Shannon HRP 220 User manual

User’s Guide

English

Plastic bending machine

HRP 220

User’s Guide

HRP 220

-1-

HS

User’s Guide

Plastic bending

machine

HRP 220

1995 SHANNON BV. All rights reserved.

No part of this User's Guide may be photocopied, altered

or translated without prior written consent.

Information contained in this User's Guide is subject

to change without notice.

User’s Guide

HRP 220

-2-

HS

Contents

Contents 2

Introduction 4

1 Description of the machine 5

2 Technical data 6

3 Safety instructions 7

4 Safety devices 9

4.1 Ribbon switch 9

4.2 Emergency stop 9

4.3Air pressure monitoring 9

5 Legend 10

5.1 Overview 10

5.2 Switch unit 11

5.3 Timer unit 11

5.4 Control unit 12

6 Installation 13

6.1 Assembly 13

6.2 Connecting compressed air 13

6.3 Connecting power cable 13

6.4Connecting foot switch 13

7 Operation 14

7.1 Preparation 14

7.2 Switching on control units 14

7.3 Switching on top frame 14

7.4 Switching on heating elements 15

7.5 Setting temperature 15

7.6 Trouble shooting 16

7.7 Setting cycle time 15

7.8 Hand or foot operation 16

7.9 Setting air pressure 16

7.10Resetting ribbon switch 16

8 Adjustment 17

8.1 Safety measures 17

8.2 Lower heating element 17

8.3 Upper heating element and pressure bar 19

8.4Lower filament height 19

8.5 Upper filament height 20

8.6Stop 21

User’s Guide

HRP 220

-3-

HS

Contents

9 Alterations 22

9.1 Safety measures 22

9.2 Lower heating element 22

9.2.1 Removal 22

9.2.2 Installation/replacement 23

9.3 Upper heating element and pressure bar 25

9.3.1 Removal 25

9.3.2 Installation 26

10 Maintenance 27

10.1 Safety measures 27

10.2 Lubrication points 27

10.2.1 Cylinder bearing: bottom 27

10.2.2 Cylinder bearing: top 27

10.2.3 Bearing blocks 28

10.3 Profiles 28

10.4 Water separator 28

10.4.1 Checking 28

10.4.2 Emptying 29

11 Trouble shooting 30

12 Installation and removal of units 31

12.1Safety measures 31

12.2 Control unit 31

12.2.1 Removal 31

12.2.2 Installation 32

12.3 Timer/switch unit 33

12.4 Main switch box 33

12.4.1 Removal 33

12.4.2 Installation 34

13 Tensioning and changing filament 35

13.1Safety measures 35

13.2 Tensioning 35

13.3 Changing 36

14 Fuse 38

14.1 Safety measures 38

14.2 Control unit fuse 38

14.3 Restoring circuit breaker 39

14.4 Main switch box fuse 39

Annexes 40

A Machine summary 40

B Diagram control unit 41

C Diagram timer unit 42

D Diagram switch unit 43

E Diagram pneumatic system 44

F Dimensions 45

G Options 46

Accessories 47

Equipment 47

H Service and warranty 49

User’s Guide

HRP 220

-4-

HS

Introduction

Congratulations on purchasing the Shannon HRP 220 plastic

bending-machine.

Read this Guide completely before installing and using the

machine.

We want to keep in contact and to know how you find the HRP

220. We are always willing to advise on the use of the machine

and its accessories.

SHANNON BV

Turfschipper 11-13

2292 JC Wateringen

P.O. box 84

2290 AB Wateringen

The Netherlands (EC)

Tel: +31 (0)174-225 240

Fax: +31 (0)174-225 249

Website: www.shannon.nl

User’s Guide

HRP 220

-5-

HS

Description of the machine

The Shannon HRP plastic bending-machine is a rapidly

convertible semi-automatic machine for the production of large

series of items with multiple bends for the plastic sheet

processing industry.

The machine has four adjustable heating elements as

standard, the temperature of which can be adjusted by

electronic controls.

