SA5 OPERATIONS MANUAL & PARTS LIST

(Rev. 2/2020)

TABLE OF CONTENTS

SECTION 1 – SAFETY INFORMATION ......................................................................... 3

1.1 – CAUTION............................................................................................................ 3

1.2 – PRECAUTIONS .................................................................................................. 4

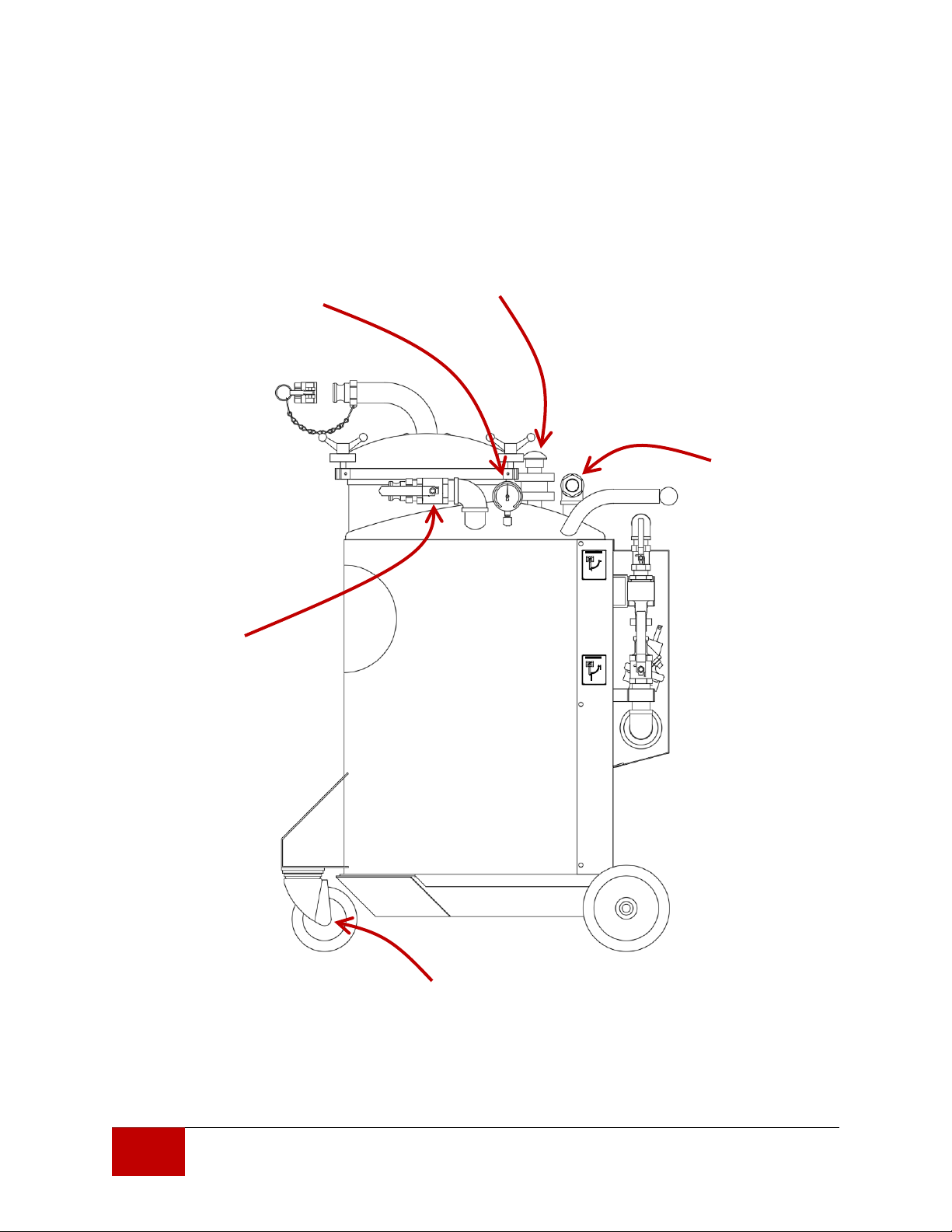

SECTION 2 – THE SUMP CLEANER............................................................................. 5

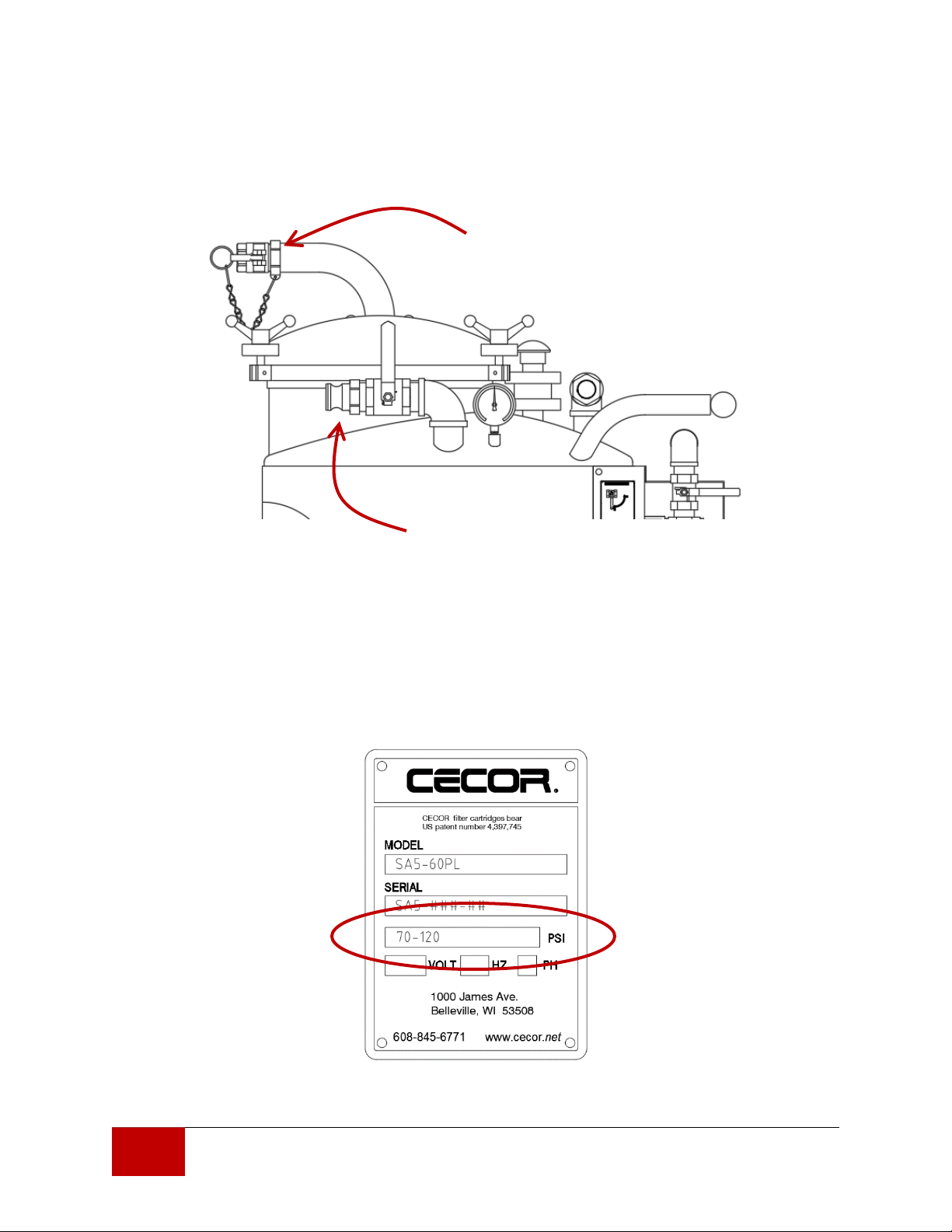

2.1 – UNIT IDENTIFICATION ...................................................................................... 5

2.2 – MODEL & SERIAL NUMBER.............................................................................. 6

2.3 – SUMP CLEANER FEATURES............................................................................ 7

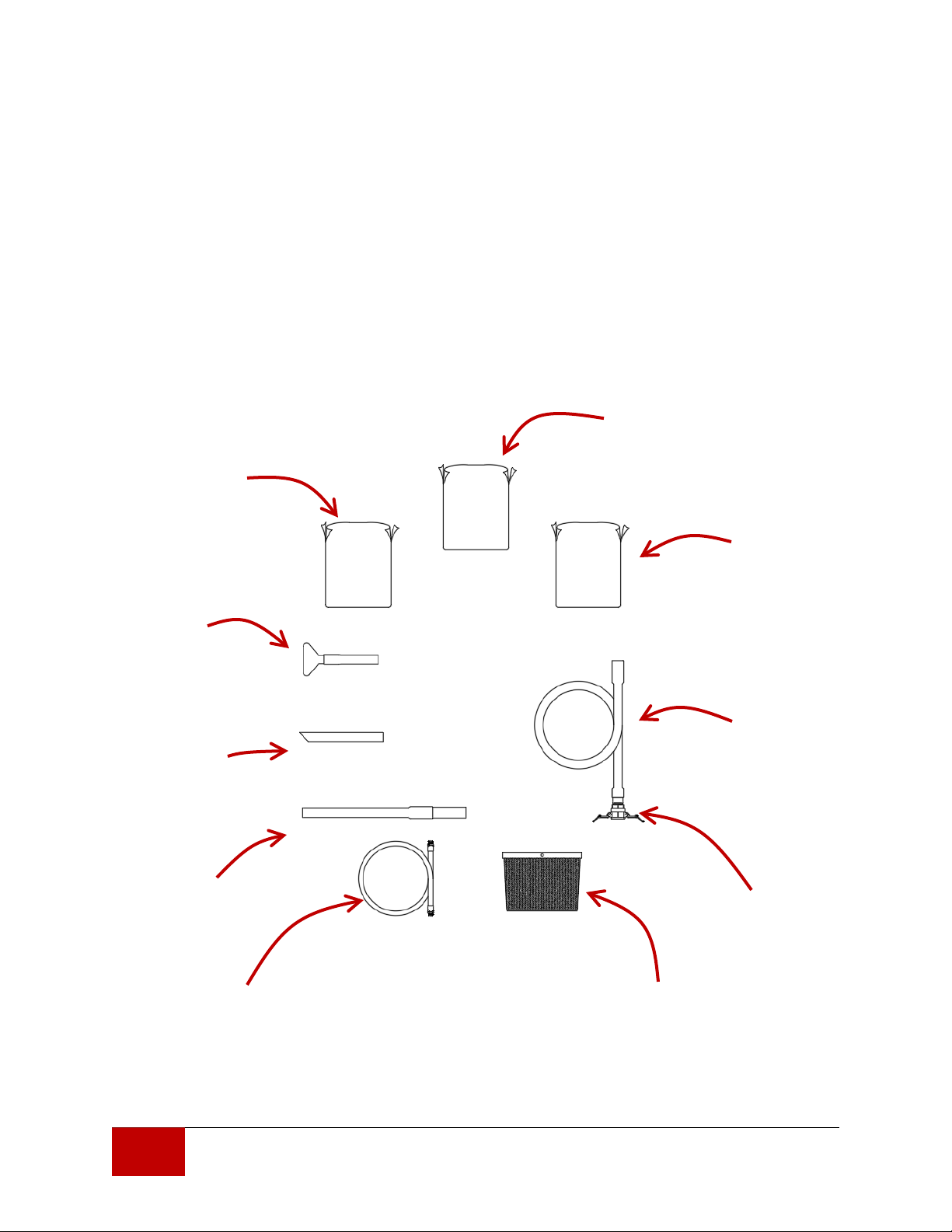

SECTION 3 – INSTALLATION........................................................................................ 9

