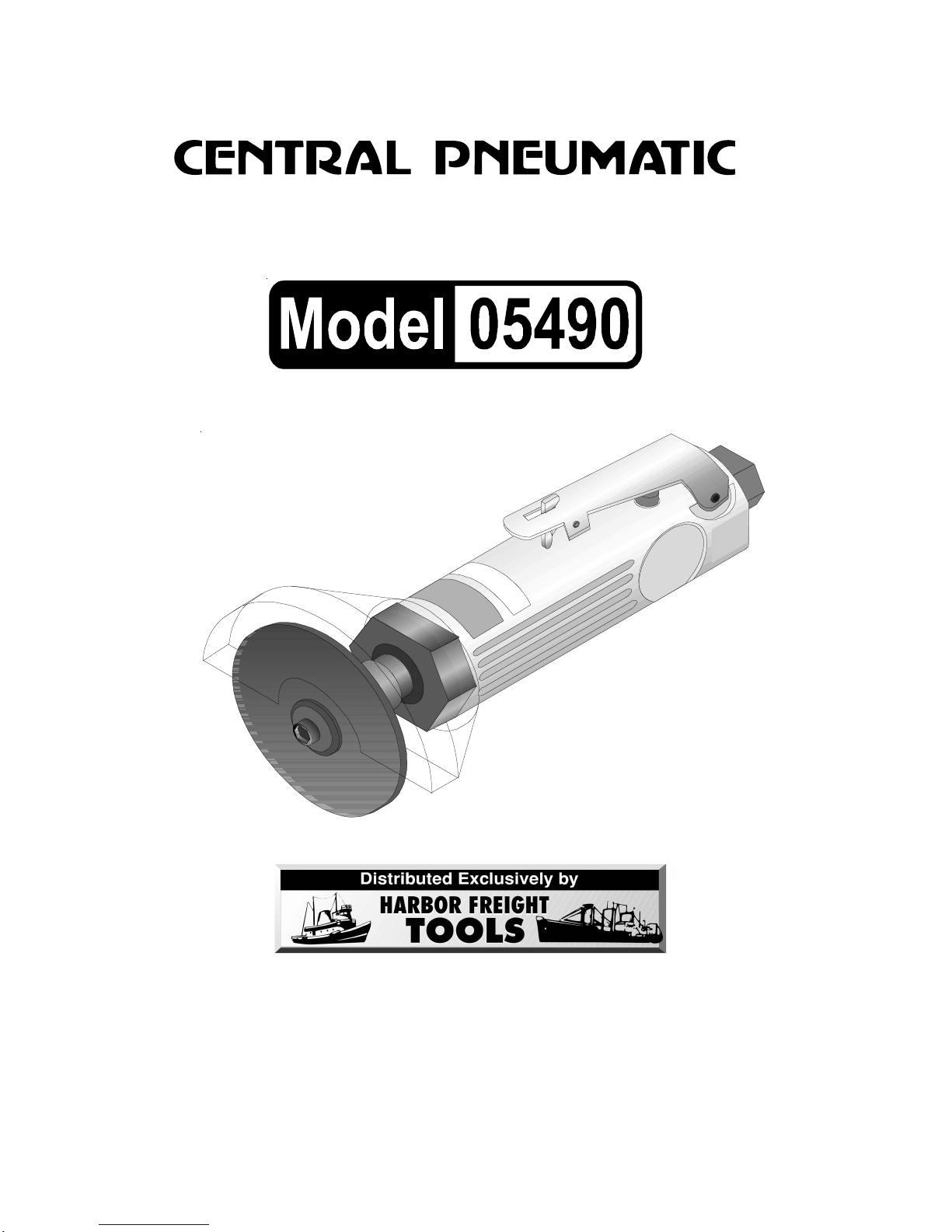

Central Pneumatic 05490 User manual

3491 Mission Oaks Blvd. / Camarillo, CA93011

Copyright © 1997 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in any

shape or form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

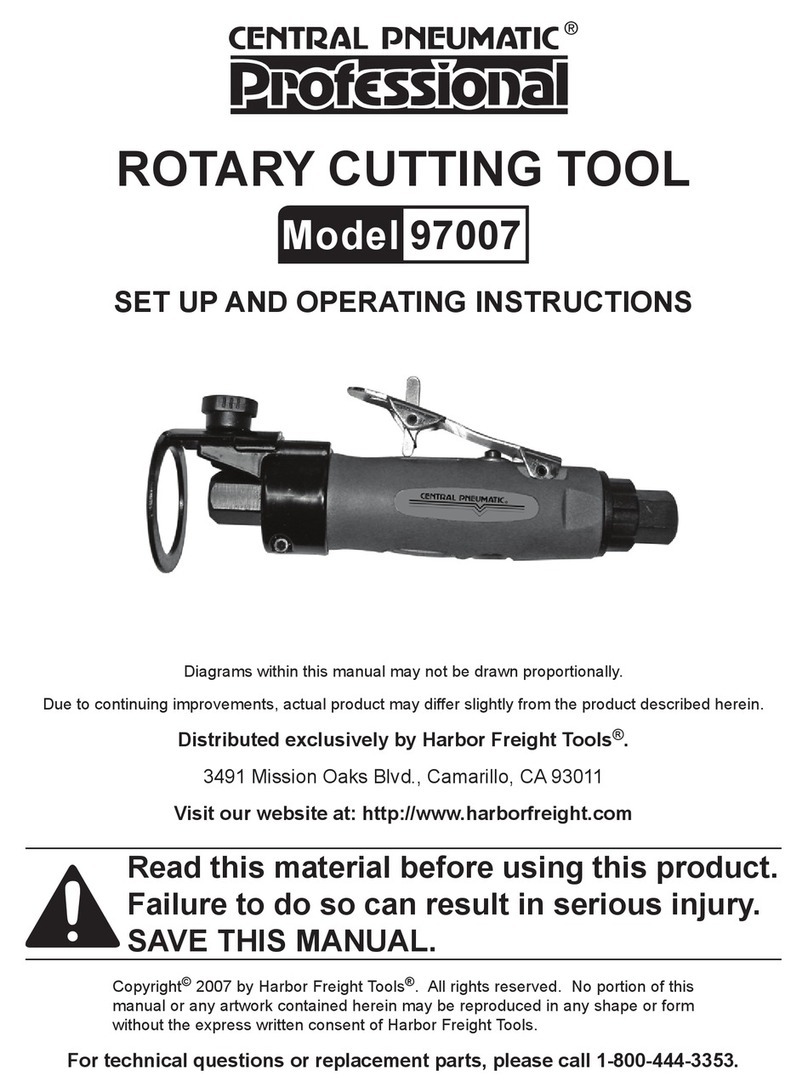

AIR HIGH SPEED CUTTER

ASSEMBLY and OPERATING INSTRUCTIONS

®

®

SPECIFICATIONS

FreeSpeed 5000 to 18000 RPM

Air Pressure 90PSI

Air Consumption 4CFM

AirInlet ¼” NPT

Weight 1-1/2 lbs.

SAVE THIS MANUAL

You will need the manual for the safety warnings and cautions, assembly instructions, operating

procedures, maintenance procedures, trouble shooting, parts list, and diagram. Keep your

invoice with this manual. Write the invoice number on the inside of the front cover. Keep both

this manual and your invoice in a safe, dry place for future reference.

SAFETY WARNING & CAUTIONS

WARNING: When using pneumatic equipment, basic safety precautions should always be

followed to reduce the risk of personal injury and hazards due to over pressurization.

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL!

1. KEEPWORK AREACLEAN. Cluttered areas invite injuries.

2. OBSERVE WORKAREACONDITIONS. Do not use tools in damp, wet, or poorly lit

locations.Don’texposetorain.Keepworkareawelllit.Donotuseelectricallypowered

air compressors in the presence of flammable gases or liquids.

3. KEEP CHILDRENAWAY. Childrenmust neverbe allowed in the workarea. Do not let

themhandlemachines, tools, orhoses.

4. STORE IDLE EQUIPMENT. When not in use, tools must be lockedupin a dry location

toinhibitrust.Alwayslockuptoolsandkeepoutof reach of children.

5. DO NOT FORCE THE TOOL. It will do the job better and more safely at the rate for

whichit wasintended.Donot useinappropriateattachments inanattempttoexceedthe

tool’s capacities.

6. USE THE RIGHT TOOL FOR THE JOB. Do not attempt to force a small tool or

attachmenttodothe work of a larger industrial tool. Donotuseatool for a purpose for

whichitwas not intended.

7. DRESS PROPERLY. Donot wear loose clothingor jewelry as they can be caught in

movingparts.Non-skidfootwearisrecommended.Wearrestrictivehaircoveringto

containlonghair.

