Lippert Components LCI User manual

Other manuals for LCI

1

Table of contents

Other Lippert Components Jack manuals

Lippert Components

Lippert Components Level-Up 5th Wheel User manual

Lippert Components

Lippert Components Stabilizer Jack User manual

Lippert Components

Lippert Components Standalone Smart Jack Manual

Lippert Components

Lippert Components Smart Jack 643589 Installation instructions

Lippert Components

Lippert Components Power Stance User manual

Lippert Components

Lippert Components Atwood RV Power Jack Owner's manual

Lippert Components

Lippert Components 285318 Manual

Lippert Components

Lippert Components JT's Strong Arm 191023 Installation instructions

Lippert Components

Lippert Components 285318 Installation instructions

Popular Jack manuals by other brands

Dannmar

Dannmar DJ Series Installation and operation manual

Torin BIG RED

Torin BIG RED T820014S owner's manual

Osculati

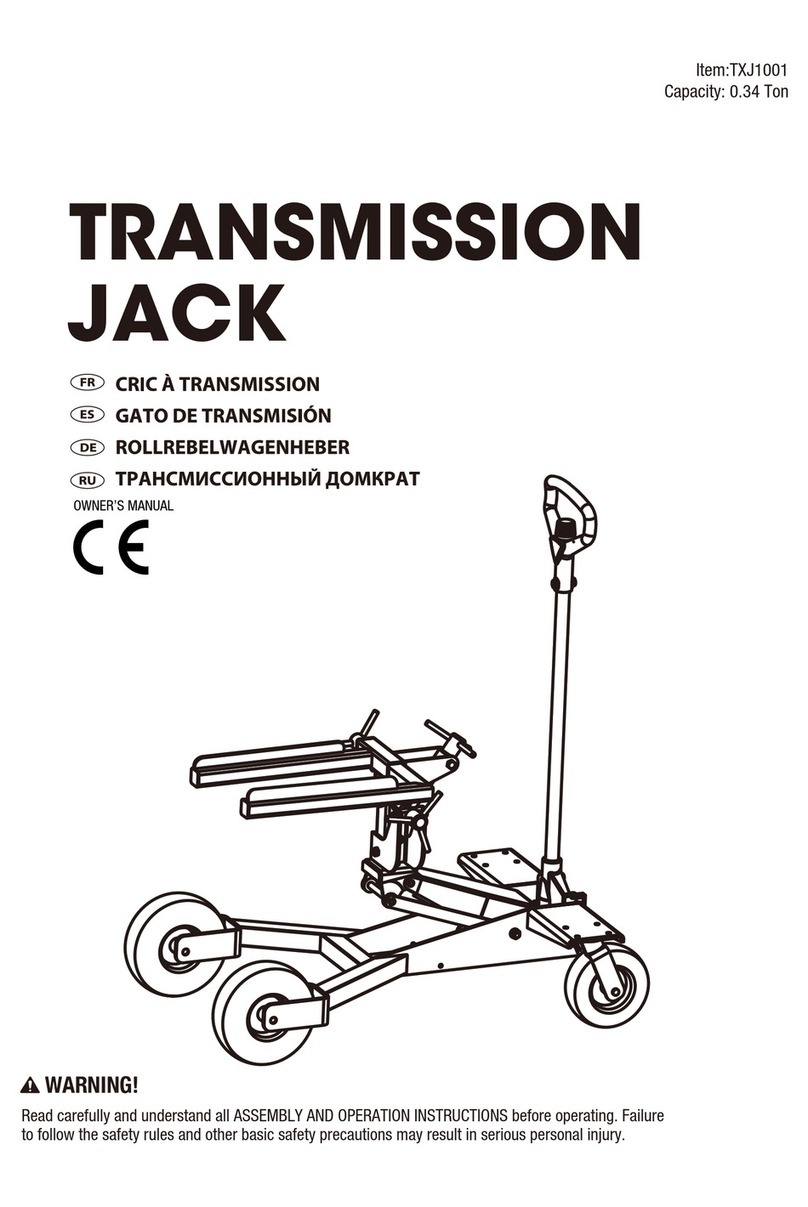

Osculati TXJ1001 owner's manual

MAG TOOLS

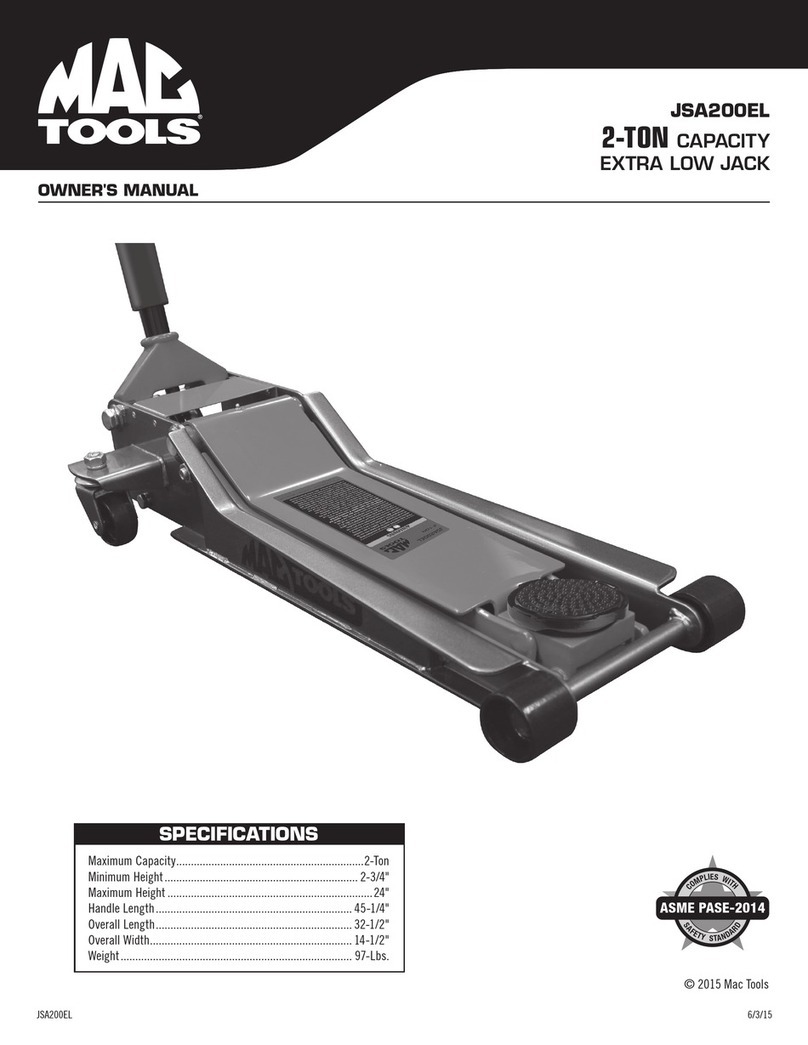

MAG TOOLS JSA200EL owner's manual

