Centrometal CSK-Touch User manual

TU-CSK-T-09-2019-v1_16-ENG

CSK-Touch

Technical instructions

for installation, use and maintenance

CSK-Touch digital room corrector

READY

www.centrometal.hr

e-mail: [email protected]

Centrometal d.o.o. Glavna 12, 40306 Macinec, Croatia

central tel: +385 40 372 600, fax: +385 40 372 611

service tel: +385 40 372 622, fax: +385 40 372 621

Company Centrometal d.o.o. assumes no responsibility for possible inaccuracies in this book

originated typographical errors or rewriting, all the pictures and diagrams are principal and it is

necessary to adjust each actual situation on the field, in any case the company reserves the right to

enter their own products such modifications as considered necessary.

TEHNIKA GRIJANJA

HEATING TECHNIQUE

Centrometal d.o.o. - Glavna 12, 40306 Macinec, Croatia, tel: +385 40 372 600, fax: +385 40 372 611

READY

Introduction, content

INTRODUCTION

CONTENT

TECHNICAL CHARACTERISTICS

DELIVERY CONTENT AND NECESSARILY ADDITIONAL EQUIPMENT

INSTALLATION CSK-Touch DIGITAL CORRECTOR

FIRST TURNING ON

MAIN DISPLAY

BOILER MENU

MENU

SCHEDULE

TEMPERATURE

SETTINGS

INTRODUCTION

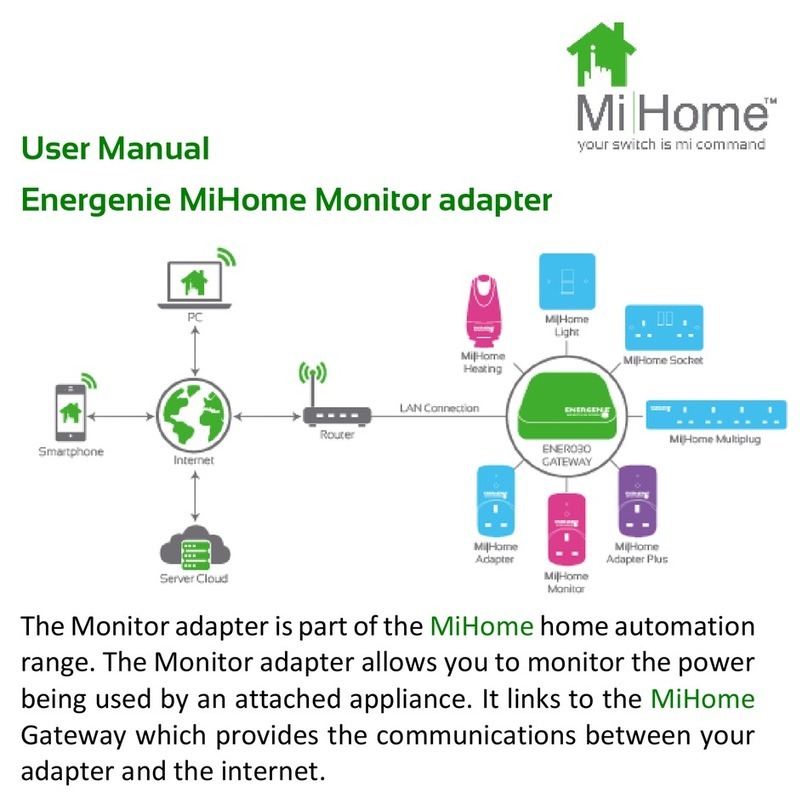

Digital room corrector CSK-Touch, with a 4.3'' color touch screen, provides room temperature control

and turning on / off of the heating circuit. In addition to measuring and correcting room temperature,

this room corrector allows you to adjust the temperature of the Accumulation tank or Hydraulic

crossover as well as to adjust the DHW temperature, if any, and to set Schedules of the heating circuit,

DHW and boiler. By connecting multiple digital room correctors to the boiler, it is possible via one

corrector to adjust the desired temperature at other correctors. The digital room corrector connects

to the PelTec boiler with a built-in CM-WiFi box and CM2K module wirelessly via wifi signal.

With compact and elegant design, it fits perfectly into any space in your home.

Thank you for purchasing the product of Centrometal d.o.o.

