WARNING

OIL PRESSURE MUST BE COMPLETELY

RELEASED WHEN PUMP IS NOT IN USE

ATTENTION

APRES USAGE RELACHER

COMPLETEMENT LA PRESSION

ACHTUNG

NACH DEM BETRIEB MUSS DER

ÖLDRUCK ABGELASSEN WERDEN

ATENCION

LA BOMBA DEBE PERMANENCER

DESPRESURIZADA SIEMPRE QUE NO SE UTILICE

ATTENZIONE

DOPO L’USO RILASCIARE COMPLETAMENTE

LA PRESSIONE DELL’OLIO

TG 0359

▲

!

WARNING LABELS - ETIQUETTES SIGNALETIQUES - HINWEISSCHILDER -

ETIQUETAS DE ATENCION - ETICHETTE D'AVVERTENZE

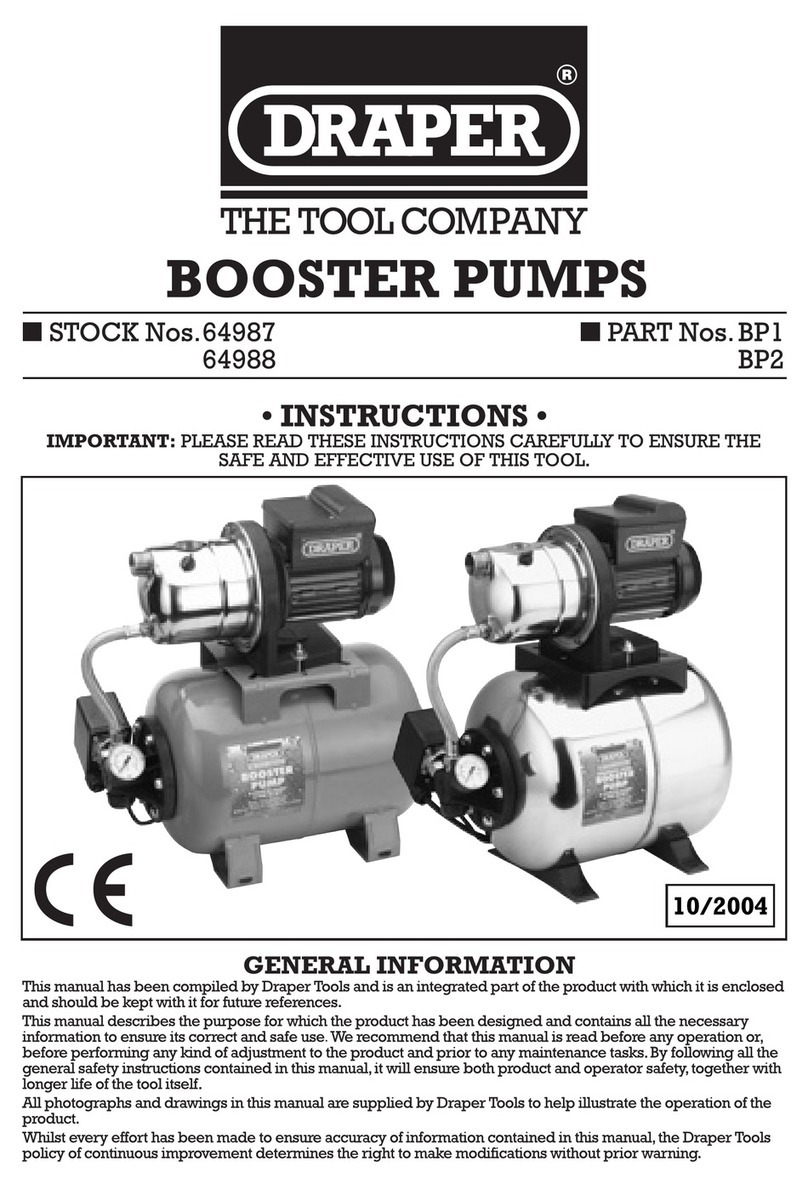

– Before using the pump, carefully read the instructions in this manual.

– Avant d'utiliser ce groupe, lire attentivement les instructions de cette notice.

– Vor Inbetriebnahme unbedingt die Bedienungsanleitung durchlesen.

– Antes de utilizar la bomba, leer atentamente las instrucciones contenidas en este manual.

– Primadiutilizzarelapompa,leggereattentamenteleistruzionicontenuteinquestomanuale.

142

Deutsch

---------------------------------------------------------------------------------------------------------------------

INFORMATION FÜR DEN BENUTZER

gemäß der “EG-Richtlinien 2002/95 und 2202/96

in Bezug auf den reduzierten Gebrauch von gefährlichen Substanzen in elektrischen und elek-

tronischen Geräten, sowie auf die Abfallentsorgung”.

Das durchkreuzte Zeichen auf dem Mülleimer, welches auf dem Gerät oder seiner Verpackung ange-

bracht ist, zeigt an, dass das Produkt am Ende seiner Lebenszeit getrennt von den anderen Abfällen

entsorgt werden muss.

