Introduction, General REFLECTA/5

Page A2 Mounting & Operations Manual

Content

Introduction, General

Compass Binnacle, Outline...................................................................................................................A3

General..................................................................................................................................................A4

Technical Data ......................................................................................................................................A4

Range of Delivery..................................................................................................................................A5

Approvals...............................................................................................................................................A5

Operation

How to Read the Heading.....................................................................................................................B1

Adjustment of Mirror Head ....................................................................................................................B1

Direct Reading of Heading on the Compass Bridge.............................................................................B2

Removing/Attaching of Binnacle Hood..................................................................................................B2

Taking Bearings ....................................................................................................................................B2

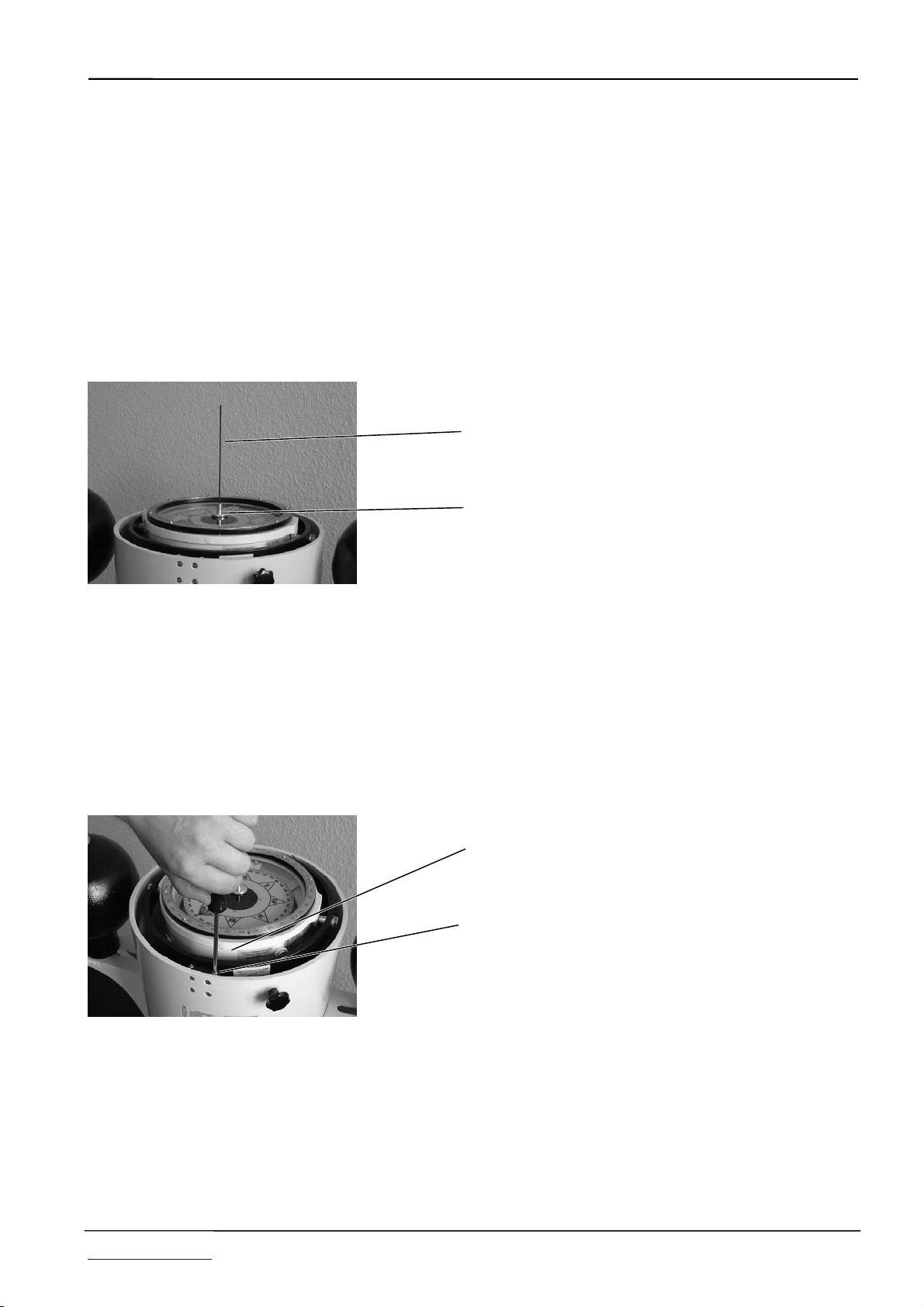

Shadow Pin ...........................................................................................................................................B3

Removing the Compass out of the Binnacle.........................................................................................B3

Spare Compass.....................................................................................................................................B3

Maintenance of Compass and Compass Binnacle...............................................................................B3

Compass Adjustment

General..................................................................................................................................................C1

A-Correction ..........................................................................................................................................C1

B+C-Correction......................................................................................................................................C1

D(μ)-Correction......................................................................................................................................C2

D(cylinder)-Correction...........................................................................................................................C3

Heeling-Correction ................................................................................................................................C3

E-Correction ..........................................................................................................................................C5

Mainenance, Errors, Repair

Maintenance

Lubrication of Compass Suspensions ........................................................................................D1

Compass Routine Service ..........................................................................................................D1

Replacing Bulbs..........................................................................................................................D1

Cleaning of Reflector Optics.......................................................................................................D2

Errors, Diagnosis and Help

Visible Compass Errors ..............................................................................................................D3

Indication Errors..........................................................................................................................D3

Replacement of compass ...........................................................................................................D3

Workshop Repair of Compass..............................................................................................................D5

Installation

Procedure, Outline ................................................................................................................................E1

Range of Delivery..................................................................................................................................E1

Location of Binnacle, Magnetic Requirements......................................................................................E2

Location of Binnacle, Constructional Requirements.............................................................................E3

Optical Arrangement (Reflection Tube), Requirements for Installation ................................................ E4

Compass Foundation, Cut-outs and Drillings .......................................................................................E5

Installation of the Optical Arrangement (Reflection Tube)....................................................................E6

Installation of Compass Binnacle..........................................................................................................E8

Illumination ..........................................................................................................................................E10

Illumination Dimmer.............................................................................................................................E10

Replacing of the Bulbs ........................................................................................................................E10

Wiring ..................................................................................................................................................E11

Setting into Operation, Function Tests & Preparing of Adjustment ....................................................E12

Alterations / Errors reserved

Cassens & Plath GmbH, Am Lunedeich 131, 27572 Bremerhaven, Germany, Tel. +49 471 483 999 0, Fax +49 471 483 999 10