4IOM-CA

8. Remove diaphragm gasket (12) for metal

diaphragm (11). NOTE: No diaphragm

gasket (12) for composition diaphragm (11).

9. Clean body (1) and diaphragm flange. NOTE:

On regulators originally supplied as “oxygen

clean”, Option -5 or Option -55, maintenance

must include a level of cleanliness equal

to Cashco's cleaning standard #S-1134.

Contact factory for details.

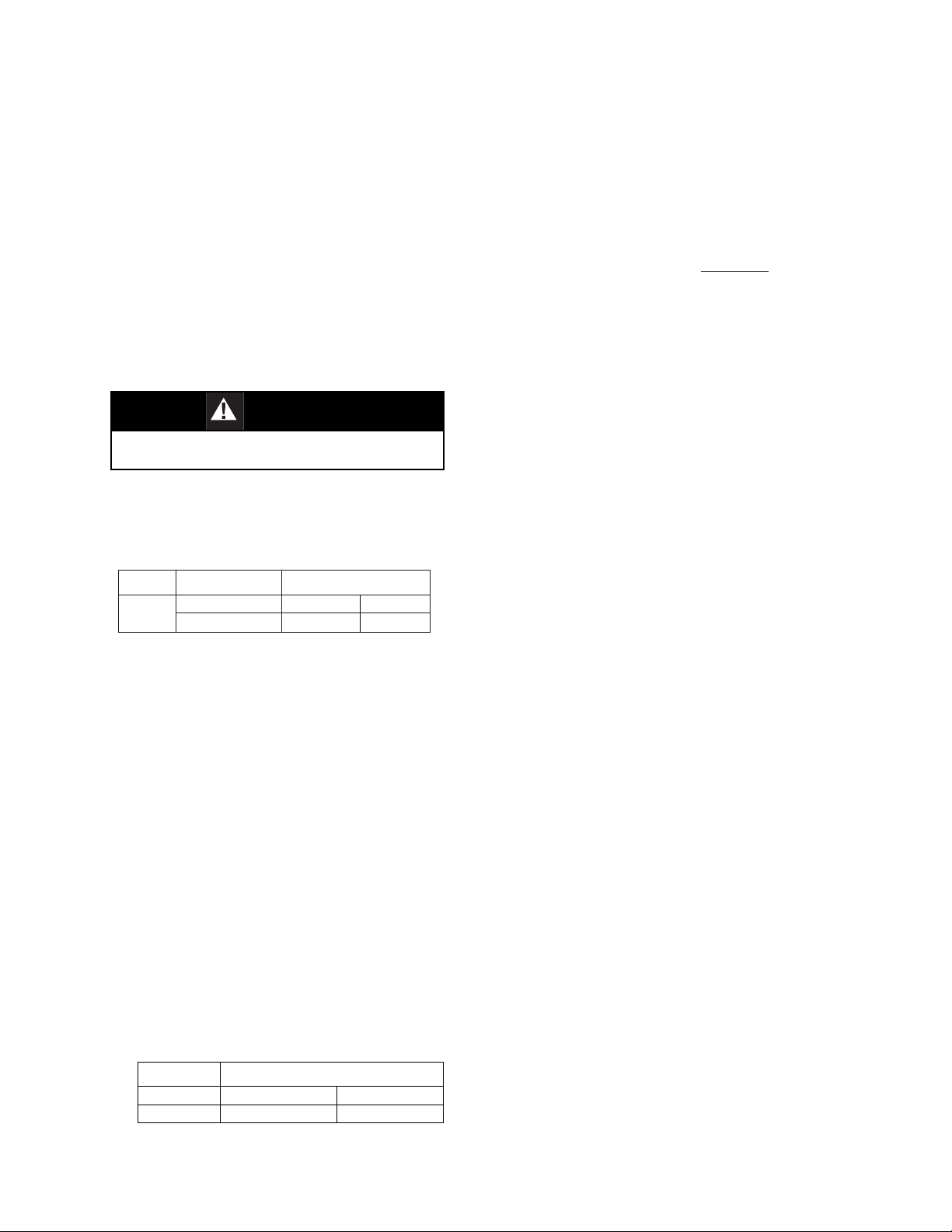

10. Reassemble diaphragm subassembly by

placing plug gasket (13), diaphragm(s) (11),

pressure plate (10) and lock washer (8)

over threaded post of plug (14). Ensure the

pressure plate (10) is placed with curved outer

rim down next to the diaphragm (11) surface.

Place a thread sealant compound similar to

Loctite #271 on the threads of the plug's (14)

post prior to tightening the pressure plate nut

(7) to the following torque values:

15. Reinstall adjusting screw (3) with locknut (4)

into the spring chamber (2).

16. Pressurize with air and spray liquid leak

detector to inspect entire body (1) and spring

chamber (2) for leakage. Ensure that an inlet

pressure is maintained during this leak test

of at least mid-range spring level; i.e. 40-90

psig (2.8-6.2 Barg) range spring, 65 psig (4.5

Barg) test pressure minimum.

C. Trim Replacement

1. Trim inspection requires the diaphragm

subassembly be removed. Refer to previous

procedure, Section VI.B.

2. Inspect inside surface of seat ring (15) and

seating surface of plug (14). If seating surface

shows signs of erosion/wear, the seat ring

(15) and plug (14) should be replaced.

3. Clean body (1) cavity. Clean all parts to be

reused. NOTE: On regulators originally

supplied as “oxygen clean”, Option -5 or

Option -55, maintenance must include a level

of cleanliness equal to Cashco's cleaning

standard #S-1134. Contact factory for details.

