TABLE OF CONTENTS

SECTION 1 –SAFETY INFORMATION.............................................................................................................3

1.1 –CAUTION ..........................................................................................................................................3

1.2 –PRECAUTIONS ..................................................................................................................................4

SECTION 2 –THE DISPENSER.........................................................................................................................5

2.1 –UNIT IDENTIFICATION ......................................................................................................................5

2.2 –MODEL & SERIAL NUMBER ..............................................................................................................6

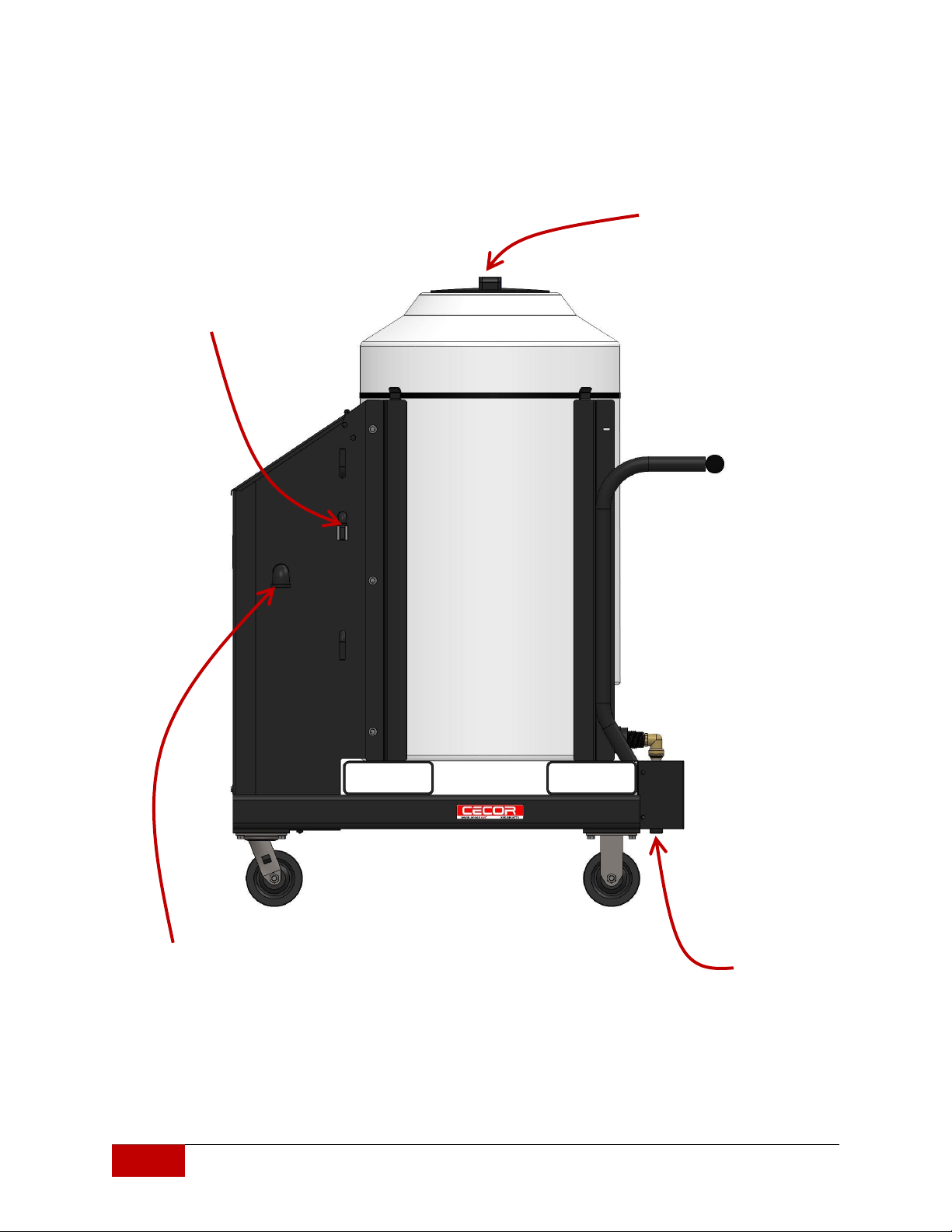

2.3 –DISPENSER FEATURES ......................................................................................................................7

SECTION 3 –SETUP .......................................................................................................................................8

