Greenlee Textron / Subsidiary of Textron Inc. 94455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

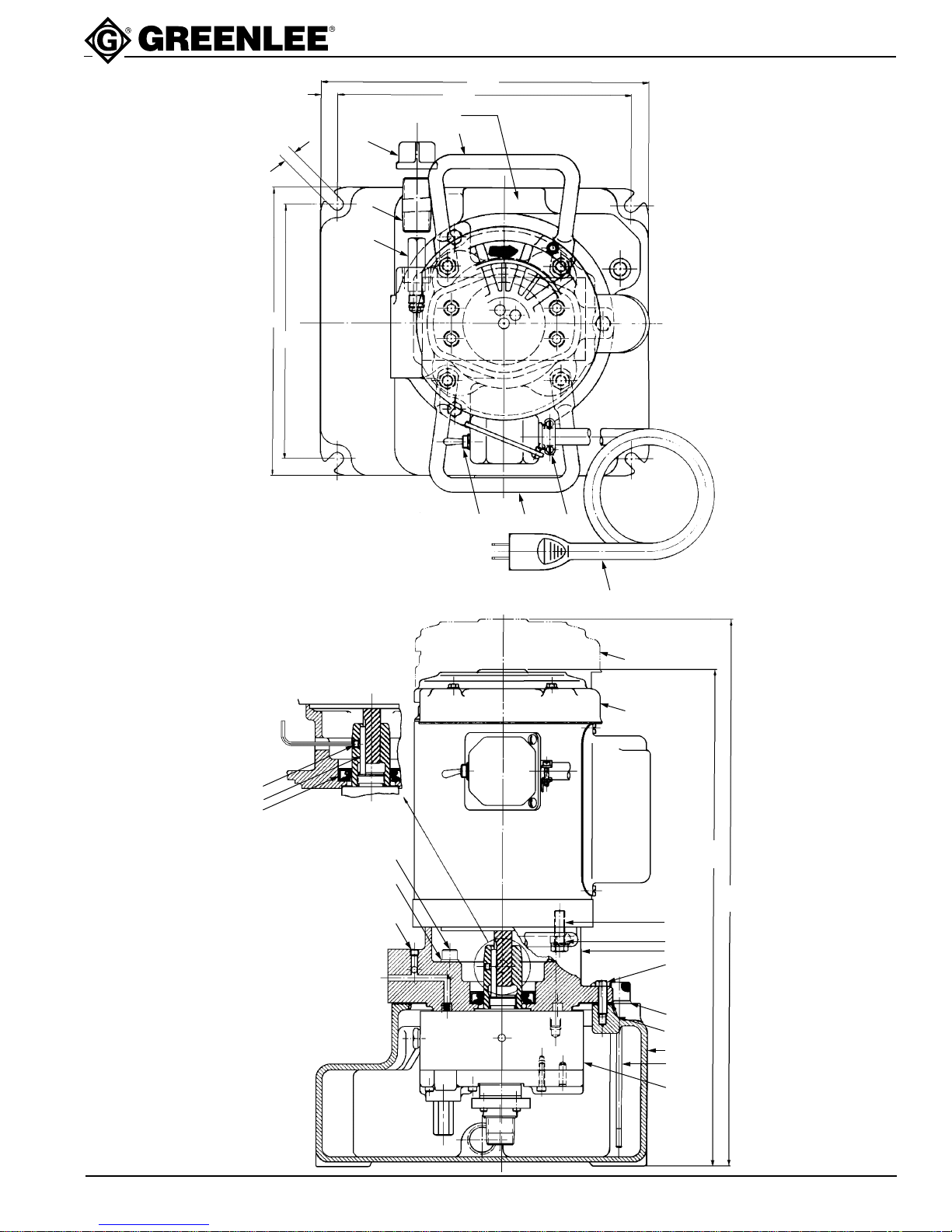

1721-M4 Basic & 1722-M4 Basic Hydraulic Power Pumps

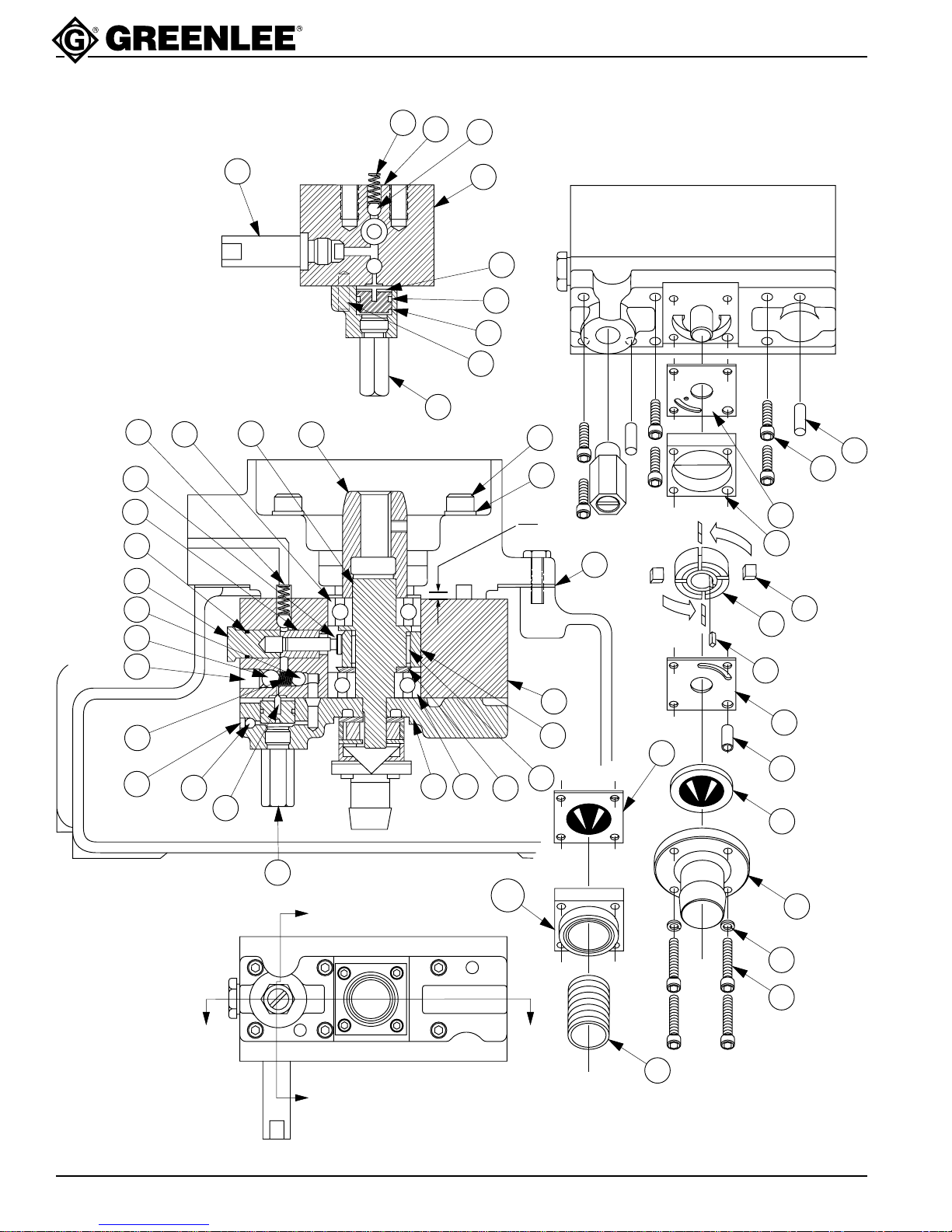

Parts - Hydraulic Power Pumps

1721-M4 Basic (501 8320.6)

1722-M4 Basic (501 8355.9)

Key Control No. Description Qty

A 501 8236.6 Block Unit, Pump (1 - 41) ...................................................................... 1

1 500 6067.8 Valve Unit, Relief ................................................................................... 1