Please read these technical manuals carefully so that you can use and adjust this control unit as easily

as possible. Once you have read the manuals, place them in an appropriate place where you can

easily find them if you need further information on the operation and use of control unit. Please make

sure that the contol unit is discontinued after the end of use to reduce the pollution of the environment.

CONTENT

2

2

3

3

4

5

6

7

8

8

9

11

Technical instructions CSK-Touch

2

Notes

Technical instructions CSK-Touch 15

TECHNICAL CHARACTERISTICS OF CSK-TOUCH

Power supply

Connection with boiler/CM2K

Temperature range

Display type

Consumption

Dimensions (WxHxD)

CSK-Touch mass

Case material

30VAC

Wirelles: WiFi (CM-WiFi box)

from -40°C to +70°C

4.3" TFT, resistive touch screen

max. 1.5W

150x100x24 mm

225 g

ABS

EC Declaration

The product complies with the requirements of the current rules and is marked EC.

The EC Declaration of Conformity is available on request, contact the manufacturer.

DELIVERY in cardboard box:

CSK-Touch Technical

instructions

Note:

CM2K and CM-WiFi box are not in the content

of the delivery

Modul CM2K CM-WiFi box

Necessarily additional equipment

DELIVERY CONTENT AND NECESSARILY ADDITIONAL

EQUIPMENT

Notes

Technical instructions CSK-Touch

14

Technical characteristics, delivery content and necessarily additional equipment

Technical instructions CSK-Touch 3

Installation

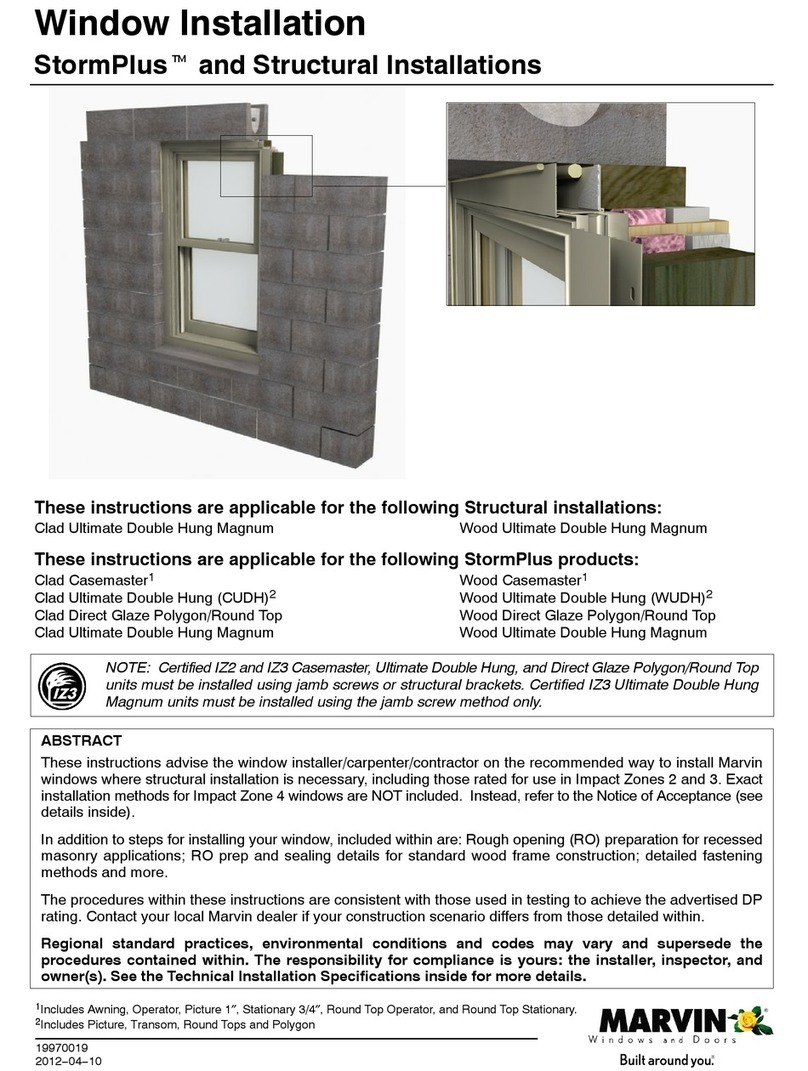

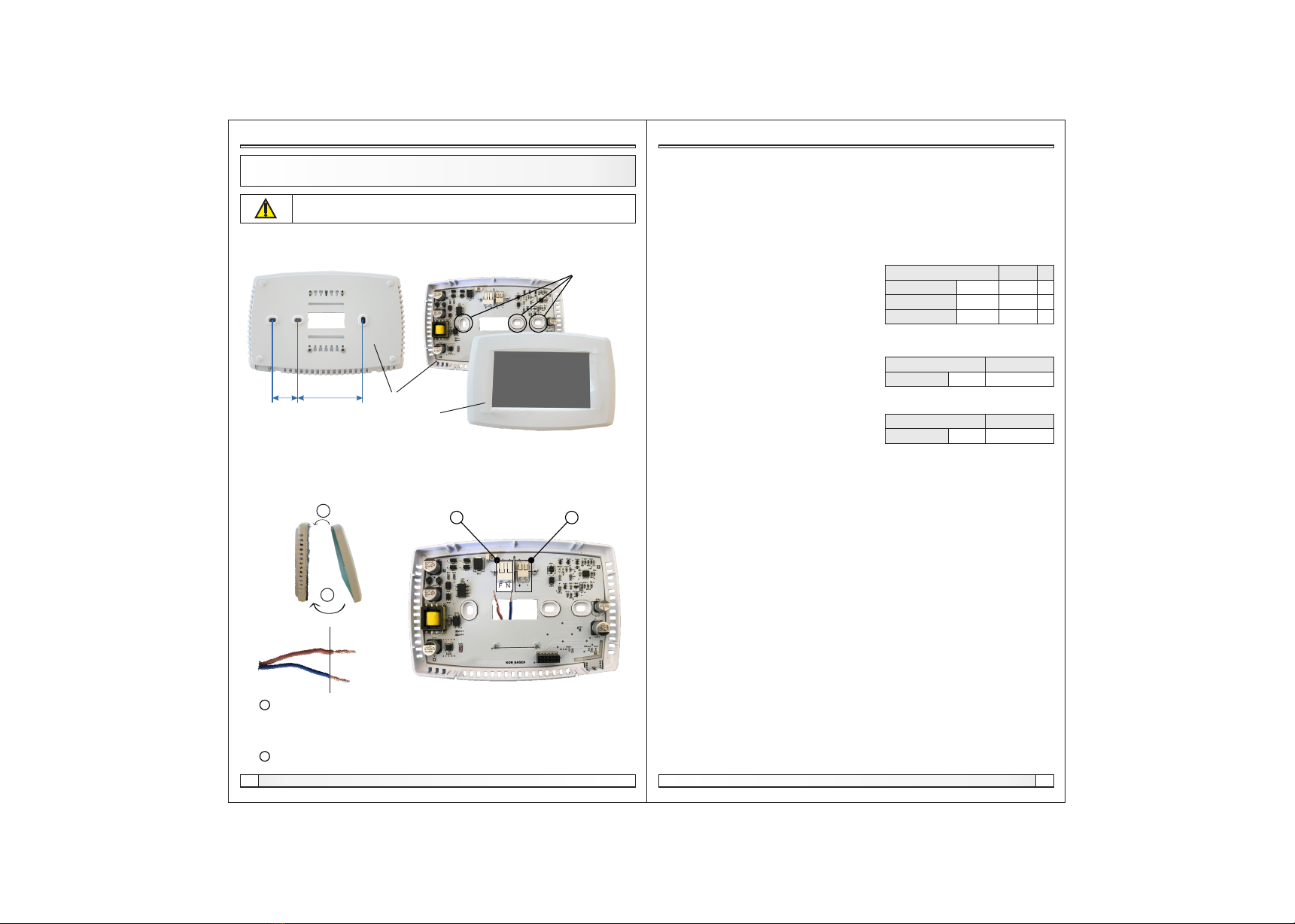

CSK-TOUCH DIGITAL CORRECTOR INSTALLATION CONNECTING TO

THE BOILER / CM2K MODULE THROUGH CM-WIFI BOX

Technical instructions CSK-Touch

4

At a height of about 130-160cm from the floor, never directly above the heat source or near the

window. At the installation site, drill 2 holes at a distance according to the bottom sketch, diameter fi

6mm, depth 35-40mm. Insert dowels into the drilled holes.

24 mm 60 mm

places to

attach to the

wall

Be sure to turn off the power supply at the place of installation of the corrector!