The filaments of the heating elements on the working

surface are adjustable in height. The other elements, which

are mounted in the pneumatically operated top frame which

clamps the workpiece in place, are adjustable in height as a

single unit in respect of the working surface.

The workpiece can be heated from two sides, considerably

reducing the production cycle time and making it possible to

bend sheet up to 20 mm thickness.

The top frame is switched on independently of the control

units and is controlled by an adjustable timer.

The working surface is made of scratch-resistant solid core

material with which the space between the zones to be

heated can be filled to support the plastic sheet.

The machine has facilities for the mounting of additional

heating elements at both top and bottom. The elements can

be mounted by the user.

When heated, thermoplastics become so flexible that they can

be shaped. When a plastic sheet is heated to its softening point

in a narrow zone, if can be bent to any angle desired.

The bending radius is determined by the width of the heated

zone. The zone is determined by the thickness of the material,

the type of heating element and the distance between the

plastic and the filament.

Every plastic has its specific softening point. By co-ordinating

the temperature, heated zone and heating time all kinds of

thermoplastic can be processed.

1

User’s Guide

HRP 220

-6-

HS

Technical Data

model

HRP 220 Standard

Assembly

control

4 (max. 8)

lower heating element

2 (max. 4), fitted with single filament

upper heating element

2 (max. 4), fitted with single filament

pressure bar

2 (max. 4)

options

see Annex G

Electrical

voltage

power

fuse

timer unit

24 V=

15 VA

100mAT

switch unit

380/220 V~

20 VA

250 mAT

control unit

220/240 V~

1000 VA

5 AT

max. power requirement

8.000 VA

circuit breaker

3x16 A

connection

CEE 4 32A 3P+0+A

network connection

CEE 4 32A 3P+0+A

Network ciruitbreaker

Min 3x16 A

filament

0-30 V, 0-19 A ~

diagram

see Annex B, C and D

Pneumatic

air

Unlubricated clean dry air

maximum

8 bar

minimum

3.5 bar

working pressure

6 bar

coupling

Festo quick action coupling

air consumption

21.6 Nl per cycle at 6 Bar

diagram

see Annex E

Mechanical

speed of top frame

rad/s (20cm/s at front)

response time ribbon switch

100 ms

force on plastic

approx. 3.5 kg/cm²

gradation of stop

0-1000 mm

dimensions

2590x1300x1092 mm (lxwxh) see Annex F

weight

650 Kg

life of filament

approx. 600 hours

Functional

bending width

2200 mm

mutually extendible

1000 mm (max.)

sheet thickness

1 - 20 mm (depending on heating element)

setting range timer

0-9999 sec

temperature range filament

20-600 C

filament height adjustment

bottom

1 - 17.5 mm

top

7 - 26 mm

Ambient

temperature

18-30 C

humidity of the air

50-80 % (no condensed)

Miscellaneous

set of socket screw keys

2, 3, 5, 6mm 1 x

spare fuse

5x20mm 250 mAT 1 x

spare fuse

6.3x32 5 AT 4 x

spare filament

1.6 x 2350 mm 4 x

2

User’s Guide

HRP 220

-7-

HS

Safety instructions

SAFETY INSTRUCTIONS:

To ensure safety when using the machine you should read this

User's Guide carefully and follow the safety instructions closely.

Attention!

The machine contains a section where there is a risk of

trapping.

Attention!

The machine contains parts which are hot. Touching them will

cause burns.

Allow hot parts to cool sufficiently (at least 10 minutes) before

touching them.

Never touch the filaments or the reflectors when the machine

is in operation.

Always wear close-fitting clothing.

Be particularly careful of sleeves and always tie back long hair.

Never leave objects on the working surface.

The machine may only be used for heating narrow zones in flat

plastic sheet.

Any other use could lead to very hazardous situations or cause

damage to the machine!

The plastic sheet to be bent should never be more than 20 mm

thick.

3

User’s Guide

HRP 220

-8-

HS

Safety instructions 3

Before commissioning and servicing always check the

connection cable and plug for defects.

When servicing switch off the machine and remove the plug

from the socket.

