Enotec OXITEC ECONOMY User manual

Doc.-ID: ECO-12022015-EN

Installation and Operation Manual

O2 Analyzer System

OXITEC

®

ECONOMY

Version 1.10

for Software Version: 4.09

ENOTEC GmbH

Process and Environmental

Measuring Technology

DIN EN ISO 9001

Höher Birken 6

D-51709 Marienheide

Germany

Tel.: +49 (0) 2264 - 45 78 0

Fax: +49 (0) 2264 - 45 78 31

Internet: www.enotec.de

Preface

Dear Customer,

Thank you for selecting OXITEC ECONOMY as your InSitu Flue Gas Oxygen Analyzer System.

For more than 30 years now ENOTEC's Analyzer Systems have been operating in numerous applications with thousands of

units being produced and shipped around the world. ENOTEC is committed to absolute quality and performance and over time

we have continuously enhanced our products to integrate various features and functions. In this package, the electronic unit

uses the very latest Microprocessor Technology, making the SME5 electronic unit one of the most advanced and up-to-date

monitoring units, permitting you to reduce your maintenance & fuel costs, and to achieve increased measuring accuracy with

more operational reliability.

In all OXITEC measuring probes, the Zirconium Oxide Sensor is soldered in place using a special process and technique devel-

oped by ENOTEC. This technique results in a considerable increase in service life compared to „glued or cemented“ measuring

cells of ENOTEC competitors, which have a tendency to leak or crack during operation. The OXITEC sensor has a proven gas-

tight design, providing greater measuring accuracy, durability and longer working life time.

All ENOTEC instruments are thoroughly tested in the factory and are subject to a strict ISO9001 Quality Assurance Procedure.

Therefore, with the correct installation, the operation of the OXITEC ECONOMY is straightforward and user friendly and will

provide you with many years of trouble free operation with perfect measuring results.

Notes concerning this Manual

This manual contains important information concerning design, installation, commissioning, operation, maintenance and trou-

bleshooting of the OXITEC ECONOMY. Please familiarise yourself with all warnings, safety instructions and maintenance in-

structions included in this manual for a trouble-free and safe operation.

Symbols used in this Manual

The symbols below are found attached to the OXITEC® 5000 ECONOMY system and in this manual. They emphasize im-

portant information as well as safety instructions for installation, operation and maintenance, to protect the personnel and the

equipment.

Warning

Follow all instructions in this manual

Consider Information

Points out important information which must be

considered before execution

Warning hot Surface

Warns of danger of burns which could occur from

hot system parts

Info

Contains further detailed information

Attention

Warns of risks by destroying the system or its

components or its functionality

Ground earth electrical protection

The content of this manual, including all written content, images, drawings or any other content is protected by

copyright.

Safety Instruction

The OXITEC ECONOMY system is operated with line voltage. After removal of terminal covers some parts of this

system may be accessible which are under high line voltage.

Only well trained and authorised personnel are allowed to work on this system. The personnel must know and understand all

precautions, safety instructions, installation and maintenance instructions of this manual. The trouble free and safe operation

of OXITEC ECONOMY require safe transportation, professional storage, installation, operation and maintenance.

Furthermore all local safety requirements at the point of installation and operation must be considered.

OXITEC ECONOMY may not be used to measure oxygen in combustible gases or in an environment with combustible gases.

Parts of this system may cause an explosion risk.

