Interroll Diverter SH 1500 User manual

INSPIRED BY EFFICIENCY

Installation and Operating Instructions

Interroll Diverter

SH 1500

Rated width 690 mm (M), 842 mm (L)

Version 1.0 (06/2022) en

Translation of original operating instructions

Manufacturer's address

Interroll Trommelmotoren GmbH

Center of Excellence Hygienic Solutions

Opelstraße 3

41836 Hueckelhoven/Baal (Germany)

www.interroll.com

Interroll Service

Our Service Team will gladly provide advice in case of questions or problems:

Hotline: +49 (0) 2193 - 23 222

E-mail: [email protected]

Contents

We strive for the information presented to be correct, up to date and complete. We have

carefully developed the contents of this document. Nevertheless, errors and changes are

expressly subject to change.

Copyright / intellectual property right

Texts, images, graphics and the like as well as their arrangement are protected by

copyright and other protection laws. Reproduction, modification, transfer or publication

of any part or the entire content of the document in any form is prohibited. This

document is intended exclusively for information purposes and for intended use and does

not authorize replicating the respective products. All signs contained in this document

(registered trademarks, such as logos and business designations) are the property of

Interroll Trommelmotoren GmbH or third parties and may not be used, copied or

distributed without prior written consent.

Interroll T. Nr. 1131914

Version 1.0 (06/2022) en

Translation of original operating instructions

Interroll Diverter SH 1500

Version 1.0 (06/2022) en

Translation of original operating instructions

3

Table of contents

Introduction............................................................................................................................ 6

Notes about working with the installation and operating instructions...................................... 6

Contents of these installation and operating instructions ...................................................... 6

Integrated part of the product ...................................................................................................... 6

Installation and operating instructions are part of the module............................................ 6

Warning notices in this document........................................................................................................ 7

Symbols....................................................................................................................................................... 7

Safety ..................................................................................................................................... 8

State of the art ......................................................................................................................................... 8

Intended use .............................................................................................................................................. 8

Field of use.......................................................................................................................................... 8

Changes to the module ................................................................................................................... 8

Unintended use......................................................................................................................................... 9

Personnel qualification ............................................................................................................................ 9

Operators............................................................................................................................................ 9

Service personnel.............................................................................................................................. 9

Electricians........................................................................................................................................... 9

Personal protective equipment ............................................................................................................. 10

Dangers ...................................................................................................................................................... 11

Safety devices.................................................................................................................................... 11

Heat ...................................................................................................................................................... 11

Electricity.............................................................................................................................................. 11

Rotating parts..................................................................................................................................... 11

Parts lying around or falling off .................................................................................................... 11

Risk of injury due to faults during operation.............................................................................. 11

Insufficient hygiene............................................................................................................................ 11

Maintenance intervals............................................................................................................................. 11

Interfaces to other devices .................................................................................................................... 12

Operating modes..................................................................................................................................... 12

Normal mode..................................................................................................................................... 12

Special mode...................................................................................................................................... 12

Product identification ........................................................................................................... 13

Diverter (SH 1500).................................................................................................................................. 13

Components........................................................................................................................................ 13

Property ............................................................................................................................................... 14

Technical data .................................................................................................................................... 15

Scope of supply........................................................................................................................................ 16

Nameplate................................................................................................................................................. 17

Transport and storage .......................................................................................................... 18

Transport..................................................................................................................................................... 18

After the delivery .............................................................................................................................. 18

Storage....................................................................................................................................................... 18

Interroll Diverter SH 1500

Table of contents

4 Version 1.0 (06/2022) en

Translation of original operating instructions

Installation ............................................................................................................................. 19

To be observed during installation...................................................................................................... 19

Electrical installation ......................................................................................................................... 19

Torque................................................................................................................................................... 20

Grounding........................................................................................................................................... 20

Orientation.......................................................................................................................................... 20

Connection.......................................................................................................................................... 20

