Di,,erential

Assembly

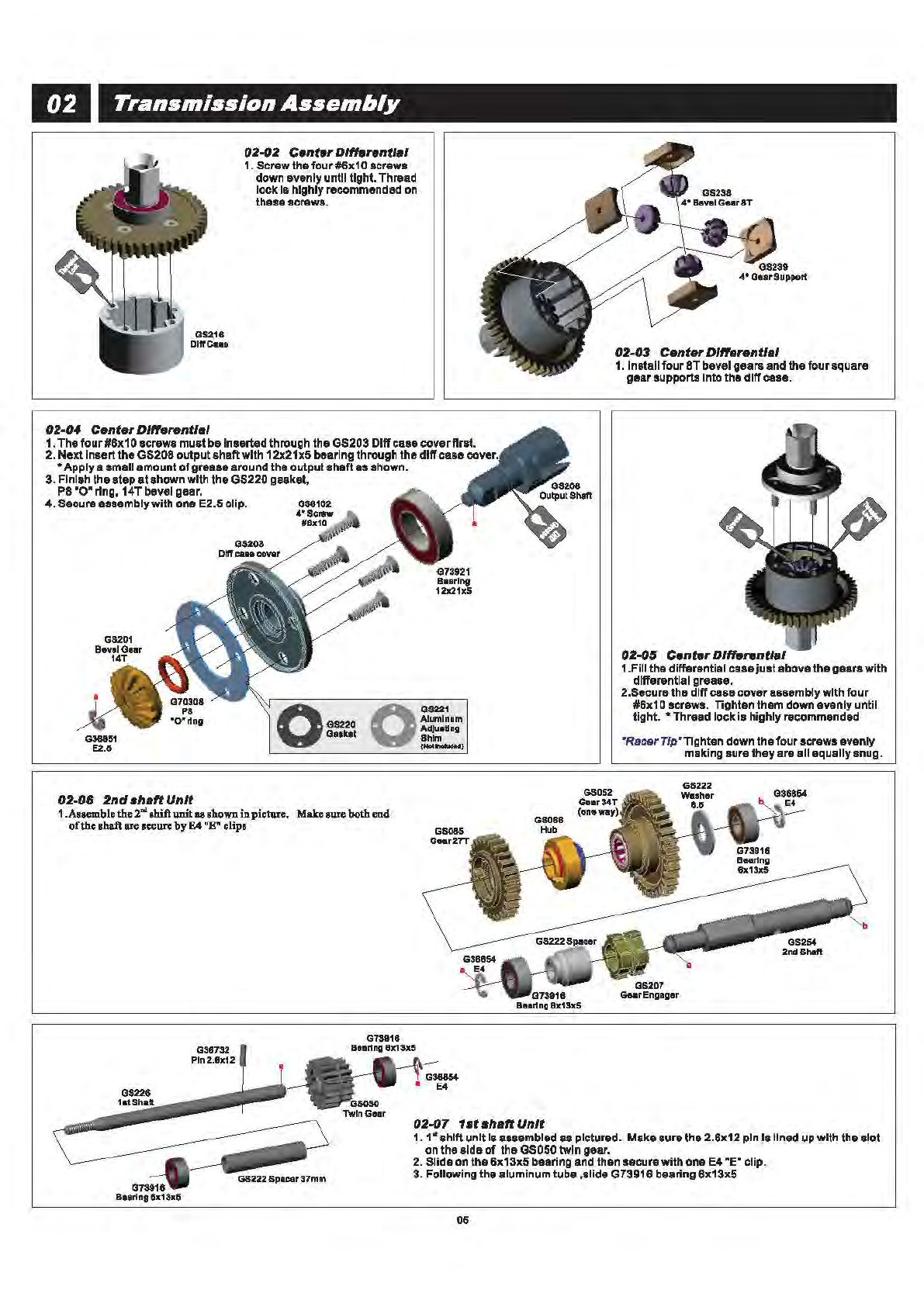

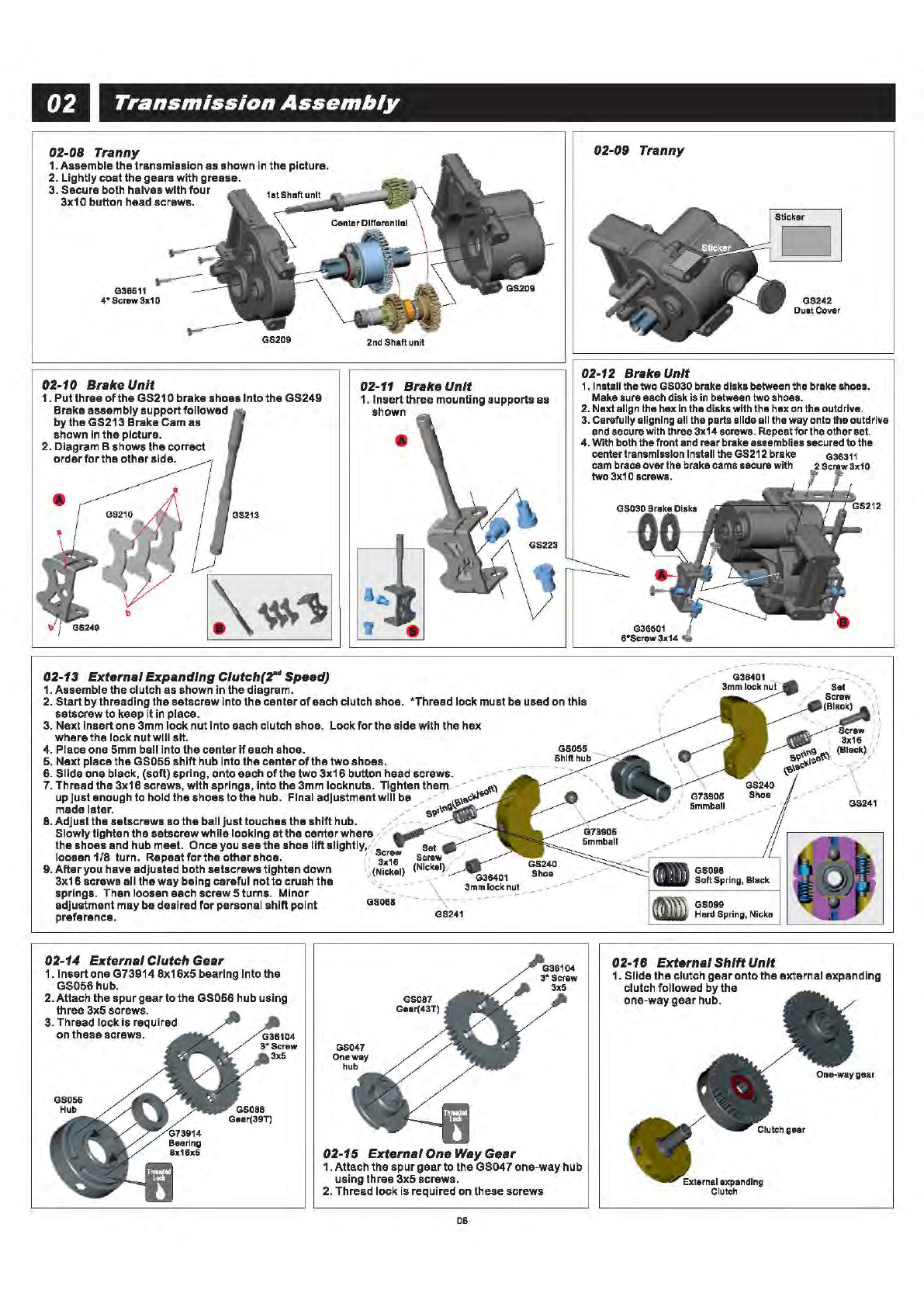

04-03 Differential

1.1nstall Bevel Gearinto GearSupport

2.Siidethe

unit

into designate

slotson thed

iff

case.

