14. CHECK DAMAGED PARTS. Before using any tool, any part that appears damaged should be

carefully checked to determine that it will operate properly and perform its intended function.

Check for alignment and binding of moving parts; any broken parts or mounting fixtures; and

any other condition that may affect proper operation. Any part that is damaged should be prop-

erly repaired or replaced by a qualified technician. Do not use the tool if any switch does not

turn on and off properly.

15. REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identical replacement

parts. Use of any other parts will void the warranty. Only use accessories intended for use with

this tool. Approved accessories are available from Harbor Freight Tools.

16. DO NOT OPERATE TOOL IF UNDER THE INFLUENCE OF ALCOHOL OR DRUGS. Read

warning labels on prescriptions to determine if your judgment or reflexes are impaired while

taking drugs. If there is any doubt, do not operate the tool.

17. Failure to heed all instructions and warnings may result in death, personal injury, and/or

property damage.

18. When using the Transmission Jack, whenever possible, keep personnel clear of the area

underload.

19. Not to be used for aircraft purposes.

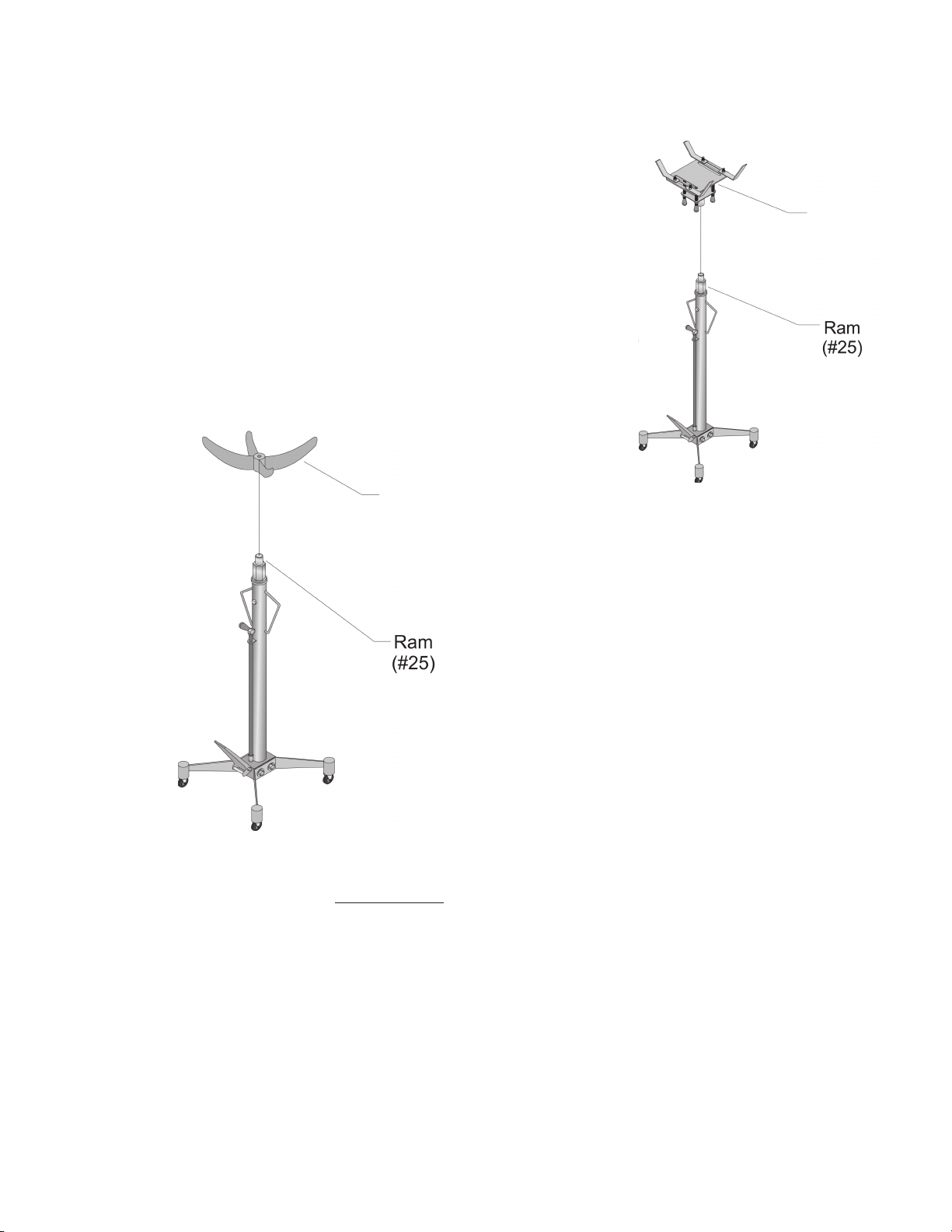

UNPACKING

When unpacking, check to make sure the following parts are included. If any parts are missing or

broken, please call Harbor Freight Tools at the number on the cover of this manual.