Anchoring............................................................................................................................................ 20

Integration into complete system .................................................................................................. 20

Installing supports .................................................................................................................................... 21

Integrating the module in a complete system................................................................................... 22

Installing the universal support............................................................................................................. 23

Installing the side guide.......................................................................................................................... 25

Installing the photo cell and reflector................................................................................................. 26

Installing the photo cell.................................................................................................................... 27

Installing the reflector....................................................................................................................... 28

Connecting the modules......................................................................................................................... 29

Straight module belt conveyor (50) - lateral diverter............................................................. 30

Lateral diverter - straight module belt conveyor (80)............................................................. 31

Straight roller conveyor - lateral diverter .................................................................................. 33

Straight roller conveyor - front diverter ..................................................................................... 34

Straight module belt conveyor (80) - front diverter................................................................ 35

Front diverter - straight module belt conveyor (50) ................................................................ 36

Module conveyor curve - front diverter...................................................................................... 36

Module conveyor curve - lateral diverter .................................................................................. 40

Roller curve - lateral diverter......................................................................................................... 41

Roller curve - front diverter............................................................................................................ 42

Initial startup and operation................................................................................................ 43

Initial startup.............................................................................................................................................. 43

Operation .................................................................................................................................................. 44

Before every operation start.......................................................................................................... 44

During operation............................................................................................................................... 44

Procedure in case of accident or fault ........................................................................................ 44

Cleaning................................................................................................................................. 45

Preparation for cleaning by hand....................................................................................................... 46

Manual cleaning....................................................................................................................................... 46

Resistance................................................................................................................................................... 48

Maintenance and repair ...................................................................................................... 49

Observe the following for maintenance and repair ...................................................................... 49

Maintenance intervals............................................................................................................................. 50

Maintenance and inspection list........................................................................................................... 50

Preparatory and follow-up maintenance work ............................................................................... 51

Removing/installing the side plates.............................................................................................. 51

Replacing the belt conveyor.................................................................................................................. 52

Replace drum motor fastening ............................................................................................................. 54

Maintenance tasks on the ball module conveyor............................................................................ 56

Interroll Diverter SH 1500

Table of contents

Version 1.0 (06/2022) en

Translation of original operating instructions

5

Replacing the ball module conveyor............................................................................................ 56

Replacing the drum motor .............................................................................................................. 57

Replace the sprockets....................................................................................................................... 59

Replacing the return wheel (outside)............................................................................................ 60

Replacing the return wheel (center) ............................................................................................. 61

Replacing the idler pulley................................................................................................................ 62

Replacing the guide plate ............................................................................................................... 63

Troubleshooting..................................................................................................................... 65

In case of a fault....................................................................................................................................... 65

Troubleshooting ........................................................................................................................................ 65

Spare and wear parts .......................................................................................................... 67

Ordering information.............................................................................................................................. 67

Spare parts drawing............................................................................................................................... 68

Spare parts list.......................................................................................................................................... 69

Decommissioning and disposal .......................................................................................... 70

Environmental protection regulations................................................................................................. 70

Declaration of incorporation ............................................................................................... 71

Declaration of incorporation ............................................................................................... 73

Appendix ............................................................................................................................... 75

Warranty for Interroll module belt conveyors ................................................................................. 75

Restrictions........................................................................................................................................... 75

Exceptions............................................................................................................................................ 75

Interroll Service......................................................................................................................................... 75

Interroll Diverter SH 1500

6 Version 1.0 (06/2022) en

Translation of original operating instructions

Introduction

Notes about working with the installation and operating instructions

The Interroll Übergabemodul product is generally referred to as "module" in this document.

Contents of these

installation and operating

instructions

These installation and operating instructions contain important notes and information about the

various operating phases of the module:

• Transport, assembly and startup

• Safe operation, required maintenance tasks, removal of any faults

• Spare parts, supplementary accessories

Integrated part of the

product

The installation and operating instructions describe the module at the time of its initial delivery

after manufacturing.

