Table of contents

Chapter 1. Introduction...................................................................................................... 6

1.1. Application ........................................................................................................... 7

1.2. Contraindication................................................................................................... 7

1.3. Service Life ........................................................................................................... 7

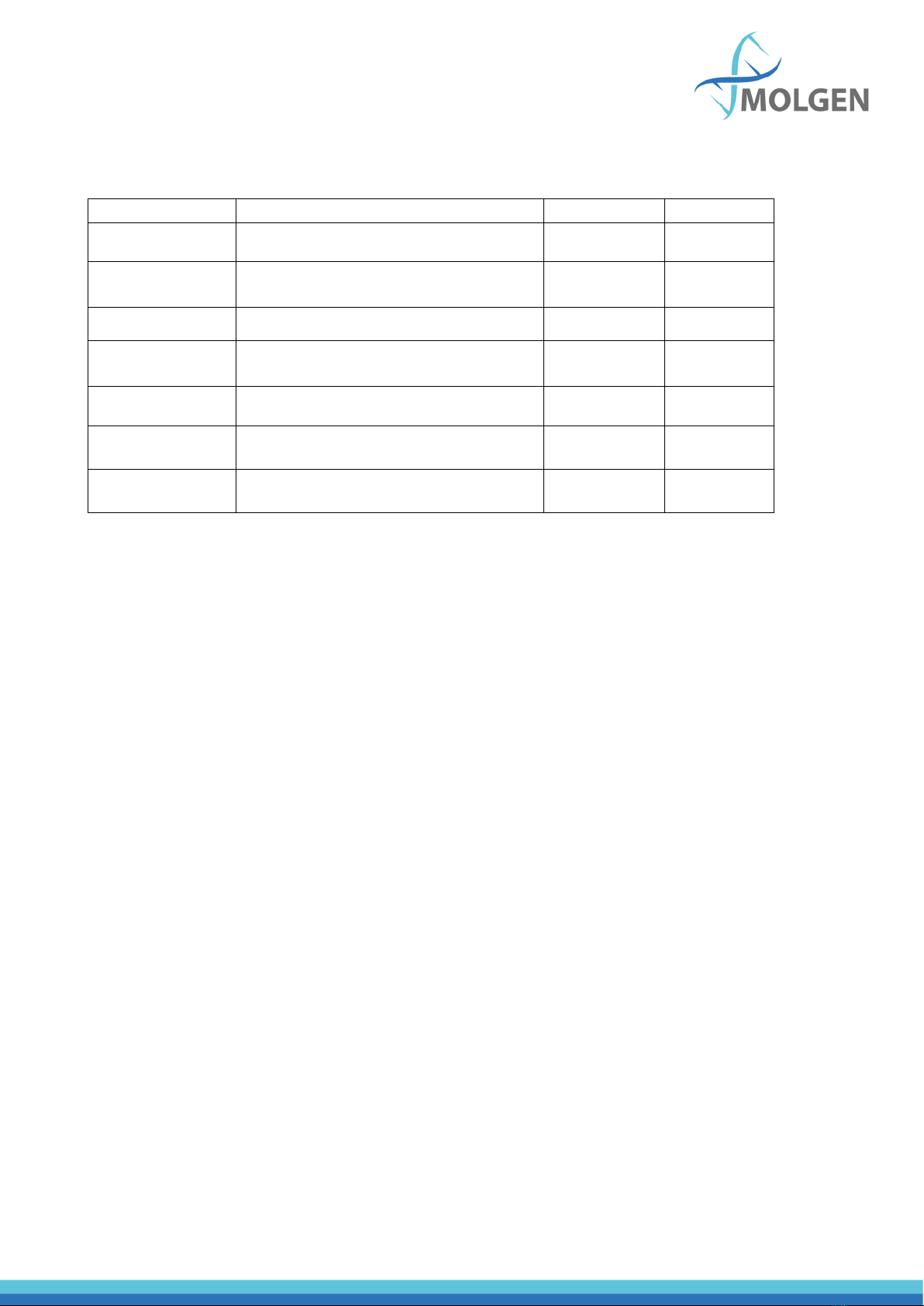

Chapter 2. Specifications.................................................................................................... 8

2.1. Working Conditions.............................................................................................. 8

2.2. Basic Parameters .................................................................................................. 8