Page #2 -- SKU: 05490

8. USE EYEAND EAR PROTECTION.Always wearANSI approved chemical splash

goggleswhenworkingwithchemicals.AlwayswearANSI approved impactsafety

gogglesatothertimes. Wear a full face shield if youareproducing metal filings or

woodchips.WearanANSI approved dust mask or respirator when working around

metal,wood,andchemicaldustsandmists.

9. DO NOTABUSE THE POWER CORD. Do not yank compressor’scord todisconnect

itfromthereceptacle.Donotcarrytoolsbythecord.

10. DO NOT OVERREACH. Keep proper footing and balance at all times. Do not reach

overoracross running machines.

11. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safer

performance.Followinstructions for lubricating and changingaccessories.Inspect

compressor’scord periodically and, if damaged, have them repairedbyanauthorized

technician.Inspect all hosesforleaksprior touse.Thehandlesmust bekeptclean,dry,

and free from oil and grease at all times.

12. REMOVE ADJUSTING KEYS AND WRENCHES. Make it a habit to check that keys

andadjustingwrenchesareremovedfrom the tool or machine work surface before

pluggingitin.

13. AVOID UNINTENTIONAL STARTING. Donot carry any tool with your finger on the

trigger, whether it is connected to the compressor or not.

14. STAYALERT. Watch whatyouaredoing,usecommon sense. Do not operateanytool

whenyouare tired.

15. CHECK DAMAGED PARTS. Before using any tool, any part that appears damaged

shouldbecarefullycheckedtodeterminethatitwill operate properly and perform its

intendedfunction. Checkforalignmentandbindingofmovingparts; anybrokenpartsor

mountingfixtures;andanyotherconditionthatmayaffectproperoperation.Anypartthat

is damaged should be properly repaired or replaced by a qualified technician. Do not

usethetoolif any switch does not turnonandoffproperly.

16. REPLACEMENT PARTSAND ACCESSORIES. When servicing, use only identical

replacementparts.Useofanyotherpartswill voidthewarranty.Onlyuseaccessories

intendedforuse with thistool.Approvedaccessoriesareavailable from HarborFreight

Tools.

17. DO NOT OPERATE TOOL IF UNDER THE INFLUENCE OFALCOHOL OR DRUGS.

Readwarninglabelsonprescriptionstodetermineifyourjudgmentor reflexes are

impairedwhiletakingdrugs.Ifthereisanydoubt,donotoperatethetool.

18. DRAIN COMPRESSOR EVERY DAY. Do not allow moisture to build up inside the

compressor.Donotallowcompressortositpressurizedforlongerthanone hour.

19. MAKE SURE ALL EQUIPMENT IS RATED TO THE APPROPRIATE CAPACITY.

Makesurethatregulator is set at least 10 PSI lower thanthelowestratedpiece of

equipmentyouare using.

20. The Safety Guard must always be tightly secured in place whenusingtheAirHigh

SpeedCutter. Keep hands offguard when operatingthistool.

Page #3 -- SKU: 05490 REV 02/04

UNPACKING

Your High Speed Cutter comes fully assembled. When unpacking your High Speed Cutter,

check to make sure the following parts are included. If any parts are missing or broken, please

call Harbor Freight Tools at the number on the cover of this manual.

ASSEMBLY

Your High Speed Cutter comes completely assembled and is ready for use. Should you need to

remove and replace the CUTTING WHEEL (#33), refer to the steps below.

Step 1:Purchase an authorized replacement CUTTING WHEEL from Harbor Freight Tools. Use

only approved replacement accessories with your High Speed Cutter.

