Page 2SKU 94682 For technical questions, please call 1-800-444-3353.

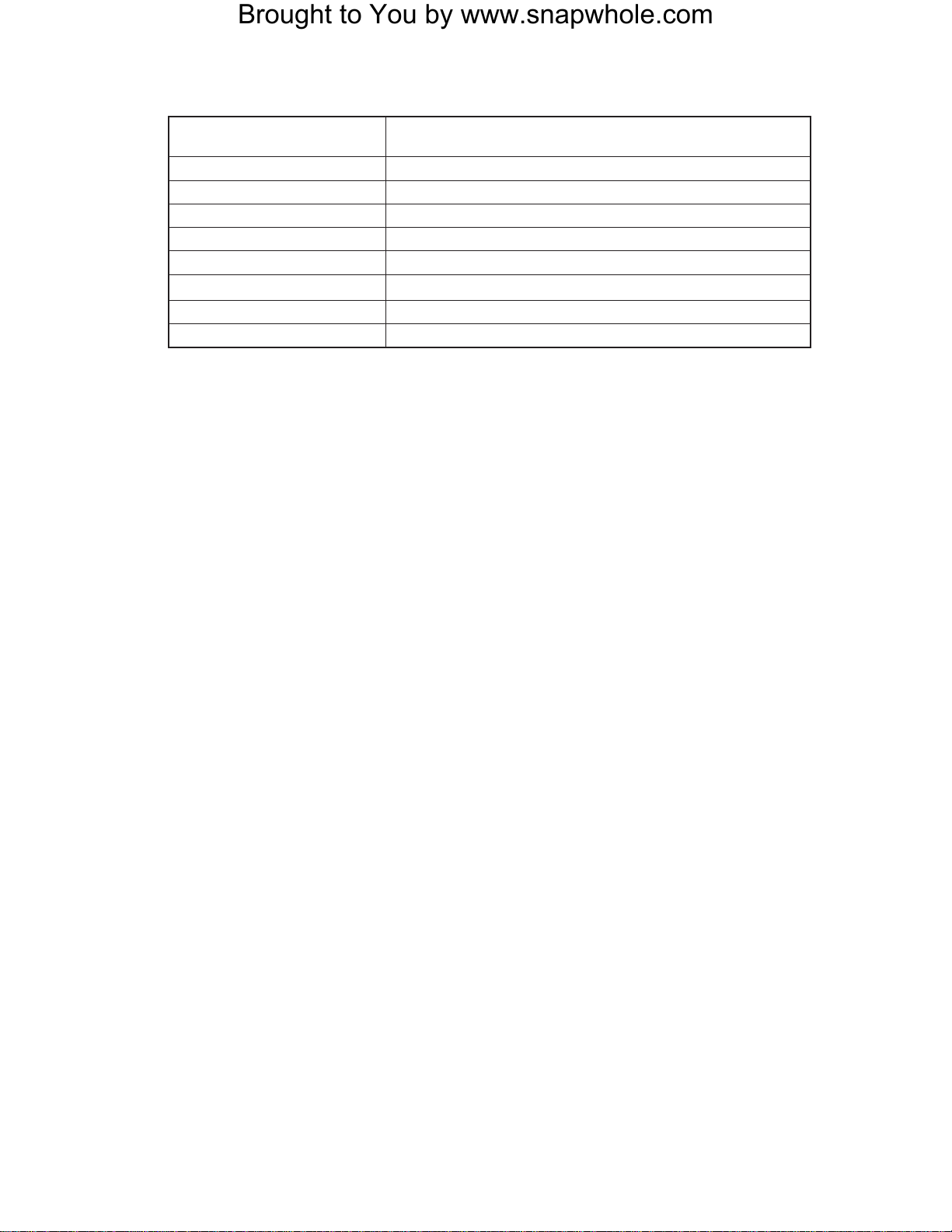

SPECIFICATIONS

Capacity Of Each Hydraulic

Wheel Dolly

1,500 lb. Weight Capacity Per Dolly, Each Dolly Fits Tires

Up to 10” Wide

Construction All Steel Construction, Aluminum Rollers, Rubber O-rings

Castor Dimensions 4” Diameter x 1-3/8” Wide x 4-3/4” Total Height

Roller Dimensions 10-5/8” Long x 2-3/4” Diameter x 4-3/8” Total Height

Distance Between Rollers 9-7/8’” Minimum to 20-3/4” Maximum

Roller Locking Width 10”

Ram Travel 10-7/8”

Ram Diameter 15/16”

Weight Per Wheel Dolly 40.7 lb.

