Centrometal HPe2/4CM User manual

Guidebook for installation, handling and maintenance –ENG

Electric heater HPe2/4CM

Electric heater for outdoor and indoor installation

FU-HPe2/4CM-10/2020

CONTENT

1. Description of symbols and instructions for safe work

2. Device data

2.1. Typology

2.2.1 Statement on compliance

2.2.2 Regular application

2.3 Instructions for mounting

2.4 Instructions for work

2.5 Anti-frost protection and inhibitors

2.6 Norms, regulations and standards

2.7 Tools, materials and auxiliary measures

2.8 Minimum distances and Inflammability of construction materials

2.9 Product description

2.10 Waste disposal

2.11 Scope of delivery

2.12 Factory data plate

2.13 Transport

3. Dimensions and technical data

3.1 Dimensions of HPe2/4CM

3.2 Components

3.3 Technical data of HPe2/4CM

4. Device installing

4.1 Warnings before mounting

4.2 Distances

4.3 Front door opening procedure for HPe2/4CM

4.4 Montage HPe2/4CM on wall

4.5 Execution of hydraulic connections

4.6.1 Installation filling with water and waterproof testing

4.6.2 Heating pump air emission and de-blocking

4.6.3 Venting and installations

5. Electrical connection

5.1 Connection of HPe2/4CM to three-phase mains

5.2 Connection of HPe2/4CM to mono-phase mains

5.3 Connecting the power cable - Safety circuit

5.4 Electrical schemes

6. Commissioning

6.1 Before commissioning

6.2 First start

6.3 Start-up log

7. Operating the electric heater

7.1 Operating instructions

8. Cleaning and maintenance

8.1 HPe2/4CM cleaning

8.2 Testing of working pressure, water replenishment and venting of the installation

8.3 Add the water and vent installation

8.4 Inspection and maintenance log

9. Environment protection / Waste disposal

10. Troubles and troubleshooting

11. Product data sheet (in accordance with EU regulation no. 811/2013)

Description of symbols and instructions for safe work

1. Objašnjenje simbola iuputstva za siguran rad

1.1 Description of symbols

Warnings

Warnings in text are marked by gray triangle,

background warnings are framed

Electric shock danger is marked by lightning

symbol in warning triangle

The signal words at the beginning of the warning mean the

way and level of consequences if protective measures are

not applied

NOTE means that smaller material damages may occur

CAUTION means that smaller to middle injuries may occur

WARNING means that heavy injuries may occur

DANGER means that heavy injuries may occur

Important information

Important information, meaning no danger for people and

things, are marked by the symbol displayed in the following text.

These are limited by lines, above and below the text.

Further symbols

Symbol

Meaning

Action step

Directives to other places in document or to other

documents

.

•

Enumeration/Entry from the list

–

Enumeration/Entry from the list (2.)

Table 1: Symbols

1.2 Instructions for safe work

General safety instructions

Non-compliance with safety instructions may cause heavy

injuries –or lethal outcomes and material damages and

environment pollution.

Electrical installation should be examined by an expert

prior to the device assembly.

All electric works should be performed by authorised

person in accordance with corresponding regulations.

Commissioning and maintenance and repairs should be

done by authorised service only.

Technical acceptance of installations should be performed

in accordance with corresponding regulations.

Danger because of disrespecting security rules in alert

situations, for example fire.

Never expose your-self to life danger. Own security

always has priority.

Damage occurred because of wrong handling

Wrong handling may lead to injuries of persons and/or

installation damage.

Make sure that device is available only to professionals.

Installation and commissioning, and maintenance and

repair, must be done only by service authorised for

electrical works.

Installation and commissioning

Placement of device can be done only by authorised

service.

Boiler can be turned on only if installation is with

corresponding pressure level and working pressure

regular. Do not close security valves in order to avoid

damage caused by too high pressure. During warming

water can leak on security valve of the hot water circuit

and hot water pipes.

Install this device only in the room where freezing is not

possible to occur.