Die getrennte Abfallsammlung des vorliegenden zu entsorgenden Geräts wird vom Hersteller organi-

siert und verwaltet. Der Besitzer, der sich des Geräts entledigen will, muss sich daher mit dem Herstel-

ler in Verbindung setzen und das von ihm angenommene System für die getrennte Sammlung des zu

entsorgenden Geräts befolgen.

Eine angemessene getrennte Sammlung, damit das Gerät für das Recycling, die Behandlung und die

umweltfreundliche Entsorgung vorbereitet werden kann, trägt dazu bei, mögliche negative Auswirkun-

gen auf die Umwelt und auf den Gesundheitszustand zu vermeiden und begünstigt die Wiederverwer-

tung und das Recycling der Materialien des Geräts.

Bei widerrechtlicher Entsorgung des Produkts durch den Benutzer werden die vom Gesetz vorgesehen

Verwaltungssanktionen angewandt.

Español

----------------------------------------------------------------------------------------------------------------------

INFORME PARA LOS USUARIOS

en los términos de las

Directivas 2002/95/CE y 2002/96/

CE, relativas a la reducción en el empleo de sustancias peligrosas en los equipos eléctricos y

electrónicos, además de la eliminación de los desechos”.

El símbolo del contenedor de basura cruzado por un aspa que aparece en el equipo o sobre su emba-

laje indica que, al final de su ciclo de vida útil, el producto debe ser eliminado independientemente de

otros desechos.

La recogida selectiva del presente equipo, llegado al final de su ciclo de vida, es organizada y ma-

nejada por el fabricante. El usuario que desee deshacerse del presente equipo deberá, por lo tanto,

contactar con el fabricante y seguir el sistema adoptado por el mismo para permitir la recogida por

separado del equipo que ha concluido su ciclo de vida.

La adecuada recogida selectiva, para el sucesivo envío del equipo dado de baja al reciclaje, al tratamiento

y al saneamiento ambiental compatible, contribuye a evitar posibles efectos negativos sobre el medio am-

biente y sobre la salud favoreciendo el reempleo y el reciclaje de los materiales que componen el equipo.

La eliminación abusiva del equipo por parte del propietario implica la aplicación de las sanciones admi-

nistrativas prevista por la legislación vigente.

Italiano

-----------------------------------------------------------------------------------------------------------------------

INFORMAZIONE AGLI UTENTI

ai sensi dell’art. 13 del Decreto Legislativo 25 Luglio 2005, n.

151 “

Attuazione delle Direttive 2002/95/CE e 2002/96/CE, relative alla riduzione dell’uso di sostanze

pericolose nelle apparecchiature elettriche ed elettroniche, nonché allo smaltimento dei rifiuti”.

Il simbolo del cassonetto barrato riportato sull’apparecchiatura o sulla sua confezione indica che il pro-

dotto, alla fine della sua vita utile, deve essere raccolto separatamente dagli altri rifiuti.

La raccolta differenziata della presente apparecchiatura giunta a fine vita è organizzata e gestita dal

produttore. L’utente che vorrà disfarsi della presente apparecchiatura dovrà quindi contattare il produt-

tore e seguire il sistema che questo ha adottato per consentire la raccolta separata dell’apparecchiatura

giunta a fine vita.

L’adeguata raccolta differenziata per l’avvio successivo dell’apparecchiatura dismessa al riciclaggio,

al trattamento ed allo smaltimento ambientalmente compatibile contribuisce ad evitare possibili effetti

negativi sull’ambiente e sulla salute e favorisce il reimpiego e/ il riciclo dei materiali di cui è composta

l’apparecchiatura. Lo smaltimento abusivo del prodotto da parte del detentore comporta l’applicazione

delle sanzioni amministrative di cui all'articolo 50 e seguenti del D.Lg. n. 22/1997.

– See page 41

– Voir page 41

– Siehe Seite 41

– Vease página 41

– Vedere pagina 41

– WARNING, electrical hazard

– ATTENTION, tension électrique

– ACHTUNG, elektrische Spannung

– ATENCION, tensión eléctrica

– ATTENZIONE, tensione elettrica

– SAVE THESE INSTRUCTIONS: this manual contains important safety and operating

instructions for the pump.

– CONSERVEZCESINSTRUCTIONS:cettenoticecontientd'importantesinstructionsrelatives

à la sécurité et au fonctionnement de la pompe.

– BEWAHREN SIE DIESE HINWEISE AUF: diese Bedienungsanleitung enthält

wichtige Siche-

rheits- und Gebrauchsanweisungen für die Pumpe.

– GUARDE ESTAS INSTRUCCIONES: este manual contiene instrucciones de seguridad y

funcionamiento importantes para la bomba.

– CONSERVARE QUESTE ISTRUZIONI: questo manuale contiene importanti istruzioni per la

sicurezza e il funzionamento della pompa.