SAVE THIS INSTRUCTION MANUAL

You will need this instruction manual for the safety warnings and precautions, inspection, maintenance,

and cleaning procedures. Keep your invoice with this instruction manual. Write the invoice number

on the front page. Keep this instruction manual and invoice in a safe and dry location for future refer-

ence.

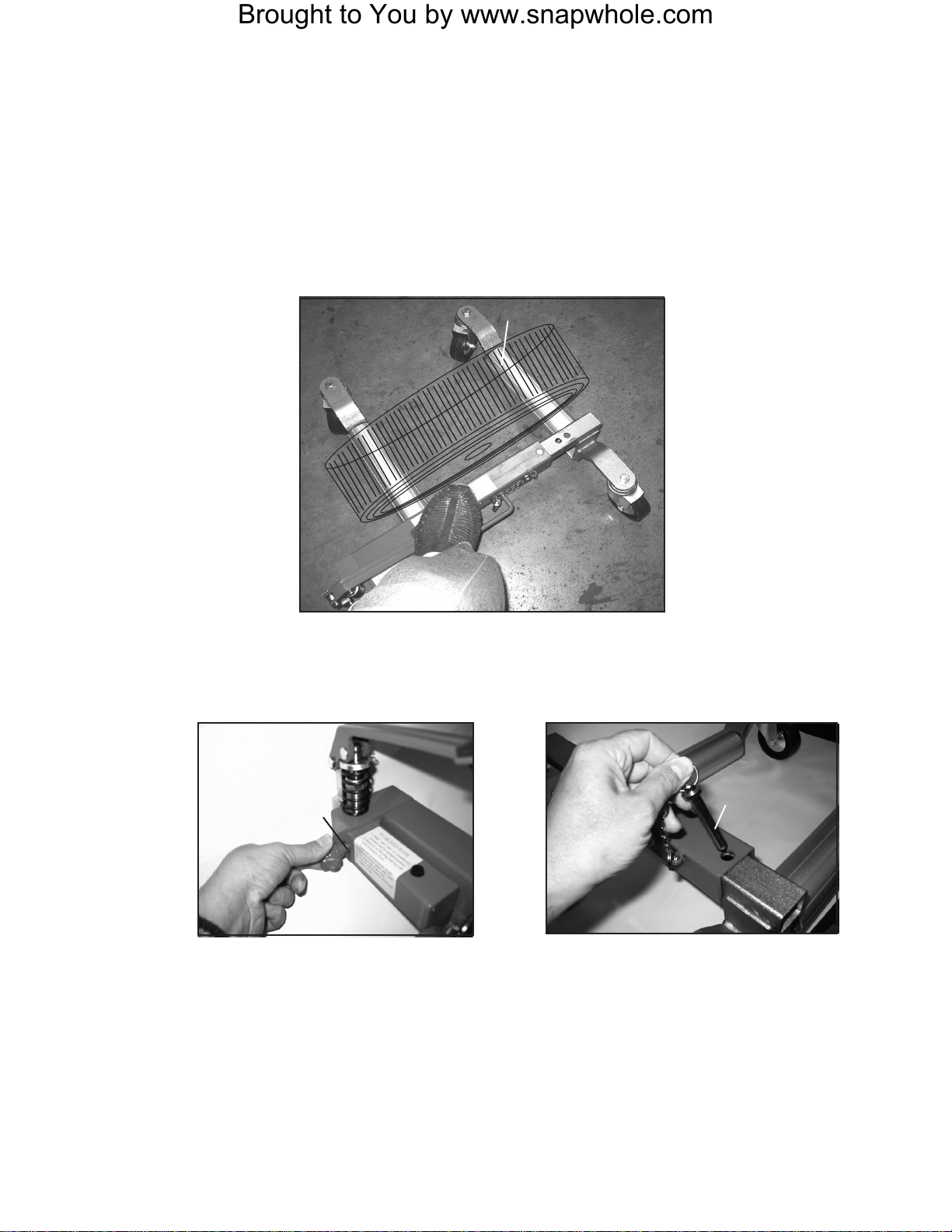

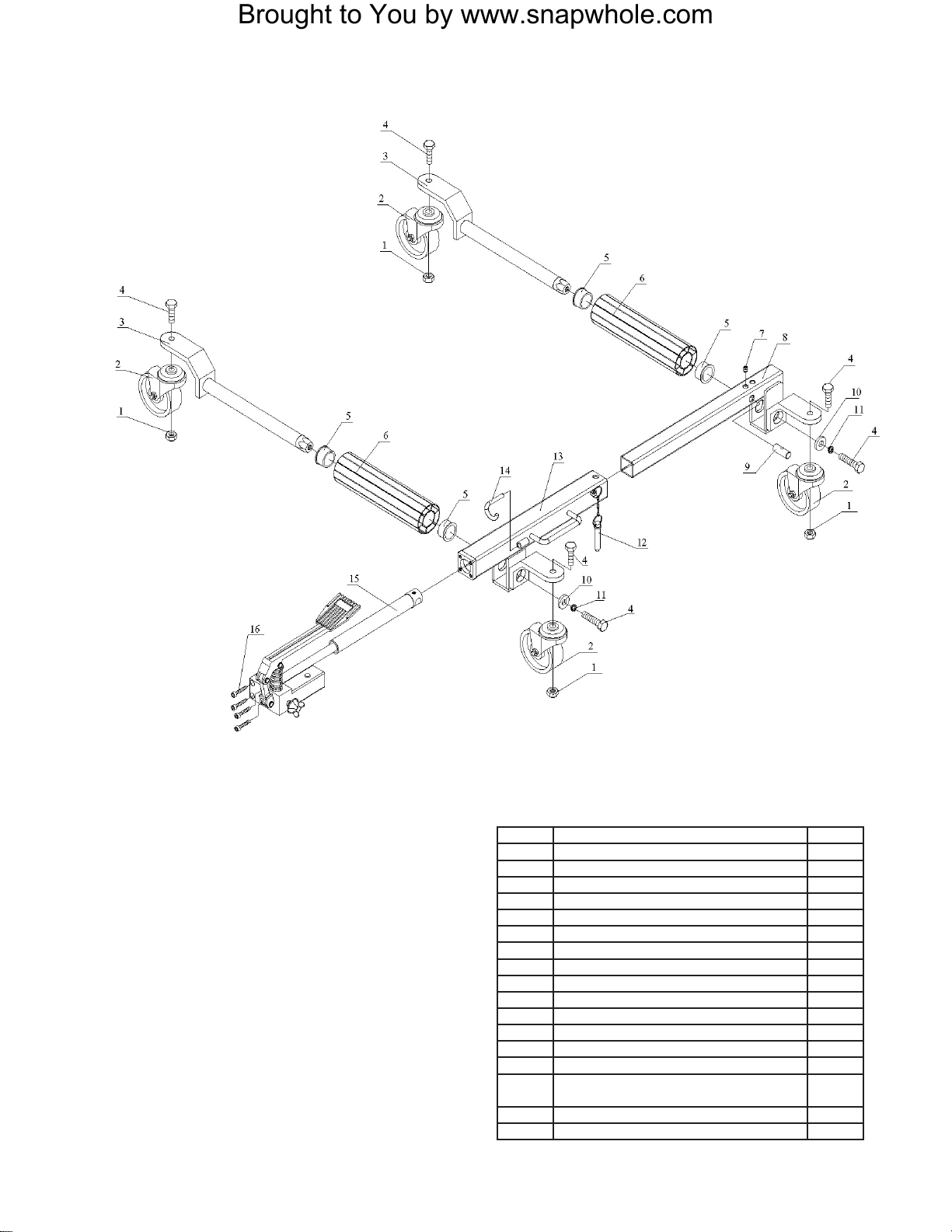

UNPACKING

When unpacking, check to make sure the parts shown on this instruction manual are included. If any

parts are missing or broken, please call Harbor Freight Tools at the telephone number shown on the

front page of this manual.

GENERAL SAFETY WARNINGS AND PRECAUTIONS

1. KEEP WORK AREA CLEAN AND DRY. Cluttered, damp or wet work areas invite injuries.

2. USE EYE PROTECTION. Wear ANSI approved safety impact eye glasses when using this

product. ANSI approved safety impact eye glasses are available from Harbor Freight Tools.

3. DO NOT ALLOW CHILDREN IN THE WORK AREA. Keep away from children. Do not allow

children to play with this product.

4. CHECK FOR DAMAGED PARTS. Before using this product, carefully check that it will operate

properly and perform its intended function. Check for damaged parts and any other condi-

tions that may affect the operation of this product. Replace or repair damaged or worn parts

immediately.

5. REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identical replace-

ment parts.

6. MAINTAIN THIS PRODUCT WITH CARE. Keep this product clean and dry for better perfor-

mance.

7. USE THE RIGHT PRODUCT FOR THE RIGHT JOB. There are certain applications for which

this product was designed. Do not use small equipment, tools or attachments to do the work

of larger industrial equipment, tools or attachments. Do not use this product for a purpose for

which it was not intended.

Brought to You by www.snapwhole.com