In addition to these installation and operating instructions, special contractual agreements and

technical documents apply to special versions of the module and its additional equipment.

Installation and operating

instructions are part of the

module

4To ensure trouble-free and safe operation, as well as the settlement of possible warranty

claims, always read these installation and operating instructions first and observe all

information contained herein.

4Keep the installation and operating instructions close to the module.

4Pass the installation and operating instructions on to any subsequent operator or occupant.

Interroll does not accept any liability for faults or defects due to non-observance of these

installation and operating instructions.

4If you have any questions after reading the installation and operating instructions, please

contact Interroll customer service. Contact persons near you can be found on the Internet

under: www.interroll.com/contact.

Interroll Diverter SH 1500

Introduction

Version 1.0 (06/2022) en

Translation of original operating instructions

7

Warning notices in this document

The warning notices refer to risks which may arise while using the module. They are available in

four danger levels identified by the signal word:

Signal word Meaning

DANGER Identifies a danger with high risk that will result in death or serious

injury if it is not avoided.

WARNING Identifies a danger with medium risk that could result in death or

serious injury if it is not avoided.

CAUTION Identifies a danger with low risk that may result in minor or medium

injury if it is not avoided.

NOTICE Identifies a danger that results in property damages.

Symbols

This symbol marks useful and important information.

Requirement:

RThis symbol represents a prerequisite to be met prior to installation and maintenance work.

4This symbol marks the steps to be carried out.

Interroll Diverter SH 1500

8 Version 1.0 (06/2022) en

Translation of original operating instructions

Safety

State of the art

The module has been built to comply with the state of the art. Nevertheless, users may encounter

hazards during its use.

Disregarding the notices in these installation and operating instructions may lead to life-

threatening injuries!

4Carefully read the installation and operating instructions and follow their content.

4Observe local accident prevention regulations and general safety regulations that apply in

the area of use.

Intended use

The module may only be used for industrial applications and in an industrial environment to

convey belt conveyor-ready goods, such as all types of boxes, packaged food or beverage units.

The module is an incomplete machine and must be integrated into a complete system prior to

operation.

Field of use The module is dimensioned only for a certain field of use and may not be operated outside of

these specific limits. For additional information, see the chapter "Technical Data".

Any other use is considered inappropriate. Deviating operating conditions require additional

clarifications, a special release of the module and new contractual agreements.

Changes to the module Any modifications that affect the safety are not permitted.

Interroll Diverter SH 1500

Safety

Version 1.0 (06/2022) en

Translation of original operating instructions

9

Unintended use

Any use beyond the intended use is considered inappropriate or, if required, must be authorized

by Interroll Trommelmotoren GmbH. Setup and operation in explosive atmospheres is prohibited.

The use in a medical-pharmaceutical area requires the approval from Interroll.

The transport of persons is prohibited.

The transport of hazardous or damaging goods is prohibited.

The transport of hot or hygroscopic goods is prohibited.

Installation in unprotected rooms exposed to the weather or in areas where the technology

deteriorates and can fail due to the prevailing climatic conditions is considered inappropriate

use.

Use of the module is not intended for private end customers! Use in a residential area is

prohibited without additional assessment and without the use of EMC protective measures that

have been adapted accordingly!

Personnel qualification

Unqualified personnel cannot recognize risks and, as a result, is subject to greater dangers.

4Authorize only qualified personnel to perform the activities described in these instructions.

4The operating company must ensure that personnel follow locally applicable regulations and

rules about safety and hazards while working.

The following target groups are addressed in these instructions:

Operators Operators have been instructed in the operation and cleaning of the module and follow the

safety guidelines.

Service personnel The service personnel features a technical training and performs the maintenance and repair

tasks.

Electricians Persons working on electrical installations must have pertinent technical training.