Do not store or dispose inflammable materials or liquids in

the vicinity of this device.

Keep safe distance in accordance with valid regulations.

Life threat of electric power shock

Secure electric power connecting is done by authorised

service! Comply with connecting scheme

Prior to any work: turn off electric power supply. Secure

against accidental turn on

Do not mount this device in moist rooms.

Control examination /Maintenance

Recommendation for user: conclude agreement on

maintenance with authorised service to perform annual

maintenance and controlling examinations

User is responsible for safety and environmental acceptance

of the installation

Comply with safety work instruction as given in the chapter

Cleaning and Maintenance.

Authentic spare parts

There shall not be undertaken any responsibility for damage

occurred due to spare parts not delivered by the

manufacturer

Use onlyoriginal spare parts.

Material damages due to freezing

When there is damage due to freezing drain water from the

boiler, tank and pipelines for heating. Danger of freezing does

not exist only when entire installation is dry.

Instructions for service

Inform users about mode of work of device and instruct them

in maintenance

Inform users not to perform any modifications or repair on

their own

Warn users that children cannot stay near heating

installations

Fill in and submit Commissioning log and Handover log

attached in this document

Deliver technical documentation to the user.

Waste disposal

Dispose packaging materials in ecologically Acceptable

manner

Secure device in ecologically acceptable manner and in

authorised place

Cleaning

Clean outside of device with wet cloth.

Device data

2. Device data

These instructions contain important information about safe

and professional assembly, commissioning and

maintenance of the boiler.

These instructions are for installers who have knowledge for

work with heating installations due to their professionalism

and experience.

2.4 Instructions for work

When working with heating installation follow next

instructions:

Boiler should work in working range up to max

temperature of 80°C and min pressure of 0.7 bars to max

pressure of 2.6 bars, which should be controlled on

regular basis.

2.1 Typology

These instructions are related to the following kind of device:

HPe2/4CM

6 kW

2.2.1 Statement on compliances

We hereby state that devices are tested in accordance with

the following directives: 2014/35/EU (low voltage directive,

LVD) and 2014/30/EU (electro-magnetic compatibility

directive, EMC).

2.2.2 Regular application

HPe2/4CM may only be used in conjunction with a heat

pump, as a supplementary heat source controlled via a

heat pump. Any other use will be considered improper

and the manufacturer assumes no responsibility for

damage caused by improper use.

To ensure proper use, it is necessary to follow the operating

instructions, data on the nameplate and technical data.

Boiler should be handled only by adults who are familiar with

instructions and work of the boiler

Do not close safety valve

Inflammatory objects must not be put on the boiler surface

or close to it (within safety distance)

Boiler surface clean only with non-inflammatory products

Inflammatory substances do not keep in the room for

boiler installation (e.g. petroleum, oil, etc.)

During the work no one lid must be open

Keep safe distance in accordance with regulations

2.5 Inhibitors and anti-frost products

It is not allowed to use protective products against frost

neither inhibitors. Id it is not possible to avoid anti-frost

protection then should use anti-frost products allowed for

heating installations.

Anti-frost products:

Reduce lifetime of the boiler and its parts

Reduce heat transmission

2.3

Instructions for mounting

Use only original spare parts of the manufacturer or

spare parts approved by the manufacturer. There

shall not be any responsibility for damages caused by

spare parts which have not been delivered by the

manufacturer.

When mounting heating installations keep with the following

instructions:

Valid regulations in construction industry

Regulations and norms on safety-technical equipment of

heating installations

Changes on the place of mounting according to valid

regulations propisima

Device data

2.6

Norms, regulations and standards

This product is in compliance with the following regulations:

EN 50110-1:2003 –Handling and work with electrical

installations

EN 55014:2001 –Electrical-magnetic compatibility –

conditions for consumers’ devices for households, electric

devices and similar devices

EN 60 335-1+ed.2:2003 Electric devices for households

EN 60 335-1+ed.2 zm.A1:2005 Electric devices for

households

EN 61000-3-2 ed.3:2006 Electrical-magnetic compatibility

(EMC) –emission limits for harmonic power

EN 61000-3-3:1997 Electrical-magnetic compatibility

(EMC) –Law on determination of fluctuation of voltage and

frequency of low power distributive network

2.6 Tools, materials and auxiliary measures

Standard tools for heating installations, water supply and

electric-installations are needed for mounting and maintenance

of the boiler.

