4. ASSEMBLY

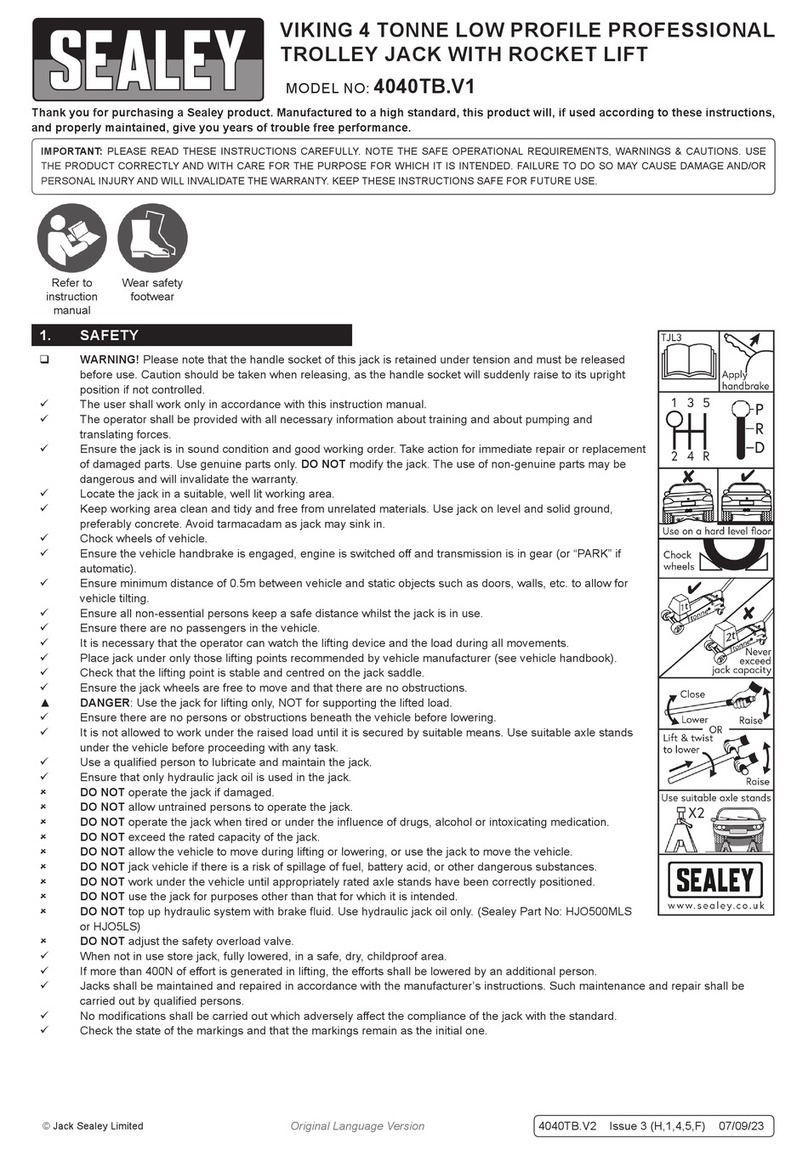

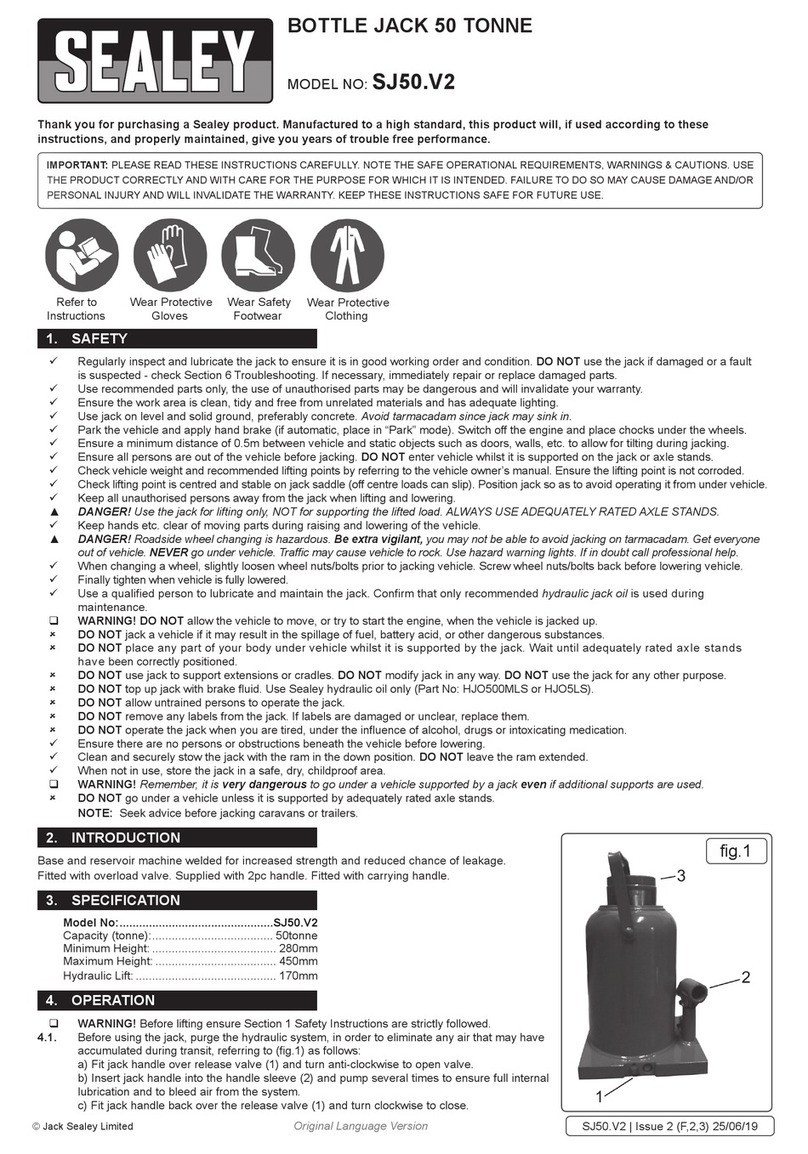

4.1. Fit the handle assembly into the handle socket with the valve control lever towards the jack. Retain with the handle fixing