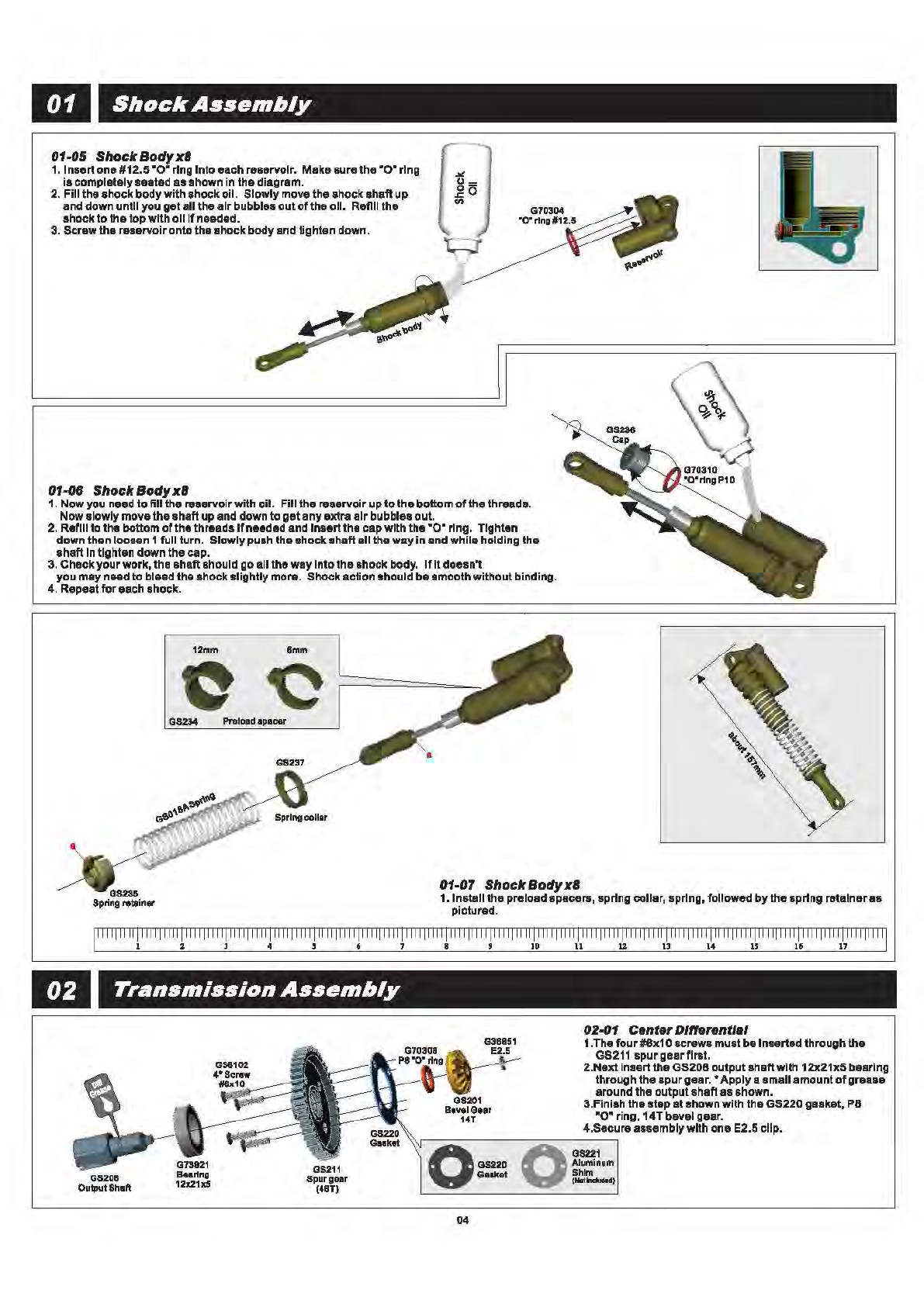

04-02 Differential

1.Screw the four#6x1 0 screws down evenly until tight.

Thread

lock

Ishighlyrecommended onthese screws.