2.8 Minimum distances and burnable 2.9 Product description

construction materials

The HPe2/4CM is designed to support a heat pump and can

only work in conjunction with a heat pump. This device does

not have a working thermostat (it has a protective thermostat),

but forwards the information from the temperature sensor to

the thermoregulator of the heat pump. The heat pump

thermostat decides whether and when the electric heater will

be switched on.

HPe2/4CM plays an important role in the proper operation of

the heat pump. Its activation is necessary (sometimes

desirable) in the following situations:

• If the water temperature is less than ≈20 ° C, the heat pump

will not be able to start without preparation (heating) using an

electric heater (it is necessary to turn on the electric

HPe2/4CM)

• Defrosting when the air temperature is low can be long-

lasting or impossible without the help of an electric heater (it is

necessary to turn on the electric HPe2/4CM).

• On extremely cold days when the heat pump COP has the

lowest value, HPe2 / 4CM is switched on as a backup to keep

the heating of the building at a comfortable level (preferably

switching on the electric HPe2/4CM).

• In case of failure (servicing) of the heat pump, the HPe2/4CM

takes over the heating of the building - until the pump is

operational (preferably switching on the electric HPe2/4CM).

For these reasons, this device does not have the option of

manual on / off, because in that case - if it is manually turned

off, the heat pump could enter the blockage. The HPe2 / 4CM

must always be ready for operation, and the decision to switch

on is made by the heat pump.

HPe2/4CM is designed for wall mounting. The HPe2/4CM is

wall-mounted using the supplied mounting kit.

The design of the HPe2/4CM is such that it allows wall

mounting so that the hydraulic connections are on the left or

right side of the HPe2/4CM with easy and fast switching of

the INFO panel from one side of the formwork to the other.

Table 2: Ignitable materials and composition of

elements according to DIN 4102 The basic components of HPe2/4CM are:

Depending on valid regulations, other minimum distances

could be applied, different than mentioned below.

Comply with regulations of electrical installations and

minimum distances which are in force in the subject

country.

Minimum distance for heavy inflammable and self-

extinguishing materials is 200 mm.

The minimum distance for flammable materials is 400 mm.

•

HPe2/4CM body with electric heaters

•Device formwork (HPe2/4CM)

•Switchboard with automatic

•Info panel

The HPe2/4CM body consists of a welded heat-insulated

sheet steel vessel in which an electric heater is mounted. The

built-in thermal insulation is vapor-tight, reduces heat loss and

prevents condensation on the HPe2/4CM vessel. This allows

the HPe2/4CM not to have to be disconnected from the mains

(by bypass valve) when the heat pump is running in cooling

mode.

The safety thermostat and temperature sensor are located on

top of the HPe2/4CM vessel.

HPe2/4CM formwork is made of pickled sheet metal,

protected by electrostatic plasticization.

A switchboard with safety assembly, connection terminals and

heater switch-on relays is available after dismantling the

HPe2/4CM door. On the info panel there are signal diodes

that indicate the operation of the heater.