Ensure an unobstructed wifi signal from the corrector to the CM-WiFi box!

base

Push the power wire through the hole at the base of the corrector and insert the wires into the power

connector (locations F and N, left connector). Before inserting the wire, press the terminal block

connector, insert the wire all the way down, and release the terminal block connector. Do the same

for the other wire. Attach the connector base to the wall with screws. Attach the screen to the upper

brackets and gently press the screen to the bottom of the corrector base. When the corrector is

properly installed, the current up to the corrector can be turned on.

a Power connectors.

It is necessary to remove the insulating part of the wire and insert the conductor

part into the connectors.

F - Phase

N - Zero

b A connector for wired connecting the module CM2K (currently unused)

insulating part conductive part

a

F N

b

screen

1.

2.

Settings

3.7. Shutdown

The Digital Room Concealer is intended for year-round use, ie room temperature measurement. If

you want to turn off the corrector completely (because it will not be used or want to save electricity

when we do not intend to use corrector), pressing the OK button will completely off the corrector.

When you want to restart the room corrector, you need to press the screen for a few seconds until a

beep sounds and the corrector lights up and starts working on the last view before shutting down.

3.5.2. Sound type

Select one of ten sound types offered when you

press the screen or an error / warning occurs

3.5. Sound

3.5.1. Sound volume

Adjusting one of three preset volume levels

or muting completely when a button is displayed on the

screen and when an error / warning occurs.

3.6. Info

Information on the version of the software entered in the corrector..

3.8. Load factory

Load the factory settings of the room corrector. After that, the room concealer must be

reconfigured.

3.4.4. Screensaver

After a certain screen idle time, the screen saver is turned on to reduce power consumption and

extend the screen life. The screen saver works in two levels: after Time 1, the backlight intensity

decreases, and after Time 2 has elapsed, the measured room temperature of the selected view and

the current clock will change on the screen. By tapping the screen, the screen saver turns off.

3.4.4.1. Backlight

The backlight intensity after Time 1 has elapsed, ie when the screen saver turns on.

3.4.4.2. Time 1

Time that starts to run after the last touch on the

screen (after which the screen saver is turned on).

3.4.4.3. Time 2

Time that begins to flow after Time 1 has passed

(in Time 2 the Backlight intensity decreases and after

that time, only the current room temperature / current clock starts to appear on the screen

Backlight 20

Factory: min./max.

5 / 50

uni.

Time 1 60 10 / 600 sec

%

Time 2 10 0 / 720 min

Sound volume 3

Factory: setting

OFF / 1/2/3

Sound type Type 6

Factory: setting

Type 1...Tip 10

Technical instructions CSK-Touch 13

Settings

3.2. Views

In the Views menu, you can define the number of views or correctors that can be monitored on this

digital corrector and define the name of each view and assign it a heating circuit that it controls. On

the main screen, depending on the number of views selected, the letters of the view appear in the

menu bar (from A to H, user-assigned names are only visible on the selected screen, not in the

menu bar). If there are more than 2 views, the other views are selected by pressing the "..." menu

(three dots) followed by the other selected views. After clicking on one of the desired views, the

menu bar returns to the possible selection of the first 2 views.

3.3. Measurement corr.

If the measured temperature on the digital corrector

deviates from the actual room temperature, in this menu the measured temperature on the digital

corrector screen can be corrected.

3.4. Display

Menu for changing the settings of the digital corrector screen.

3.4.2. Backlight

The intensity of the backlight when the corrector is in normal operation or when the settings are

changed.

3.4.3. Weather forecast

If the CM-WiFi box is connected to the Internet, there is below the measured room temperature a

weather forecast for the place where the CM-WiFi box with the currently read temperature from the

server (with the date and hour of reading the current temperature and forecast) and the weather

forecast for today appears and for the next four days (with a minimum and maximum daily

temperature). If the CM WiFi box is not connected to the Internet, the current forecast will not be

displayed on the screen. Then it is recommended to turn off the weather forecast and it will not

longer be displayed on the screen.

Background 1

Factory: min./max.

1 / 6

Backlight 100 30 / 100 %

Measurement corr. 0

Factory: min./max.

-5.0 / 5.0 °C

3.2.1. No. of views

Selects the number of views or associated room correctors that can be controlled via this digital

corrector. If only this digital corrector exists, the

number 1 must be selected

Heating circuit 0

Factory: min./max.