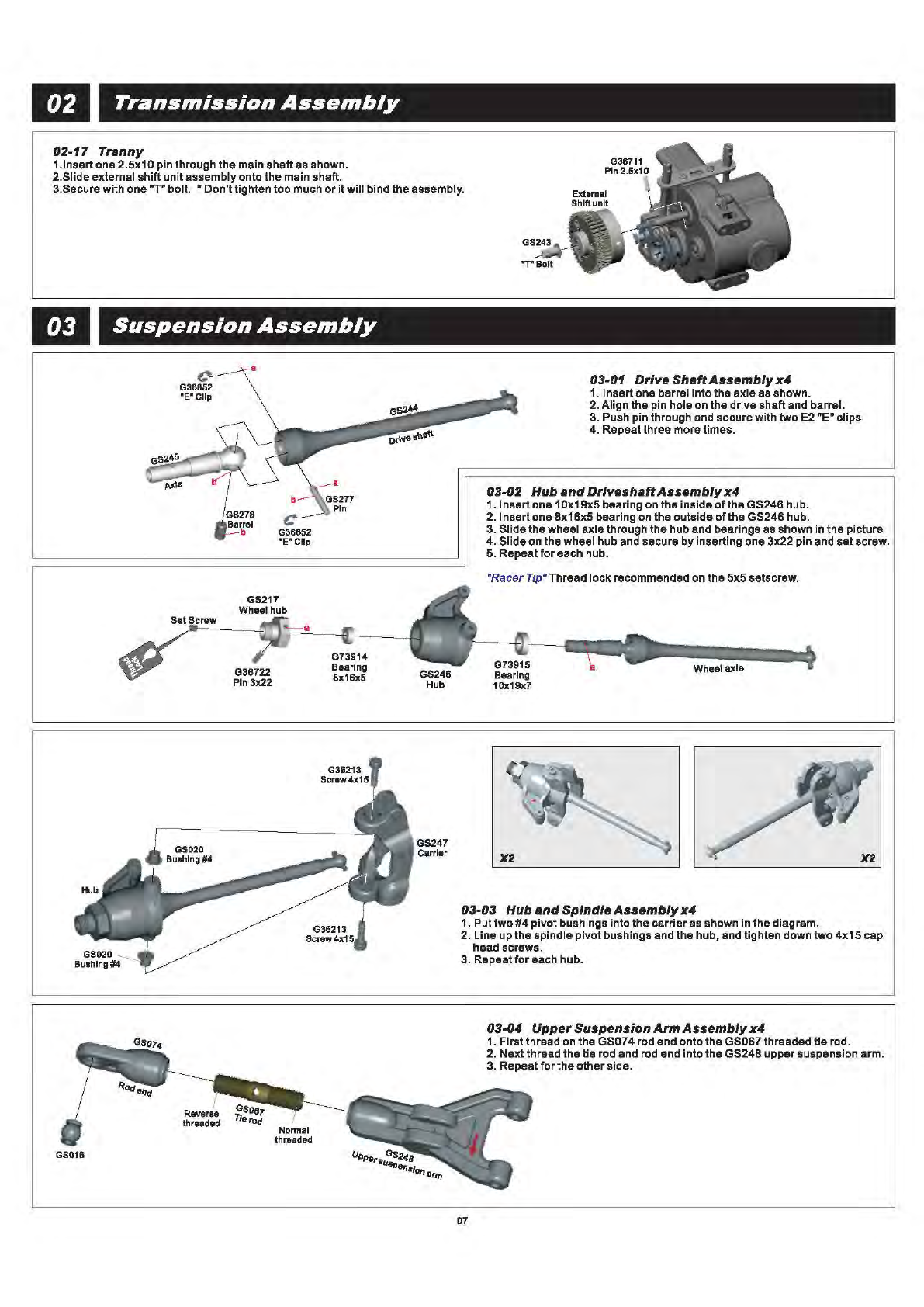

04-04 Differential

1.

Thefour#6x10

screws must

be

inserted

through

the

GS203 Diffcase coverfirst.