Device data

Inflammability of components

A

Non-inflammable

A

1:

Non-inflammable

Asbestos, stone, wall tiles, baked

clay, plaster (with no organic

additives)

A

2:

With smaller

quantity of

added elements

(organic

components)

Plaster cardboards plates, base

felt, glass fibres, plates of

ACUMIN, ISOMIN, RAIOT,

LOGNOS, VELOX, AND

HERACLITUS

B

Inflammable

B

1:

Hardly inflammable

Beech, oak, veneered wood, felt,

HOBREX, VERSALIT and

UMAKARTplates

B

2:

Normally

inflammable

Pine, larch and spruce, veneered

wood

B

3:

Inflammable

Asphalt, cardboard, cellulose

materials, tar-paper, plywood

plates, cork plates, polyurethane,

polystyrene, polyethylene, floor

fibre materials

2.10 Waste disposal

Dispose packaging materials in ecologically sound

manner

Components that should be changed dispose in ecologically

sound manner

2.11 Delivery scope

When delivery the HPe2/4CM, stick to the following:

Check if packaging is damaged during delivery

Check if delivery is complete

2.12

Factory plate

Factory data plate is placed on the external side of the

HPe2/4CM and contains the following technical data:

HPe2/4CM type

Batch / Catalogue number

Power

Input power

Maximum temperature

Working pressure

Mass

Electric power supply

Protection grade

Manufacturer

2.13

Transportation

NOTE: Transportdamages

Pay attention on instructions for transportation

on packaging

Use adequate transportation means, i.e. carts for

bags with tighten strip.

The product should be in horizontal position

during transportation

Avoid shocks or collisions

Packed HPe2/4CM put on carts for bags if needed

secure it with strip and drive it to its mounting place.

Remove packaging.

Remove packaging materials and dispose it in

ecologically acceptable manner.

Device data

Part Pieces

Electric heater

HPe2/4CM

1

Assembly Set

1

Instructions for handling

1

Dimensions and technical data

3.

Dimensions and technical data

3.1

Dimensions

HPe2/4CM

Image 1b: Dimensions HPe2/4CM

Table 3b Dimensions (mm) HPe2/4CM

A

B

C

D

E

F

HPe2/4CM

620

260

220

120

390

110

Dimensions and technical data

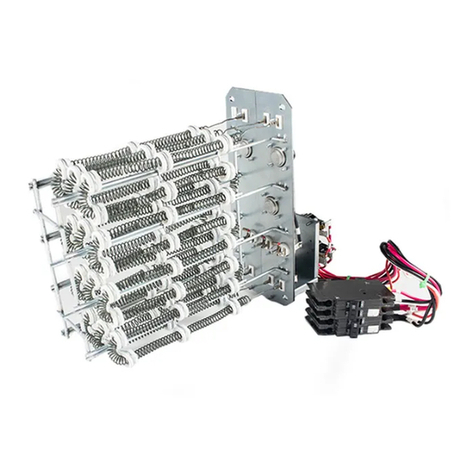

3.2 Components

1Casing of HPe2/4CM

2Exchanger in HPe2/4CM

3Electric heater in HPe2/4CM

4Thrust line

5Return line

6Safety valve 3bar

7Safety valve drain pipe

83-pole circuit breaker with upgraded

DA10 - Safety circuit

9Signal clamps for switching on relays and connecting

temperature sensors

10 Relay for switching heating group

12 Temperature sensor

13 Safety thermostat (STB)

14 Thermal insulation HPe2/4CM

Image 2: HPe2/4CM components

Dimensions and technical data

3.3

Technical data

HPe2/4CM

Unit

Mono-phase power supply

Three-phase power supply

Power

kW

2

4

6

Usability level

%

99

99

99

Number of power grades

1

2

2

Division of power grades

kW

1

×2

2

×2

2+4

Network voltage

VAC

1

N ~

230V

50

H

z

3

N ~

400

/

230V

50

H

z

Ingress protection rating

IP54

Main fuse required

A

1

×16

1

×25

3

×16

Min. cable cross-section

mm

²

3

×2,5

3

×4

5

×2,5

Max. allowed working pressure

bar

3,0

Min. allowed working pressure

bar

0,5

Max. temperature

°C

80

Water volume

l

4,5

Discharge line connection

DN25 (1”) SN

Return line connection

DN25 (1”) SN

Device weight (without water)

Kg

10,5

Table 4: technical data HPe2/4CM

Installation

4. Installation of device

CAUTION: Human or material damages occurred

because of irregular installation

!

