Contents v

A ORDERING INFORMATION.................................................................... 1

Available Configurations.........................................................................................1

XP 3000 Spare Parts..............................................................................................2

Syringes...........................................................................................................3

Syringe Seals...................................................................................................3

Syringe “O”-Rings............................................................................................3

Valves ..............................................................................................................4

Printed Circuit Board........................................................................................4

Interconnect Tubing.........................................................................................5

Pump Evaluation Accessories.........................................................................6

Miscellaneous Parts.........................................................................................6

Other Cavro Products.............................................................................................7

RSP 9000 Robotic Sample Processor.............................................................7

MSP 9000/9500 Mini Sample Processors.......................................................7

XL Series Smart Valve.....................................................................................8

XL Series Smart Peristaltic Pump....................................................................8

XL 3000 Series Multi-Channel Pumps.............................................................8

XL 3000 Modular Digital Pumps......................................................................8

XE 1000 Pump.................................................................................................8

Smart I/O Board...............................................................................................9

Cavro MiniWash...............................................................................................9

Accessories......................................................................................................9

B PLUNGER INFORMATION ..................................................................... 1

Plunger Force.........................................................................................................1

Plunger Time Calculations .....................................................................................2

Symbol Definitions...........................................................................................2

Move Calculations............................................................................................3

C ASCII CHART OF CODES FOR U.S. CHARACTERS ............................ 1

D CHEMICAL RESISTANCE CHART......................................................... 1

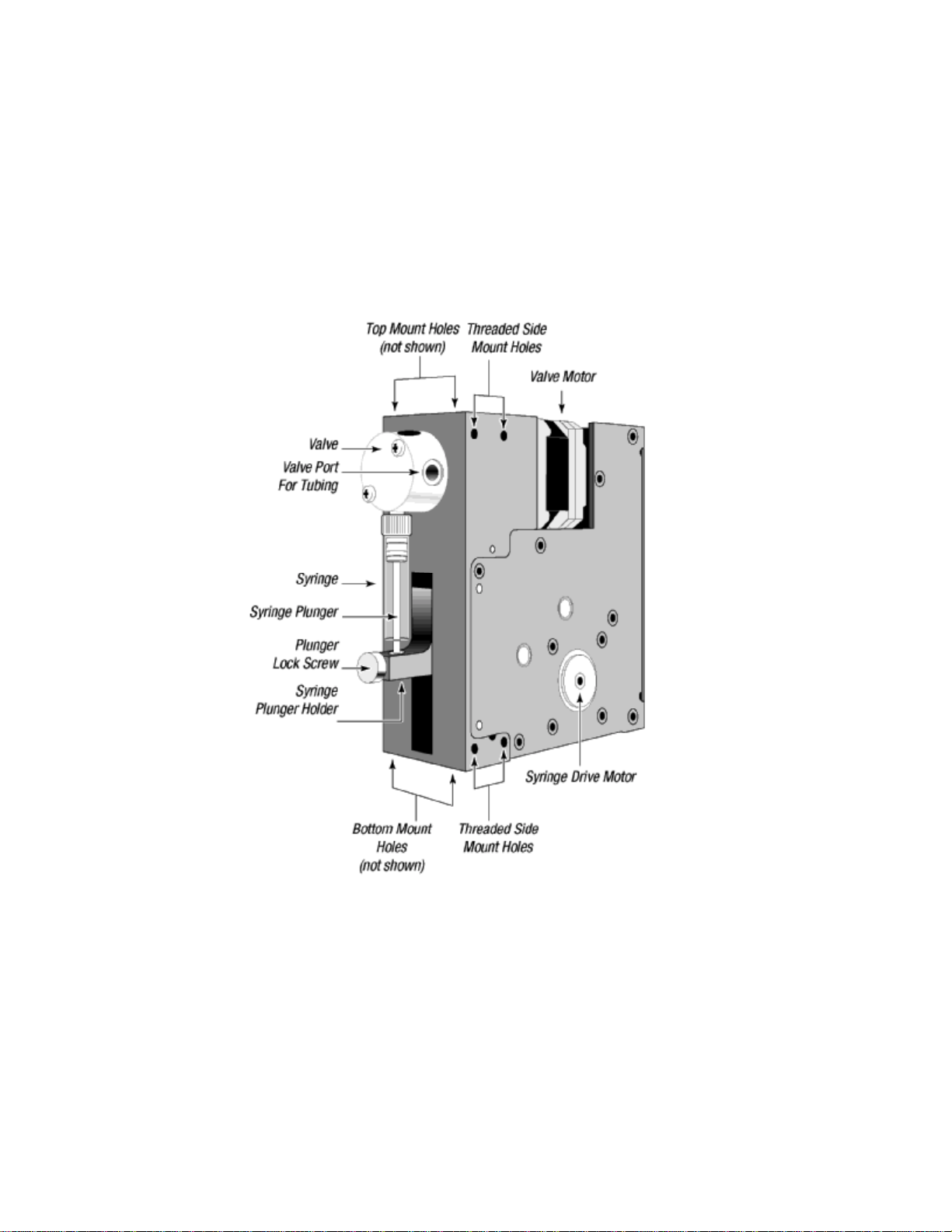

E XP 3000 PHYSICAL SPECIFICATIONS.................................................. 1

F CAN COMMUNICATION COMMANDS ................................................... 1

G COMMAND QUICK REFERENCE .......................................................... 1

Control Commands ................................................................................................1

Initialization Commands for 3-Port Valve and T-Valve...........................................1

Initialization Commands for 3-Port Distribution Valve............................................1

Plunger Movement Commands/Status Bit Reports................................................2

Valve Commands...................................................................................................2

Valve Leakage Detection Commands....................................................................2