When the machine is temporarily out of use always remove

the foot switch and keep it in a safe place.

Before use always check that all the pressure bars and heating

elements in the top frame are firmly attached.

Only switch on those heating elements which are needed.

Never operate the machine if anyone is standing close behind

or beside it.

Never introduce objects or material into the machine from the

rear.

Never leave the machine unattended without switching it off.

User’s Guide

HRP 220

-9-

HS

Safety devices

The machine is equipped with the following safety devices:

4.1 RIBBON SWITCH

When the ribbon switch is touched the power on the top frame

is interrupted and the machine opens. This avoids limbs

becoming trapped. The red lamp (J) on the timer unit lights and

the timer (K) is returned to zero (see also § 5.3.) The timer unit

must be reset after a stop.

4.2 EMERGENCY STOP

There is an emergency stop button at the front of the machine

on the left and right, which can be reached by the operator

from the normal working position. The pedal switch has also an

emergency stop function, when it is pushed in completely. By

using the emergency steps the electrical power of the

regulating units, will be disconnected and the top frame lifts up.

(see also § 5.2)

Only use the emergency stop buttons in the following

situations:

Risk of trapped limbs.

Defects in the timer, so the machine fails to open after the

pre-set time.

An outbreak of fire or situations involving a risk of fire.

Any situation which might present a risk to people or

animals.

Any other situation, which might present a risk or cause,

damage to the machine and/or objects.

When the emergency situation has been remedied, the

emergency stop button must be reset and the various functions

switched on again individually.

Pulling it out until a click is heard resets the emergency stop

button. Pushing the blue button, which is mounted, on the

pedal switch will reset the food pedal.

4.3 AIR PRESSURE MONITORING

The machine switches off if the air pressure fails.

The lamp in the main switch Aremains alight.

When the pressure is restored the top frame lifts up again. The

machine must then be started up again.

