Safety

Information about chlorine 5

© Lutz-Jesco GmbH 2017

Subject to technical changes.

170518

BA-20710-02-V05

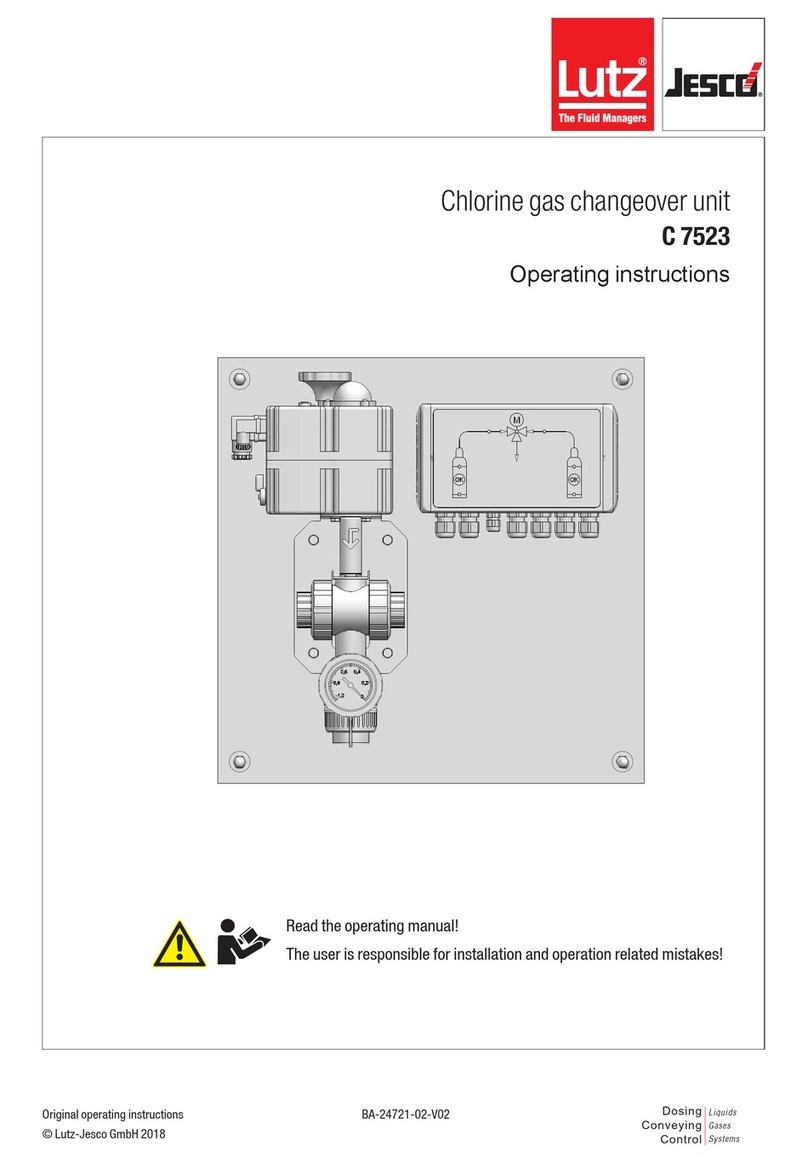

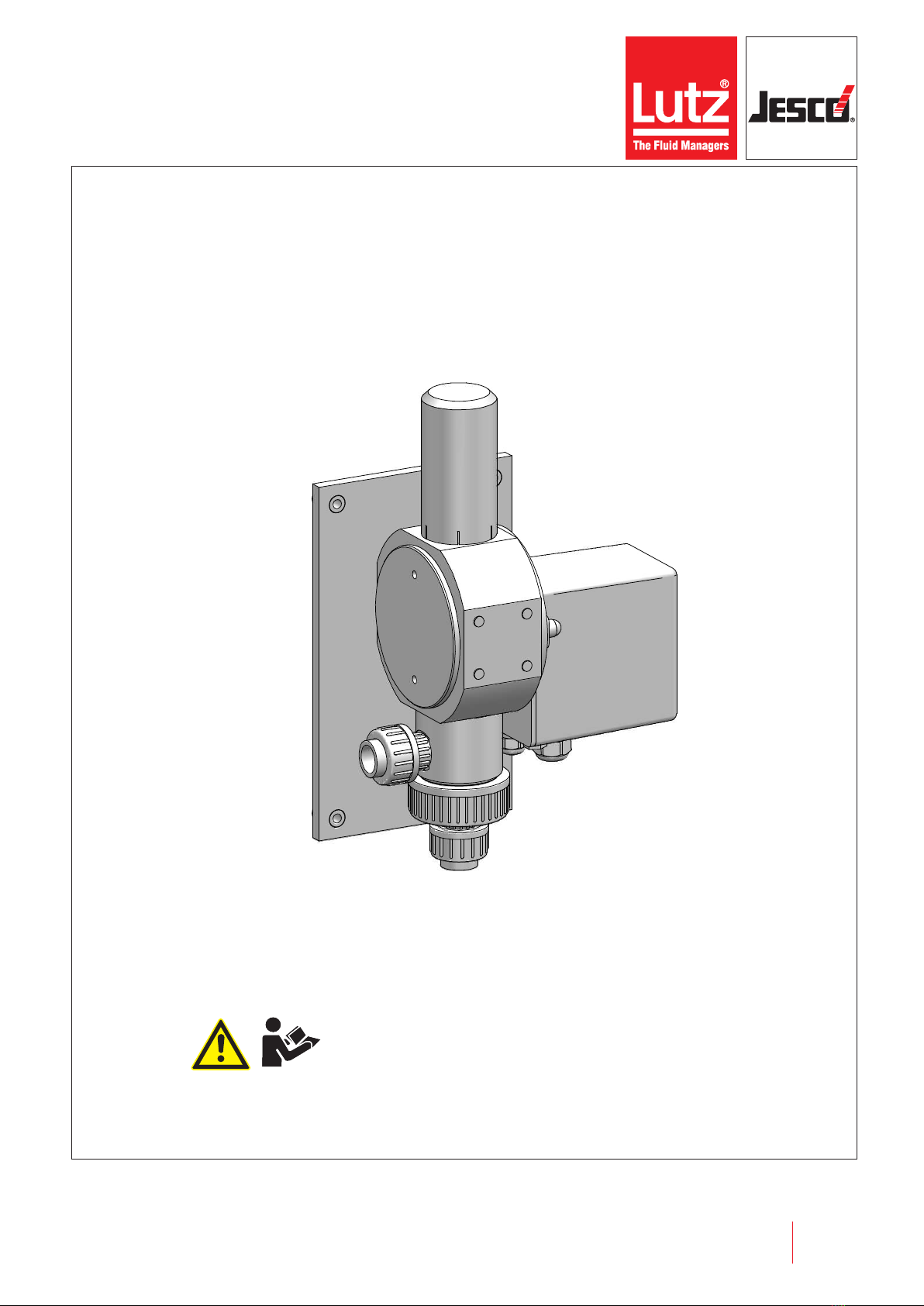

Chlorine control valve C 7700 Operating instructions

2 Safety

2.1 General warnings

The following warnings are intended to help you eliminate the dangers

that can arise while handling the control valve. Risk prevention measures

always apply regardless of any specific action.

Safety instructions warning against risks arising from specific activities

or situations can be found in the respective sub-chapters.

DANGER

Danger to life from chlorine poisoning!

Chlorine is poisonous. In severe cases, breathing in chlorine may lead

to death. It irritates the eyes, the respiratory system and the skin.

ðInstall a gas warning device.

ðUse sufficient personal protective equipment.

ðWhen carrying out any work on the system, use a respirator mask

with a Type B gas filter that complies with EN 14387.

ðAlways comply with the accident prevention regulations that apply

at the place of use.

ðGet rid of leaks without delay. You must get rid of even very minor

leaks without delay. Together with the humidity, chlorine forms

hydrochloric acid and corrosion results in rapidly increasing

leakage.

ðUse only chlorine-resistant seals.

ðOnly use seals once. Reusing them leads to leaks.

DANGER

Increased danger to life from chlorine escape

A fatal quantity of chlorine gas can be released from a leakage.

ðIf chlorine escapes, leave the room immediately.

ðUse sufficient personal protective equipment.

ðIf chlorine gas escapes, wear a Type 2 self-contained breathing

apparatus that complies with EN 137.

ðOnly initiate counter measures after putting on the protective

equipment.

ðGiven a serious escape and insufficient equipment or qualifica-

tions, leave the work to professional emergency services

personnel. Do not take any unnecessary risks.

DANGER

Danger to life through explosions!

When using dosing devices without ATEX certification in a potentially

explosive area, explosions can occur that result in fatal injuries.