2 501 7766.4 Valve Unit, Relief ................................................................................... 1

3 501 8194.7 Plate, Pump Mounting ........................................................................... 1

4 500 3493.6 Pin, Seal ................................................................................................ 1

5 501 8871.2 Spacer, Bearing..................................................................................... 1

6 501 1855.2 Race, Outer ........................................................................................... 1

7 501 1862.5 Plug, Hi-Pressure Plunger ..................................................................... 1

8 501 9060.1 Plunger, Hi-Pressure ............................................................................. 1

9 501 9059.8 Bushing, Hi-Pressure Plunger ............................................................... 1

10 502 0424.6 Block, Intake .......................................................................................... 1

10A 501 4859.1 Block, Intake (replaced by 10)............................................................... 1

11 501 4861.3 Plate, Pump ........................................................................................... 1

12 501 4862.1 Key, Lo-Pressure Pump ........................................................................ 1

13 501 4876.1 Shaft, Eccentric...................................................................................... 1

14 501 7130.5 Plate, Top .............................................................................................. 1

15 501 7131.3 Plate, Bottom ......................................................................................... 1

16 501 7135.6 Vane....................................................................................................... 4

17 501 7136.4 Rotor ...................................................................................................... 1

18 501 7467.3 Dowel, Hollow ........................................................................................ 1

19 501 8195.5 Plunger, Check Valve ............................................................................ 1

20 501 8237.4 Block, Pump........................................................................................... 1

21 501 8238.2 Adapter, Drive Shaft .............................................................................. 1

22 500 6111.9 Spring, Compression ............................................................................. 1

23 501 4865.6 Spring, Compression ............................................................................. 1

24 502 1175.7 Screen, Intake........................................................................................ 1

24A 501 6599.2 Screen, Intake (replaced by 24) ............................................................ 1

25 905 0014.8 O-Ring, 5/8 x 3/4 x 1/16......................................................................... 1

26 905 0436.4 Ball, 9/32 Grade #1 Chrome Steel ........................................................ 2

27 905 0490.9 Nipple, Intake (replaced by 10) ............................................................. 1

28 905 0677.4 Ball, 5/32 Grade #1 Chrome Steel ........................................................ 1

29 905 0681.2 Ball, 3/8 Grade #1 Chrome Steel .......................................................... 1

30 905 1526.9 Washer, #8 Hi-Collar Lock..................................................................... 4

32 905 0911.0 Roller, .125 x .750 ............................................................................... 30

33 905 1524.2 O-Ring, 1/2 x 5/8 x 1/16......................................................................... 1

34 905 0989.7 Bearing, Single Row Unshielded Ball.................................................... 1

35 905 0994.3 Screw, #8-32 NF x 1-1/4 Socket Head Cap .......................................... 4

36 905 1111.5 Screw, 7/16-20 NF x 1/2 Cup Point Socket Set .................................... 1

37 905 2817.4 O-Ring, 7/16 x 9/16 x 1/16..................................................................... 1

38 905 1241.3 Screw, #10-32 NF x 3/16 Flat Point Socket Set.................................... 1

39 905 1471.8 Screw, #10-32 NF x 7/8 Socket Head Set Cap ..................................... 6

40 905 1472.6 Lok-Dowel, 1/4 x 3/4.............................................................................. 2

41 905 1473.4 Bearing, Single Row Unshielded Ball.................................................... 1

52 500 3407.3 Valve Unit, Relief ................................................................................... 1

53 501 5646.2 Dipstick Unit........................................................................................... 1

54 503 2705.4 Plate, Motor Mounting ........................................................................... 1

55 501 5695.0 Reservoir ............................................................................................... 1

56 501 2663.6 Handle, Lifting........................................................................................ 2

57 501 4852.4 Key......................................................................................................... 1

58 501 5701.9 Gasket Reservoir ................................................................................... 1

59 905 0320.1 Seal, 1-3/8 ID x 2-3/8 OD Oil................................................................. 1

60 905 0467.4 Cap, 3/4 Pipe ......................................................................................... 1