PHENIX

Technical Manual

v2.0

CCEI

page 3

OVERVIEW

PHENIX is a complete regulation system for salt electrolysis. Combined with a salt

chlorinator, PHENIX regulates its chlorine production and adjusts the acidity (pH) of

the water.

PH

The pH or Hydrogen potential measures the degree of acidity present in water. It is

measured on a scale of 0 to 14. A solution with a pH of 7 is neutral. If it is below 7, the

solution is acidic, above 7 the solution is considered basic or alkaline.

To ensure the comfort of swimmers, the effectiveness of the treatment and reliability

of the installation, the pH of the swimming pool water must be maintained at around 7.

A pH of between 6.8 and 7.6 is generally considered to be correct.

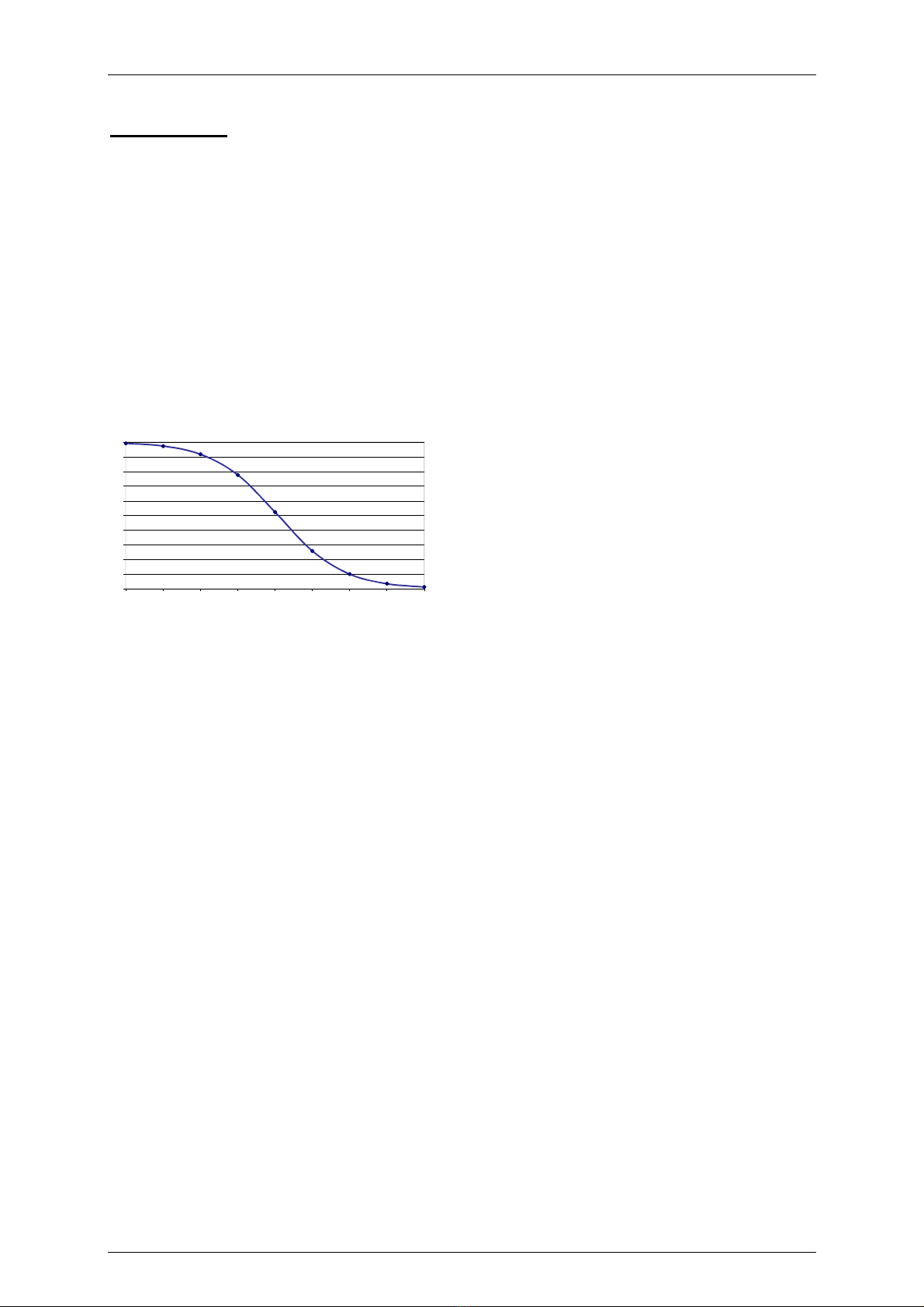

Water that is too acidic (pH <6.8) irritates

the mucous membranes, corrodes

100

90

80

70

60

50

40

30

20

10

0

5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5

pH

metal parts and may damage plastic

elements in the pool (liners).

Water which is too alkaline (pH >7.8) can

also be aggressive (caustic) and

considerably reduce the effectiveness of the

chlorine. Thus, when the pH goes from 7.2

to 8.2, the percentage of active chlorine

changes from 70% to 20%.

To ensure the optimum effectiveness of the

treatment, it is therefore essential to

maintain the pH of the water between 7.0 and 7.6.

In addition, the salt chlorinator causes an increase in pH which makes pH regulation

particularly useful.

PHENIX maintains the pH of your pool by injecting a pH correcting solution into the

water as required. The user can configure the PHENIX in pH- mode or in pH+ mode.

In pH- mode, the PHENIX injects PHminus (acid) to lower the pH in the pool and in

pH+ mode it injects PHplus (base) to increase the pH. PHENIX, specifically designed

for swimming pool water, regulates the pH between 6.0 and 8.5.

To reduce the difference with the set point value, regulation is proportional: The dosing

speed increases the greater the difference with the set point value. The injection flow

rate can vary between 0.1 l/h and 0.9 l/h.

REDOX

PHENIX measures the oxidation reduction (RedOx) potential of the water in your pool

and if this potential is below the set threshold, PHENIX activates chlorine production

from a chlorinator.

The salt water chlorinator separates the salt (NaCl) into sodium (Na) and chlorine (Cl).

which immediately dissolves in water to produce hypochlorous acid (HClO). This

powerful disinfectant destroys bacteria and its presence affects the oxidation reduction

potential measured by PHENIX.

This RedOx potential, or ORP (which stands for Oxidation Reduction Potential), is

expressed in millivolts (mV) and gives an indication of the disinfectant capacity of the

water, and thereby the quality of the water in the pool (or its sanitary status). The higher

the potential, the greater the disinfectant power

Active Free Chlorine

%