Installation and Operation Manual – OXITEC Economy Table of Contents

Doc.-ID: ECO-12022015-EN 1

Table of Contents

1System Description 2

1.1System Overview ................................................2

1.2Intended Use of OXITEC ECONOMY .................3

1.3Disruption of the Process ....................................3

1.4Storage instructions ............................................3

1.5Name Plates .......................................................3

2Installation 4

2.1Installation Requirements for Electronic Unit ......4

2.1.1Access to the Terminals......................................5

2.2Installation of Probe Signal Cable .......................5

2.3Installation of the Probe ......................................6

2.4Install O2Probe ...................................................7

2.4.1Welding of the Counter Flange............................7

2.4.2Adjustment of the probe filter head .....................7

2.4.3Installation of the O2 Probe.................................8

2.4.4O2Probe installation with Cooling Protection Tube

............................................................................8

2.5Electrical Connections of the Electronic Unit.......9

2.6Electrical Wiring Diagram..................................10

2.6.1Relay Contacts, Functions ................................11

2.6.2Probe Connection .............................................11

3Initial operation 12

3.1Checklist before commissioning the system .....12

3.2System Power Up .............................................12

3.3Display - Probe Heating Phase .........................12

3.4Display - Measuring Mode ................................13

3.5Keypad and Display ..........................................13

3.6Status LEDs ......................................................13

3.7Softkey Symbols ...............................................13

3.8System Code.....................................................13

4Software Overview and Explanations 14

4.1Software Overview - SYS-MENU ...................... 14

4.2Software Explanations - SYS-MENU ................16

4.2.1O2Measuring Ranges (Scaling)........................16

4.2.2mA output on system errors..............................16

4.2.3O2limit alarm settings .......................................16

4.2.4O2Sensor calibration values.............................17

4.2.5Time per test gas apply.....................................17

4.2.6Delay time to process........................................17

4.2.7ENOTEC REMOTE...........................................17

4.2.8Measuring units.................................................18

4.2.9Language..........................................................18

4.2.10Change system code ........................................18

4.2.11Load factory settings.........................................18

4.2.12Service..............................................................18

4.3CAL MENU .......................................................19

4.3.1Check Test air / Test gas settings.....................19

4.3.2Calibration Menu - Display Overview................19

4.3.31-point calibration (manual)...............................20

4.3.42-point calibration (manual)...............................20

4.4System Check...................................................21

5Service and Maintenance 22

5.1Test Gas Tubing (Customer supply) ................. 22

5.1.1... preparation....................................................22

5.1.2... connecting ....................................................22

5.2Test Air Supply to the O2Probe ........................ 22

5.2.1…with Test Air Pump........................................22

5.2.2…with Test Gas Bottle......................................23

5.3Bottle Test Gas Supply to the O2 Probe ........... 23

5.4O2Probe Dismounting ...................................... 23

5.5Exchange the O2Probe Filter Head.................. 24

5.5.1Remove the Filter Head....................................24

5.5.2Remove the used Probe Filter..........................24

5.5.3Glue in New Probe Filter...................................24

6Status Messages 25

6.1Error Messages ................................................ 25

6.2Alarm Messages ............................................... 26

ATechnical Data 27

A.1Technical Specifications - Electronic Unit ......... 27

A.2Technical Specifications - Probe....................... 28

A.3Technical Specifications - Probe Cable ............ 28

BDimensional Drawings 29

B.1O2Probes ......................................................... 29

B.2Counter Flanges (Optional)............................... 30

B.3Dimensions of Electronic Unit ........................... 31

CSpare Parts 32

C.1O2Probe without Filter Head ............................ 32

C.2O2Probe Components...................................... 32

C.3Components of the Cooling Tube ..................... 33

C.4Electronic Unit................................................... 33

C.5Probe Cable with Plug ...................................... 35

DSystem Options 36

D.1O2Limit Alarms ................................................. 36

D.2Duct Flange ...................................................... 36

D.3Duct Flange Insulation ...................................... 36

D.4Cooling Tube Insulation .................................... 36

EEC Declaration of Conformity 37

FWarranty 38

Index 39

System Description Installation and Operation Manual – OXITEC Economy

2 Doc.-ID: ECO-12022015-EN

1 System Description

1.1 System Overview

Figure 1- OXITEC Economy System (for flue gas temperatures of up to 400°C)

Figure 2 - OXITEC Economy System (with cooling protection tube for flue gas temperatures of up to 1400°C)

Installation and Operation Manual – OXITEC Economy System Description

Doc.-ID: ECO-12022015-EN 3

1.2 Intended Use of OXITEC ECONOMY

Warning

The system cannot be used to determine the oxygen concentration of combustible gases or in a location where

combustible gases are present as the measuring cell temperature of 800°C could present an explosion hazard!

1.3 Disruption of the Process

The analyzer system has to be kept in operation also in the event of the process being disrupted or if the plant is

powered off temporarily (e.g. at night or during the weekend). Frequently cooling down and heating up of the probe

results in thermal stress of the hot probe parts (heater, thermocouple and sensor) and reduces their product life.

ENOTEC will not accept any responsibility for resultant damage.

1.4 Storage instructions

ENOTEC equipment and spares are to be stored in a dry and ventilated environment with temperatures between 5°C

and 35°C. Paint fumes, silicone sprays, etc. must be avoided in the storage environment.