4

Reset

User’s Guide

HRP 220

-10-

HS

Legend

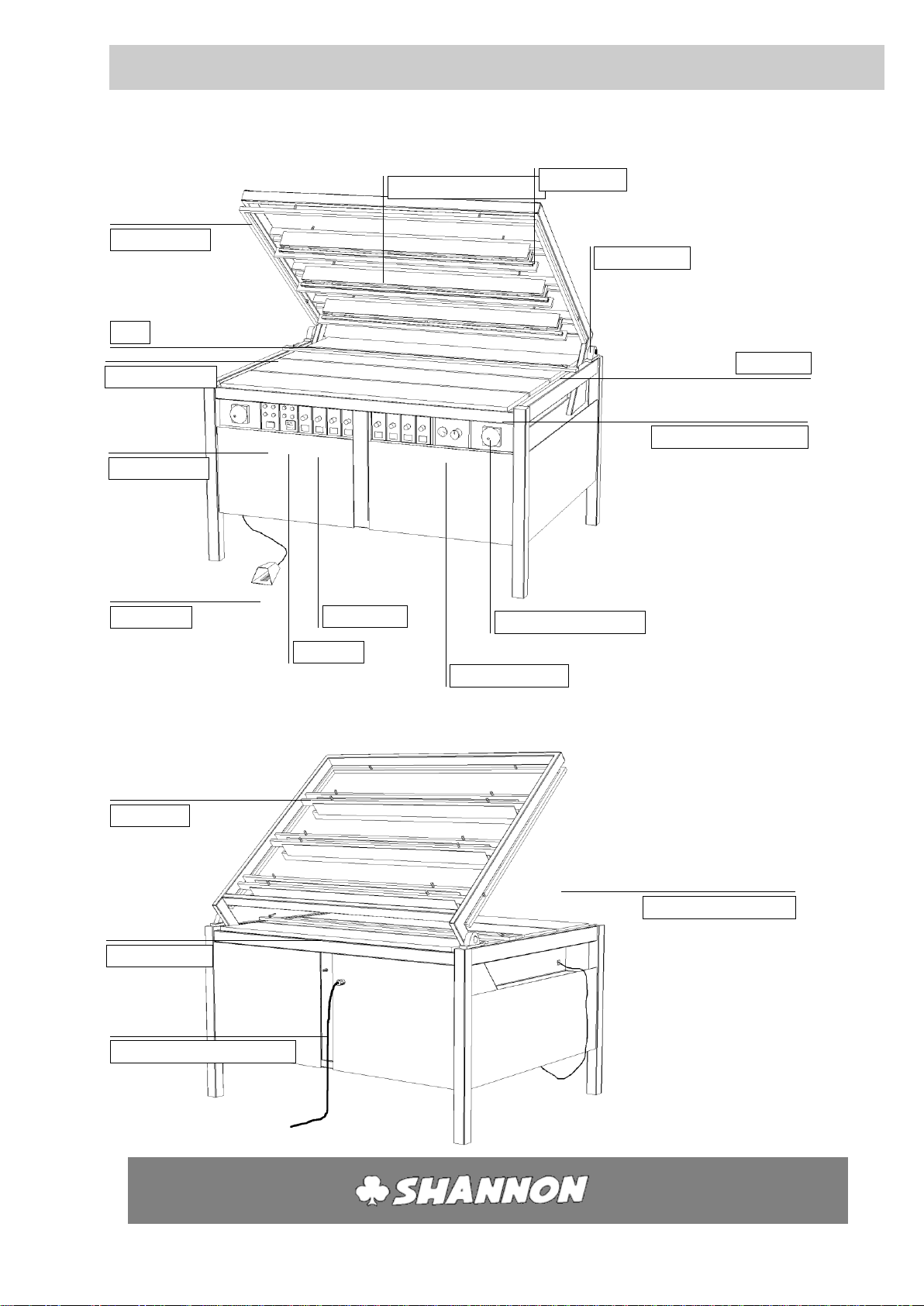

5.1 OVERVIEW

5

Front

Rear

Top frame

Upper heating element

Pressure bar

Ribbon switch

Stop

Gradation

Emergency stop button

Foot switch

Switch unit

Timer unit

Control unit

Pressure regulator

Bearing block

Lower heating element

Working surface

Foot switch connection

Air connection

Power supply cable

connection

User’s Guide

HRP 220

-11-

HS

Legend 5

5.2 SWITCH UNIT

This contains the main switch (A) of the machine and the push

button switches to start the heating and the top frame.

AMain switch.

heating

BSwitch on control units (also reset button for emergency stop).

CSwitch off control units.

top frame

DSwitch on top frame.

ESwitch off top frame.

5.3 AIR/TIMER UNIT

The timer unit is the combined unit for operation of the top

frame (Gand H), Operating the buzzer (Iand J) and setting the

cycle time (K). When the foot or push-button (H) switch is

operated, the machine closes. The counter begins to run when

the machine is fully closed, afterwards the switch can be

released. At the end of the pre-set time, the top frame opens

and the buzzer (J) makes a whistling sound for a few seconds.

This sound can be turned off by switch (I). The counter is then

returned to 0.

FSelector switch foot/hand operation.

GTop frame up.

HTop frame down.

IBuzzer on/off.

JBuzzer.

K Electronic timer.

B

C

A

D

E

User’s Guide

HRP 220

-12-

HS

Legend 5

5.4 CONTROL UNITS

The control unit contains an electronic control with which the

temperature of a filament is set.

L Switch on/off (green lamp).

M Temperature adjustment

NConnection to filaments

OConnection to 220V ACL

PFuse

N

O

P

L

M

User’s Guide

HRP 220

-13-

HS

Installation

6.1 ASSEMBLY

1. Remove packaging and blocking of top frame.

2. Place the machine on a level floor with sufficient space

around and above the machine.

3. Level the working surface of the machine, using shims

under the feet if necessary.

4. Ensure there is adequate ventilation and lighting at the

workplace.

5. Avoid draughts, in order to prevent uneven heating.

When moving the machine with a forklift truck ensure that the

machine is supported right in the centre.

Also use sufficiently long prongs on the forklift truck.

6.2 CONNECTING COMPRESSED AIR

1. Check that all heating elements and pressure bars in the

top frame are firmly attached.