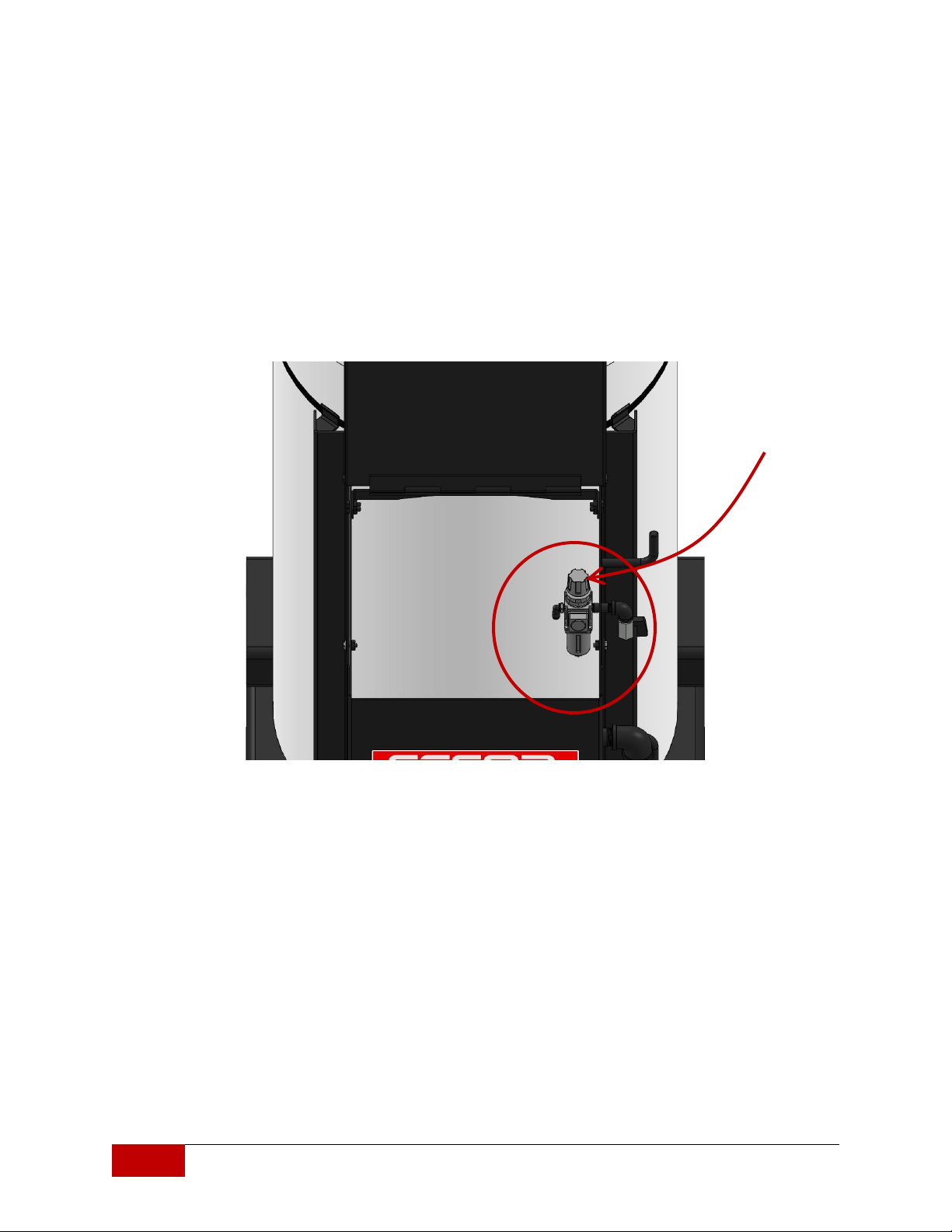

3.1 –REGULATOR SETUP ..........................................................................................................................8

SECTION 4 –OPERATION ..............................................................................................................................9

4.1 –FILLING THE DISPENSER ...................................................................................................................9

4.1.1 –FILLING ..........................................................................................................................................9

4.2 –DISCHARGING FLUID ......................................................................................................................10

SECTION 5 –MAINTENANCE.......................................................................................................................11

5.1 –PUMP MAINTENANCE....................................................................................................................11

5.2 –WEEKLY MAINTENANCE.................................................................................................................11

5.3 –MONTHLY MAINTENANCE .............................................................................................................11

SECTION 6 –TROUBLESHOOTING...............................................................................................................12

SECTION 7 –REPAIR PARTS LIST .................................................................................................................13

7.1 –WHEELS & CASTER .........................................................................................................................13

7.1.1 “PTL” PUSH TOW LIFT WHEEL TRANSPORT 90-200 GAL............... Error! Bookmark not defined.

7.2 –TANK & PUMP................................................................................................................................14

7.3 –HOSE...............................................................................................................................................15

SECTION 8 –WARRANTY.............................................................................................................................16

SECTION 9 –RECORD MODEL & SERIAL NUMBER......................................................................................17