Never install HPe2/4CM without expansion dish

(AG) and safety valve.

HPe2/4CM must not be installed in protective

zone of important area or at the place of bath.

NOTE:

Material damage due to freezing

!

HPe2/4CM must be installed only in room safe of

freezing.

4.2 Distances

DANGER: Fire threat due to burnable materials

and liquids!

Do not dispose burnable materials and liquids

close to the HPe2/4CM.

Let know the user the valid regulations for

minimum distances from burnable materials

(section 2.8).

Comply with regulations on electric installations and

minimum distances in force in subject countries.

Place HPe2/4CM on the wall in such manner to leave free

space as illustrated in the Image 3

4.1

Be careful prior to assembly

NOTE:

Material damage occurred due to

incompliance with further instructions

!

Respect instructions for boiler and all installed

components.

Prior to installing take care of the following:

All electrical connectors, protective measures and fusses should be

done by professional person respecting all valid norms, regulations

and local laws

Electric connector should be done according to the connecting plans

After corresponding installation of device execute grounding of the

plant

Before opening device and all works turn off electric supply

Non-professional and non-authorised attempts to connect device under

voltage can produce material damage of device and hazardous

electrical shocks.

Image 3: Minimum distance during installation

A=500mm /B=250mm /C=500mm /D=200mm

Installation

4.3 Front door opening procedure for

HPe2/4CM

The electric heater door can be opened very easily in a few

steps.

Remove the key that is attached to the front door lock.

Insert the key into the lock.

Turn the key to the lock (unlock).

Gently pull the handle towards you.

Turn the handle to the right and the electric heater door

will open.

4.4 WALL MOUNTING HPe2/4CM

NOTE: Material damage occurred by irregular

installation on the wall!

It is necessary to use proper material for fixing

This chapter describes mounting the HPe2/4CM on a wall.

Plot the drill hole positions for the mounting kit

respecting the minimum free space dimensions next to

the HPe2/4CM (Image 3) and the dimensions in Table 5.

Drill the holes according to the dimensions for the given

type of HPe2/4CM.

Insert plastic dowels that are part of the device

packaging (or dowels adequate for a non-standard wall

type) into the drilled holes.

Then fasten the bracket with the screws supplied with

the dowels.

Carefully hang the device on the wall

Make sure the HPe2/4CM is upright.

Take care of the correct position during installation

Installation

4.5Hydraulic attachments execution

NOTE: Material damages caused by permeable

connections!

Attachment duct lines install without connecting

on HPe2/4CM connections.

NOTE: Installation damage due to bad quality of

water! Heating installation can be damaged by

corrosion or scale depending on water

characteristics.

Comply with filling requests for water according

to VDI 2035 or project documentation and

catalogue.

Heating duct lines connect as follows:

Connect return line on connection 5(image 2).

Connect start line on connection 4(image 2).

4.6.1 Filling the HPe2/4CM with

heating water and sealing test

Waterproof should be tested prior to put on the boiler.

DANGER: Injuries and/or material damages can

occur with overpressure when testing watertight!

High pressure can damage regulatory and

safety devices and reservoir.

After filling with water set the HPe2/4CM on

pressure that is equal to the opening pressure

of safety valve.

Comply with maximum pressure of installed

components.

After testing sealing, open again closing

valves.

Make sure that all pressures, regulatory and

safety parts work correctly

DANGER: Health threat due to mix of drinking

water!

It is demanding to respect state norms and

regulations on avoiding mix drinking water

(with water from heating installations).

Comply with EN 1717.

NOTE: Material damage due to temperature

tension.

If you fill the HPe2/4CM in hot condition,

temperature tension can cause cracks due to

tensions. HPe2/4CM will start to leak

Fill the HPe2/4CM only in cold condition

(temperature of empty duct can be max 40°C)

Fill the HPe2/4CM only through quick valve

on pipe installation (return line) of the

HPe2/4CM

Connect the filling hose to the water supply network and

slowly fill it with water so that all the air comes out of it and the

water starts to flow continuously.

