CB ELECTRONICS

Loddonside, Lands End House, Beggars Hill Road, Charvil, Berks RG10 0UD, UK

Tel: +44 (0)118 9320345, Fax: +44 (0)118 9320346, www.colinbroad.com

SR-4/SR-24/SR-32/MR Custom/RM-6/Video Slave

Serial Remotes/Synchronizers

User Manual

* Multiple serial ports .............. SR-3: 3 Output, 1 Input; SR-4: 4 Output, SR-24A 5 Output

* Multiple serial ports ..............SR-24: 4 Output; SR-24A: 4 Output, 1 Output/Input, 1 Input

* Sony P2 protocol ................................ DAT’s, VTR’s, DA-88, FEG Prima ..

* P2 Plug and Play .......................... Sony P2 Auto recognition and Configuration

* ES BUS protocol ...................................Studer D820/D827, AK ES 1.11

* Studer TLS4000 protocol .............................. Studer Audio Tape Recorders

* Ampex Protocol .................................... VPR-3, VPR-80, Timeline Lynx

* 8(SR-3/4) or 24(SR-24) Record Ready keys .................... Upto48record Channels

* RS422 Input ..................... OnSR-3 and SR-24 for use with DAW or Video Editors

* Parallel In/Out ...................................6parallel inputs, 6 parallel outputs

* Parallel Remote with tallies (SR-24) ................................. SSLS29format

* Timecode Output ..............................Follows the master position and Offset

* Timecode Input .................................. Alloutputs will chase remote code

* Built in P2 Synchroniser ..................... Will synchronise any suitable 9-pin Machine

* Real or Virtual Master ...................... Perfect Machine as Master, Tapeless Master

* 11 (SR-3/4) or 15(SR-24) Macro Keys ............................. User configurable

The SR Series remote controls have been designed using experience gained from the MR series

remote control system. Designed as a stand-alone controller or to be used with Digital Audio Work-

stations the SR serial remotes make cost effective ergonomic solutions.

Although the user can control only one machine at a time from the remote both the record and un-

record commands are global so that multiple machines may be controlled simultaneously using the

internal 9-pin synchroniser or using the built in chase feature of modern machines.

SR-3

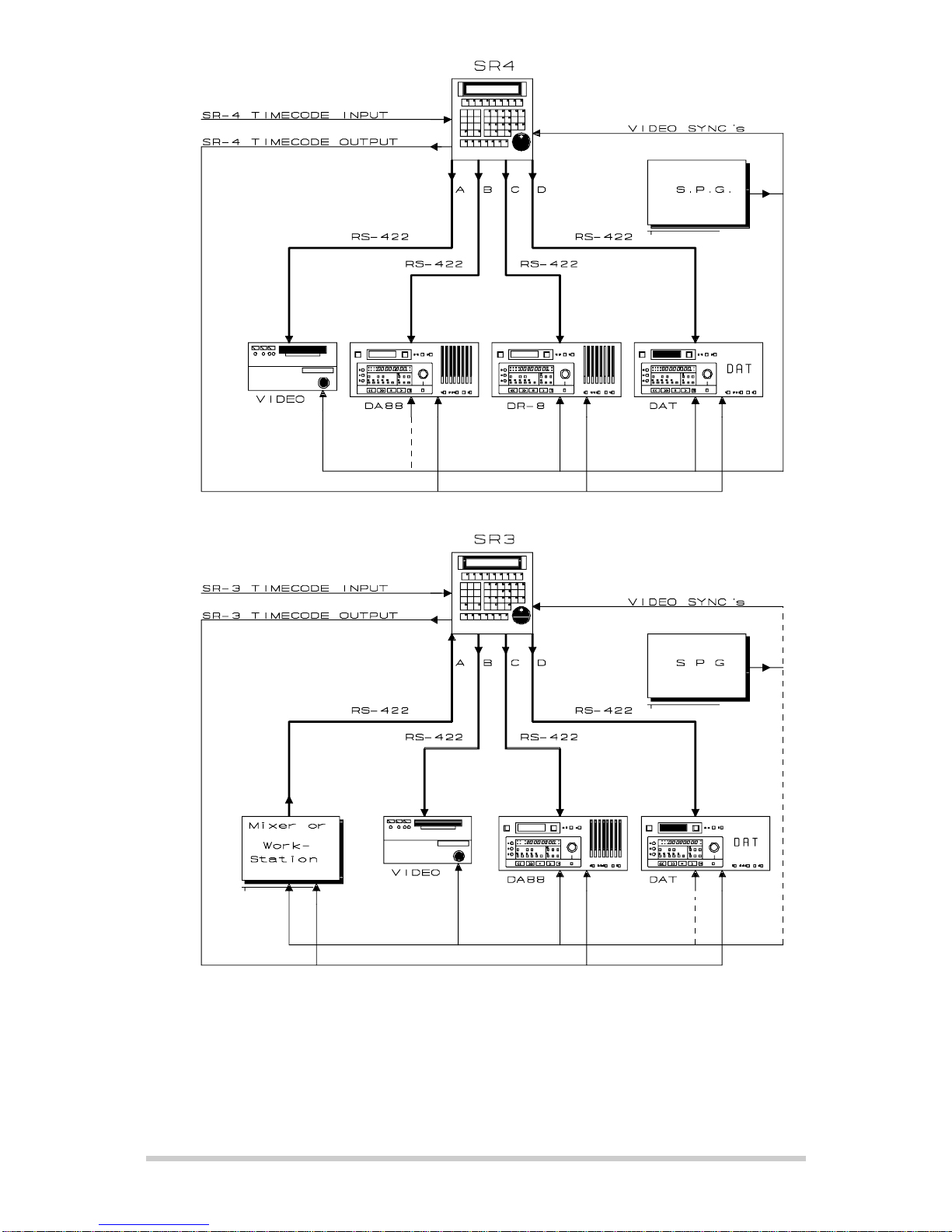

The SR-3 may be used with a Digital Audio Work-station or Video Editor to provide control of up to 3

machines from one serial port. The DAW controls the selected master machine; the timecode output

follows the selected master. The record tracks are mapped so that the Serial input may have up to 64

record tracks. The timecode input enables the SR-3 to act as a timecode to serial converter.

SR-24

The SR-24 separates the keyboard from the electronics and display. The keyboard supports 24 record

enable keys these may be mapped to one or multiple machines. A 24 character LED display built into

the keyboard is used to display the currently selected machine and the current keyboard entry.

PARALLEL INPUT/OUTPUT

There are 6 CMOS parallel inputs and 6 TTL parallel outputs provided. Currently used as machine

control and tallies and General Purpose Trigger Outputs.

RECORD ENABLE

8(SR-3/4) or 24(SR-24) record ready switches and a bank switch are provided, these are switched with

the machine selects and provide access to up to 48 tracks on each machine.

MACRO KEYS

Any of the 100+ user functions provided may be assigned to one of the 9 macro keys. The user

functions include Dat specific functions such as PNO renumber, id write, id read. Video specific

commands such as assemble or insert, ADR keys (Next Loop, Prev Loop, Join, Insert), or system

commands such as instant replay, instant record, Mark. Continual user feedback ensures that more

functions are provided on a regular basis.

CB Electronics SR/MR User Manual 29 April 2004 SR-User 1