6.B.a Page 1: maintenance alarm ........................................................................................................................................................ 31

6.B.b Page 2: counter configuration ....................................................................................................................................................32

6.B.c Page 2: fine tuning of the shooting position............................................................................................................................... 32

6.B.d Page 2: changing the language of the machine ..........................................................................................................................32

6.B.e Page 3: setting date and time .....................................................................................................................................................33

6.B.f Page 3: choosing the favorite execution screen .........................................................................................................................33

6.B.g Page 3: overriding wedge sensor:...............................................................................................................................................33

6.B.h Page 3: reading the statistics ...................................................................................................................................................... 33

6.B.i Page 3: configuring the manual mode........................................................................................................................................34

6.B.j Page 4: Reading input/outputs ................................................................................................................................................... 34

6.B.k Page 5: database management ..................................................................................................................................................34

6.B.l Page 6: barcode management:...................................................................................................................................................37

6.C ARTICLE LIST SCREEN:...................................................................................................................................................37

6.D NETWORK MENU .........................................................................................................................................................38

7MAINTENANCE ................................................................................................................................................ 40

7.A SAFETY INSTRUCTIONS .................................................................................................................................................40

7.B MAINTENANCE PLAN ...................................................................................................................................................40

7.B.a Daily maintenance: .....................................................................................................................................................................40

7.B.b Every 6 months:.......................................................................................................................................................................... 40

7.C REMOVING THE DISTRIBUTOR HEAD ...........................................................................................................................41

7.D OPENING THE SIDE PANELS..........................................................................................................................................41

7.E REMOVING THE HAMMER ..........................................................................................................................................42

7.F LUBRICATING THE DISTRIBUTOR HEAD........................................................................................................................42

7.G UNJAMMING THE MACHINE ........................................................................................................................................43

7.H RESETTING THE MAINTENANCE ALARM ......................................................................................................................43

7.I LUBRICATING THE HORIZONTAL COLUMNS .....................................................................................................................43

7.J TESTING THE SAFETIES OF THE MACHINE ........................................................................................................................44

7.K TROUBLE SHOOTING ....................................................................................................................................................45

II. MANUEL D’UTILISATION / FRANCAIS......................................................................... 47

1PRESENTATION ................................................................................................................................................ 48

1.A TABLE D’ASSEMBLAGE .................................................................................................................................................48

1.B INTRODUCTION ............................................................................................................................................................50

1.C ACCESSOIRES FOURNIS AVEC LA MACHINE.................................................................................................................50

1.A SPECIFICATIONS TECHNIQUES......................................................................................................................................51

1.B OPTIONS .......................................................................................................................................................................51

1.C GARANTIE.....................................................................................................................................................................51

2MISE EN ROUTE................................................................................................................................................ 52

2.B. DEBALLAGE DE LA MACHINE........................................................................................................................................52

2.A RACCORDS....................................................................................................................................................................53

2.B RACCORDEMENT A L’AIR COMPRIMÉ ..........................................................................................................................53

3DEMARRAGE DE LA MACHINE .......................................................................................................................... 55

3.A RACCORDEMENT ELECTRIQUE DE LA MACHINE ..........................................................................................................55

3.A SELECTION DE LA LANGUE ...........................................................................................................................................55

4REGLAGES........................................................................................................................................................ 56

4.A REGLAGE DE LA TABLE COULISSANTE ..........................................................................................................................56

4.A REGLAGE DU PRESSEUR VERTICAL ...............................................................................................................................56

4.A UTILISATION DU JEU DE BARRETTES ............................................................................................................................57