2. Next insertthe GS204

output

shaftwith

12x21x5bearing through the

dlff

case

cover. 0

O

~~~~~um

65220

Adjuating

Gasket

Shim

c_

_________

___;_(N_ot

---,lncludlld)

•

Apply

a small amount

of

grease around

the

output

shaftas shown.

3. Finishthe step at shown with the GS220

gasket, P8•o• ring, 14Tbevel gear.

4. Secure assemblywith one E2.5clip.

04-05 Differential

GS201

Baval Gaar

14T

1.

Fill thedifferential case

just

abovethe gearswith differential grease.

2. Securethe

diff

case coverassemblywith

four

#6x10 screws. Tighten

them downevenlyuntiltight. • Thread lockIshighlyrecommended.

"RacerTip"Tighten down the fourscrews evenly

makingsure they

are

all

equally snug.

Gear

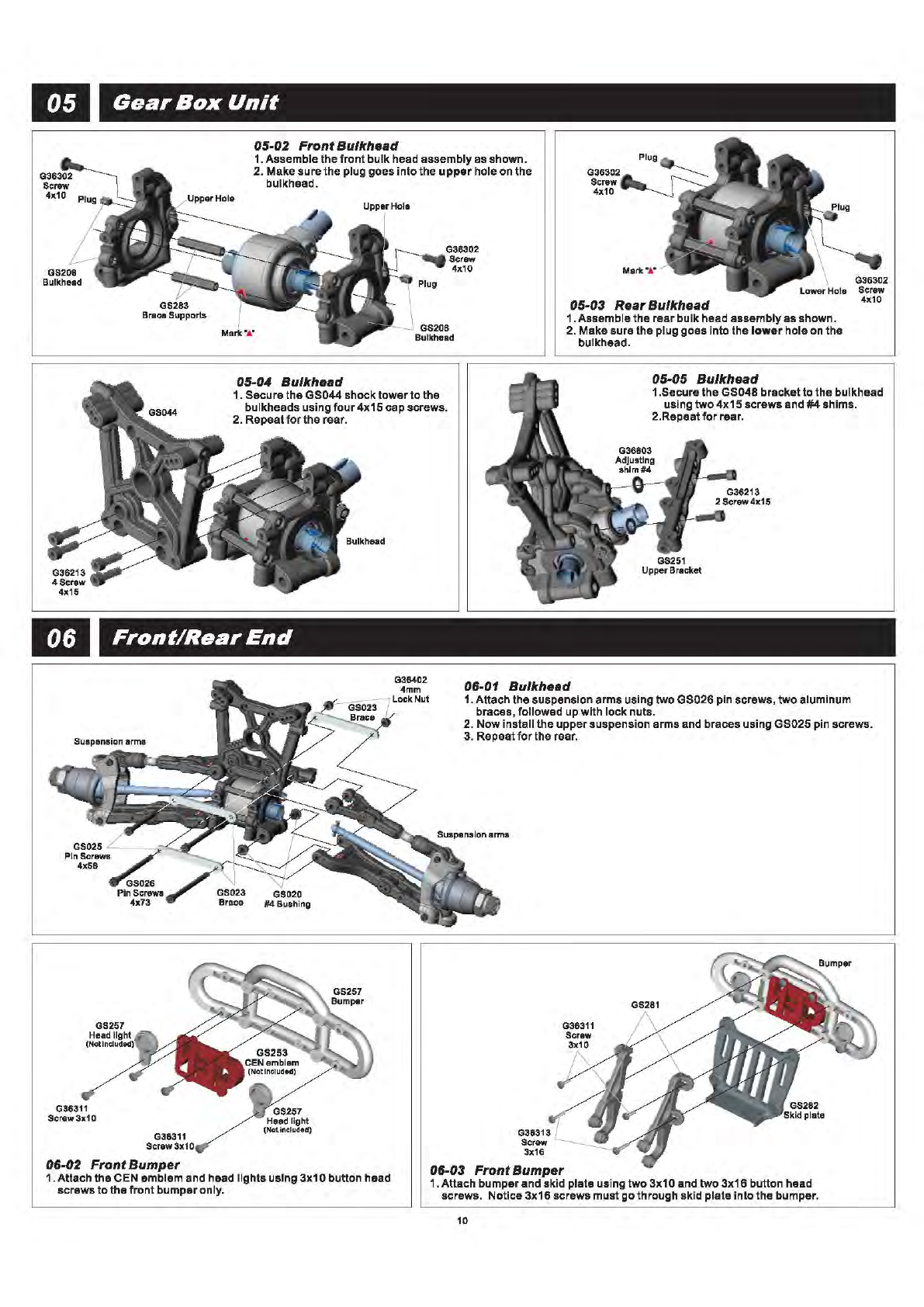

Box

