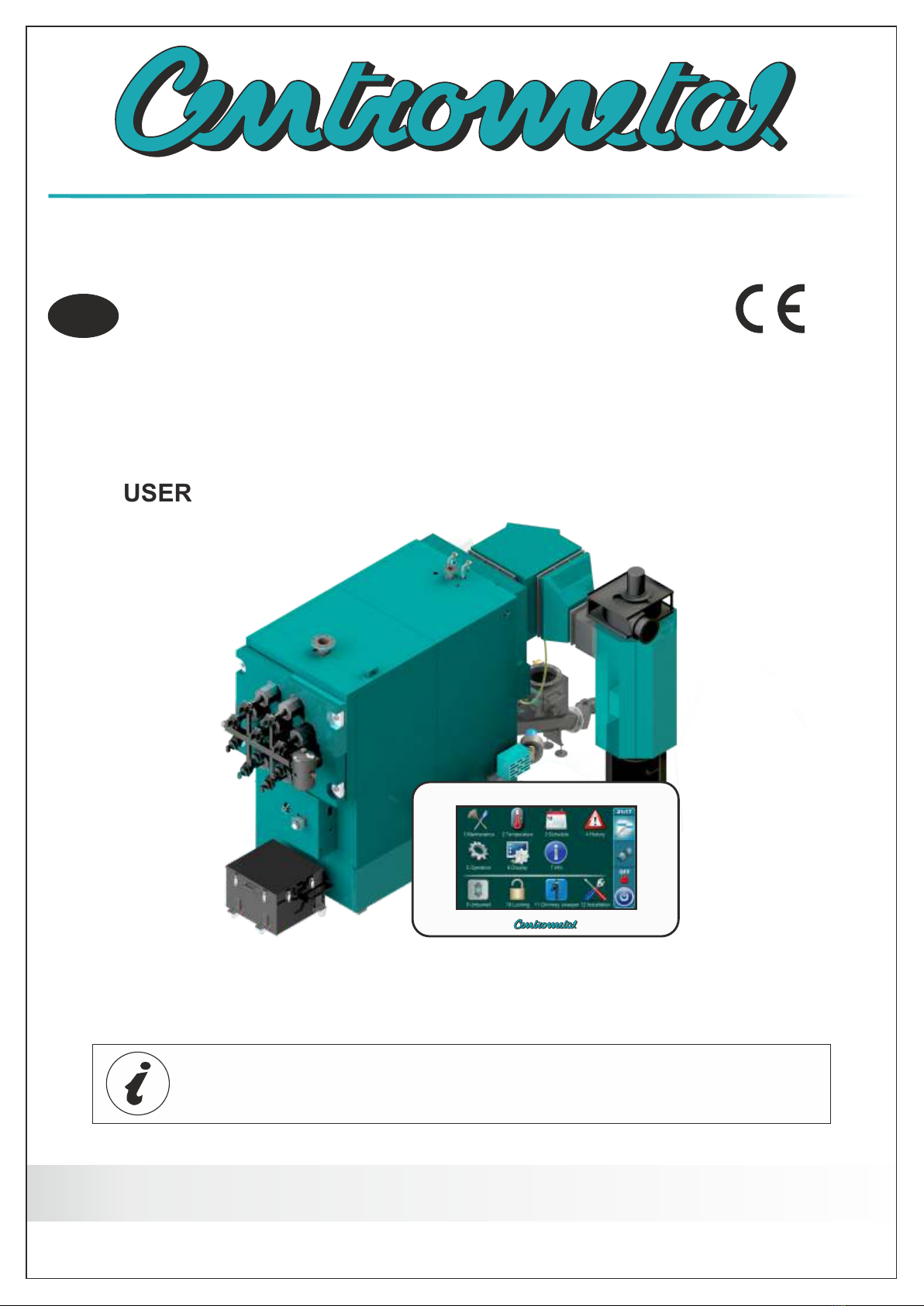

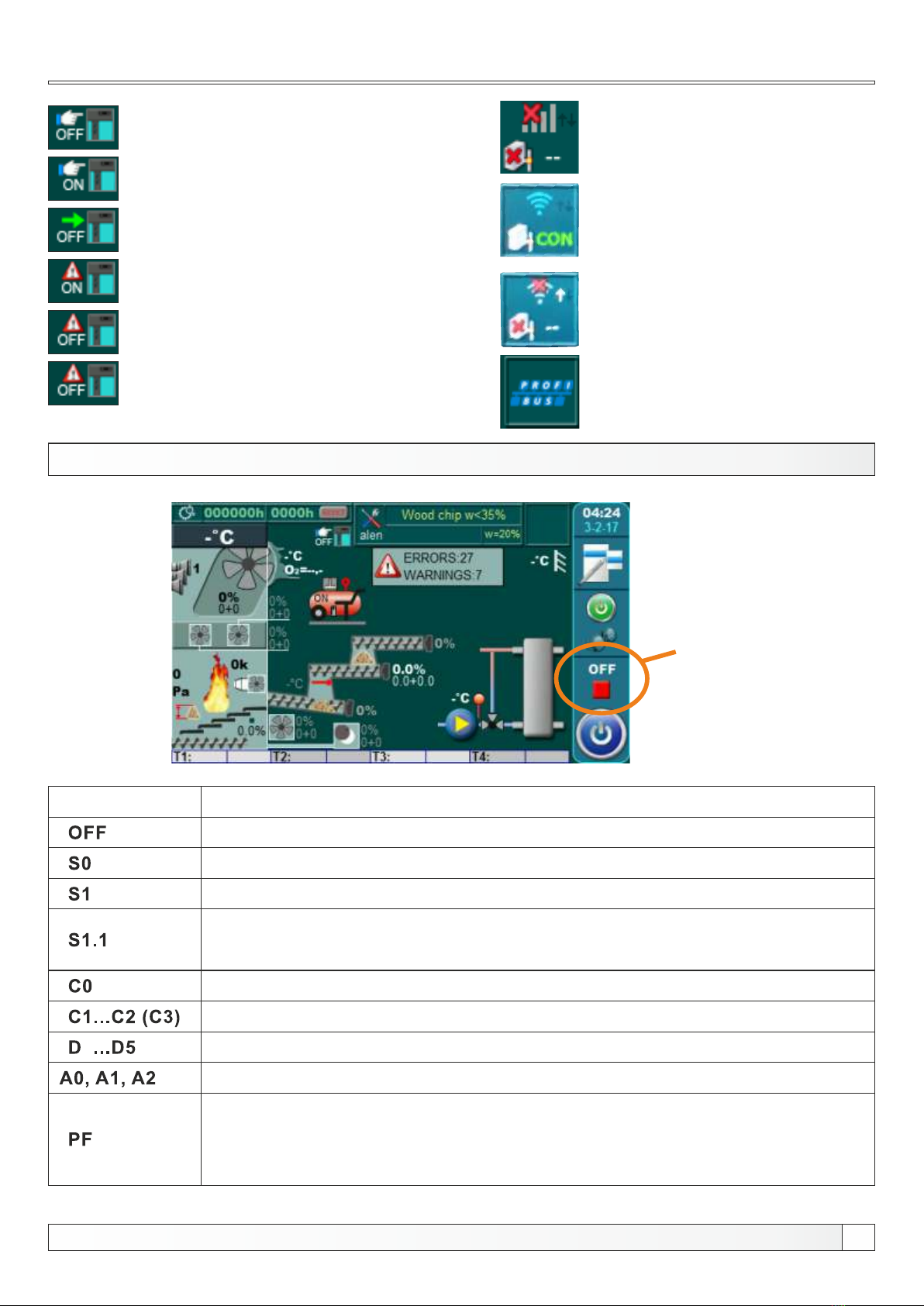

1 - Boiler temperature

2a - Working hours counter

2b - Working hours counter with

reset option

3 - Cyclone

4 - Pneumat (air cleaning)

5 - Flue gas temperatures

6 - Lambda probe

7 - Secondary air 1 fan

8 - Secondary air 2 fan

9 - Firebox pressure

10 - Photocell

11 - Conveyor 1 temperature

12 - Movable grate

13 - Primary air fan

14 - Primary air fan lid

15 - Conveyor 1

16 - Conveyor 2

17 - Conveyor 3

18 - Outdoor temperature

19 - Backfire protection lid

20 - This area depend about configuration

21 - Errors and warnings

22 - Choosen fuel

23 - Name of saved settings image

24a - Bunch with a blue angular arrow (The firebox flap

is raised to the height when the first microswitch is

pressed, the boiler conveyors (screw feeder) work

in a special mode).

24b - Bunch with a red angular arrow (The firebox flap

is raised to the height when the first and second

microswitches are pressed, the error "E119 -

FUEL TOO HIGH" is announced and the automatic

electrical fuses "DI" and "F2" eject in the el. boiler

cabinet. Conveyors (screw feeder) do not work.

25 - Compressor with showned status (off / on)

(if is installed - additional equipment)

26 - Network status (CM-GSM/WiFi) / Profibus

(if is installed - additional equipment)

27 - Alternative boiler status (if it exist)

28 - Ash transport - TP-3M/9M/3000L-Multi Plus

340-580 (only for Multi Plus 340/450/580)

(if is installed - additional equipment)

MAIN SCREEN

1

3

4

9

12

13 14

11

10

15

16

17

7

8

6

5

18

20

21

23 22

2a

25

2b

27

26

Main screen

24

28

Technical instructions REGULATION EKO-CKS Multi Plus 7

19