Hardware & Networking requirements

Supported Hardware

•The Modbus TCP solution supports PAN10, PAN12 and PAN14 sensors only. PAN42 is not

supported.

•The Modbus TCP also support reading the bridge’s pulse inputs (Gen4 and above)

•The Modbus TCP solution is supported by every Gen3/Gen4/Gen4.5 bridge. Upgrading the

bridge firmware to the latest version (V.470 and above) is needed for the support of the

Modbus TCP interface.

•Each bridge supports up to 32 sensors in stand-alone mode

Supported LAN networks

To work in the Modbus TCP mode, the bridge has to be set-up for Ethernet or WiFi network

connectivity. A bridge configured for cellular network connectivity does not support Modbus TCP.

Assigning a fixed bridge IP address

For Modbus TCP to operate properly, the Modbus master must be able to repeatedly reach a

specific bridge via its IP address or DNS name. The solution requires a fixed IP address assigned for

the bridge. This can be done by selecting ‘fixed IP’ in the bridge network settings, or alternatively

using DHCP but ensuring that the DHCP server always assigns the same IP address to the specific

bridge.

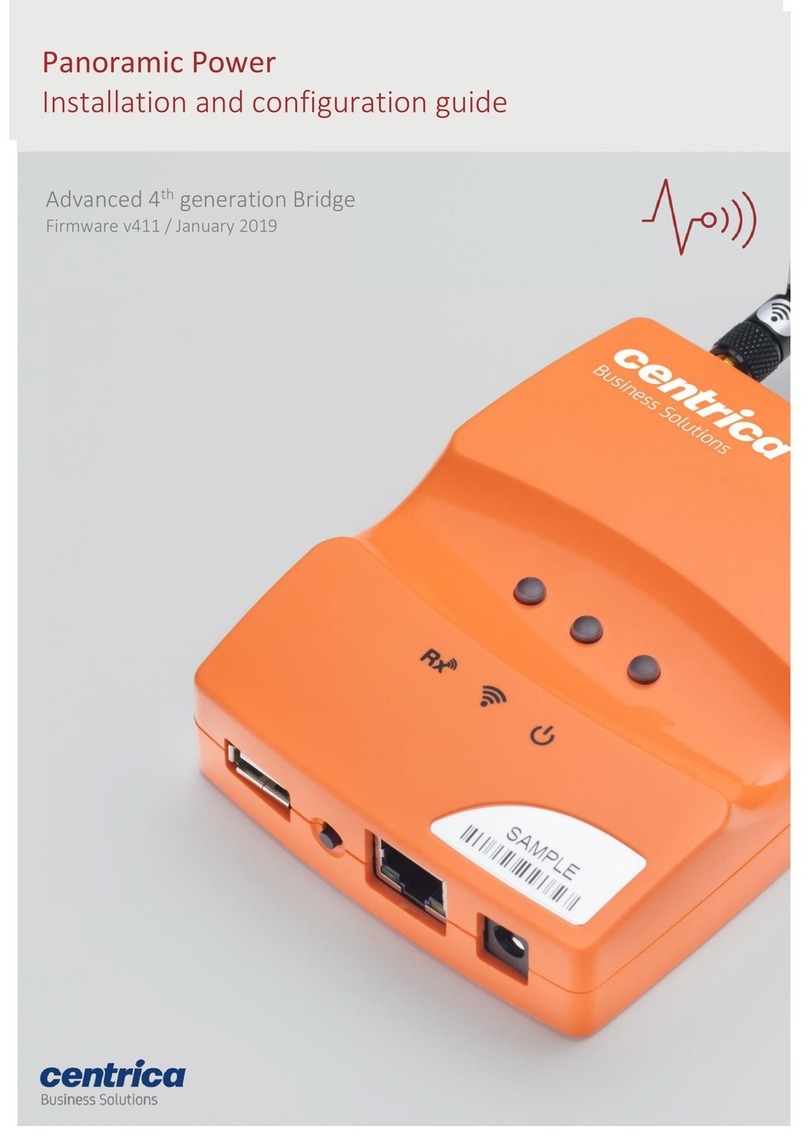

Please refer to the Gen 4 Bridge User Guide for more information about configuring the bridge

networking.

Bridge configuration

Bridge configuration is done from a laptop’s web browser using the bridge built-in web server.

Initial bridge configuration, including setting up a fixed IP address to be used later, is done via a

directly connected laptop. Please see ‘Accessing the bridge web interface’ section in the Gen 4

Bridge User Guide.

One a fixed IP has been assigned to the bridge; further configuration can be done by navigating to

the bridge IP address from a web browser. The laptop used for such configuration must have HTTP

route to the bridge.

NTP requirements

In order to operate properly the bridge needs to get the real time clock (RTC). Since the bridge has

no battery-powered hardware RTC, it gets the time using a standard NTP server.

The bridge gets the NTP time, as part of the boot process, using the following process:

1. If a dedicated NTP server IP is defined, it will try to get the time from that server

2. Alternatively, it will try to get the time from a list of well-known public NTP servers

3. If both options above fail it will get the time from PowerRadar.

Option 3 above only works in ‘PowerRadar connected mode’or ‘combined mode’ (See ‘Connection

Setup’ section below). Therefore, when working in ‘Stand-Alone Modbus TCP’mode an NTP server

must be defined in the LAN or alternatively, NTP outbound access to public servers must be

implemented in the firewall.