0 / 255

Weather forecast ON

Factory: setting

OFF / ON

3.2.x. View A/B/C/D/E/F/G/H

3.2.x.1. View Name

Each view can have a name according to the user's wishes (eg Living Room, Ground floor ...).

3.2.x.2. Heating circuit

Each view must be assigned a heating circuit wich is controled by this view (usually each corrector

controls its own heating circuit).

3.4.1. Background

Selects the background image of the screen that will

be displayed in the normal operation of the corrector.

menu bar

No. of views 1

Factory: min./max.

1 / 8

Technical instructions CSK-Touch

12

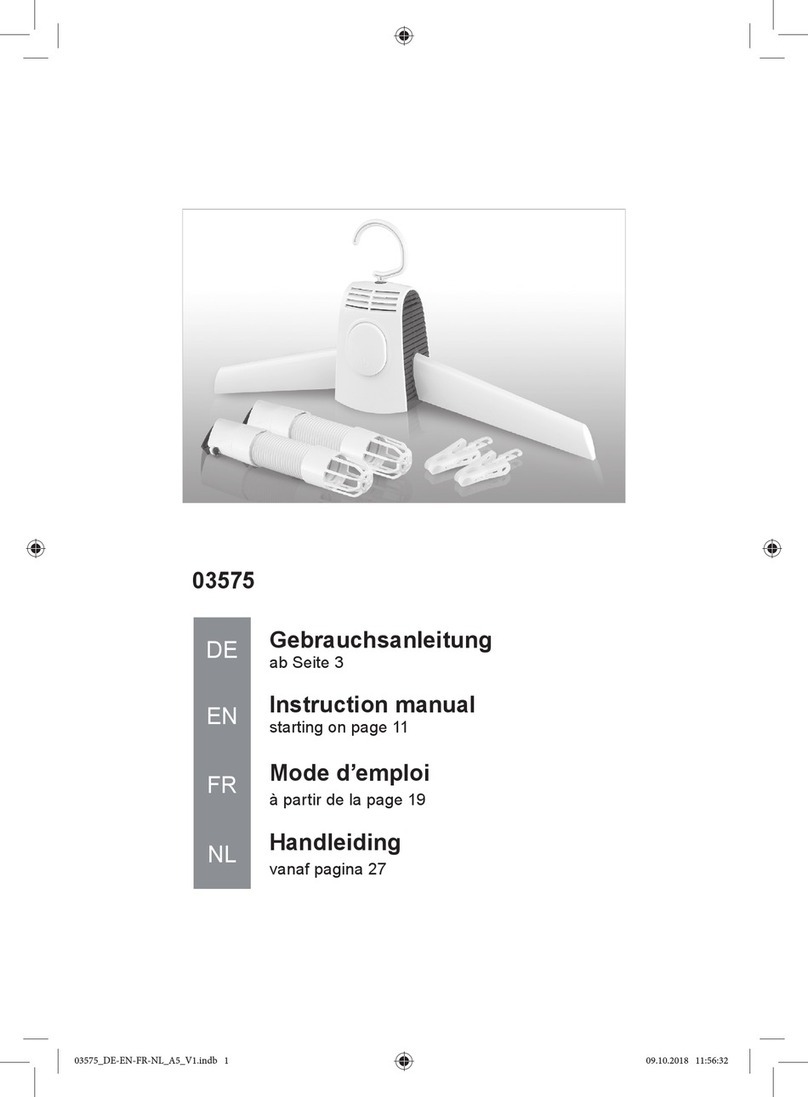

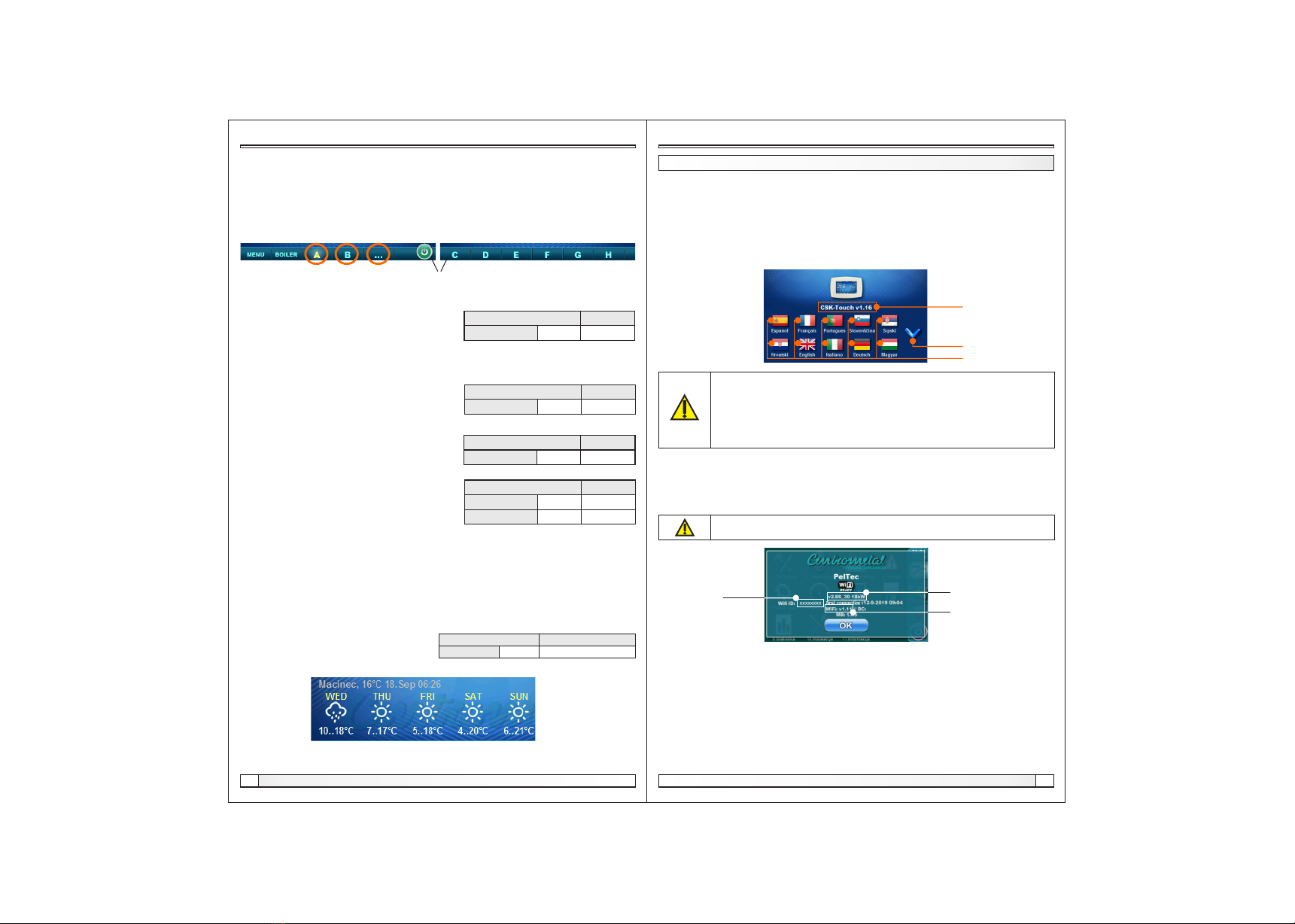

FIRST TURNING ON

First turning on

Before turn on the corrector for the first time, it is necessary to configure the heating circuit on the

boiler / CM2K module to which the corrector will be connected. On the boiler control in the

Regulator menu, in the selected heating circuit, in the Corrector menu, it is necessary to select

Digital corrector, and in the menu Addr. dig. corrector, select the desired corrector address (the

same must be selected on the corrector later ) .After starting the corrector for the first time, a menu

will appear on the first screen to select the desired corrector language. The desired language of the

corrector doesn't have to be the same as the language of the boiler. To select the desired language

for the corrector, press the flag of the desired language on the screen.

Corrector software

version

Language selection

Page scroll

The screen must not be pressed (with your finger ...) when connecting the the room

corrector to the el. power supply. If the screen of the corrector is pressed on arrival

the el. power supply (the screen shows 'Firmware update'), the corrector enters the

software insertion mode which can only be used by authorized serviceman. If the

screen is accidentally pressed, it is necessary to turn off the power on the corrector

and turn it on again without ever pressing the screen to get the corrector ready for

operation.

After selecting the language on the first screen the indicator flashes that the corrector is not

connected to the boiler. The corrector is adjusted in the menu Menu -> Settings. The menu 3.1.1.

