Nevis Edge 5 Manual (Ref No: S107)

2 CastTec Ltd

Table&of&Contents&

THE CLEAN AIR ACT 1993 AMD SMOKE CONTROL AREAS ........................................................................................ 3

PRODUCT SPECIFICATION ....................................................................................................................................... 4

IMPORTANT INFORMATION ABOUT INSTALLATION AND USING THE STOVE ............................................................ 6

UNPACKING & ASSEMBLY ....................................................................................................................................... 7

INSTALLATION OF THE STOVE ................................................................................................................................. 8

MATERIAL CLEARANCES ......................................................................................................................................... 8

FLOOR ............................................................................................................................................................................................ 8

THE CHIMNEY ................................................................................................................................................................................. 9

FUME EMISSIONS ........................................................................................................................................................................... 9

OPERATING INSTRUCTIONS .................................................................................................................................. 10

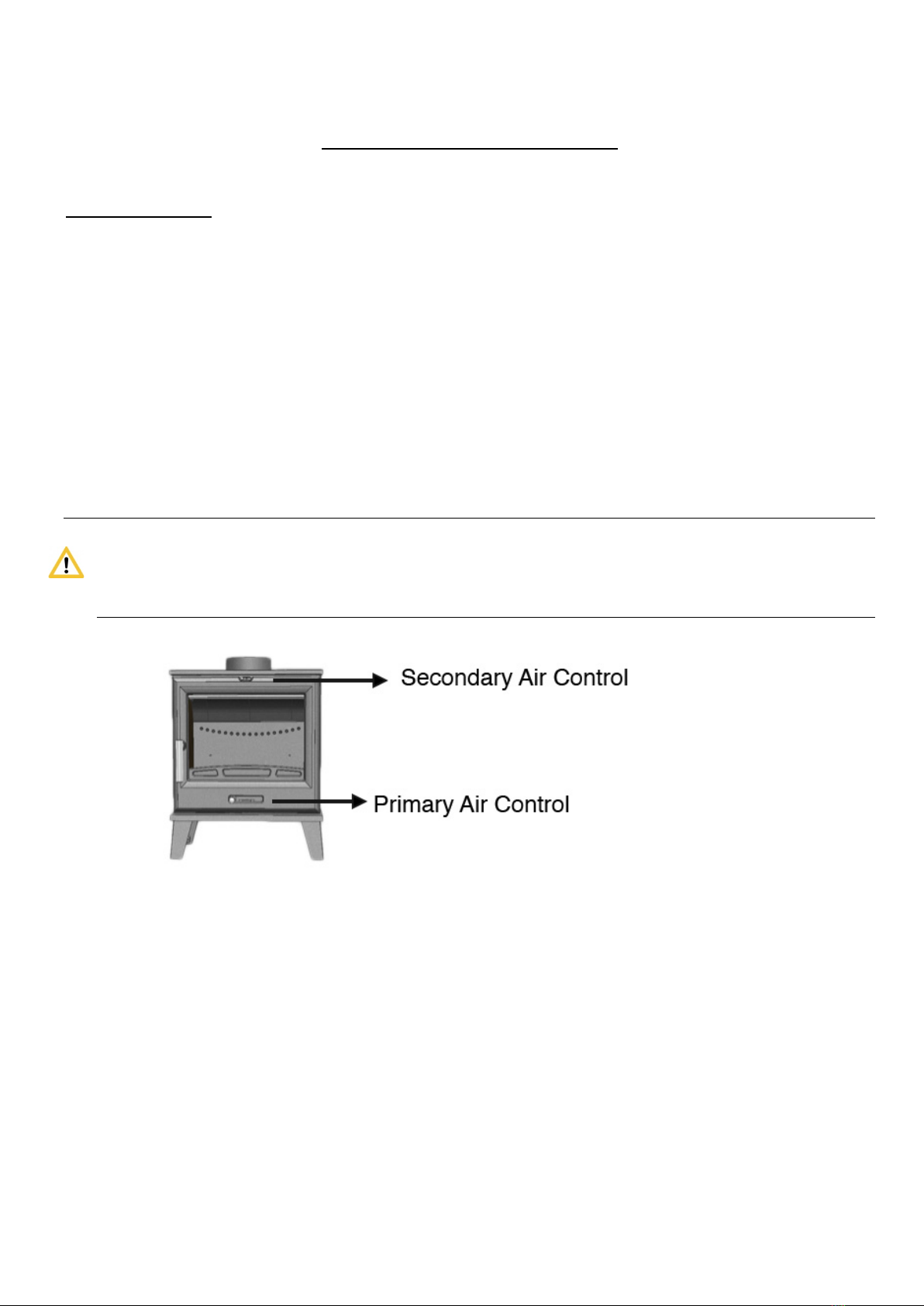

THE CONTROLS ............................................................................................................................................................................. 10

FUEL ............................................................................................................................................................................................. 11

BEFORE LIGHTING ........................................................................................................................................................................ 11

LIGHTING A WOOD FIRE ............................................................................................................................................................... 11

REFUELING PROCEDURE ............................................................................................................................................................... 12

DE-ASHING THE STOVE ................................................................................................................................................................. 13

GUIDANCE ON SAFE OPERATION .......................................................................................................................... 14

FIRE CAN BE VERY DANGEROUS ................................................................................................................................................... 14

CHIMNEY FIRE .............................................................................................................................................................................. 14

FUMES .......................................................................................................................................................................................... 14

ADVERSE WEATHER CONDITIONS ................................................................................................................................................. 14

MAINTENANCE .................................................................................................................................................... 15

CLEANING ..................................................................................................................................................................................... 15

GENERAL MAINTENANCE ............................................................................................................................................................. 15

STOVE BODY ................................................................................................................................................................................. 15

FIRE ROPE ..................................................................................................................................................................................... 16

CLEANING THE STOVE ................................................................................................................................................................... 16

STOVE GLASS ................................................................................................................................................................................ 16

CHIMNEY ...................................................................................................................................................................................... 16

FAULT FINDING ..................................................................................................................................................... 17

FIRE WILL NOT BURN .................................................................................................................................................................... 17

SOOT BUILD UP ON GLASS ............................................................................................................................................................ 17

EXCESSIVE WEAR ON INTERNAL PARTS ......................................................................................................................................... 17

SPARE PARTS ........................................................................................................................................................ 18

PART LIST ............................................................................................................................................................. 19