Page 1

MeshConnect™ Sub-G Module Series

CEL's MeshConnect™ Sub-G modules are built on the Si1000

and Si1002 highly integrated wireless SoC's from Silicon Labs.

Targeting dense operating environments, CEL’s MeshConnect

Sub-G modules deliver superior range and performance. Their

low power consumption enables longer battery life and their link

budgets provide reliable transmission in non line of sight ap-

plications such as lighting control, industrial sensor networks,

serial wire replacement, metering, irrigation and more. At +13

and +20 dBm power outputs, the new Sub-G modules offer 868

MHz (Europe) and 915 MHz (Americas) ISM band options. As

certied and qualied modules, the MeshConnect Sub-G solu-

tions eliminate the need for costly certications, reducing overall

system cost and accelerating time to market.

Development Kits Available:

ZICM0868P0-KIT1-1 and ZICM0900P2-KIT1-1

The information in this document is subject to change without notice, please conrm data is current

Document No: 0009-00-07-00-000 (Issue ES)

Date Published: June 1st, 2011

PRELIMINARY DATA SHEET

DESCRIPTION

ZICM0868P0

ZICM0900P2

868 / 900 MHz System-on-Chip (SoC) Based Modules

•FrequencyRange:

902- 928 MHz

868 MHz

•LinkBudgetupto-140dB

(for +20 dBm module)

+20 dBm and +13 dBm available

output powers

•MaxOutputPower:

+ 13 dBm @ 3.5 VDC (ZICM0868P0)

+ 20 dBm @ 3.5 VDC (ZICM0900P2)

•DataRate:0.123to150kbps

•GeneralPurposeI/Os:21

•HighSpeed8051MCU:

25 MHz - single cycle instruction execution

4kB RAM / 64 kB Flash

•10-BitADC:

300 ksps, 18-ch inputs

•SerialCommunication:

UARTs, SPI (Master/Slave)

SMBus, PCA

•Add1MBadditionalFlashmemory

toenableOverTheAir(OTA)

programming(Optional)

FEATURES

•Modulation:

FSK, GFSK, OOK

•RFPowerConsumption

24 mA Receive

18 mA @ + 1 dBm transmit

42 mA @ + 13 dBm transmit

97 mA @ + 19 dBm transmit

•SleepCurrent1.2µATYP

•Upto6milesofrange

(lineofsight)

•OperatingTemperatureRange:

-40 to +85ºC

•SoftwarePlatforms:

Synapse SNAP Embedded Firmware

Wireless M-Bus (868 MHz Only)

CEL Application Programming

Interface (API)

Silicon Labs EZMac

•FCC,CEandICcerticationsin

Progress

Multiple antenna options

FSK Modulation Only

•ROHScompliant

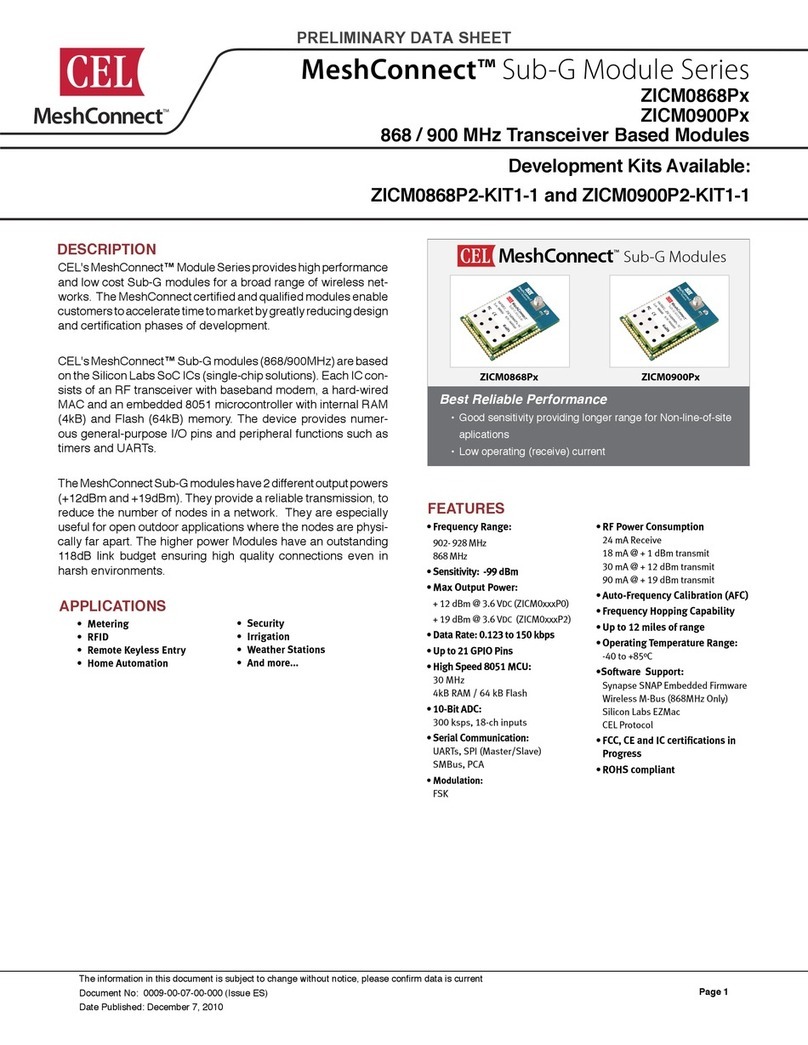

MeshConnect™Sub-G Modules

ZICM0868P0 ZICM0900P2

APPLICATIONS

• Long Range

• Low Power Consumption

• 868 and 900 MHz Frequency Ranges

• 1MB additional Flash Memory option enables

Over the Air (OTA) Programming

•LightingControl

•Irrigation

•Serialwirereplacement

•IndustrialSensorNetworks

•WirelessM-BusMetering

•HomeAutomation&SmartPlugs

•Security

•Andmore...