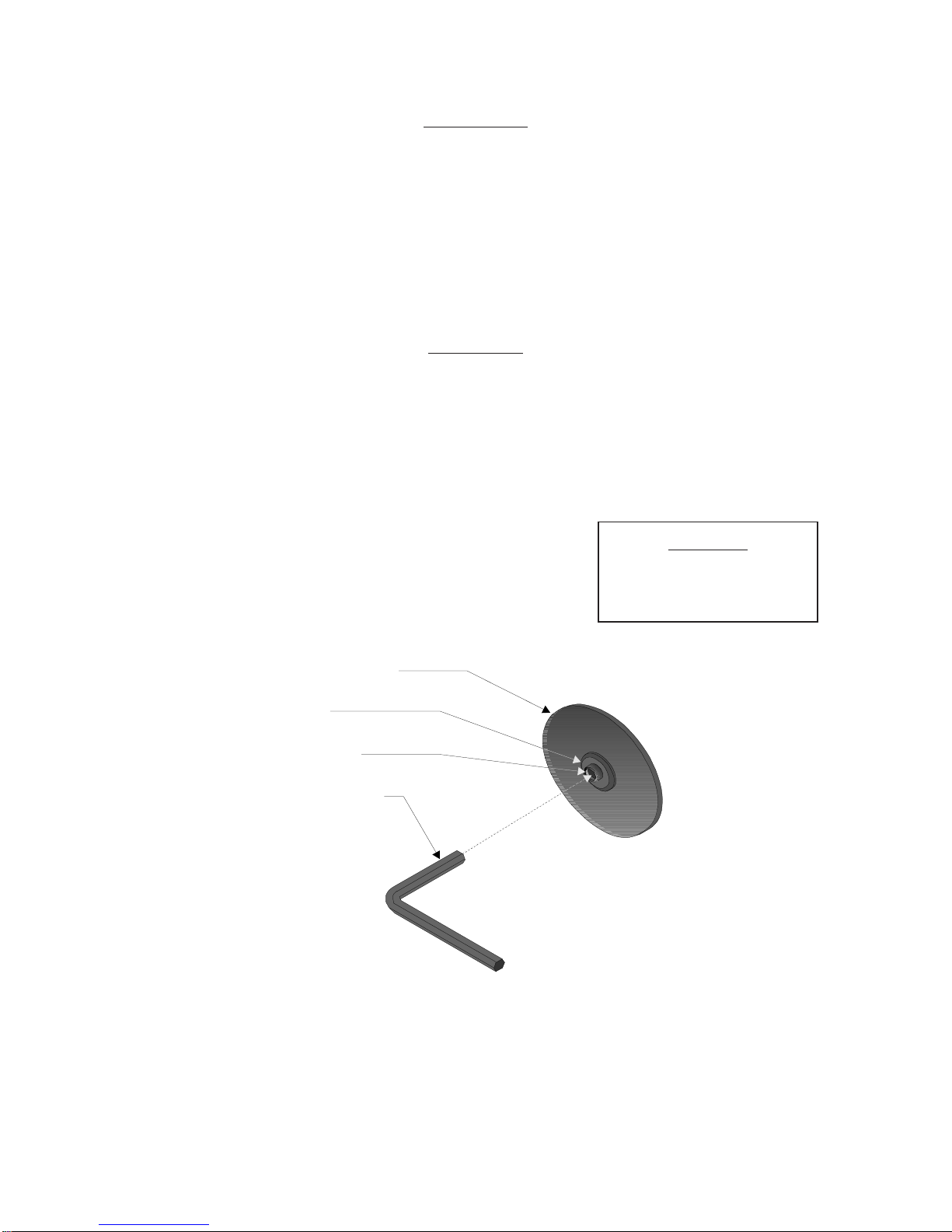

Step 2:Place the SPANNER (#32) on the flats of the

SPINDLE (#6).

Step 3:Insert the HEX WRENCH (#31) into the HEX SCREW

(#1) as shown in Figure 1.

Cutting Wheel (#33)

Spacer (#2)

Hex Screw (#1)

Hex Wrench (#31)

Figure 1 — Inserting the Hex Wrench

ITEM # DESCRIPTION

N/A HighSpeed Cutter

32 Spanner

31 HexWrench

CAUTION

Use only 3" Cutting

Wheels rated for more

than 18,000 RPM.

Page #4 -- SKU: 05490

Step 4:Hold the SPANNER and turn the HEX WRENCH counterclockwise to loosen the HEX

SCREW. Remove the HEX SCREW and SPACER (#2) as shown in Figure 2.

CAUTION

Do Not brace the SPANNER

against the PROTECTOR

GUARD while loosening or

tightening the HEX SCREW.

Spacer (#2)

Hex Screw (#1)

Hex Wrench (#31)

Spanner (#32)

Spindle (#6)

Cutting Wheel (#33)

High Speed Cutter

L

o

o

s

e

n

Step 5:Remove the CUTTING WHEEL and replace with a new one.

Figure 2 — Replacing the Cutting Wheel

Page #5 -- SKU: 05490

Step 6:Insert the HEX SCREW through the SPACER and thread into the SPINDLE as shown in

Figure3.

Hex Screw (#1)

Spacer (#2)

High Speed Cutter

Cutting Wheel (#33)

Figure 3 — Reassembling Cutting Wheel

Step 7:Place the SPANNER on the flats of the SPINDLE.

