1

SERIES PH

HORIZONTAL PROCESS PUMPS

pH2110 Series: Types pH2111, 2112, 2114, 2116, 2117, 2118 • pH2140 Series: Types pH2141, 2142, 2144, 2146, 2147, 2148

pH2170 Series: Types pH2171, 2172, 2174, 2176, 2177, 2178 • pH3170 Series: Types pH3171, 3172, 3174, 3176, 3177, 3178

pH2180 Series: Types pH2181, 2182, 2184, 2186, 2187, 2188

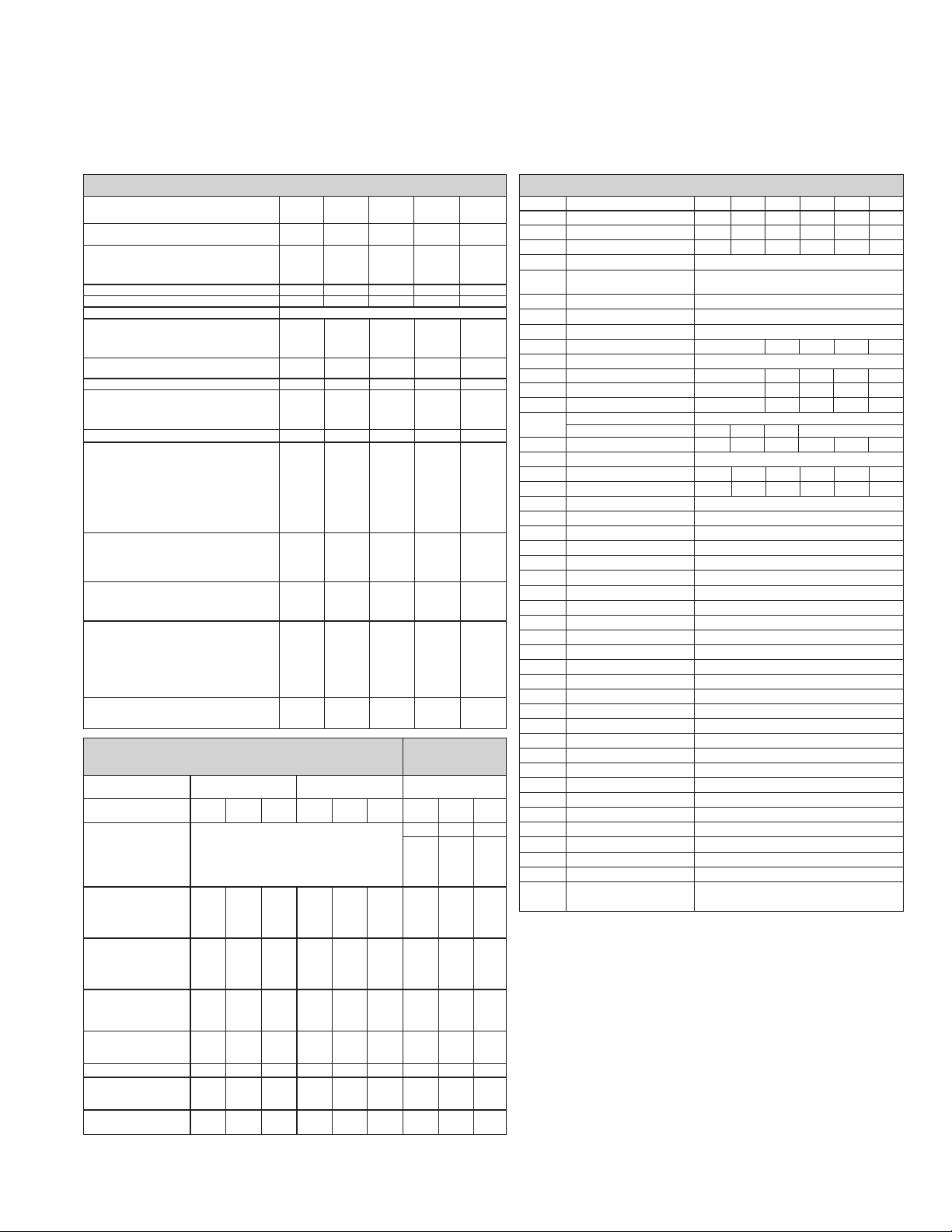

Part No. Part Name Class 22 Class 50 Class 60 CD4MCu Hast. Titanium

3 Impeller C.I. (1) 316 (12) Alloy20 (2) CD4MCu Hast. Titanium

5 Casing D.I. (10) 316 (12) Alloy20 (2) CD4MCu Hast. Titanium

5A Casing Drain Plug 1020 Steel 316 S/S Alloy20 316 S/S Hast. Titanium

5C Casing Stud Nut ±Steel (4)

5D Casing Capscrew ≠s‡Steel (11)

Casing Stud ±Steel (6)

7 Cradle Spacer ¨6‡D.I. (13)

7G Spacer to Brg. Hsg. Capscr. ¨=6‡1020 Steel

9 Bearing Housing Foot ¨C.I. (1)

10 Shaft Sleeve s=6‡316 S/S Alloy 20 316 S/S Hast. Titanium

10K Sleeve Key s=6‡304 S/S

13 Seal Chamber Gland 316 S/S Alloy 20 316 S/S Hast. Titanium

14 Gland Stud 304 S/S Alloy 20 304 S/S Hast. Titanium

15 Gland Nut 304 S/S Alloy 20 304 S/S Hast. Titanium

17 Lantern Ring ≤s= Teflon n

Lantern Ring Ø6‡C.I. (1) 316 S/S Alloy 20

22 Casing Back Cover 6‡D.I. (10) 316 (12)

Alloy 20 (2)

CD4MCu Hast. Titanium

22A Back Cover to Cradle Capscrew s=6‡1020 Steel

25 Radial Bearing s=6‡——————

25A Thrust Bearing s=6‡——————

26 Bearing Housing =6‡D.I. (13) for pH2110 & pHP2110, C.I. (1) for all others

27 Seal Ring ¨=6‡C.I. (1)