Close the tap on the water supply network and connect the

free end of the hose to the tap for filling and emptying the

heating installation. Secure the hose with a clamp.

Open the installation filling and draining tap and slowly charge

the HPe2/4CM. Monitor the pressure rise and close the tap

when the operating pressure is reached.

Bleed the installation via the valve on the radiator.

If the operating pressure drops by venting, the water must be

topped up.

Test for leaks according to local regulations.

After you have tested the tightness, open all the elements that

you closed due to filling.

Check that all safety elements are working properly.

If the HPe2/4CM is tested for leaks and no leakage is

observed, set the required operating pressure, according to

the pre-pressure of the expansion vessel.

Remove the hose from the filling and emptying tap.

Enter the operating pressure and water quality values in the

operating instructions.

4.6.2 Heating pump air emission and de-

blocking

This device does not have a circulation pump in it.

When the external pump is blocked, do the following:

Unscrew the center screw in the middle of the "head" of the

pump

Carefully try to unlock the pump shaft with a suitable

screwdriver.

4.6.3 HPe2/4CM venting and installation

This device does not have a built-in vent, because the

construction of the HPe2/4CM vessel is such that air cannot

remain trapped in the boiler but exits the HPe2/4CM through

the pressure pipe.

Ventilation must be installed on the installation, so as to

ensure venting of the air that can come out of the pressure

pipe, as well as venting of the entire installation.

In case only 2 phases are available, the boiler can be connected

according to Figure 6b, where the power is limited to 4kW, the

cross-sectional dimensions of the cable and fuse from Table 6 apply.

NOTE:

If the heat pump is supplied via a differential current protection

device - RSD (FID switch), and the HPe2/4CM is supplied

directly from the mains, or via another FID switch, the neutral

line (N) from the heat pump must be connected to the RSP3

clamps - to prevent until the FID switches "fall"

If both the HPe2/4CM and the Heat Pump are supplied from

the same place or there are no FID switches on the installation,

a neutral line from the RSN clamps can be fed to the RSP3

clamps.

Electric connecting

5. Electric connecting

DANGER: Life threat from electric shock!

Electric works must be done only by qualified

person.

Turn off voltage supply before opening

device and secure it against accidental turn

on.

Comply with assembly regulations.

When connecting HPe2/4CM on electric installation take

care on connections scheme and connecting plans.

Respect mandatory diameters of cables and fusses

power outside the HPe2/4CM.

This device is manufactured for connection to three-phase

power supply (3N ~ 400/230V 50Hz).

Connection to a single-phase network is possible with

a power limit of 2kW or 4kW, where the connection

must be fixed (no connection is allowed with a socket)

and the cross-section of the connection cable must be

according to Table 7a (7b).

5.1 Connecting HPe2/4CM to three-phase mains

Image

6a:

Connection to a three-phase network

Image

6b

Connecting in two phases

RSP1, RSP2 –Temperature sensor connection clamps

(with Heat Pump)

RSP3 –Neutral line connection clamps (from Heat Pump)

RSP4, RSP5 –Signal connection clamps (230V AC) for

switching on the heater relay (from the Heat Pump).

Table

6:

Nominal current, el. fuses and cross-section of power cables

for HPe2/4CM 6kW for three-phase power supply

.

3N ~ 400/230V 50Hz

TK - 6

In[A]

3 × 8,7

Main fuses [A]

3 × 16

Min. cable cross section

5 × 2,5mm²

THREE-PHASE CONNECTION

POWER 6kW

TWO-PHASE POWER

CONNECTION 4kW (2kW + 2kW)

MONO-PHASE CONNECTION,

POWER 4kW (2kW + 2kW)

5.2 Connection of HPe2/4CM to mono-phase mains

Connection to a mono-phase network is possible with a power limit of 2kW or 4kW, where the connection must be fixed

(no connection is allowed with a socket) and the cross-section of the connection cable must be according to Table 7a,

or 7b for 4kW power.