Step 8:Hold the SPANNER and firmly tighten the HEX SCREW with the HEX WRENCH.

Step 9:You will need a union fitting (sold separately) before you can connect your High Speed

Cutter to an air compressor.

Step 10:Attach anAir Coupler (sold separately) to the Union fitting if desired. This is a useful

accessory as it allows quick-coupling action when using a variety of tools with the same

air compressor.

Step 11:Your High Speed Cutter is ready for use.

Page #6 -- SKU: 05490

OPERATION

Setup

Frequent, but not excessive, lubrication is required for best performance. Oil added through the

airline connection will lubricate internal parts. An automatic airline oiler is recommended but oil

may be added manually before every operation or after about 1 hour of continuous use. Only a

few drops of oil at a time are necessary. Too much oil will collect inside the tool and be blown

out during the exhaust cycle. ONLY USE PNEUMATIC TOOL OIL. Do not use detergent oil or

additives as these lubricants will cause accelerated wear to the seals in the tool.

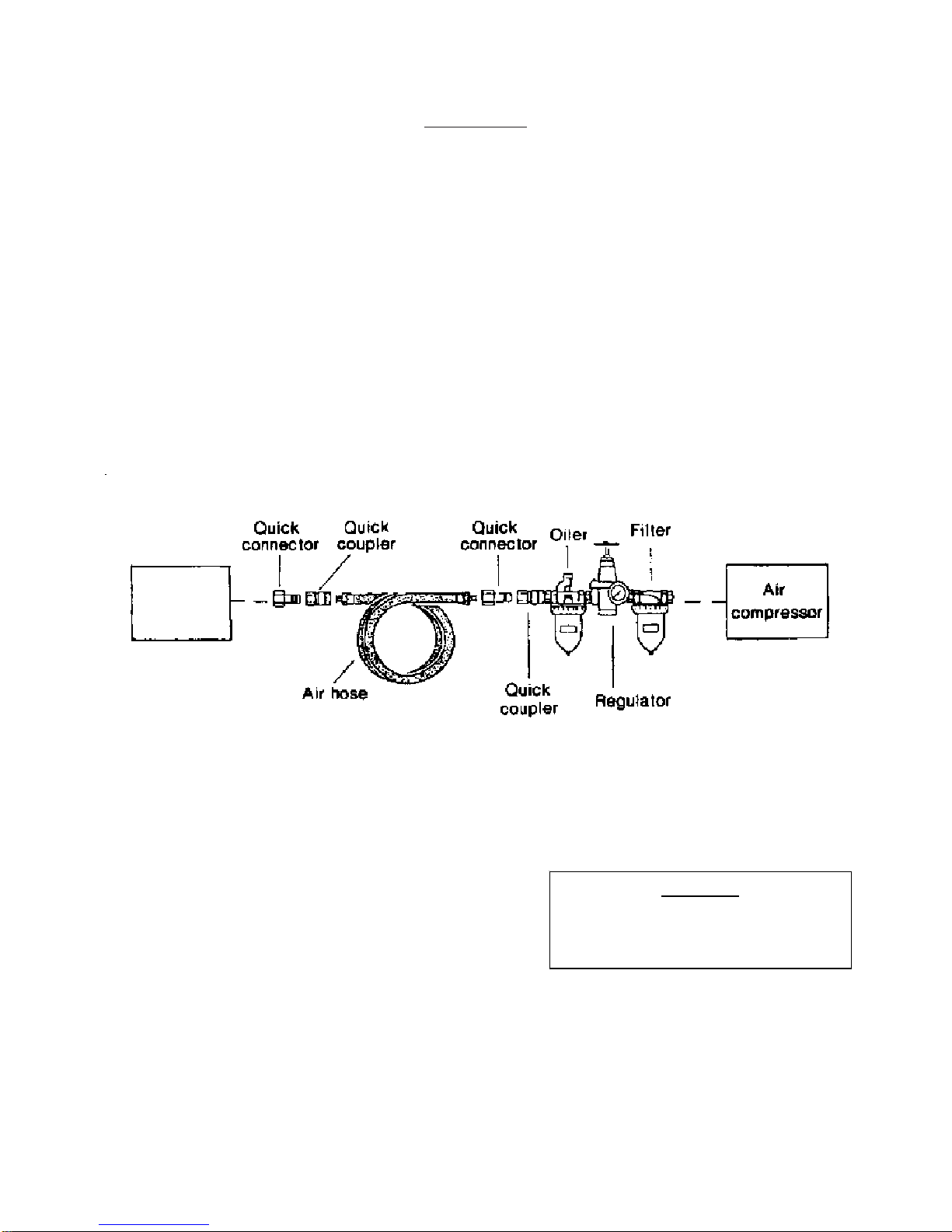

Dirt and water in the air supply are major causes of pneumatic tool wear. Use a filter/oiler for

better performance and longer life. The filter must have adequate flow capacity for the specific

application. Consult the manufacturer’s instructions for proper maintenance of your filter.

