IOM-P4 3

SECTION VI

VI. MAINTENANCE

To prevent damage to body, use soft jaws when

placing body in a vise. Position so that vise closes

over the flats on lower end of body.

5

SPRING UNDER COMPRESSION. Prior to

removing spring chamber, relieve range spring

compression by turning knob CCW until rotation

comes to a complete stop. Failure to do so may

result in flying parts that could cause personal

injury.

WARNING

CAUTION

A. General:

1. Maintenance procedures hereinafter are

based upon removal of the regulator unit from

the pipeline where installed.

2. Owner should refer to owner's procedures for

removal, handling, cleaning and disposal of

nonreusable parts, i.e. gaskets, etc.

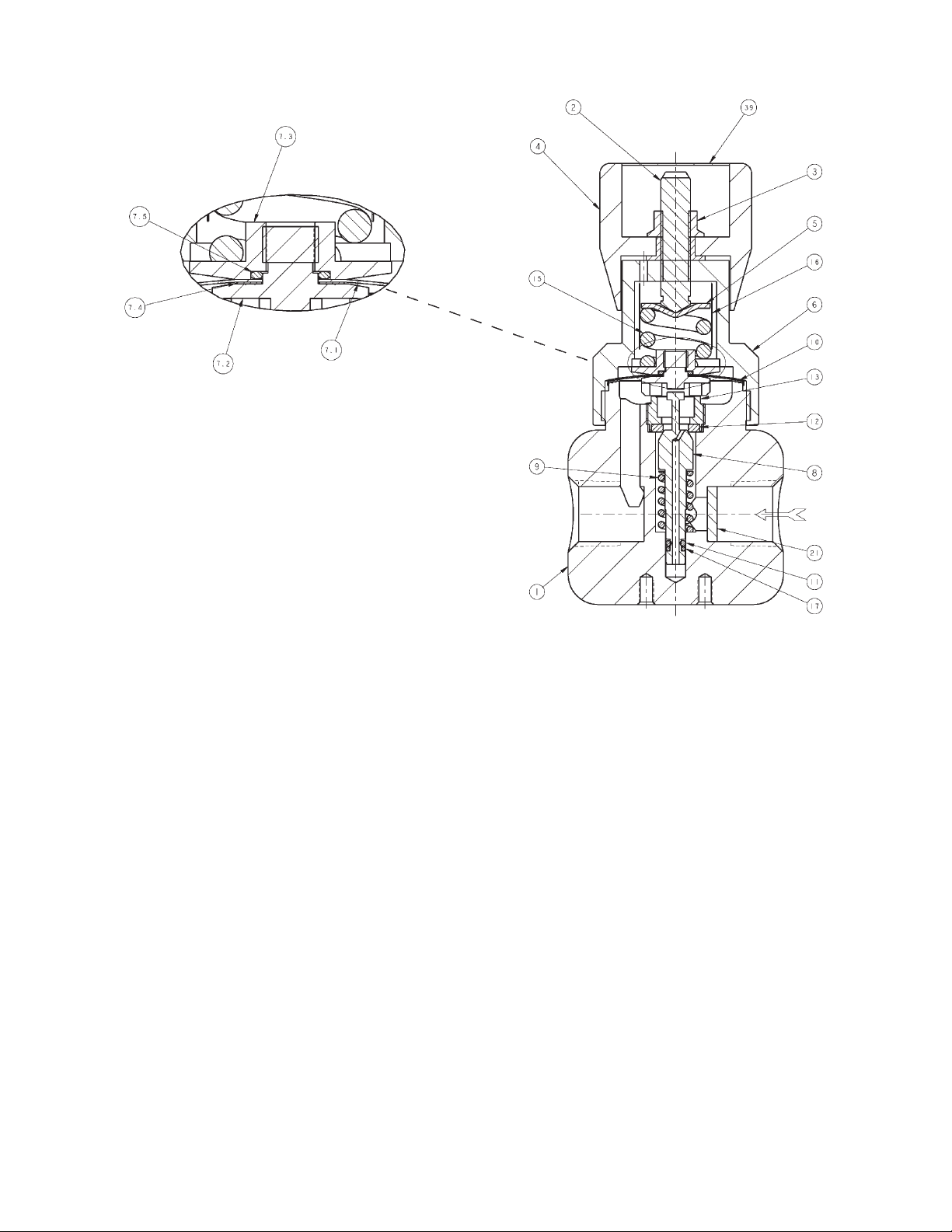

3. Refer to Figure 2 for basic regulator and Fig-

ure 1 for the diaphragm subassembly.

B. Diaphragm Replacement:

1. Securely install the body (1) in a vise with

knob (4) directed upwards.

2. Relax range spring (15) by turning knob (4)

CCW until rotation comes to a complete stop.

NOTE: It is not necessary to remove the knob

before removing the spring chamber (6) from

the body (1).

3. Remove spring chamber (6) by grasping the

flats and turning CCW. Upon removal, the

range spring (15), range spring clip (16), and

spring button (5) should remain inside the

spring chamber subassembly.