28 Bearing End Cover s=6‡C.I. (1)

28A Bearing End Cover Capscrew s=6‡1020 Steel

28B End Cover Adjusting Screw s=6‡1020 Steel

28C Adjusting Screw Locking Nut s=6‡1020 Steel

29 Pump Shaft s=6‡Steel (5)

31 Thrust Bearing Lock Nut ¨=6‡1020 Steel

31A Thrust Bearing Lock Washer ¨=6‡1020 Steel

56 Casing Foot ∞C.I. (1)

56A Casing Foot Capscrew ∞= 1020 Steel

56B Casing Foot Dowel ∞= 1020 Steel

75A Tapered Retaining Ring Æs Steel

75B Large Retaining Ring ≤s= Steel

76 Labyrinth Seal – Front s=6‡Bronze & Viton n

76A Labyrinth Seal – Rear s=6‡Bronze & Viton n

77 Casing Gasket 6‡Teflon n

77A Impeller Gasket s=6‡Teflon n

77B End Cover Gasket s=6‡Buna (7)

80 Vent s=6‡—

83 Motor Support (C Face) ≤s= C.I. (1)

95A Mechanical Seal Stationary s=6‡

95B Mechanical Seal Rotary s=6‡

109 Oil Cooler s=6‡S/S Tubing with Steel Fins and Steel Fittings

231 Bearing Lock Ring Ø6‡1020 Steel

231A Bearing Lock Ring Screw Ø6‡1020 Steel

231B Bearing Lock Ring Washer Ø6‡1020 Steel

pH2110 pH2140

PUMP TYPE pHP2110 pHP2140 pH2170 pH3170 pH2180

Direction of Rotation

(Viewed from Coupling End) CW CW CW CW CW

Horsepower Rating

@ 3500 rpm 35 HP 100 HP — 200 HP —

@ 1750 rpm 15 HP 40 HP 100 HP 100 HP 125 HP

@ 1150 rpm 10 HP 30 HP 60 HP — 75 HP

Hydrostatic Test Pressure 430 psig 430 psig 430 psig 565 psig 450 psig

Corrosion Allowance 1/8"1/8"1/8"1/8"1/8"

Impeller Balance Single Plane Dynamic Balance

Flanges ANSI Class 150 150 150 300 300

Facing – standard F.F. F.F. F.F. F.F. F.F.