The connector on the tool must not hold pressure when the air supply is disconnected. If the

wrong fitting is used, the tool can remain charged with air after being disconnected and still be

able to drive a fastener. See Figure 4 for the recommended accessories and connection order.

High

Speed

Cutter

CAUTION

Always check CUTTING DISC for

possible wear. Never use a worn,

torn, or defective disc.

Use

Step 1:Check the CUTTING WHEEL for wear. Replace

if necessary.

Step 2:Set the compressor’s pressure regulator to 90

PSI. Do not set the compressor’s outlet regulator over

90PSI.

Step 3: Connect the High Speed Cutter to the air compressor’s hose. If leaking is detected,

disconnect the air hose and repair before use.

Figure 4 — Airline Oiler Assembly

Page #7 -- SKU: 05490

Warning: TheSafetyGuardmustalwaysbetightlysecured in place when using theAir

HighSpeedCutter. Keep hands offguardwhenoperatingthistool.

REV 02/04

Step 4:It is highly recommended that you wear protective gloves and eye protection when using

the High Speed Cutter.

Step 5:Place the material you will be cutting into a vise or otherwise secure material so that it

can not move while you are cutting. Mark the material

where you wish to cut it.

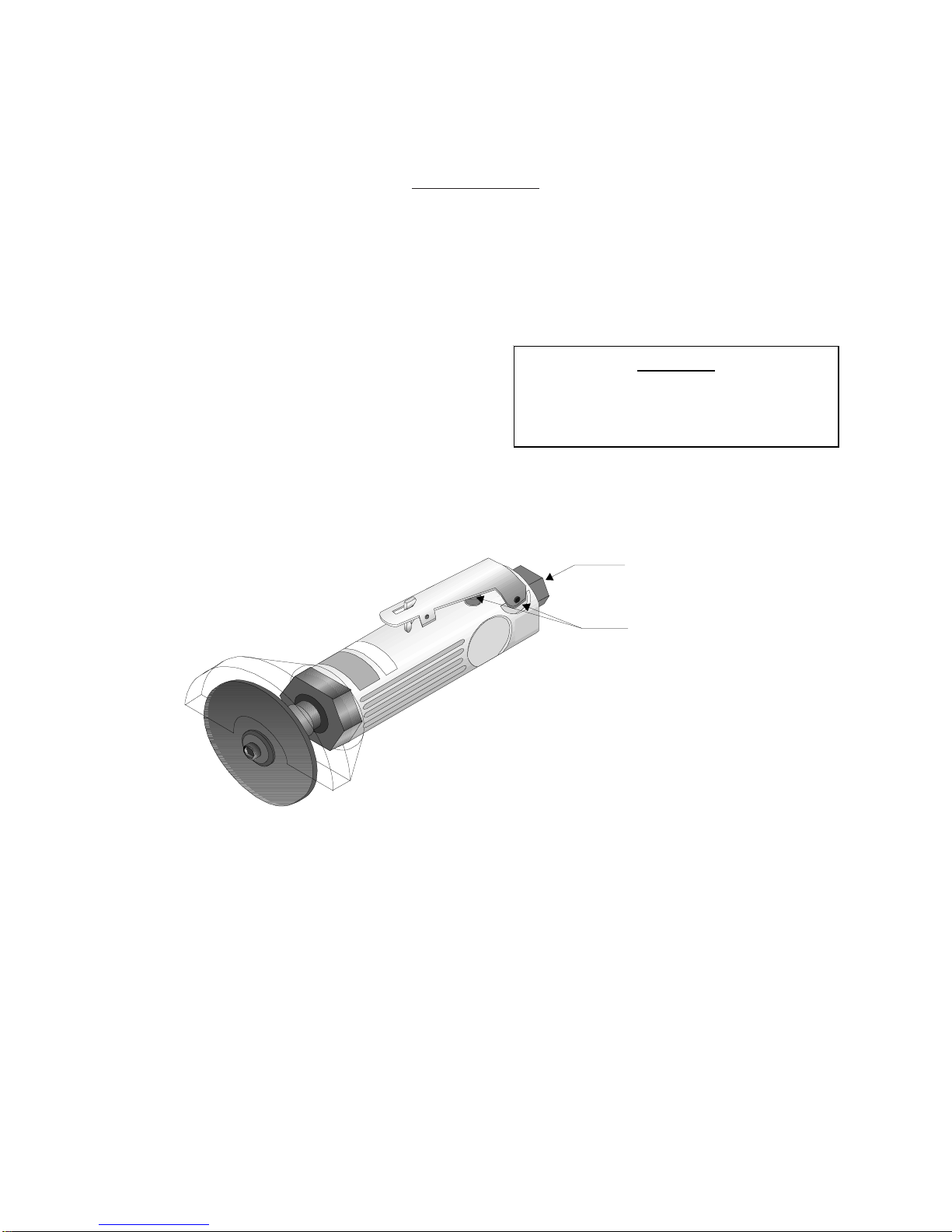

Step 6:Grip the High Speed Cutter so that your thumb

rests on the THROTTLE LEVER and Safety Latch. This

will keep the PROTECTOR GUARD properly oriented.

Step 7:Make sure the CUTTING WHEEL is not touching the cutting surface.

Step 8:Press the Safety Latch forward with your thumb as you press down on the THROTTLE

LEVER as shown in Figure 5.

Safety Latch

Throttle Lever (#26)

High Speed Cutter

