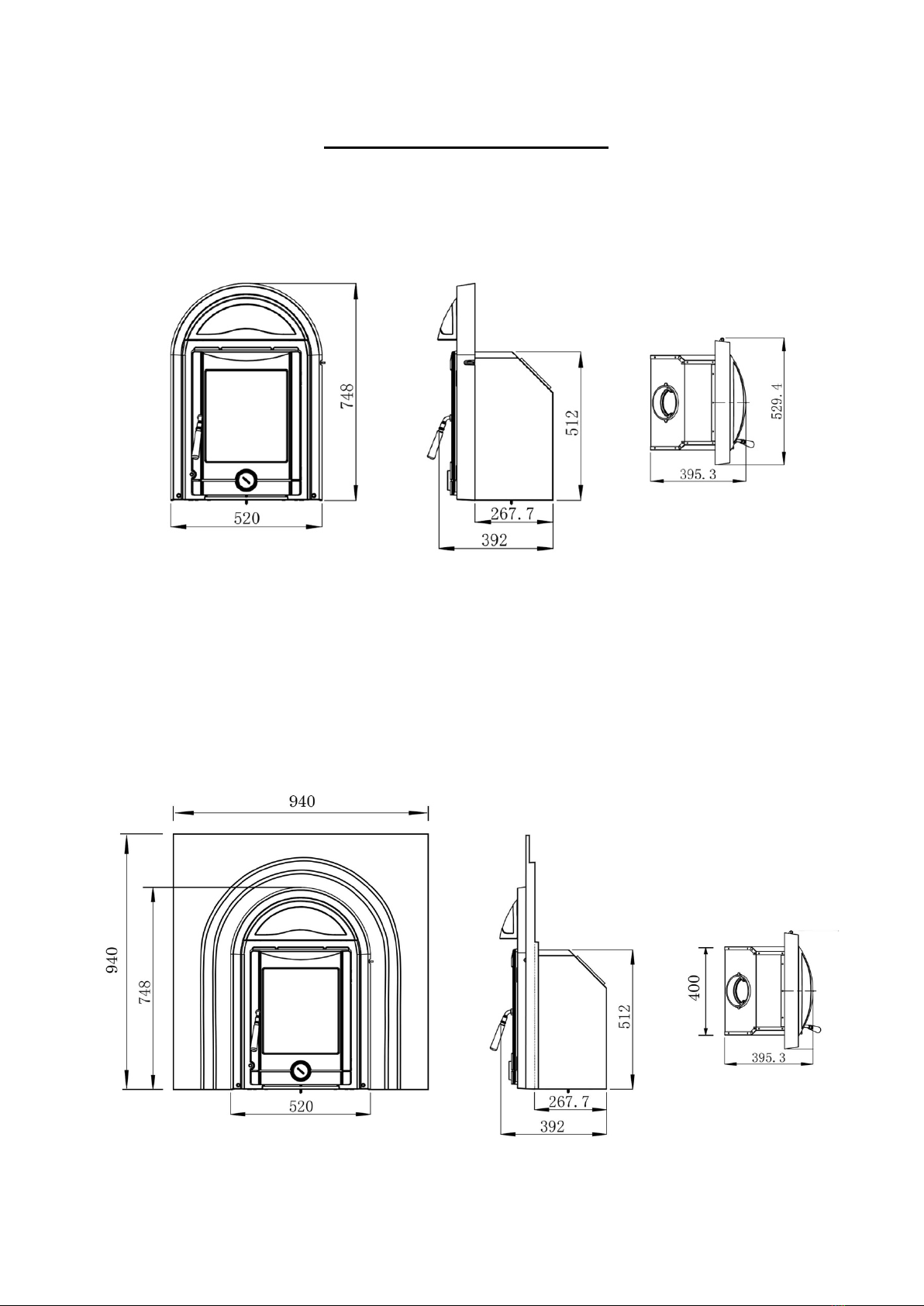

Polaris Inset Eco Manual Ref No: I17. V1.