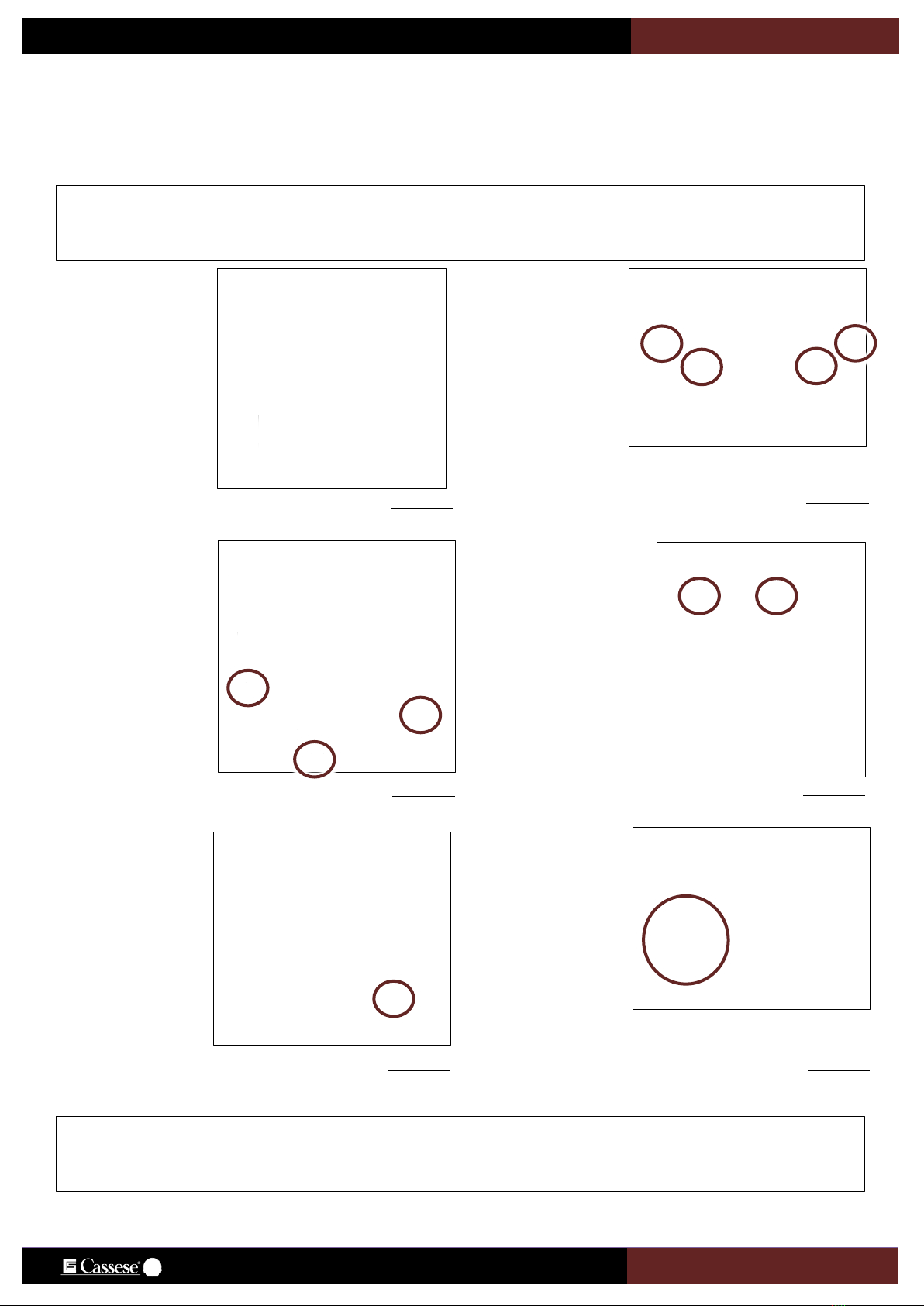

4.A SELECTION DES POSITIONS D’AGRAFAGE ....................................................................................................................58

4.B TROIS REGLES ESSENTIELLES POUR L’ASSEMBLAGE.....................................................................................................58

4.C REGLAGE DE L’ANGLE D’ASSEMBLAGE.........................................................................................................................58

4.D MOYEN D’ASSEMBLAGE ...............................................................................................................................................59