3.1 – LOOSE ITEMS.................................................................................................... 9

3.2 – INITIAL STARTUP ............................................................................................ 10

SECTION 4 – OPERATION .......................................................................................... 14

4.1 – CLEANING A SUMP......................................................................................... 14

4.2 – DISCHARGING FLUID FROM THE SUMP CLEANER..................................... 15

4.3 – FILTER.............................................................................................................. 15

4.4 – CLEANING THE SUMP CLEANER .................................................................. 16

SECTION 5 – MAINTENANCE ..................................................................................... 17

5.1 – DAILY MAINTENANCE..................................................................................... 17

5.2 – WEEKLY MAINTENANCE ................................................................................ 17

5.3 – MONTHLY MAINTENANCE ............................................................................. 18

5.4 – SEMI ANNUAL.................................................................................................. 18

SECTION 6 – TROUBLESHOOTING ........................................................................... 19

SECTION 7 – REPAIR PARTS LIST............................................................................. 20

7.1 – WHEELS & CASTER ........................................................................................ 20

7.2 – TANK & PUMP.................................................................................................. 21

7.3 – FILTER, TOOLS & HOSE ................................................................................. 22

7.4 – TANK CONNECTIONS, GAUGE, MOTOR & CONTROL SYSTEMS ............... 23

SECTION 8 – WARRANTY........................................................................................... 26

SECTION 9 – RECORD MODEL & SERIAL NUMBER................................................. 27