10 Cast Tec Ltd

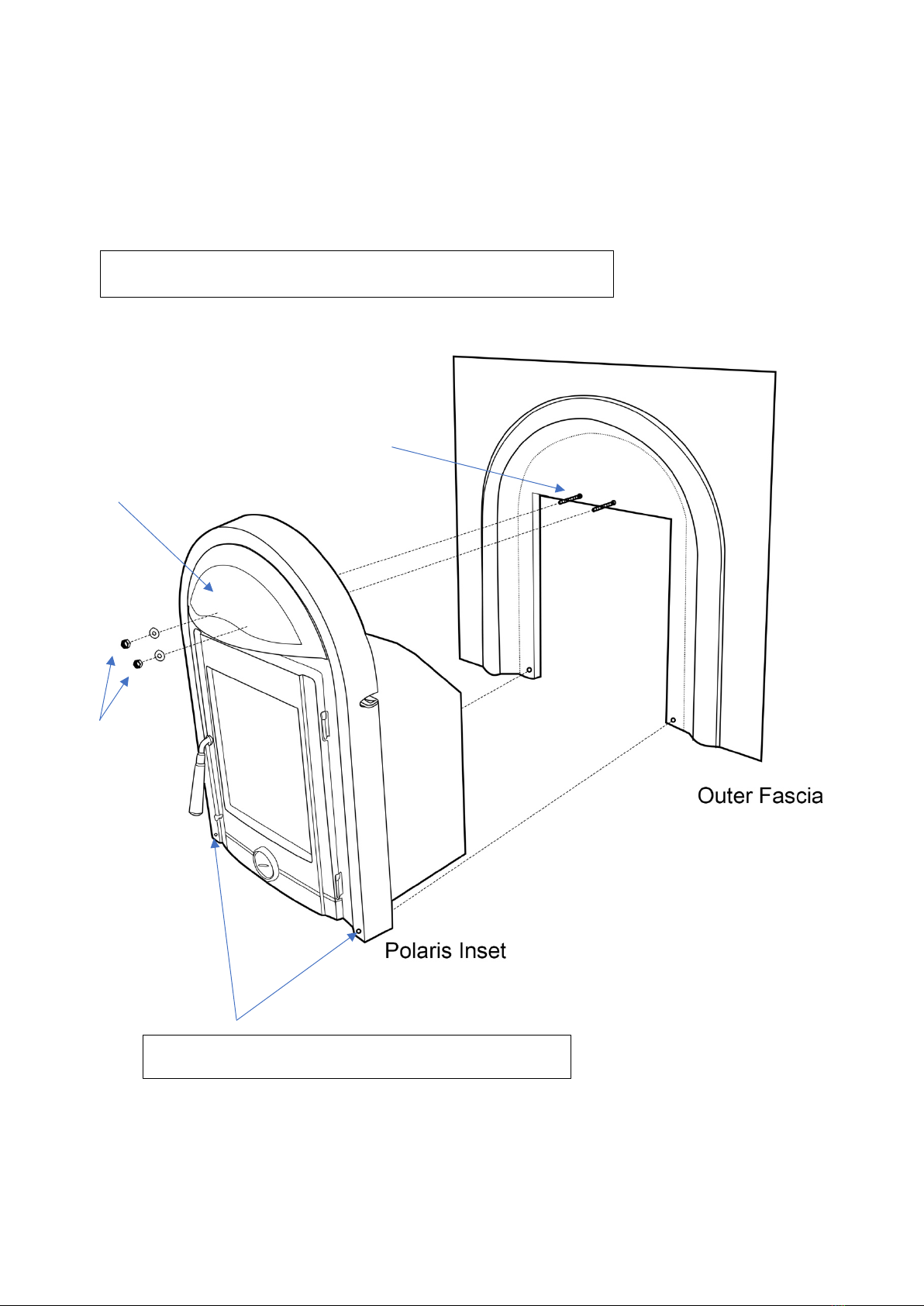

FITTING INSTRUCTIONS (POLARIS INSET ONLY)

Step 1. Prepare the fireplace area

with fireback or milner brick removal.

Ensure the opening is suitable for

fitting of the insert stove opening

required, i.e., remove fire surround

trim if fitted. (See Fig. 6.)