Interroll Diverter SH 1500

Safety

10 Version 1.0 (06/2022) en

Translation of original operating instructions

Personal protective equipment

4For all work, such as assembly, maintenance and cleaning tasks, wear personal protective

equipment that is suitable and appropriate for the hazard situation.

Close-fitting work clothing

Protective gloves

Safety shoes

Hard hat

Hearing protection

Interroll Diverter SH 1500

Safety

Version 1.0 (06/2022) en

Translation of original operating instructions

11

Dangers

The following list informs you about the various types of danger or damage that may occur

while working with the module.

Safety devices 4Perform any maintenance and repair work on the module only when it is powered down and

ensure that it cannot be started accidentally.

4In an area frequented by people or if people can reach between conveying goods, take

additional protective measures.

4Do not remove protective covers or housing.

4Regularly check the safety devices.

Heat 4Do not touch the drum motor during operation. Risk of burns.

Electricity 4Reach into the module only if the module is de-energized.

Rotating parts 4Never wear loose clothing.

4Never wear jewelery, such as necklaces or bracelets.

4If you have long hair, always wear a hair net.

Parts lying around or

falling off

4Remove equipment or material which is not required from the workspace.

4Wear safety shoes.

4Specify and monitor careful placement of the goods on the conveyor.

Risk of injury due to faults

during operation

4Regularly check the module for visible damage.

4Stop the module at once and ensure that it cannot be started accidentally in case of:

Smoke from a fire, unusual noise, blocked or defective conveying good, defective supports,

side guides or accessory devices, unauthorized removal of safety covers.

4Promptly have qualified personnel determine the cause of the fault.

4Immediately remove any escaping gear oil.

4Do not step onto the module during operation.

Insufficient hygiene 4Clean the module regularly.

4Follow all notices relevant to hygiene in these instructions.

Maintenance intervals

4Regularly perform maintenance and inspection work.

4Use only OEM spare parts.

Interroll Diverter SH 1500

Safety

12 Version 1.0 (06/2022) en

Translation of original operating instructions

Interfaces to other devices

Hazard locations may occur while integrating the module into a complete system. These are not

part of this manual and have to be analyzed during the installation and startup of the complete

system.

4When combining the module with other modules or machinery, check for new hazard

locations before startup.

4If necessary, take further construction measures.

Operating modes

Normal mode The module is installed at the customer in a complete system and operated as part of the system.

Special mode Special operation refers to all operating modes that are required to guarantee and maintain

regular operation.

Special operating mode Explanation Comment

Transport/storage Loading and unloading, transport and storage -

Assembly/initial startup Installation at the end customer and performing the test run -

Cleaning External cleaning without removing protective devices When powered down

Maintenance/repairs Maintenance and inspection tasks When powered down

Troubleshooting Troubleshooting in the event of a fault -

Fault elimination Eliminating the fault When powered down

Decommissioning Removal from the complete system When powered down

Disposal Removal from the complete system and disassembly When powered down

Interroll Diverter SH 1500

Version 1.0 (06/2022) en

Translation of original operating instructions

13

Product identification

Diverter (SH 1500)