1.5 Name Plates

Figure 3 - Name Plate Electronic Unit

Figure 4 - Name Plate O

2

Probe

The name plates contain year of manufacture, probe serial number, O

2

sensor number and system order

code . The system order code contains detailed system information which is detailed in the system test

report and is supplied with the system.

Installation Installation and Operation Manual – OXITEC Economy

4 Doc.-ID: ECO-12022015-EN

2 Installation

Warning

The device must be provided with an external power-off switch. The line voltage switch/fuse/breaker must be in

accordance with the local technical standards and should be near to the electronic unit and must be clearly marked as

such. The probe cable is suitable for an ambient temperature range from -40°C to +90°C. All other installed cables

must be suitable for the ambient temperature range at side and must have the required size. All electronic unit termi-

nals are specified from 0,08mm² (AWG 26) to 2,5mm² (AWG 14). If wire end ferrules are used the next smaller size is

required. Before removal of the electronic terminal cover the line voltage must be switched off. The line voltage to the

electronic unit must be switched on again after the cover is back in position. After installation power conducting parts

may not be accessible.

2.1 Installation Requirements for Electronic Unit

Keep the minimum distance to adjacent objects Install at eye level

Avoid vibrations greater than 2g Mind the IP code

Drilled holes for the electronic unit

Use suitable screws

Electronic unit

Figure 5 - Installation of the Electronic unit

Installation and Operation Manual – OXITEC Economy Installation

Doc.-ID: ECO-12022015-EN 5

2.1.1 Access to the Terminals

Figure 6 - Access to the terminals

2.2 Installation of Probe Signal Cable

Abide by the maximum cable length (max. 150m)

Cross the probe signal cable (FEP-0001) at right angle to power supply cables.

Note the minimum bending radius

Ambient temperatures

Temp. during installation

Temp. during operation

Installation Installation and Operation Manual – OXITEC Economy

6 Doc.-ID: ECO-12022015-EN

Figure 7 - Probe cable FEP-0001

Probe Cable FEP-0001

No. Function Diameter Colours Additional info.

Measuring cell 2 x 0,75 mm

2

white-brown / brown With shield

Thermocouple 2 x 0,75 mm

2

green / white With shield

Probe heating 3 x 1,5 mm

2

black / blue / green-

yellow

Solenoid valve 2 x 0,75mm

2

grey / grey-blue

Warning

The shielding of the probe cable FEP-0001 must be connected only to the electronic unit ground (PE) clamp. In no

case should the shield of the probe cable be also connected at the probe end.

2.3 Installation of the Probe

The ambient temperature at the connection box and

process temperatures may not be exceeded

Avoid vibrations greater 2g

Maintain the protection class of the connection box

Installation and Operation Manual – OXITEC Economy Installation

Doc.-ID: ECO-12022015-EN 7

2.4 Install O2Probe

2.4.1 Welding of the Counter Flange

Caution

The counter flange must be welded gas tight to the duct wall at the required angle.

Make sure that the combustion process is not in operation and the temperature of the flue gas duct at the mounting

place allows work without any risk of burns.

2.4.2 Adjustment of the probe filter head

Info

Please take note of the flue gas flow direction at the place of installation

Figure 9 - Filter head adjustment

Figure 8 - Welding of duct flange

Flue gas duct for the probe counter flange

The counter flange has to be welded with the

required negative angle.

Welding must be gas tight

Duct flange (optional from ENOTEC)

Installation Installation and Operation Manual – OXITEC Economy

8 Doc.-ID: ECO-12022015-EN

2.4.3 Installation of the O2 Probe

Caution

For probe installation into the duct flange use only new and undamaged gaskets .

Tighten the flange nuts correctly to get a gas tight flange connection. Insulate the duct flange to prevent

against dew point corrosion problems.

Do not leave the O

2

probe unheated inside of the duct for a period longer than 30 minutes.

Figure 10 - O

2

probe Installation

Duct Flange

Insulation of the duct flange

Probe flange gasket

Nut M12 with washer and spring

O

2

probe terminal socket

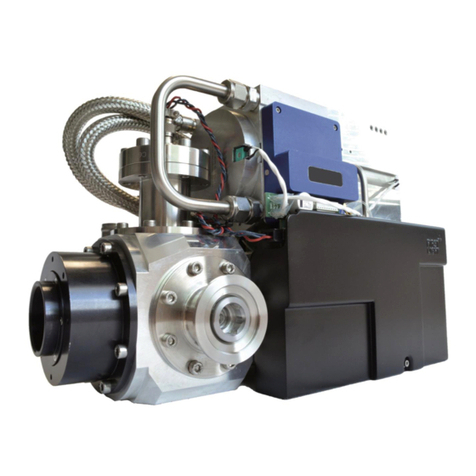

2.4.4 O2Probe installation with Cooling Protection Tube

Adjust the cooling

protection tube so

that the gas exit is

directed into the flue

gas flow direction.