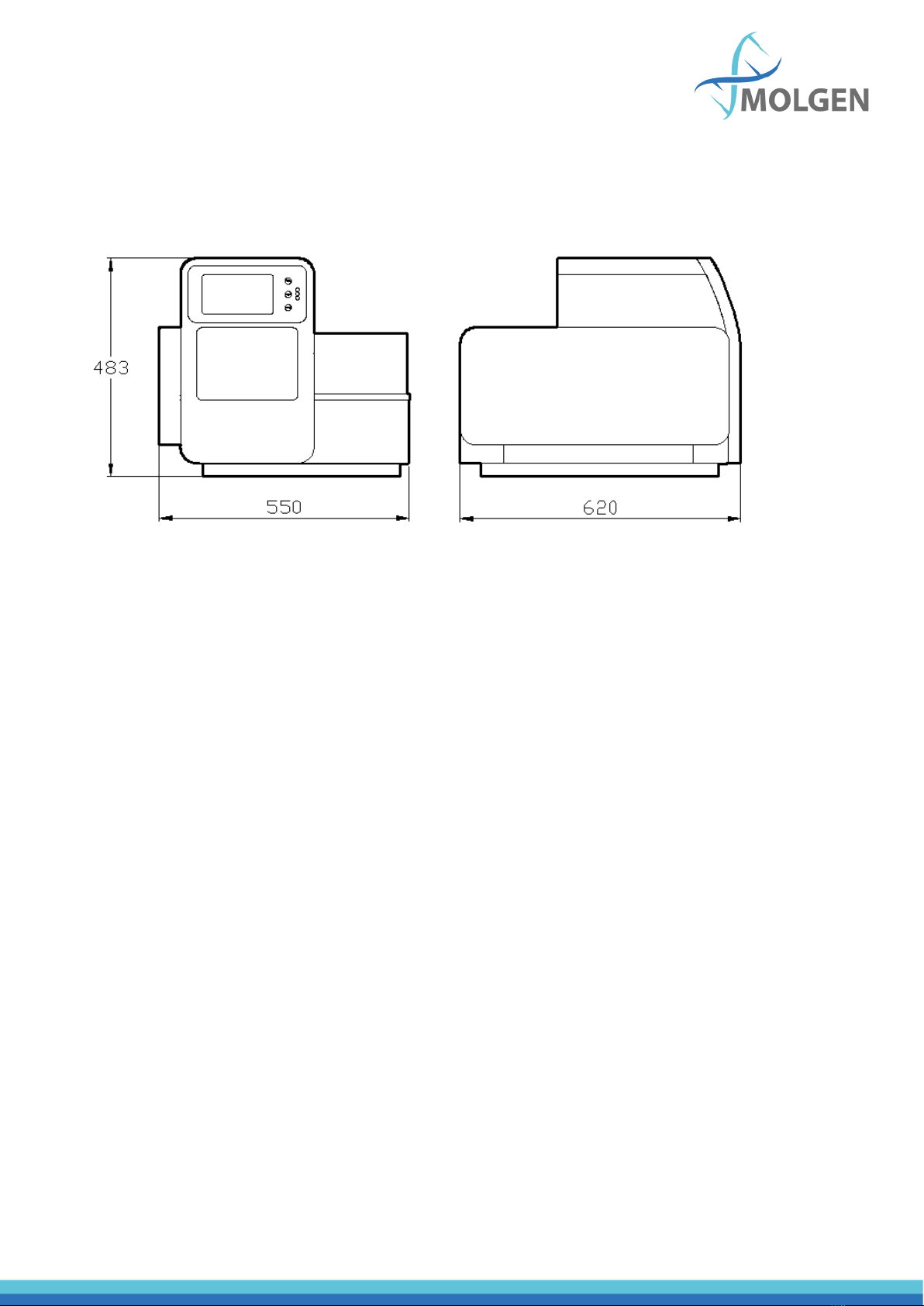

2.3. Overall Dimensions ........................................................................................... 9

Chapter 3. Basic Operating Instructions ........................................................................... 10