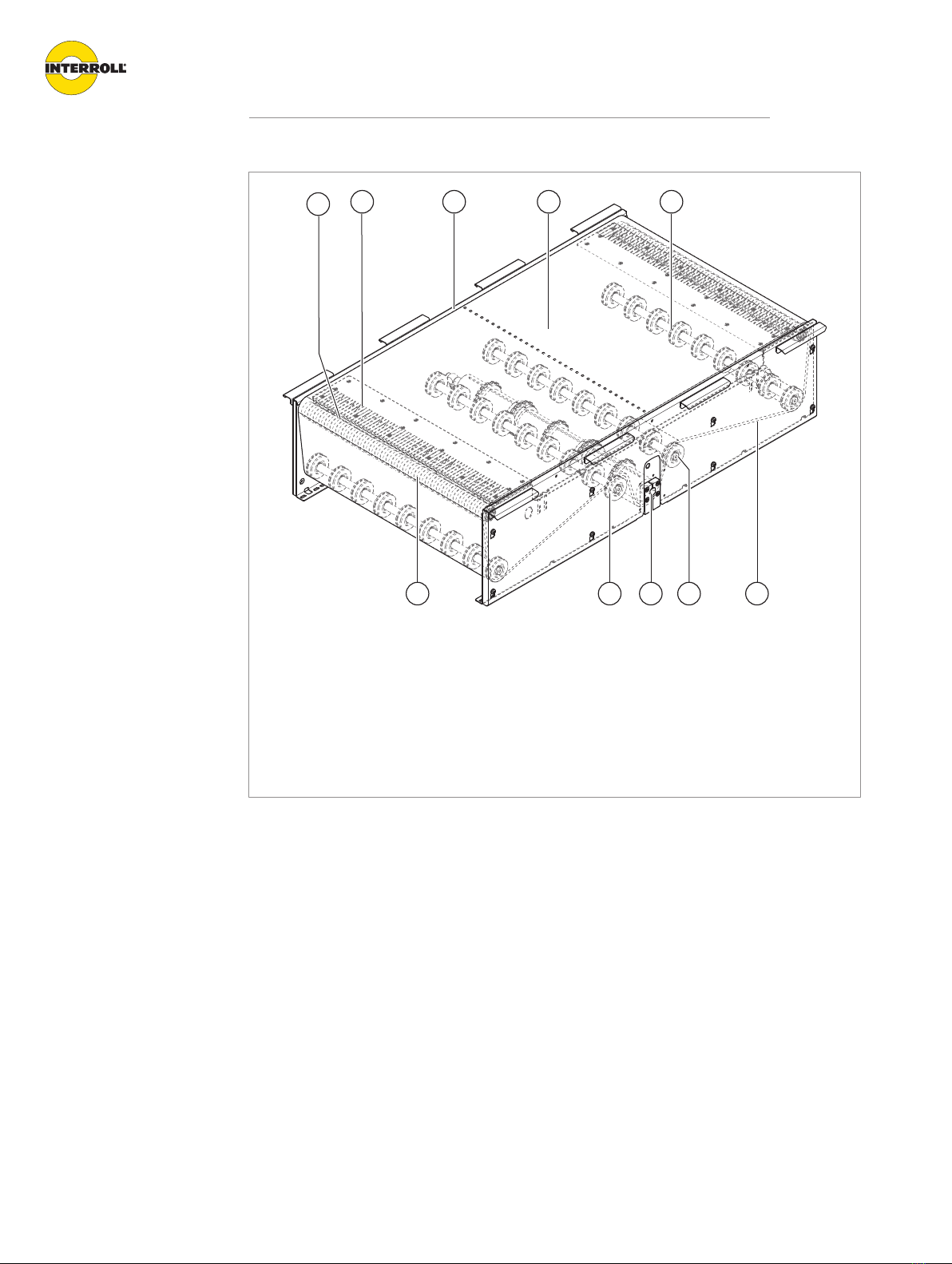

Components The diverter consists of a cassette (belt conveyor) and a frame (ball module conveyor). They are

assembled into a diverter.

1

1

3 4

2

58 67

Belt conveyor cassette

1 Idler pulley 5 Belt

2 Drum motor 6 Side frame

3 Tensioning roller 7 Tensioning tab

4 Pressure plate 8 Cable tie holder

Interroll Diverter SH 1500

Product identification

14 Version 1.0 (06/2022) en

Translation of original operating instructions

1

3 4 5

2

68 779

Diverter (ball module conveyor frame with inserted belt conveyor)

1 Transfer plate 6 Ball module conveyor

2 Guide plate 7 Return wheel (center)

3 Cover plate with sensor holders 8 Drum motor with installed sprockets

4 Control belt for ball conveyor (on belt

conveyor cassette)

9 Idler pulley

5 Return wheel (outside)

Property The diverter SH 1500 is used for diverting a suitable conveying goods into 6 different directions.