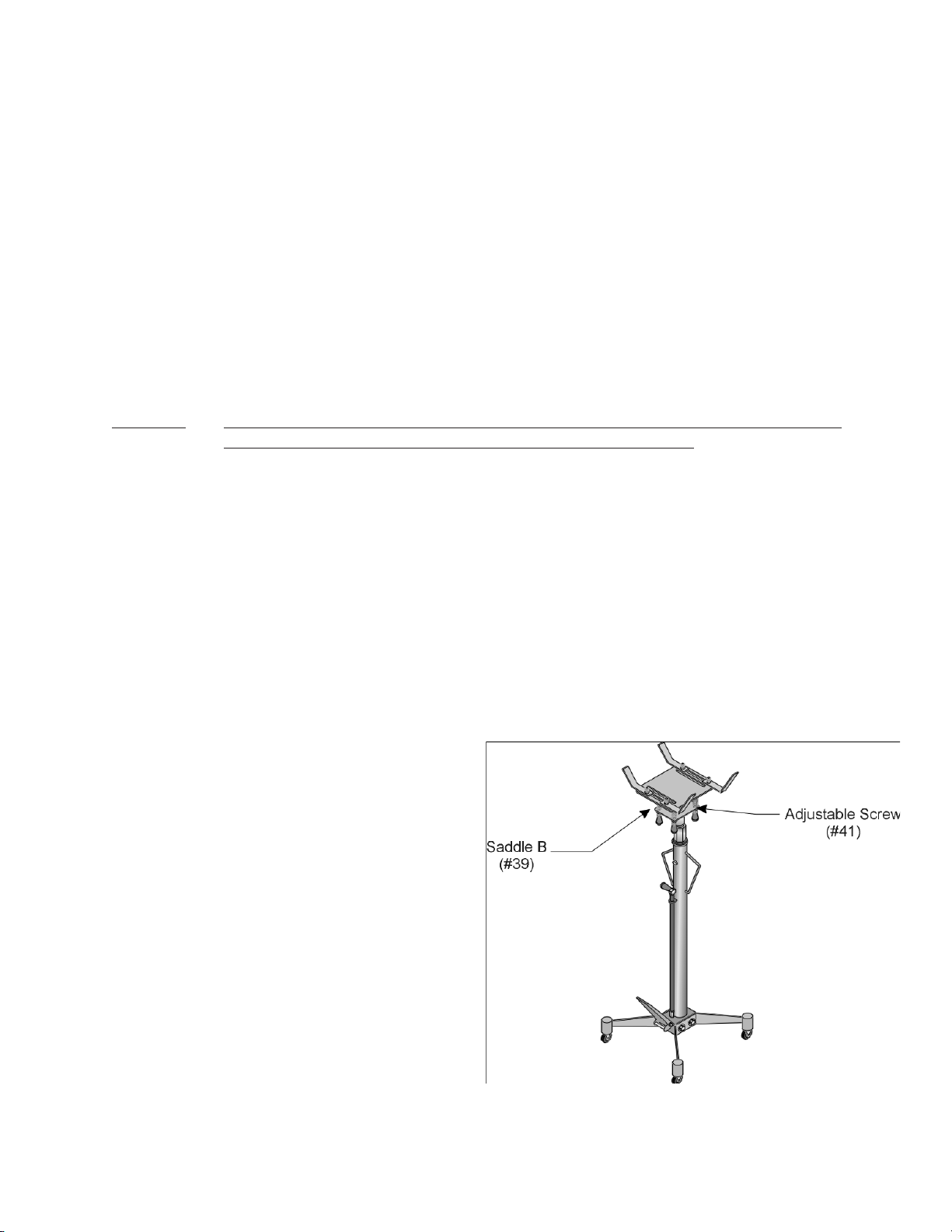

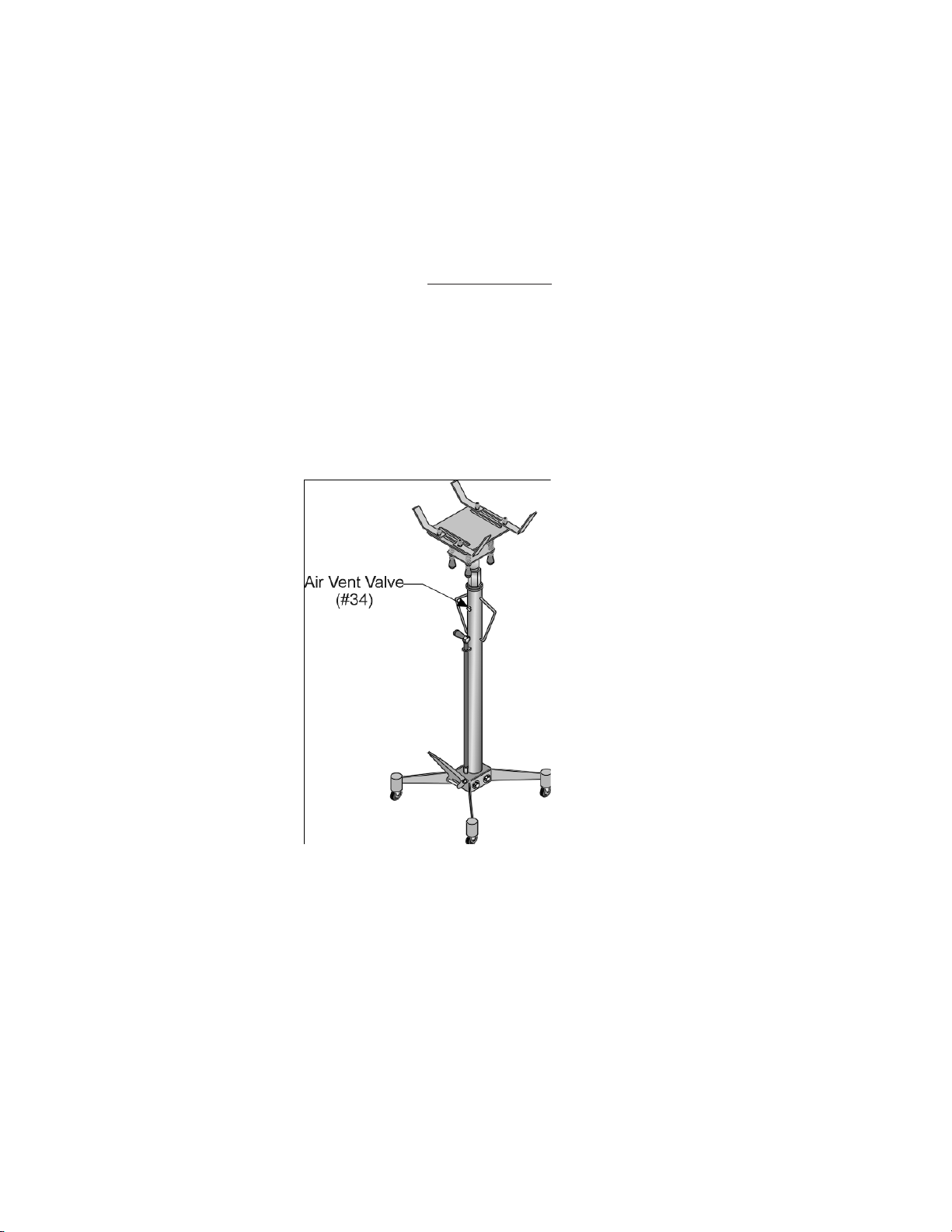

Item# Description Item# Description

N/A Saddle Assembly N/A Leg Assembly

38 Saddle A 18 Reservoir Assembly

#33610 Page 3

WARNING:

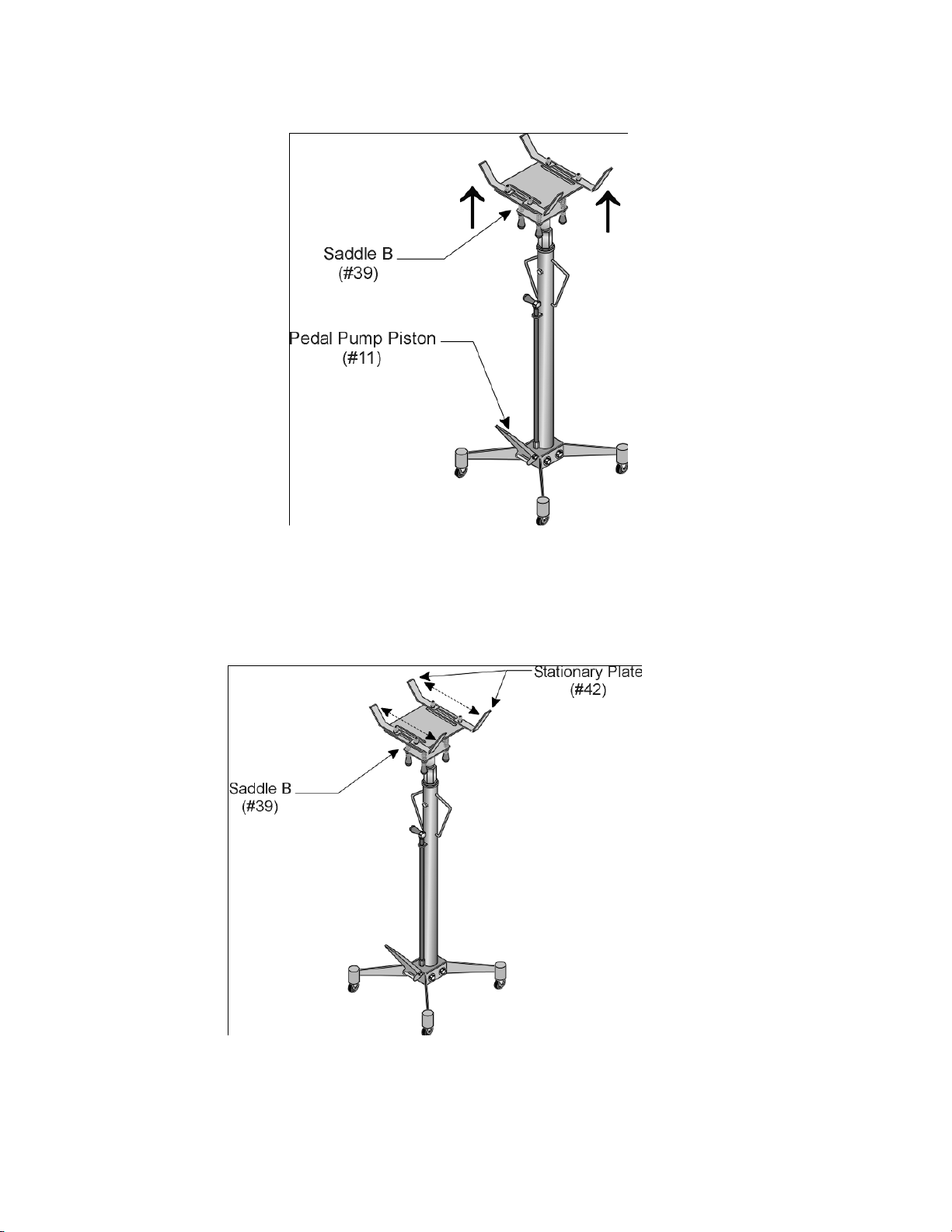

ALWAYS EVALUATEYOUR TASK BEFORE USING THIS JACK. Thisjack isdesignedto support

a transmission or a differential as individual components. Assemblies such as a differential with

axle,ora transmission with bellhousing,canbe bulky and difficulttobalance on the jack’splatform

or cradle.

LIFTING OR SUPPORTING SUCH ASSEMBLIES, EVEN WITHIN THE WEIGHT LIMIT, CAN

CREATE AN OFF-BALANCE SITUATION, CAUSING THE JACK TO TIP OVER AND LEAD TO

SERIOUS PERSONAL INJURYOR PROPERTY DAMAGE.

The load should be evenly distributed on the jack, and should not extend beyond the area of the

castor wheelbase. Always use safety straps or chains to secure the load.

If you are working and the load becomes off-balance and/or the jack begins to tip over,

DO NOT ATTEMPT TO CATCH OR LIFT WHEN FALLING. SERIOUS PERSONAL INJURY

CAN BE SUFFERED! In this event, clear the area as quickly and safely as possible in order to

avoid injury from the falling load, including getting hit with flying fragments.

IF IN DOUBT ABOUT THE SAFETY OF YOUR PROJECT, WE ADVISE YOU TO HAVE THE

WORK DONE BY A PROFESSIONAL FAMILIAR WITH APPLICABLE SAFE PRACTICES.

REV 09/02 REV 03/04