2. Check the air pressure in your system (max. 8 bar).

3. Close the reducing valve on the air unit (turn to the left).

Unlock if necessary (pull out).

4. Using a quick-action coupling connect the rear of the

machine to your compressed air system or compressor.

5. Slowly open the reducing valve (turn to the right) and set

the air pressure in the system at 6 bar (see 7.8, page 16).

6.3 CONNECTING POWER CABLE

1. Check that the rating of the electrical system is adequate

(see technical data).

2. Check that the main switch Ais in the -position.

3. Plug in the machine.

6.4 CONNECTING FOOT SWITCH

1. Insert the plug of the foot switch into the connection on

the side of the machine. The plug will click into place.

N.B. To remove the foot switch the small stop above the

plug must be pressed.

6

25cm

User’s Guide

HRP 220

-14-

HS

Operation

7.1 PREPARATION

1. Check that the air pressure is set at 6 Bar (see 7.8, page

16).

2. Clear the working surface.

3. Check that all the heating elements are connected to the

control units.

4. Check that no scraps of material remain in the reflectors.

5. Check that all the upper heating elements and pressure

bars are firmly attached to the top frame.

6. Turn the potentiometers in the control units to "0".

7. Switch off all the control units (position "").

8. Turn on the main switch A(position I).

The red lamp in switch Cwill light.

The yellow lamp in switch Ewill light.

If switch F is set to Hand Operation, the yellow lamp in

switch Hwill light.

7.2 SWITCHING ON CONTROL UNITS

The power supply to the control units must be switched on

separately.

1. Press switch B.

The red lamp in switch Cwill go out..

The green lamp in switch Bwill light.

The control units are now ready for use!

7.3 SWITCHING ON TOP FRAME

The top frame is switched on separately. The safety system

with the ribbon switch must then be released.

1. Press switch D.

The yellow lamp in switch Ewill go out.

The green lamp in switch Dwill light.

7

User’s Guide

HRP 220

-15-

HS

Operation 7

7.4 SWITCHING ON HEATING ELEMENTS

Each heating element can be switched on and controlled

individually.

Switch on the desired control unit with switch (L). See 5.4.

7.5 SETTING THE TEMPERATURE

The temperature of the filament can be set using the

temperature regulator.

1. When turning on the on/off switch, the display will show the

value that was last saved (keeping the machine on a certain

value for >20 seconds will make it remember this value).

2. Press the right button (arrow up) to increase the value, up to

99 (keeping this pressed in will make the value cycle much

faster)

3. Press the left button (arrow down) to decrease the value,

down to 00 (keeping this pressed in will make the value cycle

much faster)

4. Press both buttons at the same time to go directly to 00.

Doing this also resets the machine.

7.6 TROUBLE SHOOTING

Error message

Meaning

Solution

E1

The wire is loose (not connected)

Turn off the machine, check the filament, and reset the

machine

(see §9.1 for changing filament)

Note: Between the values 00 and 04, this fault cannot be

detected

E2

The wire is loose (spark detection)

Check the connection of the filament

Check the filament, and reset the machine

This fault can also be reset by the arrow down button

(see §9.1 for changing filament)

E9

Broken circuit board

Contact the supplier for a new circuit board

Empty display

No power

Alert a maintenance engineer

Check the fuse (see §10.1)

Check the power supply cable

Contact the supplier if necessary

80

User’s Guide

HRP 220

-16-

HS

Operation 7

7.7 SETTING CYCLE TIME

The time during which the machine is closed to heat

the plastic sheet on two sides is set using the

electronical timer K.

7.8 HAND OR FOOT OPERATION

Select hand or foot operation using switch F.

Position 1: Hand operation.

The frame closes when switch His

pressed.

Position 2: Foot operation.

The frame closes when the foot pedal is pressed.

Press switch G(arrow up) to open the machine before the end

of the set time. The timer (K) is returned to 0.

7.9 SET AIR PRESSURE

Control the pressure in the system with reducing valve

M, which can be found on the water separator (see

10.4, page 28). The air pressure is set by the factory at 6

bar.