Turning the conveying goods is not possible in this process.

Depending on the size of the module, the rated width is 690mm (M) or 842mm (L).

The module consists of a cassette (belt conveyor) and a frame (ball module conveyor). They are

assembled into a diverter: The belt conveyor controls the diverter with a transverse running belt.

In the outside frame of the diverter, the ball module conveyor is controlled by the module

conveyor drive assembly.

A frequency inverter can be used as an option. Observe the installation guidelines of the

frequency inverter manufacturer (e.g. the frequency inverter from Getriebebau Nord).

Interroll Diverter SH 1500

Product identification

Version 1.0 (06/2022) en

Translation of original operating instructions

15

Technical data SH 1500

Rated width (BF) 690 mm (M)

842 mm (L)

Conveying width (CW)

Dimensions of conveying good Min.: 100 x 100 mm

Max.: 700 x 800 mm

Max. load capacity 35 kg/m

Conveyor speed control belt 1.0 m/s

Conveyor speed ball belt 0.4 m/s

Ball circumferential speed 0.8 m/s

Max. conveying speed for straight transported

goods

1 m/s

Max. conveying speed for 45° transported

goods

1.18 m/s

Max. conveying speed for 90° transported

goods

0.8 m/s

Ambient temperature –5 to +40 °C

Incline/decline Not suitable

Module length 1500 mm

Conveying height (TOB) Preselected in the layouter

Motor type control belt (webbing) Drum motor DM 0080 synchr./asynchr. rubber-

coated

Motor type ball belt Drum motor DM 0080 synchr./asynchr. with

sprockets

Rated voltage 230/400 V 50 Hz

230/460 V 60 Hz

Electrical power 2x 550 W

Drive system ball belt Center drive

Transmission of force Sprockets

Frequency inverter Standard: Getriebebau Nord

Throughput approx. 1400 goods per hour

Diverter direction 0°, 45°, 90°, 180°

Conveyor material control belt Ammeraal Ropanyl

Conveyor material ball belt Ammeraal Uni QNB-Ball

Protection rating Drum motor: IP 69 K

Frequency inverter: IP 20 or IP 66

Interroll Diverter SH 1500

Product identification

16 Version 1.0 (06/2022) en

Translation of original operating instructions

Scope of supply

The module is delivered completely assembled.

The scope of delivery includes:

• Rack for cassette including side frames, crossbeams and pressure plate

• Rack for frame including side frames and transfer plates

• Drive (drum motor with installed sprockets as OMEGA center drive (ball module conveyor)

and drum motor (belt conveyor))

• Rollers (idler pulleys, return wheels)

• Webbing

• Ball module conveyor, transfer plates

• Side plates

Optional:

• Photo cell and reflector, sensor holder and universal support

• Side guides, side guide brackets and universal support

• Connector sets incl. module connectors and contact guards

• Frequency inverter (e.g. from Getriebebau Nord)

• Electronics

• Supports

The side guide profiles and sensors are delivered installed (if ordered).

Interroll Diverter SH 1500

Product identification

Version 1.0 (06/2022) en

Translation of original operating instructions

17

Nameplate

Conveyor Type

Interroll Trommelmotoren GmbH

Center of Excellence Hygienic Solutions

Opelstraße 3

41836 Hueckelhoven/Baal (Germany)

www.interroll.com

TypePlate

Level

Layout Position .No.

Sales Order No. / Pos. Serial Number

Build Year

Weight [kg]

10

4

1

3

2

5

7

8

9

6

Nameplate

1 Arrow in transport direction 6 Machine number

2 Company address 7 Serial number

3 Type designation 8 QR code

4 Level 9 Year of manufacture

5 Layout item no. 10 Weight in kg

The information on the nameplate is used to identify the conveyor. The type designation is

required to use the conveyor according to its intended use.