Chicago Pneumatic

Chicago Pneumatic CP9603 Instruction manual/safety instruction

OTC

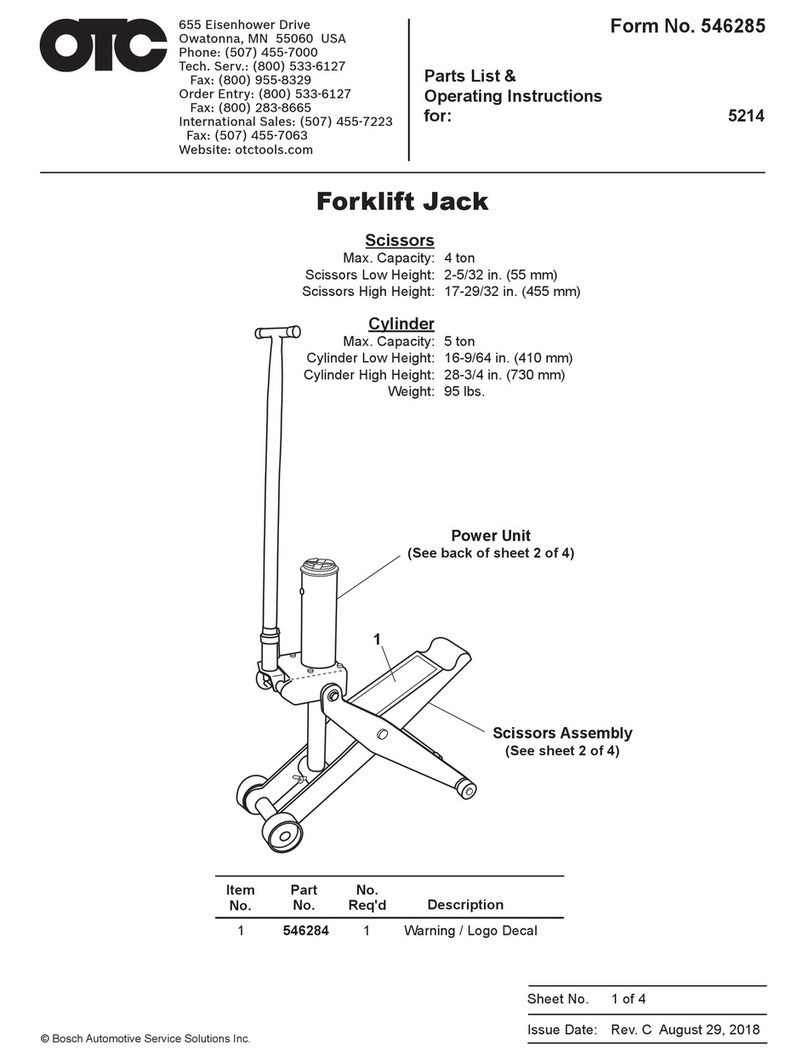

OTC 5214 operating instructions

MAG TOOLS

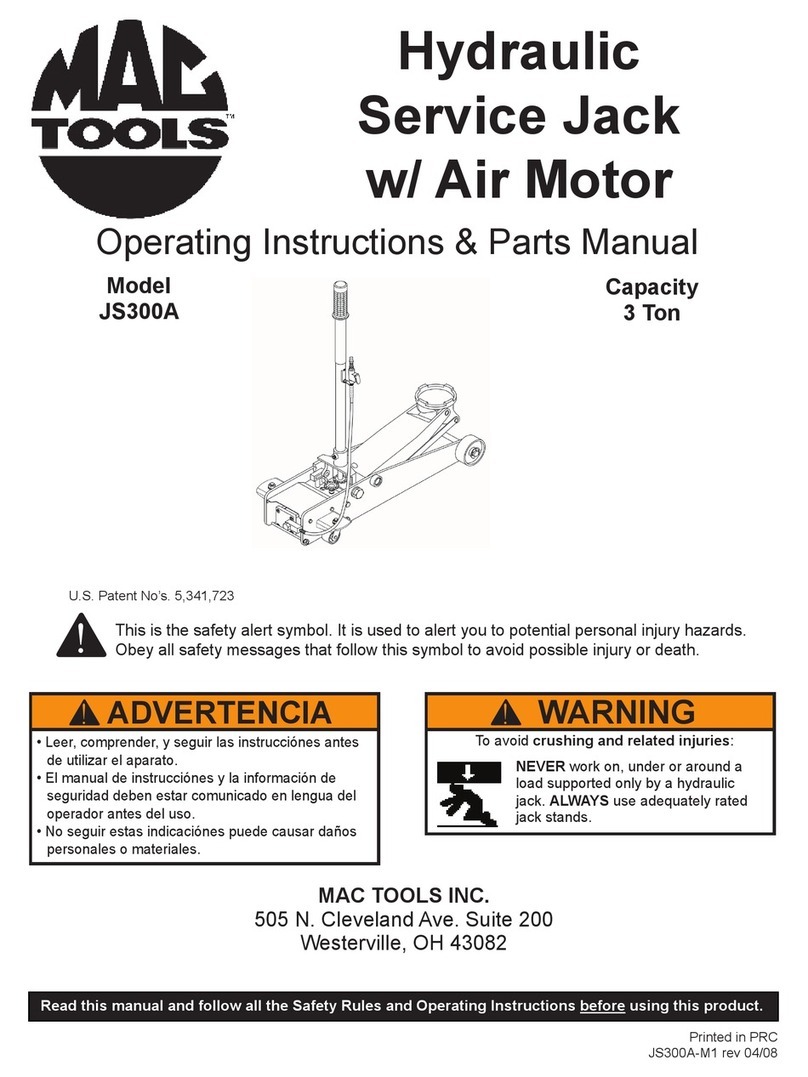

MAG TOOLS JS300A Operating instructions & parts manual

Omega Lift Equipment

Omega Lift Equipment 21260AA Operating instructions & parts manual

Bannon

Bannon 55829 owner's manual

ATD Tools

ATD Tools ATD-7385W owner's manual

Winntec

Winntec Wheel Assist Y472270 user manual

DURHAND

DURHAND C20-048V00 instruction manual