Figure 5 — Operating the Safety Latch

Step 8:The High Speed Cutter’s cutting speed is variable between 5000 and 18,000 RPM. Vary

the pressure placed on the THROTTLE LEVER to vary the speed. Use only enough speed as

needed to cut through the material.

Step 9:Place the edge of the CUTTING WHEEL onto the surface to be cut.

Step 10:Keep a steady pressure on the High Speed Cutter as it cuts, but do not force the

CUTTING WHEEL as you will stall the High Speed Cutter. Use only enough pressure to keep

the CUTTING WHEEL moving through the material.

WARNING

Do Not place hands, hair, or

loose clothing near the CUTTING

WHEEL while using the High

Speed Cutter.

Page #8 -- SKU: 05490

Step 11:When you are finished with the High Speed Cutter, release all pressure on the

THROTTLE LEVER to stop the CUTTING WHEEL.

MAINTENANCE

Your High Speed Cutter is best operated with anAirline Oiler. If you are using the High Speed

Cutter without anAirline Oiler, follow the steps below for maintenance.

Step 1: Disconnect the High Speed Cutter from the air hose.

Step 2:Apply a few drops of PNEUMATIC TOOL OIL through the air line before each use, or

every hour if used continuously.

Step 3:Apply a few drops of oil to the THROTTLE

LEVER (#26) as shown in Figure 6. Work the

THROTTLE LEVER a few times to lubricate.

Air Line

Throttle Lever

Figure 6 — Lubrication Points

Step 4:Check the condition of the CUTTING WHEEL. Replace if necessary.

Step 5: Wipe off the High Speed Cutter. Pay special attention to cleaning the PROTECTOR

GUARD in order to be able to see your work when you cut.

CAUTION

Do not use detergent oil or additives as

these lubricants will cause accelerated

wear to the seals in the tool.