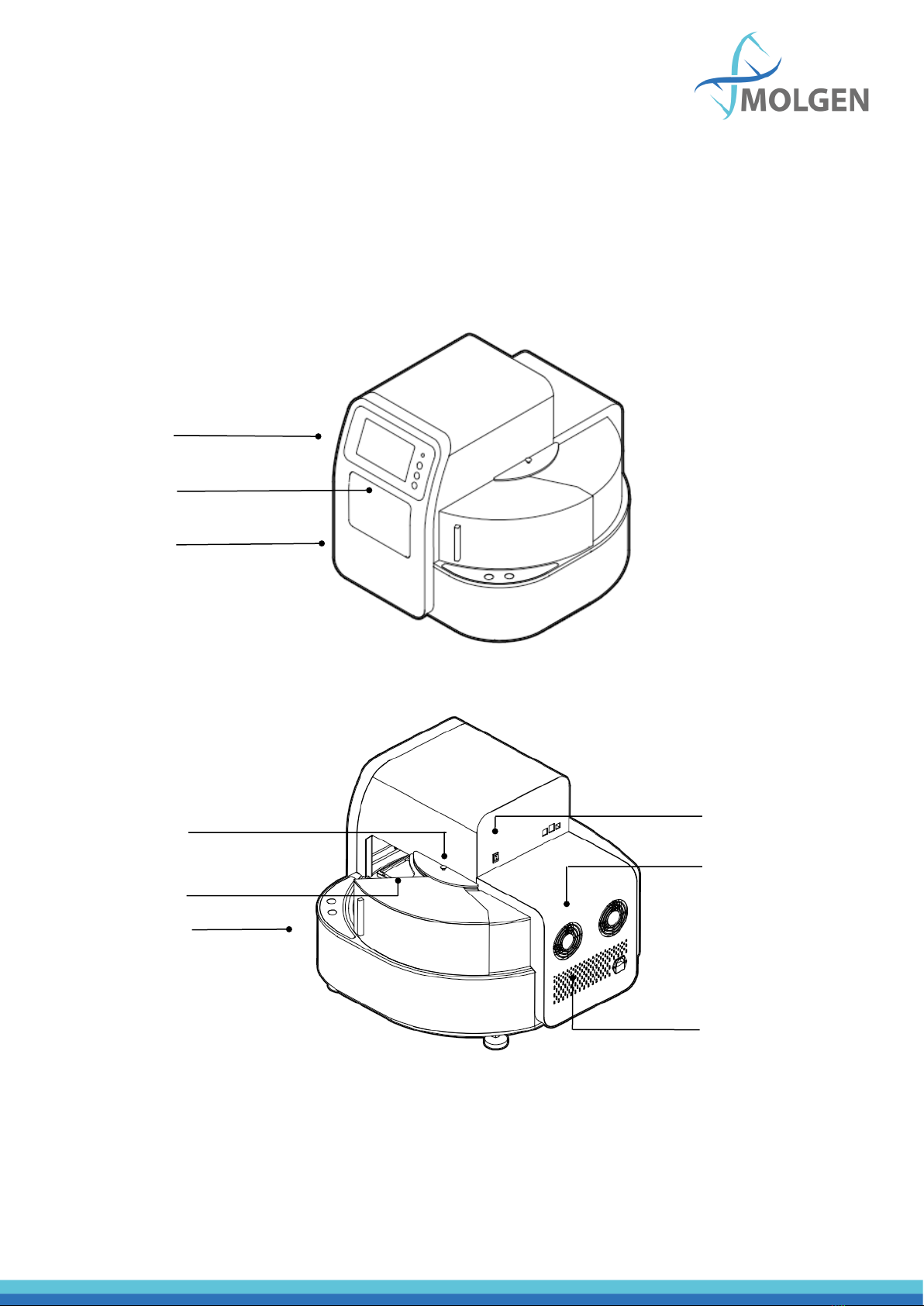

3.1. Structures........................................................................................................ 10

3.1.1. Front..................................................................................................... 10

3.1.2. Back...................................................................................................... 10

3.1.3. Cabin Door ........................................................................................... 11

3.1.4. Transparent Cover ................................................................................ 11

3.1.5. Touch Screen ........................................................................................ 12

Chapter 4. Operations ...................................................................................................... 13

4.1. Power Connection .............................................................................................. 13

4.2. Kits Installation................................................................................................... 13

4.3. Detailed Operations............................................................................................ 14

4.3.1. Start-up Interface..................................................................................... 14

4.3.2. Run Program Interface............................................................................. 14

4.3.3. Run Interface ........................................................................................... 16

4.3.4. View......................................................................................................... 19

4.3.5. Manage Program ..................................................................................... 21

4.3.6. System Settings........................................................................................ 25

4.3.6. Lighting.................................................................................................... 29

4.3.7. Auxiliary function..................................................................................... 29

4.3.8. UV Sterilization ........................................................................................ 30

Chapter 5. Trouble Shooting............................................................................................. 31

5.1. Troubleshooting ................................................................................................. 31

5.2. Software error alarm list..................................................................................... 32

Chapter 6 Accessory......................................................................................................... 33

Chapter 7. Abbreviations and Tags.................................................................................... 34

7.1. Abbreviations ..................................................................................................... 34

7.2. Tags .................................................................................................................... 35