– optional R.F. R.F. R.F. R.F. R.F.

Finish 125 Ra 125 Ra 125 Ra 125 Ra 125 Ra

Stuffing box jacket pressure maximum 125 psig 125 psig 125 psig 125 psig 125 psig

Bearing housing cooler pressure maximum 125 psig 125 psig 125 psig 125 psig 125 psig

Maximum Suction Pressure 275 psig 275 psig 275 psig 375 psig 300 psig

Bearings:

Thrust Bearing 5306 5309 7311 BG 7311 BG 5312

Radial Bearing 6207 6309 6311 6311 6312

Lubrication Oil Oil Oil Oil Oil

Approximate oil capacity of bearing housing 26 oz 42 oz 36 oz 36 oz 64 oz

Seal Chamber Dimensions:

Tapered Seal Chamber

Length (Depth) 23/8"3

1/16"3

1/16"3

1/16"4

5/8"

Inside Diameter (Bore) 27/8"3

1/2"3

7/8"3

7/8"4

1/4"

Shaft Sleeve Diameter 13/8"1

3/4"2

1/8"2

1/8"2

1/4"

Cylindrical Seal Chamber

Length (Depth) 17/8"2

1/4"2

3/16"2

3/16"3

5/16"

Inside Diameter (Bore) 27/8"3

1/2"3

7/8"3

7/8"4

1/4"

Shaft Sleeve Diameter 13/8"1

3/4"2

1/8"2

1/8"2

1/4"

Stuffing Box Dimensions:

Length (Depth) 21/8"2

3/4"2

3/4"2

3/4"3

7/8"

Inside Diameter (Bore) 2" 21/2"2

7/8"2

7/8"3

1/4"

Shaft Sleeve Diameter 13/8"1

3/4"2

1/8"2

1/8"2

1/4"

Lantern Gland Width 7/16"5/8"5/8"5/8"3/4"

Packing Size – Square 5/16"3/8"3/8"3/8"1/2"

Number of Rings with Lantern Ring 55556

Number of Rings without Lantern Ring 67 7 77

Spacing with Lantern Ring 2-G-3 2-G-3 2-G-3 2-G-3 3-G-3

Pump Shaft Dimensions:

Span Between Bearings 315/16"6

3/8"5

15/16"5

15/16"8

7/16"

Span Between Radial Bearing and Impeller 513/16"7

7/8"8

3/16"8

3/16" 103/4"

Diameter Under the Sleeve 11/8"1

1/2"1

7/8"1

7/8" 2"

Diameter with No Sleeve 13/8"1

3/4"2

1/8"2

1/8"2

1/4"

Diameter at Coupling 7/8"1

1/8"1

5/8"1

5/8"1

5/8"

Diameter Between Bearings 11/2"2

1/8"2

5/8"2

5/8"2

3/4"

Diameter at Impeller 3/4"1

1/4"1

1/4"1

1/4"1

5/8"

L3/D4 Ratio

Sleeved Shaft 123 96 44 44 78

Solid Shaft (No Sleeve) 55 52 27 27 48

STANDARD MATERIALS OF CONSTRUCTION

¨pH2140, pH2170, pH3170, pH2180 and pHP2140 only

≠pH2110, pH2140, pH2170, pH2180, pHP2110 and pHP2140 only

ÆpH2110, and pHP2110 only

ØpH2170, pH3170, and pH2180 only

∞pH2140 and pHP2140 only

±pH3170 only

≤pH2110, pH2140, pHP2110, and pHP2140 only

sDenoted parts are interchangeable in all pH2110 and pHP2110 pumps

=Denoted parts are interchangeable in all pH2140 and pHP2140 pumps

6Denoted parts are interchangeable in all pH2170 and pH3170 pumps

‡Denoted parts are interchangeable in all pH2180 pumps

nRegistered Trademark of the E.I. DuPont Company

MATERIAL SPECIFICATIONS (REFER TO NUMBERS IN PARENTHESES)