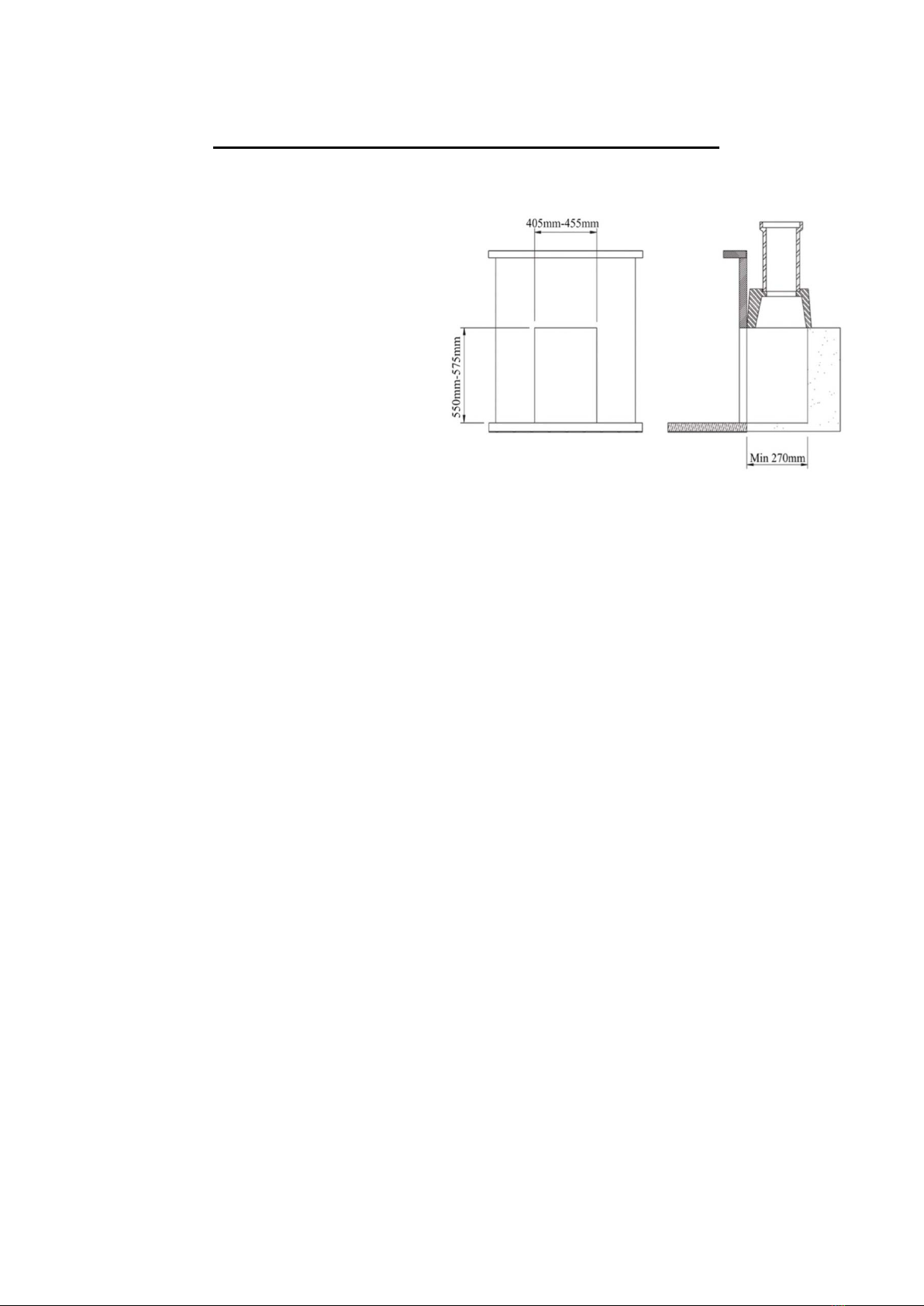

Step 2. Ensure the floor area is level

with the hearth, this area needs to be

level as the insert fire is screw fixed

to the floor.

Step 3. Lay the external casing into

the opening and position so that the front edge protrudes 20mm past the front edge of

the opening.

Step 4. Mark the drill location and drill the holes using a 4.5mm drill bit. Fix the casing

to the floor using the self-tapping screws provided.

Step 5. Lift the stove into the external casing. Remove all internal parts as per pre-

assembly instructions prior to lifting it. The stove can be lifted into the casing

approximately 125mm first and then it can be pushed into the final position while taking

care to lift the front edge to preserve the hearth.

Step 6. Drop the flexi flue liner with adaptor end attached into the fire opening ready to

connect to the appliance.

Step 7. Lay the sealing gasket on to the flue spigot, and then fit the flue spigot to the

end of the flexi flue liner using the 2 grub screws provided.

Step 8. Then using the M6 screws secure the stove to the convection chamber. Push

the insert stove against the fireplace before fully tightening these bolts.

Step 9. Reach up through the stove and pull the stove collar down and secure the flue

collar to the stove with the two flue collar’s bolts. (See fig. 7.)

Step 10. Complete the installation of the flexi liner at the top of the chimney in

accordance with the manufacturer’s instructions.