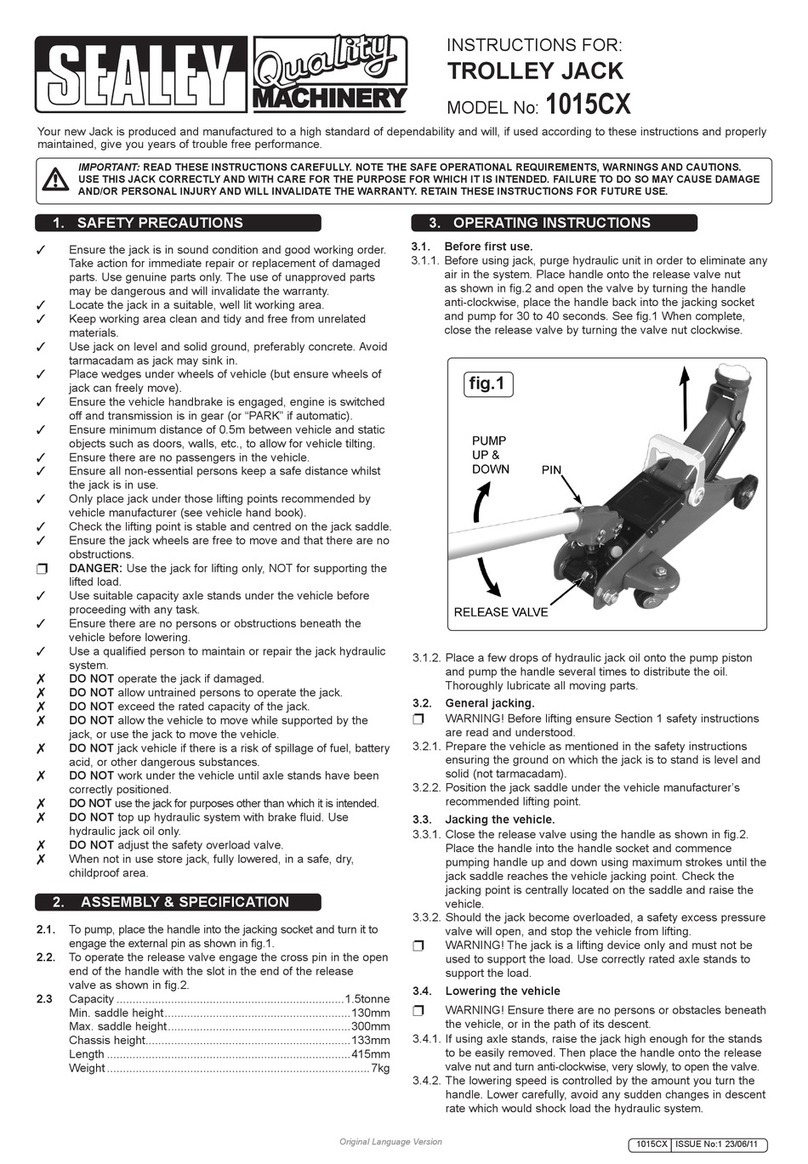

bolt. See fig.1.

4.2. Before using the jack for the first time, purge the hydraulic circuit in order to eliminate any air in the system. To do this, open

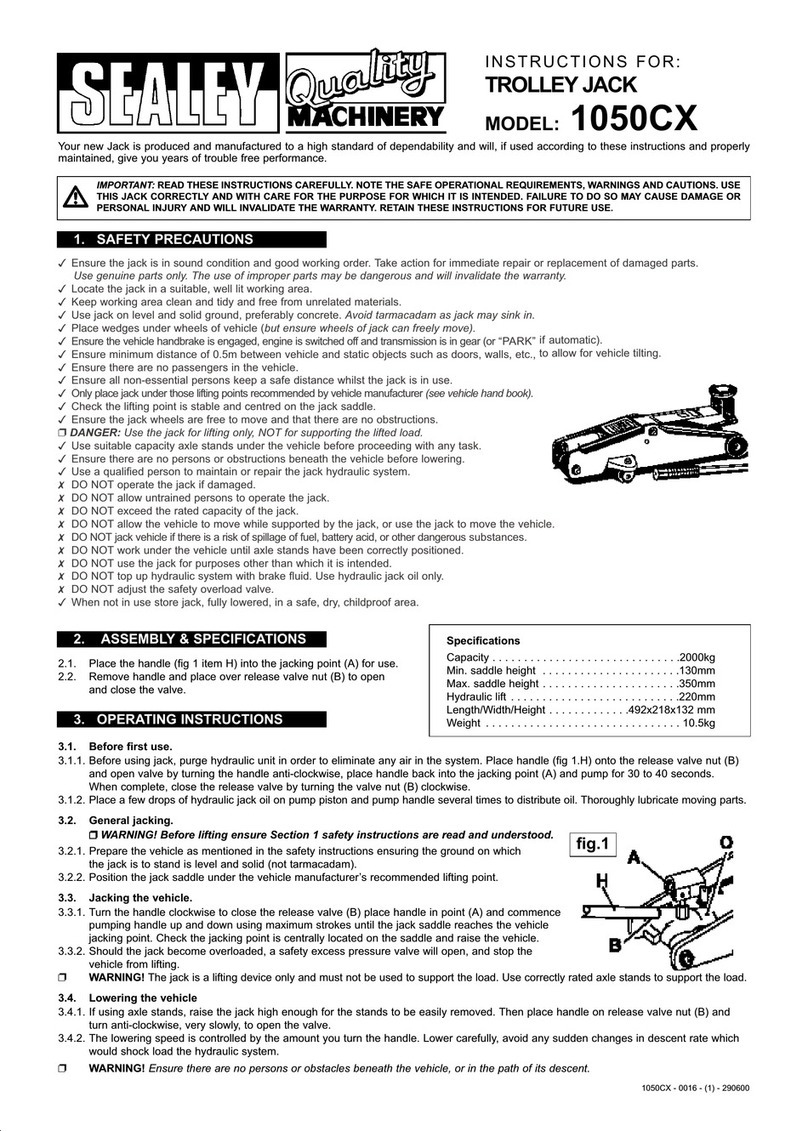

the release valve by moving the lever downwards from position A to position B as shown in fig.2. In the lower position B the handle

must engage with one of the 3 handle locations indicated in fig.1. Once engaged the release valve can be opened by rotating the

lever fully sideways as shown in fig.2-C. Pump the foot pedal through its full travel 3 or 4 times. Return the release valve lever to

the upper closed position (see fig.2-A)