Figure 11 - O

2

probe installation with cooling protection tube

Installation and Operation Manual – OXITEC Economy Installation

Doc.-ID: ECO-12022015-EN 9

2.5 Electrical Connections of the Electronic Unit

Figure 12 - Electrical connections of the electronic unit

Ferrite sleeves (ENOTEC supply) Analogue output cable (Customer)

Line voltage supply cable (Customer) Digital output cable (Customer)

O

2

Probe cable (already connected)

Line Voltage

1

O

2

Sensor Signal

1 L Phase 12 + brown

2 N Neutral Conductor 13 - Brown/white

3 PE Ground Earth thermocouple

Internal Power Supply (not in use) 14 + green

4 L 15 - white

5 N O

2

Analogue Output 4-20 mA

2

(active)

Shielding 17 A / B A + / B -

6 PE Relays contact Outputs

3

O

2

Probe heater 0-115V AC (controlled) 18 A / B Maintenance

8 L Black, phase 19 A / B System fault

9 N blue, neutral conductor 21 A / B O

2

Limit alarm 1

4

10 PE green/yellow, protective earth conductor 22 A / B O

2

Limit alarm 2

5

1

Line voltage, frequency and rated current, see electronic name plate

2

Isolated mA output, Burden see technical data electronic unit

3

Voltage and current limits see technical data electronic unit

4

Option

5

In certain applications, it is possible that the contact function is inverted

Installation Installation and Operation Manual – OXITEC Economy

10 Doc.-ID: ECO-12022015-EN

2.6 Electrical Wiring Diagram

Figure 13 - Electrical wiring diagram

Installation and Operation Manual – OXITEC Economy Installation

Doc.-ID: ECO-12022015-EN 11

2.6.1 Relay Contacts, Functions

Relay Contact for Contact closed Contact open

System fault No System fault System fault has occurred (error code on display)

Maintenance System switched off or Maintenance

active

No maintenance

O

2

Limit alarm 1 (optional) O

2

Limit alarm 1 not active System switched off or O

2

Limit alarm 1 active

O

2

Limit alarm 2 (optional) O

2

Limit alarm 2 not active System switched off or O

2

Limit alarm 2 active

2.6.2 Probe Connection

O

2

Probe plug has to be

inserted into the probe socket and

locked with the retaining clip .

Figure 14 - Probe connection

Initial operation Installation and Operation Manual – OXITEC Economy

12 Doc.-ID: ECO-12022015-EN

3 Initial operation

3.1 Checklist before commissioning the system

Is the system number of the probe identical to the system number of the electronic unit? If not, change the

assignment.

Does the voltage specified on the name plate correspond to the line voltage? (See section 1.5 - Name Plates)

If not, contact ENOTEC.

Is the electrical wiring connected correctly? (See section 2.6 - Wiring Diagram)

Make sure that there are no leakages at the probe - e.g. is the counter flange welded gas tight to the duct and are

the flange bolts tightened sufficiently? Are gaskets in use? (See section 2.4 – Install O2 Probe)

Do the conditions at site match the specification in the data sheets? (See section A- Technical Data)

3.2 System Power Up

Switch on the line voltage to the system. After a short power up information, the user is prompted to

Select language, set the System date, System time, enter a TAG number and ENOTEC REMOTE code (only if

option ENOTEC REMOTE is factory activated).

The probe heating phase now begins which is followed by the measuring mode.

Figure 15 - System Power up. Note the software

version at the bottom right of the display.

3.3 Display - Probe Heating Phase

Figure 16 - O

2

sensor heating phase

The probe heating phase begins with the heating

up of the O

2

sensor.

