rev001 pg. 1

i-KI Commissioning with Nadi Controller

This document must be read in association with the i-KI installation manual provided with the

unit. The purpose of this document is to assist with the commissioning of the heat pump. It is

essential the manual is read and followed to ensure the installation is per manufacturers

criteria.

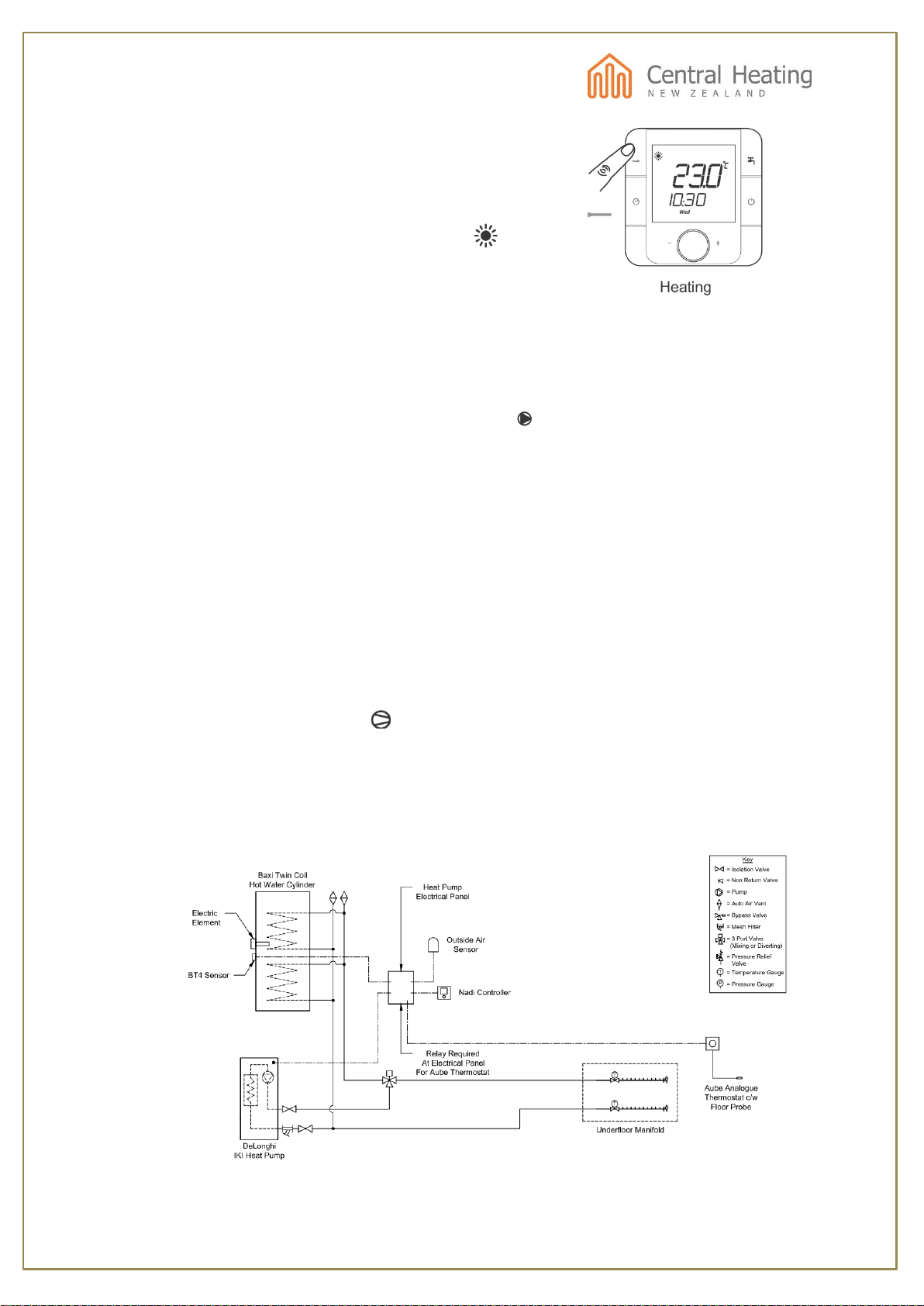

There are various systems/set ups the Heat Pump can be installed to. This document will

covers the most common options:

Pre-Commissioning Page 1

B. Underfloor with Aube Thermostat Page 6

C. Underfloor with Aube Thermostat and DHW Page 8

D. Underfloor with Buffer Tank, Aube Thermostat and DHW Page 12

E. Underfloor with Nadi Controller Page 14

Final Notes –Complete commissioning, checking

Temperatures, Troubleshooting Page 16

A) Ensure the heat pump is installed in accordance with the installation manual.

B) Ensure the power is isolated to the unit

C) Remove the side cover of the unit to expose the water pump, compressor and electrical

enclosure.

D) Check that the water pump on the unit is free to turn and not seized. In addition please

check any internal pumps.

E) Fill the system with water and ensure all air is removed.

Fill the system with water

The system can now be filled with

water to around 1 bar pressure.

The iKi heat pumps have a pump

run switch on the small PCB

under the front cover of the heat

pump on the smaller heat pumps,

and under a panel on the side of

the larger models. This allows

the circulation pump to be run

manually to help vent the system.

Leave the unit on standby for 2 hours once filled.

Before the heat pump runs for the first time it is necessary to let it stand for 2 hours

with the power on. This is to allow the heating band around the compressor to heat

the compressor to drive off any liquid refrigerant in the compressor. This is