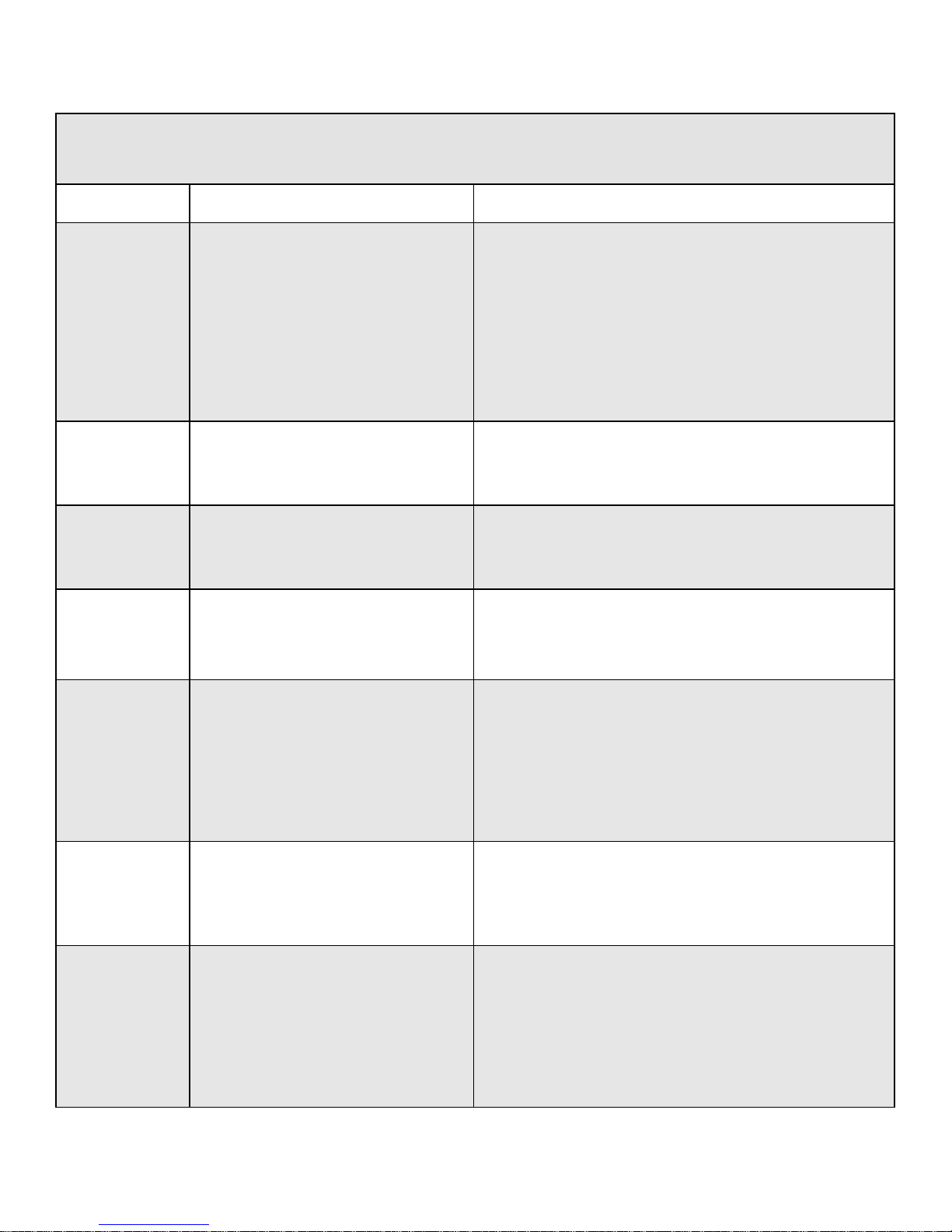

TROUBLESHOOTING GUIDE

WARNING: To reduce the risk of electrical shock unplu

the dispenser power cord before repairin

or replacin

an

internal components

of the unit.. Before any attempt to replace a component be sure to check all electrical connections for proper contact

PROBLEM PROBABLE CAUSE REMEDY

1

Brewed Cold Tea.

a) Heater Switch OFF.

b) Run out of hot water

c) Thermostat is OFF.

d) Loose electrical connection.

e) Thermostat is defective.

f) Hi-Limit Temperature Switch is tripped.

g) Bad Heating Element or Heater is burned out.

h) Bad low temperature cutout circuit.

