www.cellpath.com | T: +44 (0)1686 611333

6

User Manual

Operating Instructions

Place the hotplate on a smooth and level

work surface.

Place the four microscope slide support

rods in position according to user

preference.

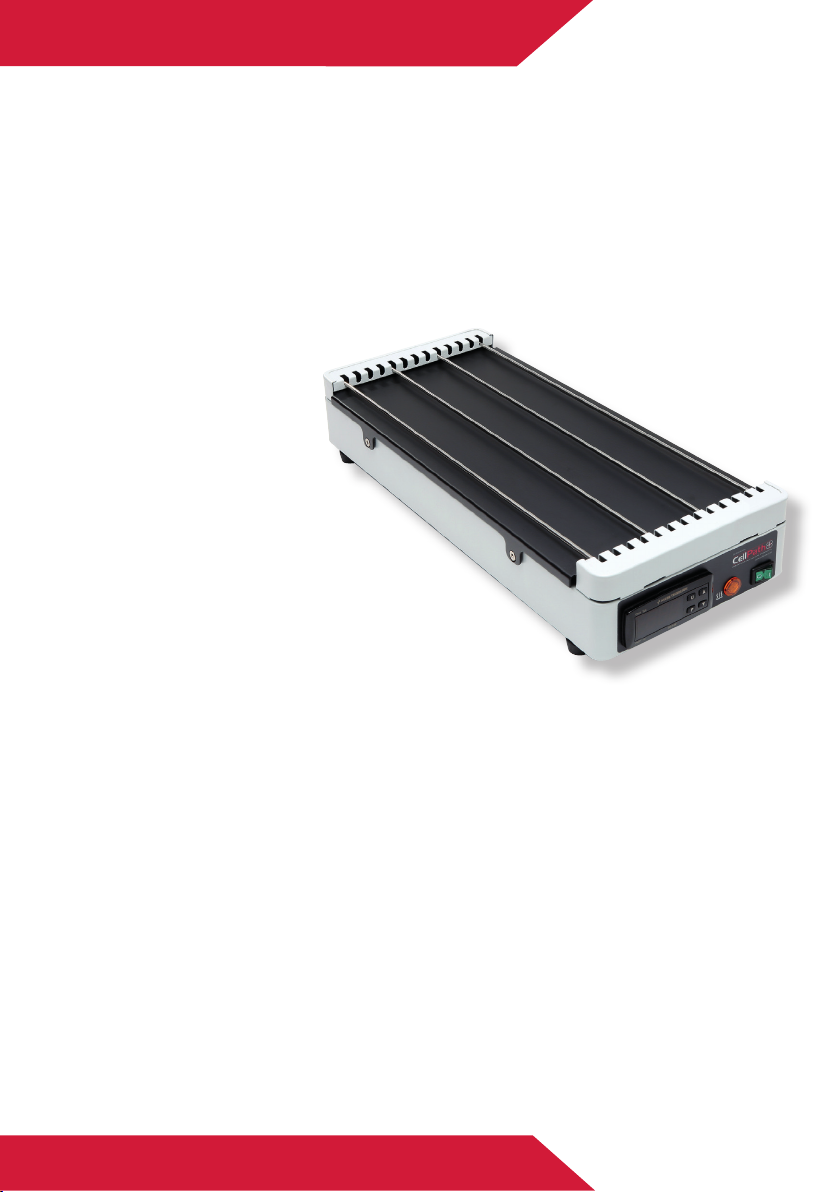

Connect the mains plug to the electrical

supply and switch on (Ensure the power

supply is properly earthed).

Turn on the hotplate.

Select the desired temperature.

A. Press button Pthen release it (do not

hold down button Pfor 5 seconds).

B. The display will show SP alternating

with the current set temperature.

C. To change the set temperature

press the UP key to increase the value

or DOWN to decrease it. These keys

increase or decrease the value one

digit at a time, but if the button is

pressed for more than one second

the value increases/decreases rapidly,

and aer two seconds pressed, the

speed increases even more to allow the

desired values to be reached rapidly.

D. Exiting the Set mode is achieved by

pressing the Pkey or automatically if

no key is pressed for 15 seconds.

Aer that time the display returns

to the normal function mode.

The heater indicator will illuminate to

show heater activity.

The instrument will then warm up to the

desired temperature, you will observe

the temperature rise on the display.

The instrument is designed to warm

up quickly (roughly 3 to 5 minutes).

This means that when initially warming

up, the instruments will slightly over

shoot the set target temperature

(by 2-5

°

C). The heater will then stop

and allow the instrument to cool to the

desired working temperature and then

maintain the set working temperature

at +/-1

°

C, by alternating heating and

cooling.