1.A EMPLACEMENT DES ETIQUETTES DE SECURITE SUR LA MACHINE. .............................................................................39

1.B CONDITIONS D’UTILISATION ........................................................................................................................................41

1.C CE QU’IL NE FAUT PAS FAIRE........................................................................................................................................41

1.D PRATIQUES DE TRAVAIL EN TOUTE SECURITE..............................................................................................................41

2PRESENTATION ................................................................................................................................................ 43

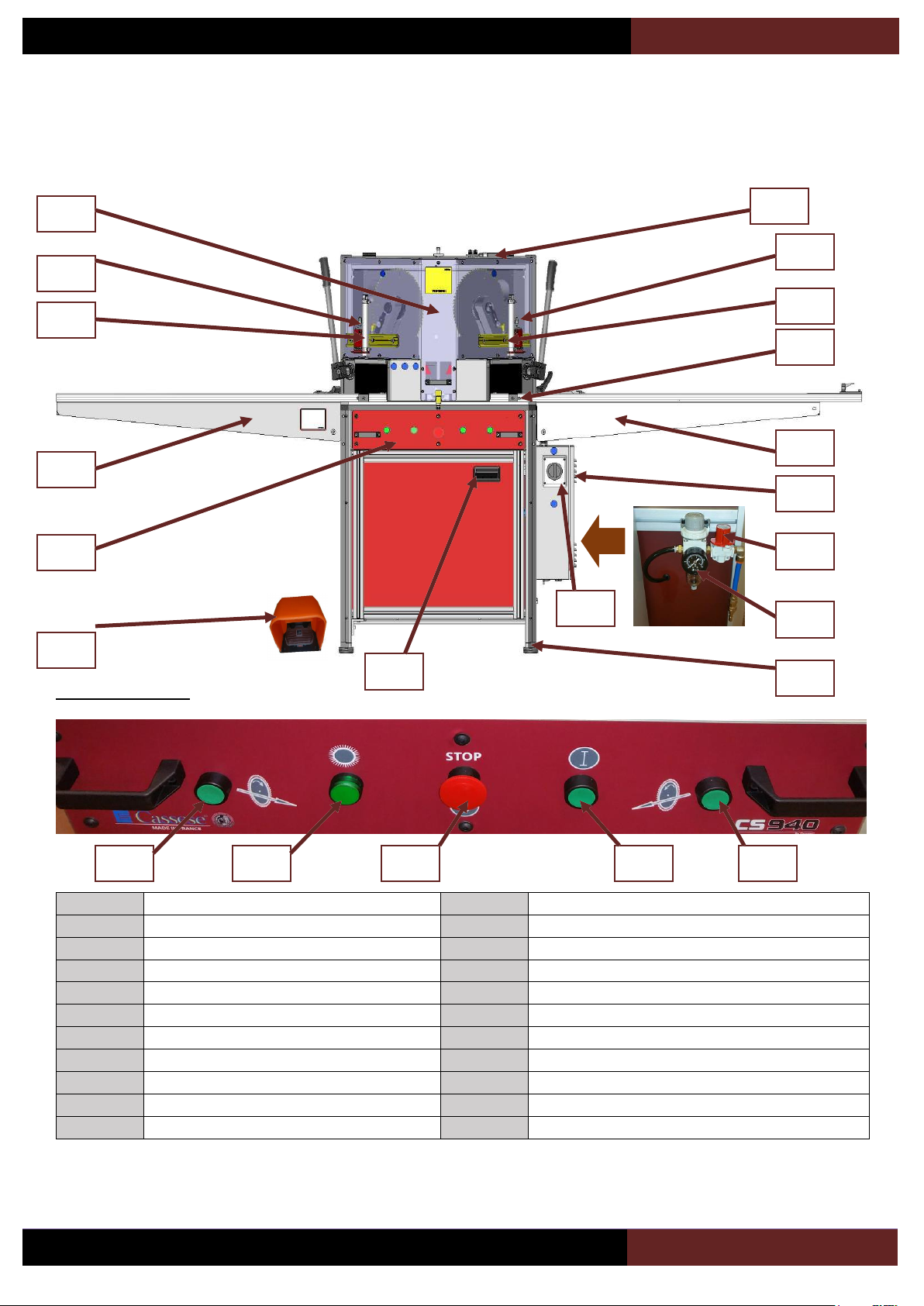

2.A DESCRIPTION DES PRINCIPAUX ELEMENTS DE LA CS940 .............................................................................................43

2.B CONTENU DE LA BOITE D’ACCESSOIRES :.....................................................................................................................44

2.C ELEMENTS OPTIONNELS...............................................................................................................................................44

2.D CARACTERISTIQUES TECHNIQUES ................................................................................................................................45

2.E CAPACITE DE COUPE ....................................................................................................................................................46

2.F PLAN D’ENCOMBREMENT............................................................................................................................................47

2.G RISQUES RESIDUELS .....................................................................................................................................................48

2.H GARANTIE.....................................................................................................................................................................48

3DEBALLAGE ET MANUTENTION ........................................................................................................................ 49

4INSTALLATION DE LA MACHINE........................................................................................................................ 50

4.A MISE EN PLACE DE LA MACHINE .................................................................................................................................50

4.B MONTAGE DES BRAS....................................................................................................................................................51

4.B.a Montage du bras droit................................................................................................................................................................51

4.B.b Montage du bras gauche ............................................................................................................................................................ 54

4.C BRANCHEMENT ELECTRIQUE .......................................................................................................................................56

4.D BRANCHEMENT PNEUMATIQUE ..................................................................................................................................56

4.E ASPIRATION..................................................................................................................................................................57

5UTILISATION .................................................................................................................................................... 58

5.A MISE EN ROUTE............................................................................................................................................................58

5.B SCIAGE..........................................................................................................................................................................59

5.B.a Réglage des presseurs horizontaux ............................................................................................................................................ 59

5.B.b Réglage des presseurs verticaux (optionnels) ............................................................................................................................59

5.B.c Première coupe à gauche ...........................................................................................................................................................60

5.B.d Mesure fond de feuillure ( cote interieure ) ............................................................................................................................... 61

5.B.e Mesure de la cote externe du cadre :.........................................................................................................................................61

5.B.f Coupe du premier morceau........................................................................................................................................................ 62

5.B.g Fin de moulure............................................................................................................................................................................63

6MAINTENANCE &ENTRETIEN........................................................................................................................... 65

6.A PROCEDURE POUR ACCÉDER A L’INTÉRIEUR DE LA MACHINE.....................................................................................65

6.B REMPLACEMENT DES LAMES ......................................................................................................................................65

6.C REMPLACEMENT DE L’ AXE SUPPORT DE CHUTE .........................................................................................................67

6.D VIDAGE DU BAC A CHUTES...........................................................................................................................................68

6.E MAINTENANCE PÈRIODIQUE........................................................................................................................................68

6.F DIAGNOSTIQUE ............................................................................................................................................................69

6.F.a La machine ne démarre pas........................................................................................................................................................69

6.F.b Les coupes sont de mauvaise qualité ......................................................................................................................................... 69

6.G CONTRÔLE MENSUEL DES ORGANES DE SÉCURITÉ .....................................................................................................70

6.H NOMENCLATURE / SPARE PART LIST............................................................................................................................71

III. ECLATES / EXPLODED VIEW ....................................................................................... 81

IV. SCHEMAS ELECTRIQUE / ELECTRICAL SCHEMATICS ................................................... 99

V. CERTIFICATE / CERTIFICAT DE CONFORMITE ............................................................ 103