Non contractual document - Cassese France®- Document non contractuel

- 3 -

1. INTRODUCTION

1.A. WORK POSITION REFERENCE 4-5

1.B. PRODUCER 6

1.C. ACCESSORIES SUPPLIED WITH

THE MACHINE 6

1.D. TECHNICAL SPECIFICATIONS OF

MACH 1 UNI 6

1.E. OPTIONS 7

1.F. GUARANTEE 7

2. SETUP

2.A. UNPACKING THE MACHINE 8

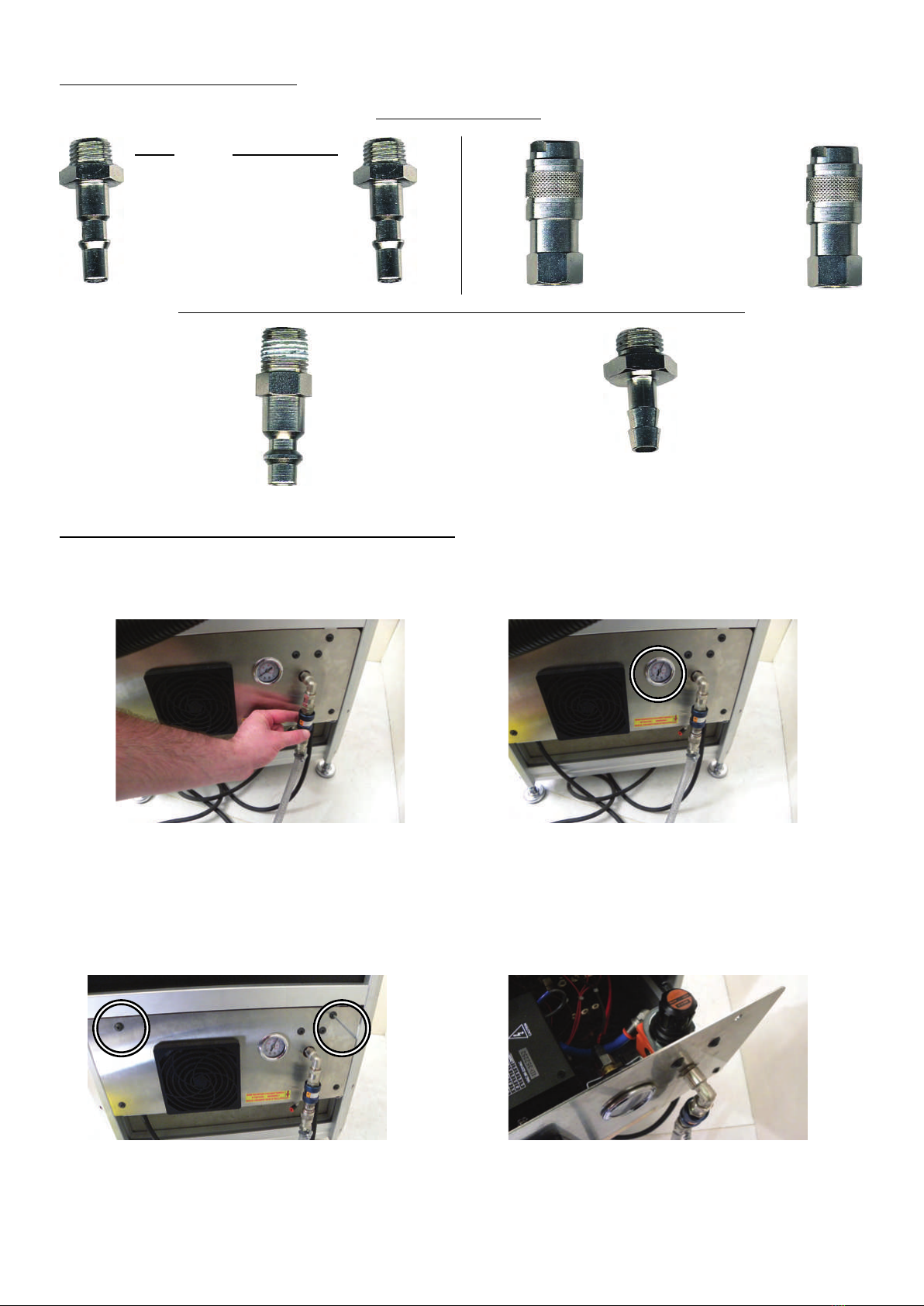

2.B. AIR LINE FITTINGS 9

2.C. CONNECTING TO THE AIR SOURCE 9

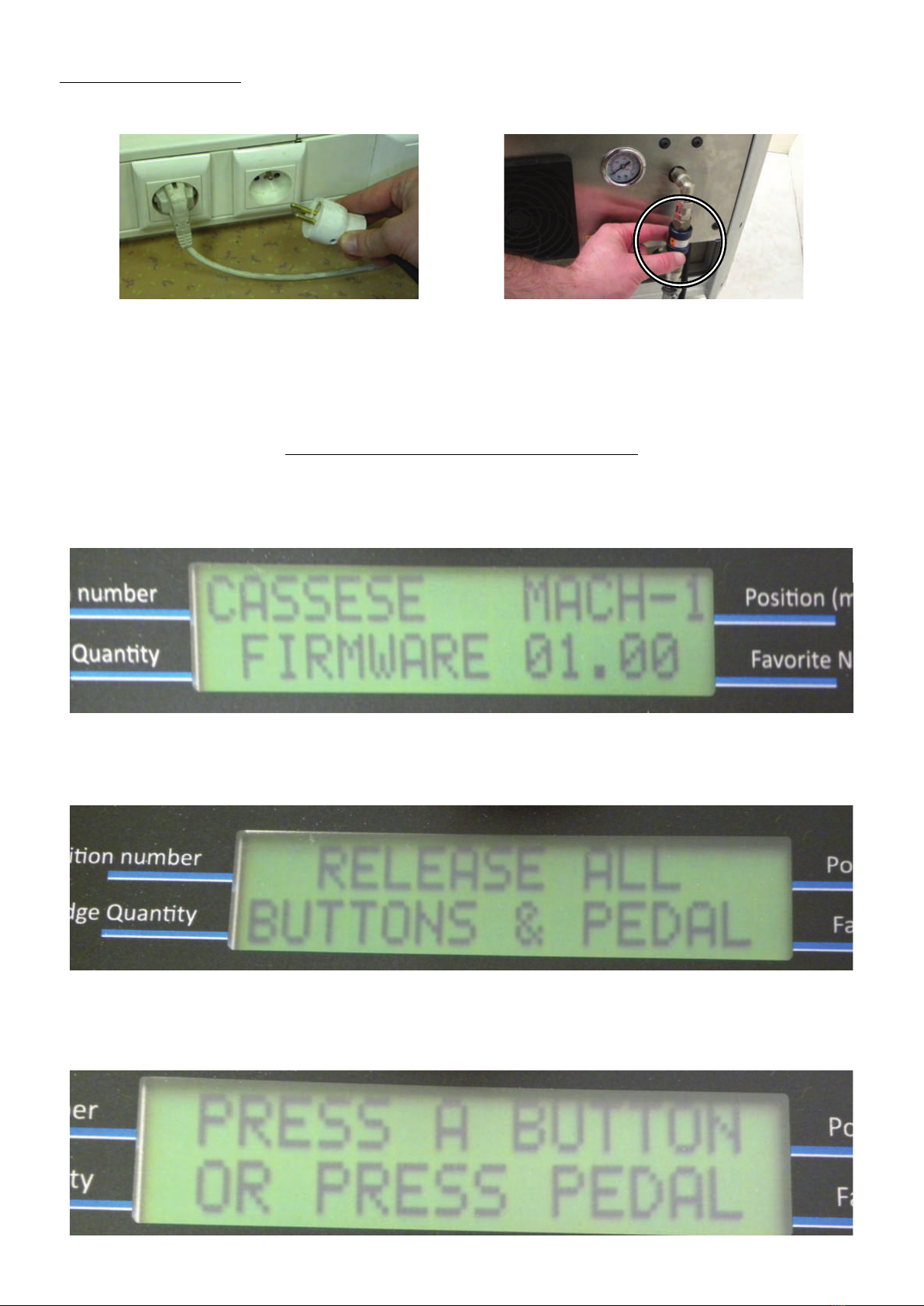

2.D. STARTING UP 10

3. ADJUSTMENTS

3.A. PROPER ADJUSTMENT OF MAGNETIC

ADJUSTABLE ROD CLAMP ASSEMBLY 11

3.B. SPECIFIC USE OF THE SPACER BARS 12

3.C. SELECTING THE STAPLING POSITION 12-13

3.D. ADJUSTING THE JOINING ANGLE 13

4. USE

4.A. MEANS OF JOINING 14

4.B. LOADING WEDGES 14

4.C. CHANGING THE SIZE OF WEDGES 15