ðNever use the device in potentially explosive areas.

WARNING

Increased risk of accidents due to insufficient qualifica-

tion of personnel!

Chlorinators and their accessories must only be installed, operated

and maintained by personnel with sufficient qualifications. Insufficient

qualification will increase the risk of accidents.

ðEnsure that all action is taken only by personnel with sufficient and

corresponding qualifications.

ðPrevent access to the system for unauthorised persons.

NOTE

Damage to the system due to corrosion

Chlorine gas is highly hygroscopic. This means that humidity enters

the system at any open connection on devices or pipes, which results

in the formation of hydrochloric acid and contamination. Thus

inevitably causing damage to the units.

ðKeep all connections (including in the vacuum system and on all

devices not currently in use) closed at all times.

ðAfter maintenance work is complete, remove all water residues

from the system before placing it into operation.

2.2 Information about chlorine

Chlorine is a hazardous substance. The chemical element chlorine is a

greenish-yellow, toxic gas with a pungent odour, which can be detected

in the air at concentrations below 1 ppm (= 1 ml/m³).

Chlorine is 2.5 times heavier than air and accumulates at ground level.

Chlorine is extremely toxic for water organisms. The reason for the

toxicity of chlorine is its extraordinary reactivity. It reacts with animal and

vegetable tissue and thus destroys it.

Air with a chlorine gas content of 0.5 -1% leads to a quick death in

mammals and humans, as it attacks the respiratory tract and the

pulmonary alveolus (formation of hydrogen chloride or hydrochloride

acid).

NOTE

Faults due to insufficient chlorine quality

Impurities in the chlorine gas form deposits in devices and valves and

can attack the components chemically. This can lead to malfunctions.

ðOnly use technically pure chlorine that meets the following

requirements:

- Mass content of chlorine at least 99.5%

- Water content max. 20 mg/kg

Chlorine that complies with EN 937 or EN 15363 meets these

requirements.