4. Inspect the surface in the body (1) cavity

where seat ring (15) rests. If surface area of

either mating part shows signs of erosion/

wear, replace with new regulator.

5. Place seat ring (15) in center of body (1)

cavity. Ensure that the shoulder on outer

edge of seat ring (15) faces up towards the

diaphragm (11).

6. Reinstall diaphragm subassembly per

Section VI.B., Diaphragm Replacement.

7. Bench test unit for suitable operation. NOTE:

Regulators are not tight shut off devices.

Even if pressure falls below setpoint, a

regulator may or may not develop bubble

tight shut off. In general, tighter shut off can

be expected with composition seat.

8. Pressurize with air and spray liquid leak

detector to inspect entire body (1) and spring

chamber (2) for leakage. Test pressure

should be the maximum allowed by the range

spring at the inlet.

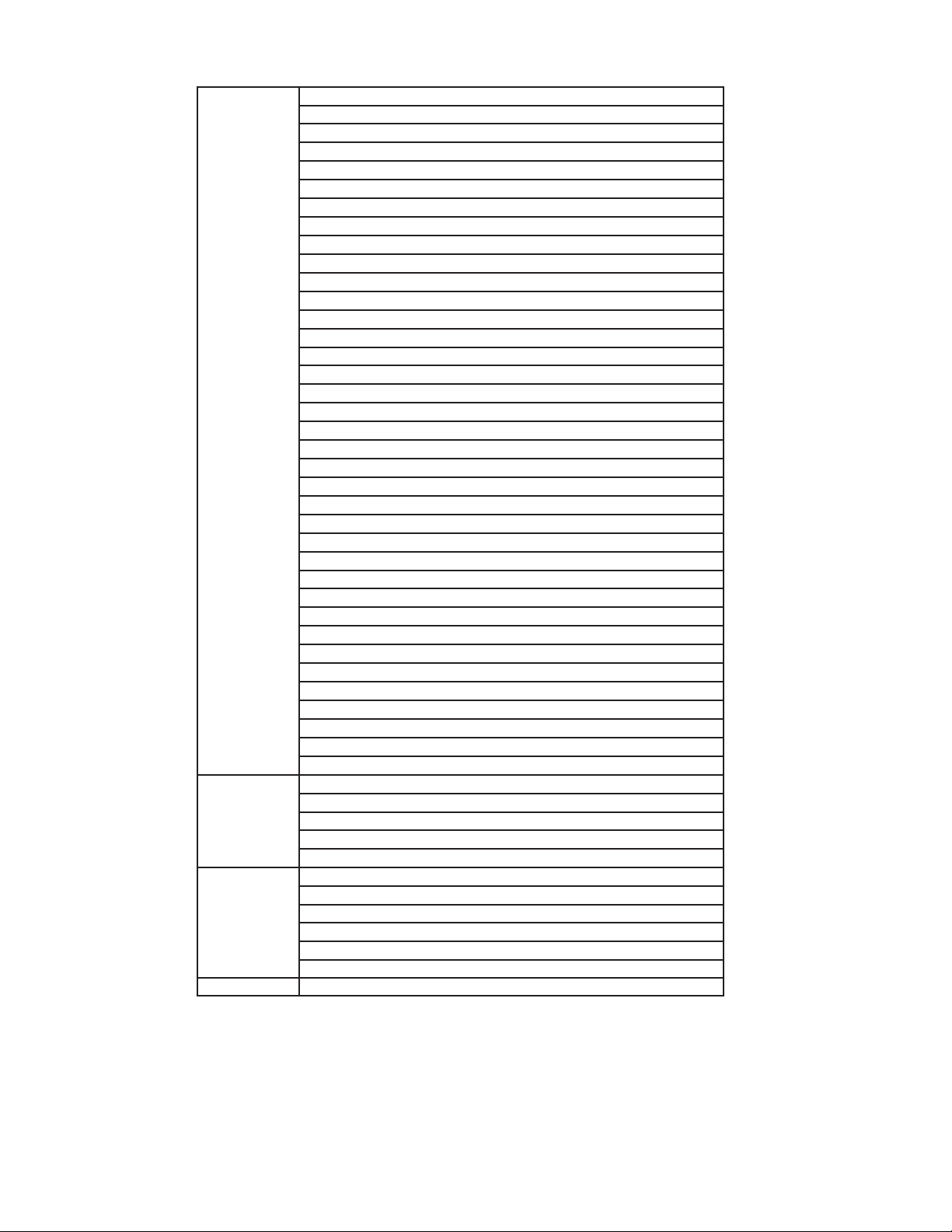

Model Torque

CA-1 20-25 Ft-lbs. 27-34 N-m

CA-2 25-30 Ft-lbs. 34-40 N-m

Sizes Diaphragm Torque

ALL Metal 60 In-lbs. 6.8 N-m

Composition 15 In-lbs. 1.7 N-m

11. Place diaphragm gasket (12) on

body (1), then insert the diaphragm

subassembly into the body (1).

12. Place diaphragm stop (9) and range

spring (6) over the pressure plate nut

(7) of the diaphragm subassembly.

13. Place multi-purpose, high temperature

grease into depression of spring button

(5) where adjusting screw (3) bears. Set

spring button (5) onto range spring (6);

ensure spring button (5) is laying flat.

14. Rotate the spring chamber (2) CW by

hand into the threaded portion of the

body (1) assuring not to cross thread.

Continue hand rotating CW until firmly

seated against the diaphragm stop (9).

Wrench tighten securely to the following

torque values:

Use only gaskets supplied by Cashco, Inc.

for these products.

CAUTION