Page #9 -- SKU: 05490

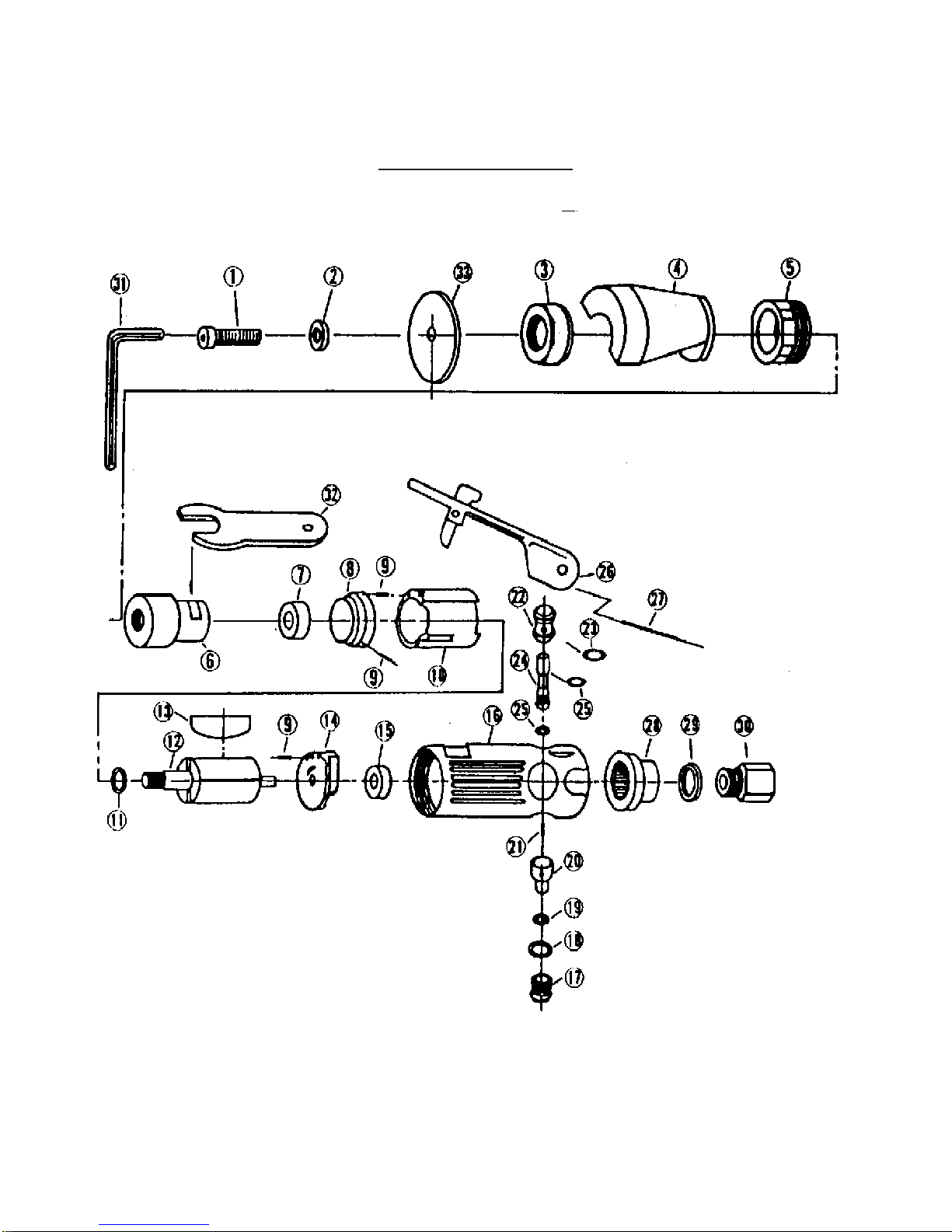

PARTS LIST

Item# Description Qty Item# Description Qty

1 Hex Screw 1 18 Valve Screw “O” Ring 1

2 Spacer 1 19 Regulator “O” Ring 1

3 Lock Nut 1 20 Air Regulator 1

4 Protector Guard 1 21 ThrottleValve Spring 1

5 Lock Nut 1 22 ThrottleValve Bushing 1

6 Spindle 1 23 Valve Bushing “O” Ring 1

7 Front Rotor Ball Bearing 1 24 ThrottleValve 1

8 Front End Plate 1 25 Throttle Valve “O” Ring 2

9 Roll Pin 3 26 Throttle Lever with Safety Latch 1

10 Cylinder 1 27 Throttle Lever Pin 1

11 Rotor Collar 1 28 Exhaust Deflector 1

12 Rotor 1 29 Inlet Bushing “O” Ring 1

13 Rotor Blade 4 30 Air InletBushing 1

14 Rear End Plate 1 31 Hex Wrench 1

15 Rear End Ball Bearing 1 32 Spanner 1

16 MotorHousing 1 33 Cutting Wheel 1

17 Valve Screw 1

Page #10 -- SKU: 05490

ASSEMBLYDIAGRAM

Page #11 -- SKU: 05490

Table of contents

Other Central Pneumatic Cutter manuals

Popular Cutter manuals by other brands

Bosch

Bosch GWS 18V-180 P Professional Original instructions

Ripley

Ripley Cablematic QCST Series manual

Scheppach

Scheppach FS3600 Translation from the original manual

Makita

Makita PC01 instruction manual

ESAB

ESAB Precision Plasmarc Installation, operation and maintenance manual

EINHELL

EINHELL TE-TC 620 U Original operating instructions