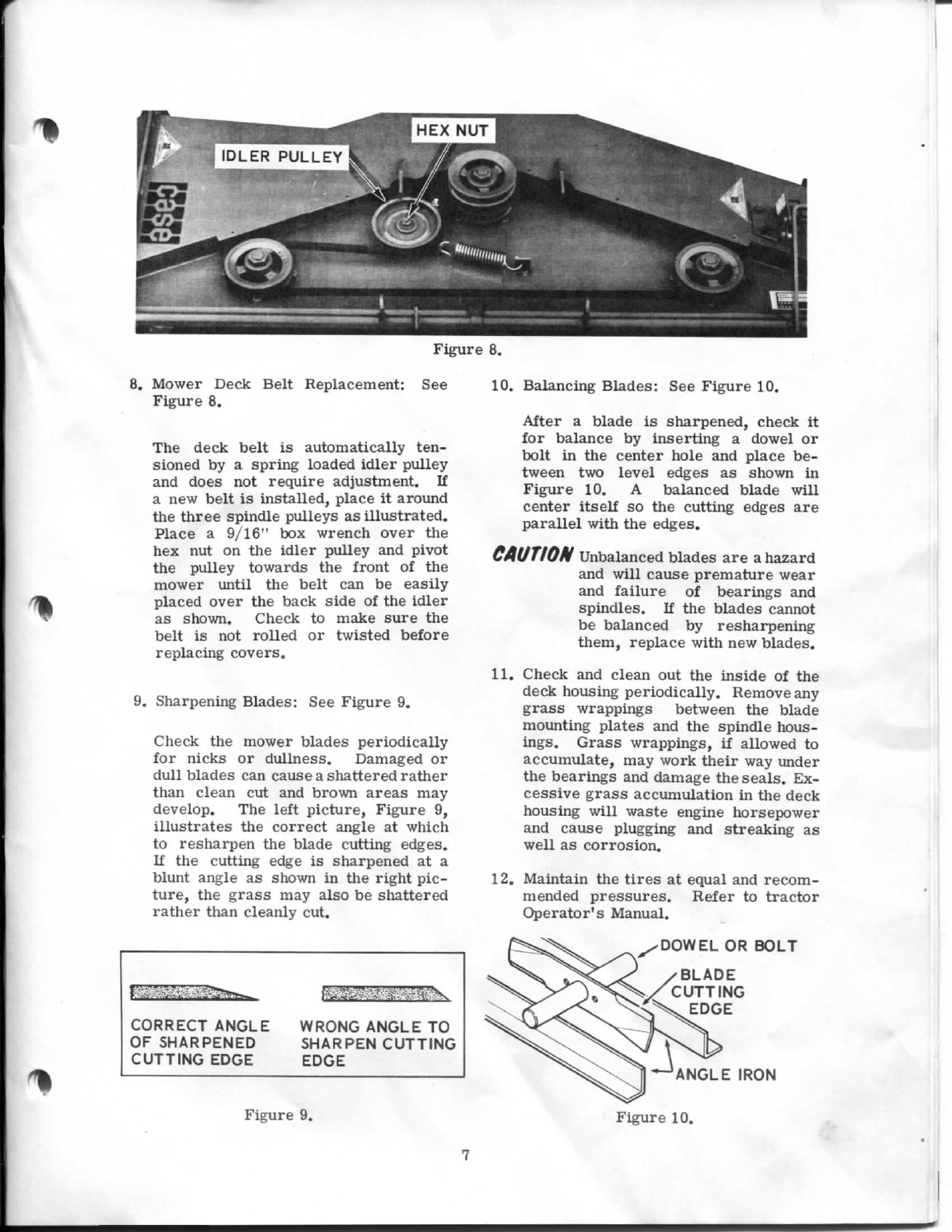

MowerFore-AftLevelingLinks:See

Figure7,

Theselinksareadjustedatthefactory

forcorrectmowerdecklevel.Clean

cuttingandminimumhorsepowercon-

sumptionaredependentuponthemower

beinglevel,foreandaft.Ifreadjust-

mentshouldbecomenecessary,locate

thetractorandmowerona levelsur-

faceandplacetheHeightSelectorLever

inthe2-1/2"settingbeforemaking

adjustments.Toraisethefrontof

themower,firstloosentheouternut

oneachlinkandthenequallyturnthe

innernutsrearward.Tolowerthefront

ofthemower,loosentheinnernuton

eachlinkandturntheouternutsfore-

ward.Checkbladeheightsasclose

tothefrontandrearedgesofthemower

aspossible.Distancebetweenthe

bladesandthelevelsurfaceshouldbe

thesameatbothfrontandrearedges

ofmower,

6,MowerSideToSideLeveling:See

Figure7,

Mowersidetosidelevelingisad-

justedatthefactory.However,should

readjustmentbecomenecessaryitmay

bedonebylooseningthetwocarriage

boltsontherighthandsidethatsecure

thegaugewheelcarriertothedeck.

Theholesmaybeslottedifadditional

adjustmentisrequired.Afterob-

taininga levelposition,retightenthe

carriagebolts.

7,

MowerGaugeWheels:SeeFigure7,

Removethegaugewheelsaftereach

10hoursofmowingandluricatethe

bushingsandaxleboltswithchassis

grease.

Asanalternatetogrease,the

wheelscanbeoiledeachfourhours

ofoperation.Makesuretheoil

penetratestotheinsideofthe

bushingsbyholdingthedeckat

aslantedanglewhilelubricating.

Figure7.

-sr.

6