5. CONTROLS OF THE KEYBOARD

5.A. DESCRIPTION OF SCREEN DISPLAY 16

5.B. STAPLING MODE 16

5.C. PROGRAMMING OF POSITION AND

WEDGES QUANTITIES PER POSITION 17

5.D. FILE MANAGEMENT OF STORED

POSITIONS FROM F1 TO F9 18

5.E. DESCRIPTION OF THE

STAPLING CYCLE 18

5.F. RELOADING WEDGES 19

5.G. SAFETY CLAMP 19

6. MACH 1 UNI PARAMETERS

6.A. PROCEDURE OF PARAMETERS ACCESS 20

6.B. PARAMETERS DESCRIPTION

PARAMETER 7 : VISU IN/OUT 21

PARAMETER 8 : LOCK PROGRAM 22

PARAMETER 40 : SAVE FAVORITES 22

PARAMETER 22 : SERIAL BC 23

PARAMETER 25 : BC OFCET 23

PARAMETER 26 : BC SCALE 24

7. MAINTENANCE

7.A. WARNING 25

7.B. REMOVING THE STAPLING HEAD 25

7.C. REMOVING THE SIDE PANEL 25

7.D. LUBRICATION OF THE WEDGE DRIVER

AND/OR ITS REPLACEMENT 26-27