The nameplate is located on the right side frame.

Interroll Diverter SH 1500

18 Version 1.0 (06/2022) en

Translation of original operating instructions

Transport and storage

Transport

WARNING

Risk of injury during transport

4Fasten the module securely and slip-proof for transport.

4Ensure that the lifting device (e.g. fork lift) is rated for the weight of the module.

4Ensure that there are no persons under the suspended load while lifting and moving the

module.

4Have any persons leave the danger zone.

4Wear safety shoes.

4Check correct fastening for transport.

Loosen the transport locks around the package. The crossbeams above the top module can then

be removed, thereby exposing the module. The individual module is lifted out of the package

using a suitable lifting device.

After the delivery 4Inspect module for transport damages.

4Immediately notify the carrier and manufacturer in case of damages to avoid losing any

claims for compensation.

Storage

WARNING

Risk of injury due to improper storage

4Do not stack modules. Do not place any other objects on the module.

4Check module for stability.

4If the module is not immediately placed in operation, store it at a location protected against

humidity and dust.

Interroll Diverter SH 1500

Version 1.0 (06/2022) en

Translation of original operating instructions

19

Installation

WARNING

Risk of injury due to improper assembly

4Mechanical assembly tasks should be performed only by service personnel. Observe the

safety information.

4Electrical assembly tasks should be performed only by authorized electricians. Observe the

safety information.

4Carefully install all terminals and connections, such as cables, hoses and pipework, and

check for correct fit.

The module is delivered to the installation site as a pre-assembled unit and must be set up,

connected and integrated into a system on site.

If available, photo cell and reflector are already pre-assembled and connected. The side guides

(universal support, side guide brackets and side guides) are also delivered assembled.

The installation tasks are divided into two sections:

• Setting up the module

• Integrating the module into a complete system

To be observed during installation

Electrical installation

DANGER

Danger - energized cable ends!

4Electrical installation should only be performed by qualified electricians.

4Ensure that the device is powered down.

4Minimum bending radii of cables, hoses and lines must be maintained.

DANGER

Danger to life from electrocution and crushing

Installation and maintenance tasks on 400-V conveyor systems while they are in operation can

cause life-threatening electrocution and serious crushing.

4Power down the entire conveyor module and ensure that it cannot be started accidentally.

Interroll Diverter SH 1500

Installation

20 Version 1.0 (06/2022) en

Translation of original operating instructions

The module is provided with voltage either via CEE plug or direct installation in the control

cabinet.

4Check cables and components for damage before installation.

4The connection values of the module are listed on the motor nameplate.

Static electricity

Take proper measures for grounding and potential equalization.

Use only original fuses with specified amperage.

Torque When tightening screws and nuts, always observe the standard tightening torque, unless

specifically indicated otherwise. Standard screw lockers should be replaced as needed.

Grounding During installation of the module, its grounding must be ensured. A grounding connection, which

is fastened at the supports, is intended for this purpose. It is recommended to connect a

grounding connection with grounding cable every 20 m.

Orientation 4Align the module using the height-adjustable feet of the support. The roller top edge (for

roller conveyors) or the module conveyor top edge (for module belt conveyors) is the

relevant height for aligning the modules. Use suitable tools for the alignment (spirit level or

rotation laser).

4Secure the adjusted height.

4During alignment of the module, ensure that no moving parts are touching.

Connection 4Connect the individual modules with each other using the profile connector.

4During the setup of the module, check the passageways for the personnel. Install transitions

as necessary.

Anchoring 4Anchor or fasten the module torsion-free, e.g. to the floor or to adjacent components.

Integration into complete

system

4When integrating the module into the complete system, consider possible danger spots,

particularly infeed locations and interfaces.

Table of contents

Other Interroll Industrial Equipment manuals