Contactor/Relay

a) Turn Heater Switch ON.

b) Allow time for water in tank to heat after filling.

c) Set Thermostat at 197°F [to max. position].

d) Check all electrical connections for contact.

e) Replace Thermostat.

f) Replace the Hi-limit Temperature Switch..

g) Replace Heater.

h) Replace Contactor/ Relay.

2

Tea too weak.

a) Not enough Tea in the brew funnel.

b) Water flow too low.

c) Brew time is too short.

d) Water is too cold.

a) Put more Tea in the brew funnel [see chart]

b) Check flow [should be .26 gal /min.] Replace Dispense Valve.

c) Adjust hot water timer to 3 min. max.

d) Adjust Thermostat to 197°F [to max. position]

3

Tea too strong.

a) Too much tea in the brew funnel.

b) Water flow is high

c) Brew time is too long.

d) Water is too hot.

a) Put less Tea in the brew funnel [see chart]

b) Check flow [should be .26 gal /min.] Replace Dispense Valve.

c) Adjust hot water timer to 3 min. 197°F [to max. position]

d) Adjust Thermostat to 197°F [to max. position]

4

Water keeps dripping

or running from

dilution nozzle.

a) Leaking Water Inlet Valve.

b) Clogged/ stuck Water Dispense Valve

a) Clean/check fittings of Water Inlet Valve.

Replace Water Inlet Valve if needed. See ”Water Inlet Valve Test”

b) Clean/unclog Water Dispense Valve.

Replace Dispense Valve if defective.

5

No water is going

into tank at all.

or

No water is coming

from dilution nozzle

a) Water Inlet Valve malfunction.

b) Hi-Level Float Switch malfunction.

c) Probe malfunction.

d) Solid State Water Level Controls board

malfunction.

e) Timer malfunction.

a) Check Water Inlet Valve. Replace if necessary.

See “Water Inlet Valve Test”

b) Test High-Level Float Switch. See “High-Level Float Test”

c) Check Probe. Replace if necessary.

d) Check The Water Level Controls. Replace if necessary.

e) Check Timer: Time dispensing time vs. set time on Timer.

Replace if necessary.

6

Water will not stop

flowing into water tank.

a) Water Level Probe malfunction.

b) Solenoid (Water Inlet Valve) malfunction.

c) Solid State Water Level Control board

malfunction.

d) Float Switch malfunction.

a) Check Level Control Probe. Replace if necessary. See “ProbeTest”.

b) Check Solenoid. Replace if necessary.

c) Check The Water Level Controls. Replace if necessary.

d) Replace Float Switch.

7

Water is not heatin

up

in the water tank.

a) Heater Switch is OFF.

b) Thermostat is OFF.

c) Loose connection on Thermostat.

d) Hi-Limit Temperature Switch is tripped

or it is defective.

e) Heater is burned out or defective.

h) Bad Low Temperature Cutout Circuit.

Contactor/Relay.

a) Turn Heater Switch ON.

b) Turn Thermostat ON. Turn Thermostat Knob Clockwise.

c) Make sure all wires and ring terminals on the thermostat are tight.

d) Reset the Hi-Limit Button, If heater still does not work,

replace the Hi-limit Temperature Switch (see Item 6 in Tank ill.).

e) Replace the Heater.

h) Replace Contactor/Relay. See item 2 of Description of Components.