TAG number

Analogue temperature bar

Last access with corresponding date

Rising probe temperature

(or) waiting period

(or) heater error

Current temperature

Softkey title: e.g. System menu

Installation and Operation Manual – OXITEC Economy Initial operation

Doc.-ID: ECO-12022015-EN 13

3.4 Display - Measuring Mode

TAG number

Measured value

Blinking indicators showing under or over

measuring range

Last access

Measured component

Softkey titles

Figure 17 - Measuring mode

3.5 Keypad and Display

Figure 18 - Keypad and display

The controls and display of the

COMTEC® 6000 are housed in the

electronic unit and are

comprised of:

Three LED indicators depicting

active status

reports for limit alarms, mainte-

nance and system faults

Graphic enabled, back-lit dis-

play

Four softkeys with varying lay-

out

(softkeys)

Numeric number bloc

3.6 Status LEDs 3.7 Softkey Symbols

Alarm, - orange - is lit when an

alarm has been activated (e.g.

O

2

limit alarm)

Moves the selection one position upwards

Moves the selection one position down-

wards

Maint. - Orange - a function has

been accessed which may

affect the measurement

Leave an area

Abort a function or entry

Error - red - is lit when a system

error has occurred

Select or confirm a function/value

3.8 System Code

Info

The system code on delivery is 0000. In this state, entry into the system is granted without having to enter the

system code. The system code protects the system from unauthorised use. Functions which may alter the

measurements are therefore also protected.

Software Overview and Explanations Installation and Operation Manual – OXITEC Economy

14 Doc.-ID: ECO-12022015-EN

4 Software Overview and Explanations

4.1 Software Overview - SYS-MENU

SYS-MENU

System Information

Actual measured values

O2measured value (% O2)

O2-mA output 17A/B (mA)

O2sensor input (mV)

O2probe temperature (°C / °F)

O2probe heater power (%)

Thermocouple input (mV)

Terminal temperature (°C / °F)

Internal temperature (°C / °F)

O2 sensor life (%)

Calibration results

e.g. 2011-01-31 (Choose date/time)

Executed at

Calibration method

O2 sensor calibration

~~ Calibration results ~~

O2value at test air (20,95 % O2)

♦calibrated to (% O2)

O2value at test gas (% O2) } only if determined

♦calibrated to (% O2)

~~ Calibration data ~~

O2sensor offset (mV)

O2sensor slope (mV / dec) } only 2 point calibration

~~ Test gas data ~~

Test air (20,95 % O2)

Test gas (e.g. 2,1 % O2)

~~ Sensor raw data~~

O2voltage at test air (mV)

O2voltage at test gas (mV) } only if determined

O2response to test gas (s) } only if determined

O2response to process (s) } only if determined

O2sensor life

Device operating data

Powers on counter

Hours in operation

Min. internal temperature

Max. internal temperature

Software version and options

Software OXITEC 5000 ECONOMY

~~ Options ~~

Installation and Operation Manual – OXITEC Economy Software Overview and Explanations

Doc.-ID: ECO-12022015-EN 15

♦.....

SYS-MENU

System configuration

O2Measuring ranges

Meas.range from (% O2)

Meas.range to (% O2)

mA output type (0-20 mA / 4-20 mA)

mA output on system error (mA)

O2sensor calibration values

O2cal.value - offset (mV)

O2cal.value - slope (mV/dec)

Calibration settings

Time per test gas apply (Min.)

Delay time to process (Min.)

ENOTEC REMOTE settings (optional)

ENOTEC REMOTE (ON/OFF)

Passkey (8 digit code)

Range (Short / Medium / Maximum)

System clock/TAG number

System date (jjjj-mm-tt)

System time (hh:mm:ss)

Measuring units

Temperature (°C / °F)

Language

Choose language (Deutsch / English / Spanish / Polish)

Change system code

Load factory settings

Service

Software Overview and Explanations Installation and Operation Manual – OXITEC Economy

16 Doc.-ID: ECO-12022015-EN

4.2 Software Explanations - SYS-MENU

4.2.1 O2Measuring Ranges (Scaling)

Figure 19 - O

2

Measuring Ranges

The O

2

Measuring range is linearly scaled and converted to a

linear current output (0/ 4-20 mA).

The parameter „O

2

Measuring range from“ is the start value of the

O

2

range, leading to an analogue output of 4,00 mA.

„O

2

measuring range to“ is the end value of the O

2

range, leading

to an output of 20,00 mA.

If a measured value is lower than the start value of the O

2

measuring

range, the current output signal drops to 3,60 mA.

(If the current output is set to 0- 20 mA the output is 0 mA)

If the measured O

2

value is higher than the end value of the O

2

measuring range end, the analogue output rises to 20,40 mA.