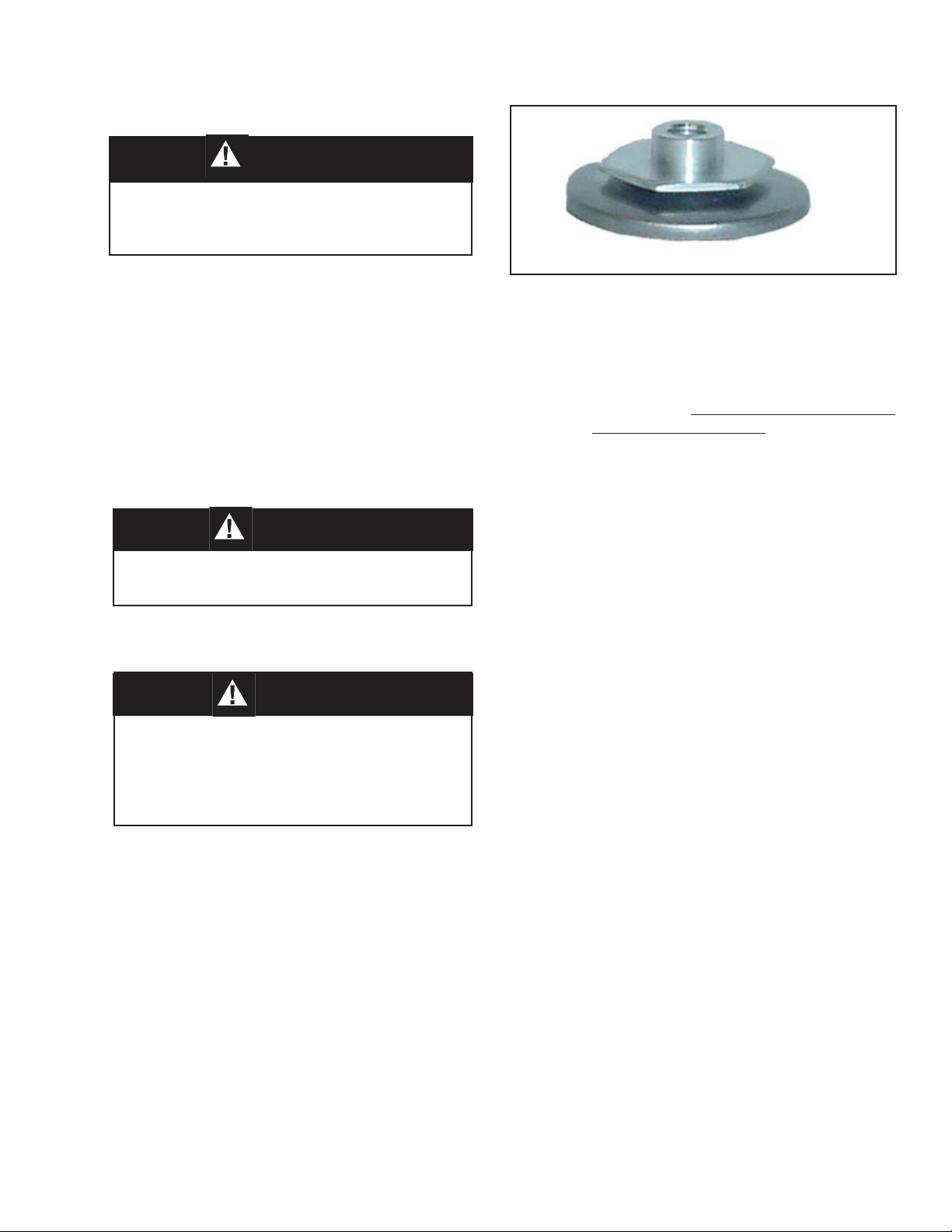

4. Remove diaphragm subassembly (7) consist-

ing of the actuator nut (7.3), diaphragm (7.1),

actuator post (7.2), actuator gasket (7.4),

actuator o-ring (7.5). Remove diaphragm

gasket (10).

5. Remove actuator nut (7.3) and separate all

parts of the diaphragm subassembly (7).

6. Clean body (1) diaphragm flange surface

and all reusable parts according to owner's

procedures. Do not scratch diaphragm

gasket seating surface. NOTE: On regu-

lators originally supplied as “oxygen clean”,

Option-M, maintenance must include a level

of cleanliness equal to Cashco's cleaning

standard #S-1134. On regulators originally

supplied for Sanitary Service, maintenance

must include a level of cleanliness equal to

Cashco cleaning standard #S-1576. Contact

factory for details.

7. Inspect and replace any necessary parts.

NOTE: Use only parts manufactured and

supplied by Cashco, Inc. for these products.

See Section VIII.

8. Reassemble diaphragm subassembly (7) by

placing the actuator gasket (7.4), diaphragm

(7.1), and actuator o-ring (7.5) over the

threads of the actuator post (7.2). Place a

thread sealant compound on the threads of

the actuator post (7.2) prior to installing the

actuator nut (7.3). Install actuator nut (7.3)

and tighten to the following torque value: 15

Ft-lbs (20 Nm).

9. Place the diaphragm gasket (10) onto the

body (1) diaphragm flange. Place diaphragm

subassembly (7) on top of the gasket (10).

10. Lubricate the threads of the body (1) with

a lightweight grease that is compatible with

service use. Rotate the spring chamber (6)

CW by hand onto the threaded portion of

the body (1) until firmly seated against the

diaphragm gasket (10). Tighten to the follow-

ing torque value: 65–70 Ft lbs (88–95 Nm).

11. Pressurize with air and spray liquid leak de-

tector around body (1) and spring chamber

(6) to test for leakage. Ensure that an outlet

pres

sure is maintained during this leak test

Figure 1: Diaphragm Subassembly

WARNING

SYSTEM UNDER PRESSURE. Prior to performing

any maintenance, isolate the regulator from the

system and relieve all pressure. Failure to do so

could result in personal injury.