Image 7a: Shema for connecting cable to mono-phase

power supply

RSP1, RSP2 –Temperature sensor connection terminals

(with heat pump)

RSP3–Neutral line connection clamps

(from Heat Pump)

RSP4 –Signal connection clamps (230V AC) for switching

on the heater relay (from the Heat Pump).

Table

7a:

Nominal current, el. fuses and cross section of

power supplies 2kW limited power cables for

mono phase

power supply

.

Image 7b: Shema for connecting cable to mono-phase power

supply

RSP1, RSP2 –Temperature sensor connection terminals (with heat

pump)

RSP3–Neutral line connection clamps

(from Heat Pump)

RSP4, RSP5 –Signal connection clamps (230V AC) for switching

on the heater relay (from the Heat Pump).

Table

7b:

Nominal current, el. fuses and cross section of power

supplies 4kW limited power cables for

mono phase power

supply

.

Electric connecting

1N ~ 230V 50Hz

LIMITED

POWER –2kW

In[A]

1 × 8,7

Fuses [A]

1 × 16

Min. cable cross section

3 × 2,5mm²

1N ~ 230V 50Hz

LIMITED

POWER –4kW

In[A]

1 × 17,4

Fuses [A]

1 × 25

Min. cable cross section

3 × 4mm²

MONO-PHASE CONNECTION,

POWER 2kW

Electric connecting

5.3 Connecting the power cable –

Safety circuit

The connection is made according to the wiring diagram

given for each type of connection.

Phase conductors are connected to circuit breakers, and

line terminals of appropriate dimensions according to

HPe2/4CM power are provided for connecting neutral and

protective conductors.

A remote voltage trigger has been upgraded to the

automatic fuses, so that together they form a SAFETY

ASSEMBLY. In the event of overheating of the HPe2 /

4CM, the safety thermostat sends a signal to the remote

voltage trigger, which activates and switches off the

"fuse" of the circuit breakers, ie the HPe2 / 4CM remains

without power - thus preventing any major breakdown. In

order for the HPe2 / 4CM to continue to operate, the

automatic fuses must be activated manually, which must

be done by a service technician, after determining the

cause of the overheating.

ATTENTION! When connecting phase

conductors, be sure to tighten the screws in the

terminal blocks well to achieve the best

possible connection between the conductors

and the clamps.

DANGER! Failure to connect the conductor and

clamps properly may result in overheating of the

terminal and failure.

NOTE! The connection of this device must be

carried out by a qualified person who is qualified to

perform this type of work.

The neutral (neutral) line is connected to the appropriate

clamps block (N). The neutral clamps line is blue.

Connect the earth conductor to the clamps block marked

with the earth sign. The line clamps for grounding the

device is yellow-green.

When inserting the power cord into the HPe2/4CM,

carefully route the cable to the clamps blocks, taking care

not to damage the cables inside the device.

5.4Electrical scheme

Image 8: Electrical scheme HPe2/4CM rated power 6 kW

Electric connecting

6. Commissioning

When complete below described works fill in the

Commissioning log (chapter 6.3)

6.2

First turn on

NOTE: Material damage due to incorrect handling!

6.1 Before commissioning

NOTE: Material damage occurred due to

unprofessional operating!

Start-up without sufficient quantity of water

destroys device.

Turn on the HPe2/4CM and use it only if there

is sufficient quantity of water

HPe2/4CM must work with minimum pressure of

0.5 bars

.

Klijenta/korisnika uređaja uputite u

rukovanje uređajem.

Prior to commissioning for the first time, make sure that

the heating system is filled with water and vented

Check all electrical connections

Switch on circuit breakers (protective circuit)

Before turn on, test if the following elements and joints are

connecter correctly and work correctly:

Watertight of heating installation

All pipes connected into ducts

All electric connectors

6.3 Start-up log

Commissioning works

Measured values

Notes

1.

HPe2/4CM type

2.

