CDA HVG970 Specification sheet

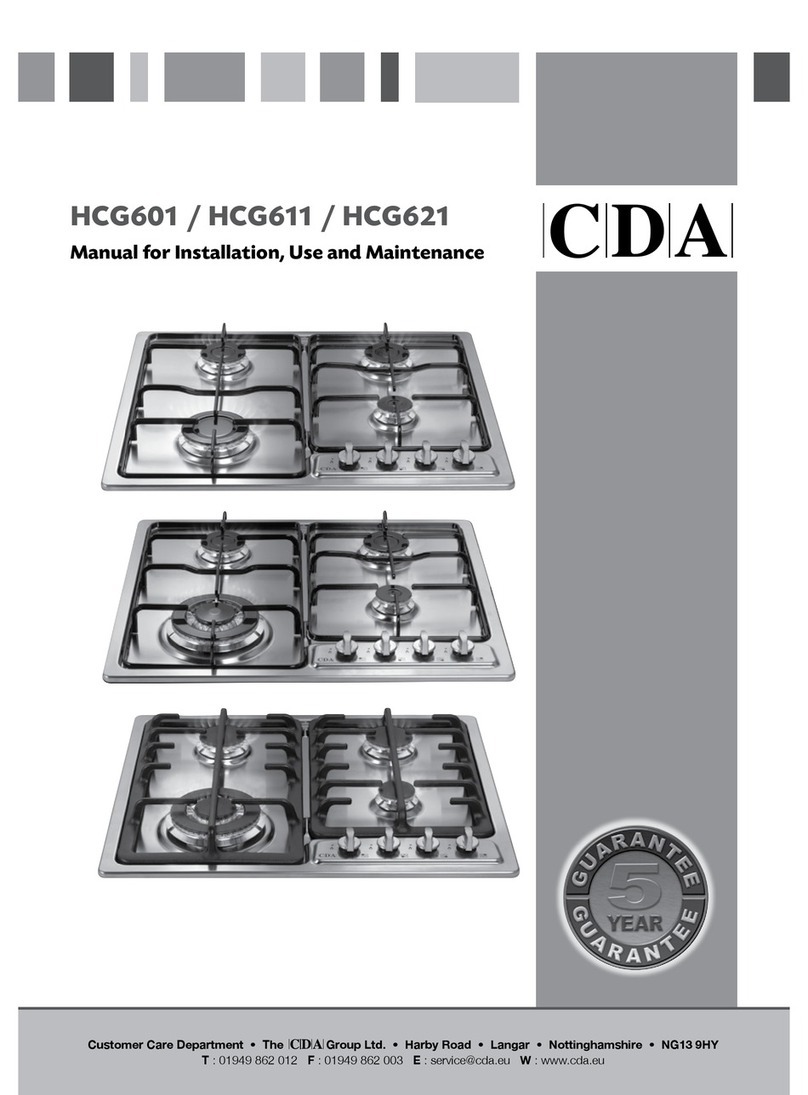

Other CDA Hob manuals

CDA

CDA HCG501 Reference manual

CDA

CDA hg6300 Reference manual

CDA

CDA HCN610 Reference manual

CDA

CDA HN6111 User manual

CDA

CDA HCG602 Reference manual

CDA

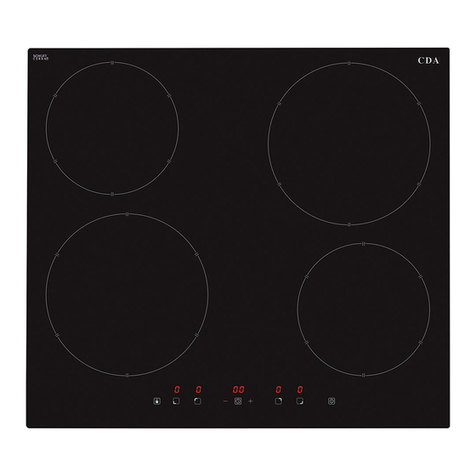

CDA INDUCTION HOB HVN61/81 Instructions for use

CDA

CDA HCN510 Reference manual

CDA

CDA HC3621FR User manual

CDA

CDA HVN93 Reference manual

CDA

CDA hn6110 Reference manual

CDA

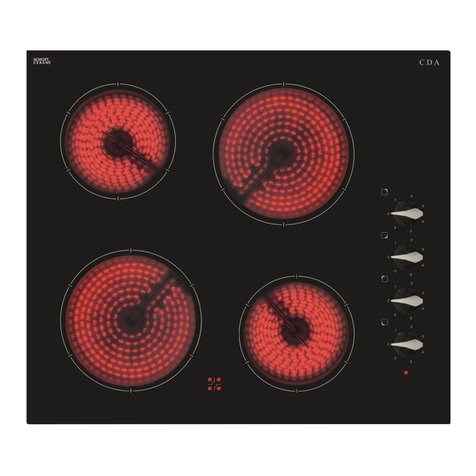

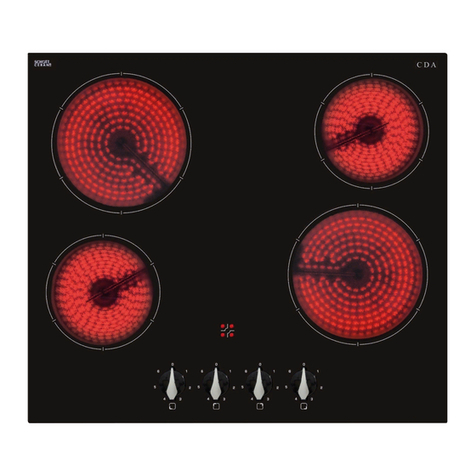

CDA HCC762 Reference manual

CDA

CDA HC6212FR Quick start guide

CDA

CDA HC6312FR Quick start guide

CDA

CDA HN6013FR Specification sheet

CDA

CDA HN9850FR Installation and operating instructions

CDA

CDA HCC561/1 Reference manual

CDA

CDA HCE550 Reference manual

CDA

CDA PEB4.7SVR User manual

CDA

CDA HN9611FR Quick start guide

CDA

CDA hn9840 Reference manual