If during normal operation the measured O

2

value is under, or over

the programmed measuring range, an error message appears on

the display (in measuring mode).

4.2.2 mA output on system errors

Here the mA output value is set corresponding to a measurement error. The measurement output range for the

shown value (3,60 mA .... 20,40 mA) cannot be defined in this case.

4.2.3 O2limit alarm settings

Figure 20 - O

2

limit alarm settings

The entry "by" sets the value at which the O

2

limit alarm is activated.

The O

2

limit alarm function "min" defines a value by which the

limit alarm is activated if the measured O

2

value falls below the

set limit.

If the hysteresis is set to greater than 0,00,

the limit alarm is reset when the measured O

2

value rises above the

set O

2

limit plus the hysteresis value .

The O

2

limit alarm function "max" defines a value by which the

limit alarm is activated if the measured O

2

value rises above the

limit.

If the hysteresis is set to greater than 0,00,

the limit alarm is reset when the measured O

2

value falls below the

O

2

limit minus the hysteresis value.

If the hysteresis is set to 0,00 % O

2

, the triggered limit alarm must be

manually reset.

Installation and Operation Manual – OXITEC Economy Software Overview and Explanations

Doc.-ID: ECO-12022015-EN 17

4.2.4 O2Sensor calibration values

Info

The sensor calibration values can be altered through a 1 or 2 point calibration. Manual entry of values is only

necessary after replacing the O

2

sensor.

4.2.5 Time per test gas apply

Here the maximum duration of time for the application of test gas or test air is set. If sensor stability is not reached

within the maximum time, the following error message is displayed: “O

2

Sensor calibration failed - O

2

sensor

signal instable” This problem can be offset by setting a longer duration. The factory setting for maximal duration is

10 Minutes. If necessary, the time can be adjusted between 5 minutes and 30 minutes.

4.2.6 Delay time to process

Here the delay time showing the last measured O

2

value from the data storage is frozen after test air or test gas has

been applied (only when "Meas. value hold on cal. is set to on) This value also sets the time for showing the trend

representation on the display after test air or test gas application after a sensor calibration is set.

4.2.7 ENOTEC REMOTE

Info

If ENOTEC REMOTE is set to "OFF", password and range are not displayed.

The ENOTEC REMOTE password is used for:

authentification and pairing with a smartphone / tablet / laptop / pc.

authentification / login after every connection. Without Authentication / login, device data cannot be read or

modified. The device configuration can also not be altered.

Range limits the transmission power of the ENOTEC REMOTE module. Maximum = 100m, medium = 10m, short =

1m. The actual possible range may vary due to structural factors and the reception strength of the strength of the

Smartphone/Tablet.

When an ENOTEC REMOTE connection to the

analyzer is active, the connection is shown in the

upper right corner of the display .

Figure 21 - ENOTEC REMOTE connection active

Info

A maximum of 16 users (smartphones /tablets) can connect to the ENOTEC REMOTE module of an ENOTEC

analyzer. Should additional users attempt a connection, the connection will fail. In this case, manually switch off the

ENOTEC REMOTE and switch it back on again SYS MENU => System configuration => ENOTEC REMOTE Set-

tings which will reset the module.All previously paired users will need to delete their saved connection to the ana-

lyzer and re-pair their devices.

Software Overview and Explanations Installation and Operation Manual – OXITEC Economy

18 Doc.-ID: ECO-12022015-EN

4.2.8 Measuring units

Measuring units can be set for temperature (°C / °F).

4.2.9 Language

Set the language for all text shown on the display. One can choose between English, German, Spanish and Polish.

4.2.10 Change system code

Info

The system code on delivery is 0000. In this state, entry into the system is granted without entering the

system code. For security reasons, change the code and store it in safety. In case of loss of the system

code, a system reset has to be carried out. The reset process may only be carried out by trained service

technicians. As an option, a 6 digit code is available.

4.2.11 Load factory settings

Loading factory settings will restore all original settings and values to the default values programmed in the factory. If

activated, all set parameters and also values such as sensor calibration values and calibration results are lost. Take

note of the sensor calibration values beforehand and re-enter them after the loading the factory settings. If this is not

done, a calibration has to be carried out.

4.2.12 Service

The service functions are password protected and are only accessible by trained service personnel. These functions

are protected with a code, different to the system code.

Table of contents

Other Enotec Analytical Instrument manuals