(1) Cast Iron (8) Fibre Sheet — Non-Asbestos Fibre

(2) Alloy 20 S/S: ASTM #A744, Grade CN-7M (9) Manila Paper

(3) Cast Steel: ASTM #A216, Grade WCB (10) Ductile Iron: ASTM A395

(4) Steel: ASTM #A194, Grade 2 (11) Steel: ASTM #A449

(5) Alloy Steel: 125,000 TS, 100,000 YP (12) 316 S/S: ASTM #A744 Grade CF-8M

(6) Steel: ASTM #A193, Grade B7 (13) Ductile Iron: ASTM A536

(7) Buna “N” Rubber

STANDARD, HORIZONTAL, SINGLE STAGE, END SUCTION, OPEN IMPELLER, CENTRIFUGAL PROCESS PUMPS

PUMP SIZE With Without Values of Fn

Balance Holes Balance Holes

pH/pHP 3500 1750 1150 3500 1750 1150 3500 1750 1150

RPM RPM RPM RPM RPM RPM RPM RPM RPM

psi psi psi

1 x 11/2x 6 pH2110 maximum allowable 18 4.5 2.0

11/2 x 3 x 6 suction pressure = 18 4.5 2.0

2 x 3 x 6 maximum allowable 18 4.5 2.0

1 x 11/2x 8 discharge pressure 22 5.5 3.5

11/2x 3 x 8/ 11/2x 11/2x 8 less developed head 18 4.5 2.0

1 x 2 x 81/2pH2140 110 185 200 180 200 205 25.2 6.3 2.7

11/2 x 3 x 81/2115 185 200 190 195 205 25.2 6.3 2.7

2 x 3 x 81/2115 185 200 190 195 205 25.2 6.3 2.7

3 x 4 x 81/2 #1 110 180 200 210 200 205 39.0 9.7 4.2

3 x 4 x 81/2 #2 175 200 230 220 9.7 4.2

1 x 2 x 10 110 180 200 185 195 205 25.2 6.3 2.7

11/2x 3 x 10/ 2 x 2 10 110 180 200 185 195 205 25.2 6.3 2.7

2 x 3 x 10/ 3 x 3 x 10 110 180 200 190 185 205 25.5 6.3 2.7

3 x 4 x 10 #1/ 4 x 4 x 10 110 180 200 210 205 210 25.2 6.3 2.7

3 x 4 x 10 #2 180 200 200 205 9.7 4.2

11/2x 3 x 111/2105 180 180 200 25.2 6.3 2.7

2 x 3 x 111/2105 180 180 200 25.2 6.3 2.7

3 x 4 x 111/2170 200 190 200 14.0 6.0

4 x 6 x 111/2150 180 200 205 14.0 6.0

11/2x 3 x 131/2165 195 185 200 6.3 2.7

2 x 3 x 131/2165 195 185 200 6.3 2.7

3 x 4 131/2/ 4 x 4 131/2165 195 185 200 6.3 2.7

4 x 6 x 131/2pH2170 240 260 240 260 23 10.0

11/2x 3 x 131/2pH3170 300 25.2

2 x 3 x 131/2300 25.2

3 x 4 x 131/2285 25.2

4 x 6 x 131/2pH2180 225 275 275 275 22.0 10.0

6 x 8 x 131/2225 275 275 275 15.0 6.7

MAX. ALLOWABLE PUMP SUCTION PRESSURE (psi)

WITH 2 YR. MIN. THRUST BEARING LIFE

MECHANICAL DESIGN SPECIFICATIONS

Seal Chamber Pressure:

With Balance Holes: seal chamber pressure = suction pressure

Without Balance Holes: Pumps are normally furnished without balance holes.

seal chamber pressure = (suction pressure) + (Fn x sp. gr.)