7.E. LUBRICATION OF THE CROSSBAR 27

7.F. EXTRACTING A WEDGE CAUGHT IN

THE DISTRIBUTOR 27

7.G. REPLACEMENT OF THE WEDGE

DISTRIBUTION CHANNEL

ELASTIC CORD 28

APPENDIX

A. SPARE PARTS MACH 1 UNI 60-65

B. GENERAL EXPLODED VIEW 66

C. EXPLODED VIEW S/A TOP CLAMP

COLUMN 67

D. EXPLODED VIEW S/A SLIDING TABLE 68

E. EXPLODED VIEW S/A MECHANICAL

ASSEMBLY 69

F. EXPLODED VIEW S/A “UNI” REBATE

CLAMP 70

G. EXPLODED VIEW S/A “UNI” DISTRIBUTION

CHANNEL 71

H. EXPLODED VIEW S/A REBATE CLAMP BAR 72

I. EXPLODED VIEW S/A WEDGE DRIVER

SUPPORT 73

J. EXPLODED VIEW S/A STAPLING POSITION

ENGINE 74

K. EXPLODED VIEW S/A KEYBOARD 75

L. EXPLODED VIEW S/A COMPONENTS

DRAWER 76

M. EXPLODED VIEW S/A EXTENSION ARMS 77

MACH 1 UNI - INDEX

CONTENTS CONTENTSPAGE PAGE