Unit

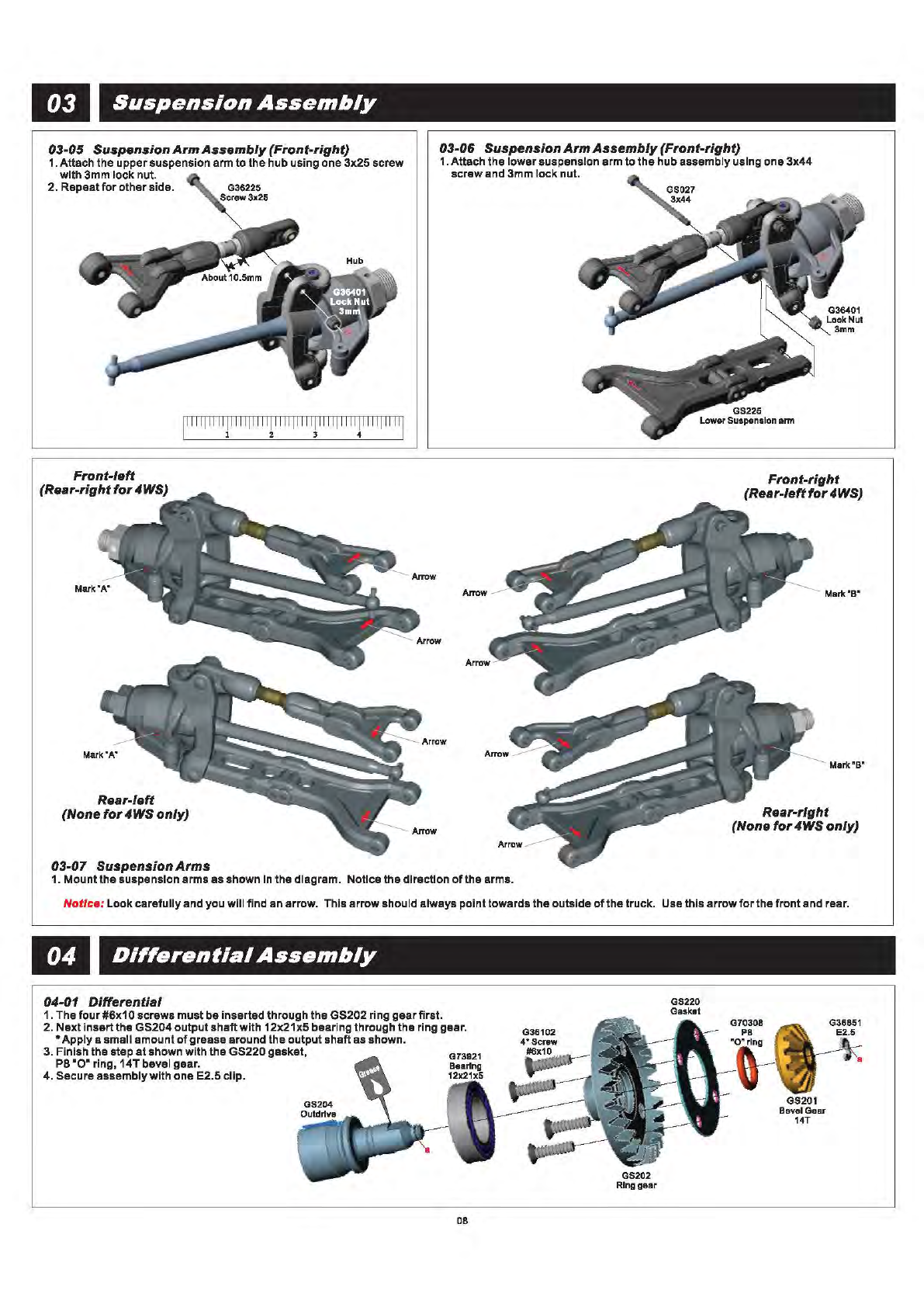

05-01 Gear

Box

Unit

1.Siide2 8x16x5bearing onto the

diff

housing

2.Siideon Bevel Gearand Differential

3.Ciosethe

dlff

casewith

dlff

housing marked

"A"

4.SiideGS093 ontothe Bevel

Gear

shaft

5.ApplyThreaded Lockon the 5x5 screw

09

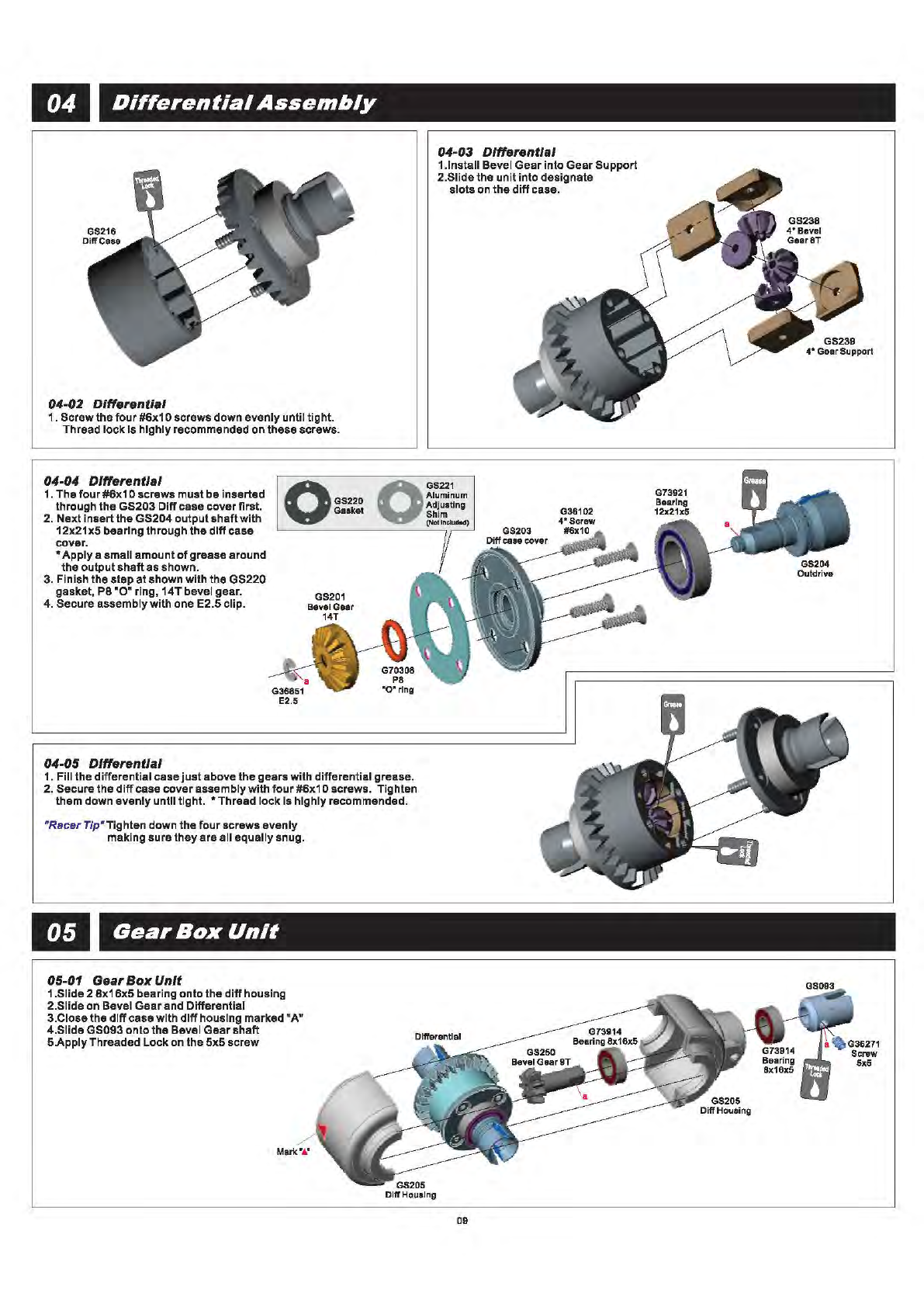

G36102

G73921

Bearing

12x21xi;

GS204

Outdrive