N.B. To right: valve open

To left: valve closed

press knob in: lock

pull knob out: unlock

Always lock the reducing valve when the air is being

disconnected from the machine.

7.10 RESET RIBBON SWITCH

When the ribbon switch is touched the machine opens

immediately. It is then impossible to close the machine with the

foot switch or pressure switch H. The red lamp Ewill light. Press

switch Dto start the machine again. The green lamp in switch D

will light.

M

User’s Guide

HRP 220

-17-

HS

Adjustment

8.1 SAFETY MEASURES

Always take the following safety measures before adjusting the

heating elements:

1. Switch off the foot switch by setting switch Fto hand

operation (page 11).

2. Ensure that the upper heating elements and pressure bars

is firmly attached.

3. Switch off the heating elements one at a time (Switch L).

4. Switch off the control units and top frame (Switches Cand

E, page 11).

5. Clear the working surface.

6. Allow the heating elements to cool for at least 10 minutes.

8.2 LOWER HEATING ELEMENT

1. Remove the strips of solid core material next to the

heating element to be adjusted by loosening the two

socket head screws. (Use socket screw key no. 5).

2. Loosen the socket head screws in the supporting prongs

on the left and right of the heating element one half turn.

8

10 minutes

2

Supporting prong

1

User’s Guide

HRP 220

-18-

HS

Adjustment 8

3. Loosen the socket head screw in the centre of the heating

element one half turn.

(Use socket screw key no. 3)

4. Take the heating element with both hands close to the

supporting prongs on the left and right and slide it into the

desired position.

Hold the heating element parallel to the front of the

machine and the supporting prongs. This prevents the

notched nuts in the aluminium X-profiles from binding.

5. Hand tighten the socket head screws, starting in the

supporting prongs and then in the centre.

6. Position the other profiles in the same way if necessary.

7. Fill up the space between the heating elements as far as

possible with solid core strips and hand tighten them. First

slide the notched nuts into the aluminium X-profile

roughly level with the holes and then lay the solid core

strip on top.

8. Switch on the machine again as in Section 7.

3

4

User’s Guide

HRP 220

-19-

HS

Adjustment 8

8.3 UPPER HEATING ELEMENT AND

PRESSURE BAR

1. Disconnect the compressed air.

The top frame will then slowly lower while air escapes.

The power is automatically switched off.

2. Loosen the socket head screws on the support bar clamps

one turn. (Use socket screw no. 6).

3. Take hold of the heating element at the sides, left and

right, and slide it into the desired position. Move the

support bar parallel to the front of the top frame, so that

you position the top filament above the bottom one.

4. Tighten the support bar clamps again.

5. Switch on the machine again as in Section 7.

The upper heating elements and pressure bars may fall out of

the top frame if they are loose or not properly attached.

8.4 LOWER FILAMENT HEIGHT

1. Adjust the height of the filament using the knurled nut.

These can be reached from the sides. Make sure that the

filament height is the same on both sides.

2. Start up the machine again as in Section 7.

Knurled nut

1

2

3

Support bar clamp

Table of contents

Other Shannon Cutter manuals

Shannon

Shannon HRT 65 User manual

Shannon

Shannon ABM-D 135 User manual

Shannon

Shannon HRT 220 User manual

Shannon

Shannon HRK 65 User manual

Shannon

Shannon HRP/S User manual

Shannon

Shannon AFF/D 135 User manual

Shannon

Shannon HRT/D 300 User manual

Shannon

Shannon HR 220-300 User manual

Shannon

Shannon HRP/D User manual

Popular Cutter manuals by other brands

EINHELL

EINHELL TE-TC 18/115 Li-Solo Original operating instructions

ARCBRO

ARCBRO Voyager Series user manual

Loepfe

Loepfe WeftMaster CUT-iT installation manual

Toolson

Toolson PRO-RF 620 Original operating instructions

Emerson

Emerson Klauke EK 60VPFTCFB manual

Meusburger

Meusburger GMT 6000 operating manual