Serial number

3.

Set thermostat regulation

4.

Fill and air-vent heating installation and

check sealing of all connectors

5.

Operating pressure established

• Checked expansion vessel pressure

_____________ bar

6.

Test safety devices

7.

Set electric connection according to local

regulations

8.

Test function

9.

Users informed, technical documentation

submitted

10.

Confirmation of professional

commissioning

Service seal / Signature / Date

T

a

ble

5:

Start-up log

Commissioning

Heating installation handling

7. Operating the electric heater

7.1

Operating instructions

Safety instructions

Only adults familiar with instructions and working

mode may operate the HPe2/4CM

Make sure there are no children in the HPe2/4CM

area

Do not dispose or store inflammable materials within

safe distance of 400 mm round the boiler

Inflammable materials must not be placed on the

HPe2/4CM

User must comply with instructions for operating the

HPe2/4CM

User may only turn on the HPe2/4CM (except the first

start-up), adjust temperature on the regulating device

and turn off the HPe2/4CM. All other operations must

be performed by authorised service

Authorised person who performed installation is

obliged to inform the user about handling and correct

and safe work of HPe2/4CM

In the event of alert situation, explosion, fire, gas or

steam leaking, the HPe2/4CM must not work

Be aware of inflammable characteristics of

components (Instructions on installations and

maintenance)

Cleaning and maintenance

8. Cleaning and maintenance

8.1 HPe2/4CM cleaning

DANGER! Life threat of electric power shock! Clean this device externally with wet cloth.

Electric power work must be done only by

qualified person.

Before opening device: turn heating installation

off electric power supply using safety switcher

and disconnect it from power supply net

through corresponding fuse

Secure heating installation against accidental

turn on.

Comply with instructions for installation.

8.2 Check working pressure; re-fill water

and air-vent installation

DANGER: Health threat due to mix of

drinking water!

It is demanding to respect state regulations to

avoid mix of drinking water (with water from

heating installations)

Comply with EN 1717.

Establish an operating pressure of at least 0.5 bar,

depending on the installation height

WARNING: Material damage due to

unprofessional maintenance!

Insufficient or unprofessional maintenance of

HPe2/4CM can lead to damage or destruction and

to loss of Warranty rights

Secure regular, entire and professional

maintenance of heating installation.

Electric parts and work units protect against

water and humidity.

Use only spare parts delivered by the manufacturer

or those approved by manufacturer. There will be

no responsibility for damage occurred due to spare

parts not delivered by the manufacturer.

Control examination log is provided on chapter 8.4

Perform works in accordance with log on control and

maintenance

All deficiencies remove immediately.

The volume of newly filled water is reduced in the first days

after charging due to heating. This creates airbags that create

interference in the heating system.

Testing working pressure

Working pressure of new heating installation should control

on daily basis at the beginning of its work. If needed, re-fill

water and air vent the system

Later check working pressure once per month. If needed,

re-fill water and air vent the system

Check working pressure. If it decreases below 1 bar re-fill

water

Re-fill the water

Air vent the heating installation

Check working pressure again

Table of contents

Popular Electric Heater manuals by other brands

MrCool

MrCool MHK U Series Owners & installation manual

Gasmate

Gasmate EH431 instructions

Heatscope

Heatscope MHS-SM1600 Original installation and instruction manual

DeLonghi

DeLonghi TRD0715T Important instructions

Harvia

Harvia Spirit Owner's/operator's manual

Baxi Fires Division

Baxi Fires Division 826 dream longlite Installer and owner guide

Global Industrial

Global Industrial 653579 user manual

HEATSTRIP

HEATSTRIP ELEGANCE product manual

Varma Tec

Varma Tec FIRE IRK instruction manual

Intertec Data Systems

Intertec Data Systems CP MEGATHERM DN.A HI operating instructions

STIEBEL ELTRON

STIEBEL ELTRON RHM 300 Operation and installation

IRIT

IRIT IR-6008 Manual instruction