4.3. Place a few drops of hydraulic jack oil on the pump piston and pump the handle several times to distribute the oil. Thoroughly

lubricate all moving parts.

5. OPERATION

5.1. General jacking.

WARNING! Before lifting, ensure Section 1 safety instructions are strictly followed.

5.1.1. Prepare vehicle as described in safety instructions ensuring the ground on which jack is to stand is level and solid (not tarmacadam).

We recommend concrete.

5.1.2. Position the jack saddle under the vehicle manufacturer’s recommended lifting point (see vehicle handbook).

5.2. Jacking the vehicle.

5.2.1. Ensure that the release valve lever is in the upper closed position, see fig.2A. The jack saddle may be raised quickly up to the load

using the foot pedal. DO NOT attempt to raise the load with the foot pedal.

5.2.2. Commence pumping the handle up and down through its full stroke until the vehicle reaches the required height.

Note: If the jack becomes overloaded, the safety valve will operate and prevent the jack from lifting further.

5.3. Lowering the vehicle.

5.3.1. To lower the vehicle, open the release valve by moving the lever downwards from position A to position B as shown in fig.2. In the

lower position B the handle must engage with one of the 3 handle locations indicated in fig.1. Once engaged the release valve can be

opened by rotating the lever fully sideways as shown in fig.2-C.

WARNING! Always lower in a slow and controlled manner and ensure that there are no persons or obstacles beneath the

vehicle, or in the path of descent.

6. MAINTENANCE

IMPORTANT: Only fully qualified personnel should attempt maintenance or repair.

6.1. When the jack is not in use, the ram should be in the lowest position to minimise corrosion. Remove the handle to inactivate the jack.

6.2. Keep the jack clean and lubricate all moving parts with oil on a regular basis.

6.3. Every 3 months grease the lifting arm pivot pin and the rear castors via the grease nipples provided.

6.4. The pump and cylinder form a closed hydraulic system and refilling with oil is only necessary in exceptional cases. To check oil level:

1) Place jack on a level surface with the saddle fully lowered.

2) Remove the 4 top cover retaining screws and lift off the cover.

3) The oil is topped up via the rubber bung which is situated on top of the cylinder nearest to the ram end of the pump.

NOTE: Use a good quality jack oil, such as SEALEY HYDRAULIC JACK OIL.

WARNING: DO NOT use brake fluid, or any fluid other than hydraulic jack fluid as this will cause serious damage to the jack

and will invalidate the warranty!

6.5. Before each use check for broken, cracked, bent, or loose parts, or any visible damage to ram, pump, saddle, lifting arm, frame and

all parts including nuts, bolts, pins and other fasteners. If any suspect item is found, remove jack from service and take the necessary

action to remedy the problem.

8DO NOT use the jack if it is believed to have been subjected to abnormal or shock loading. Inspect and take appropriate action.

6.6. Periodically check the pump piston and the ram for signs of corrosion. Clean exposed areas with a clean cloth and jack oil.

IMPORTANT: NO RESPONSIBILITY IS ACCEPTED FOR INCORRECT USE OF THIS PRODUCT.

Hydraulic products are repaired by local service agents only. We have service/repair agents in all parts of the UK.

DO NOT return jacks to us. Please telephone us on 01284 757500 to obtain the address and telephone number of your local agent.

If jack is under guarantee you can also contact your local dealer.

6.7. De-commissioning.

Should the jack become completely unserviceable, draw off the oil into an approved container and dispose of the jack and the oil

according to local regulations.

10QJ.V3 Issue 2 (HF) 24/07/18

Original Language Version

© Jack Sealey Limited

g.2