Connection type selects how the corrector will be connected to the boiler / CM2K module. If the

corrector is connected via the CM-WiFi box (currently the only option), the correct WiFi ID from the

menu Info on the boiler control must be entered in the corrector menu 3.1.2. WiFi ID.

If a specific corrector address is selected on the boiler control unit (if there is more than one digital

corrector, selection of the address of each individual corrector is obligatory), the same address

should be selected on the corrector in the menu 3.1.3. Corrector address.

The corrector can be connected to the boiler / CM2K either directly via the CM-WiFI box or through

another digital corrector. If you want to connect the corrector directly to the boiler / CM2K, in the

menu 3.1.4. Destination address you need to select a WiFi box, and if you want to connect the

corrector to the boiler / CM2K via another corrector (in case the corrector cannot receive the CM-

WiFi box signal ), in the menu 3.1.4. Destination address it is necessary to select the address of

another corrector to be connected.

The CSK-Touch room corrector can be connected to a CM-WiFi box with software

version v.1.11 or later and a Peltec / -L boiler with software version v.2.86 or later.

WiFi ID Boiler sofware version

Software vesrion of

CM-WiFi box

Technical instructions CSK-Touch 5

Technical instructions CSK-Touch

6

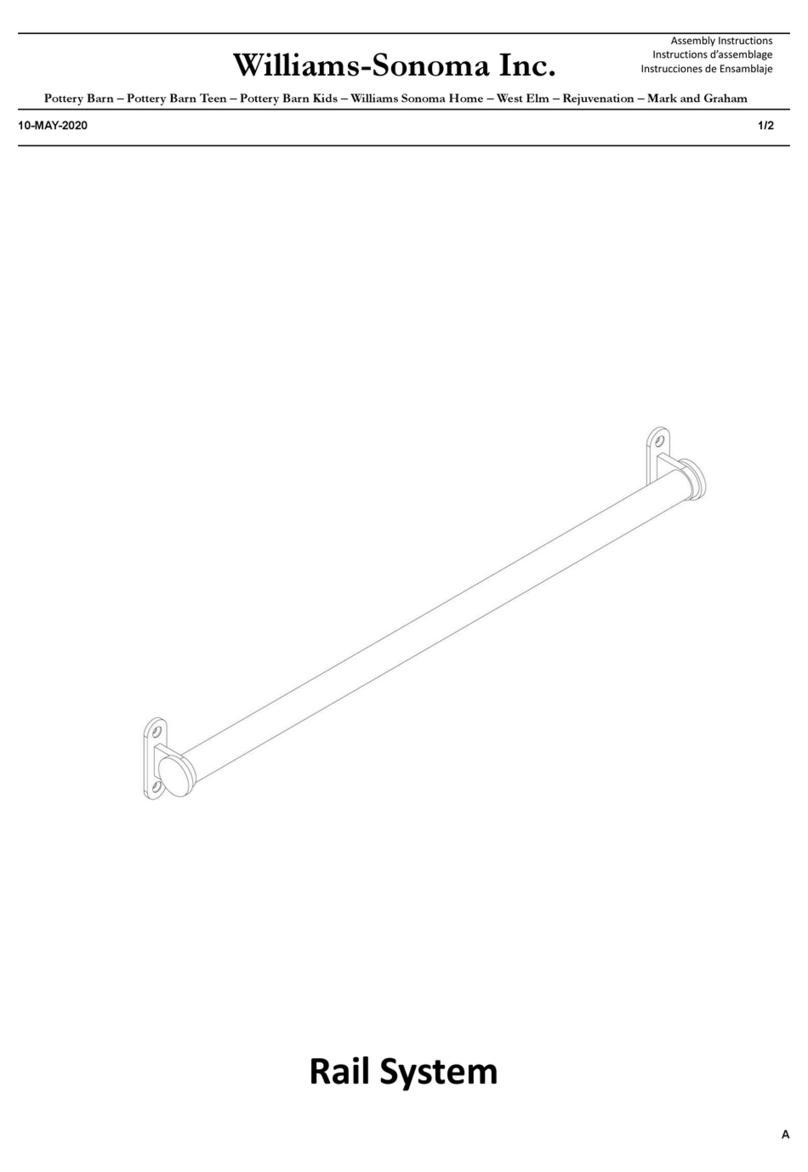

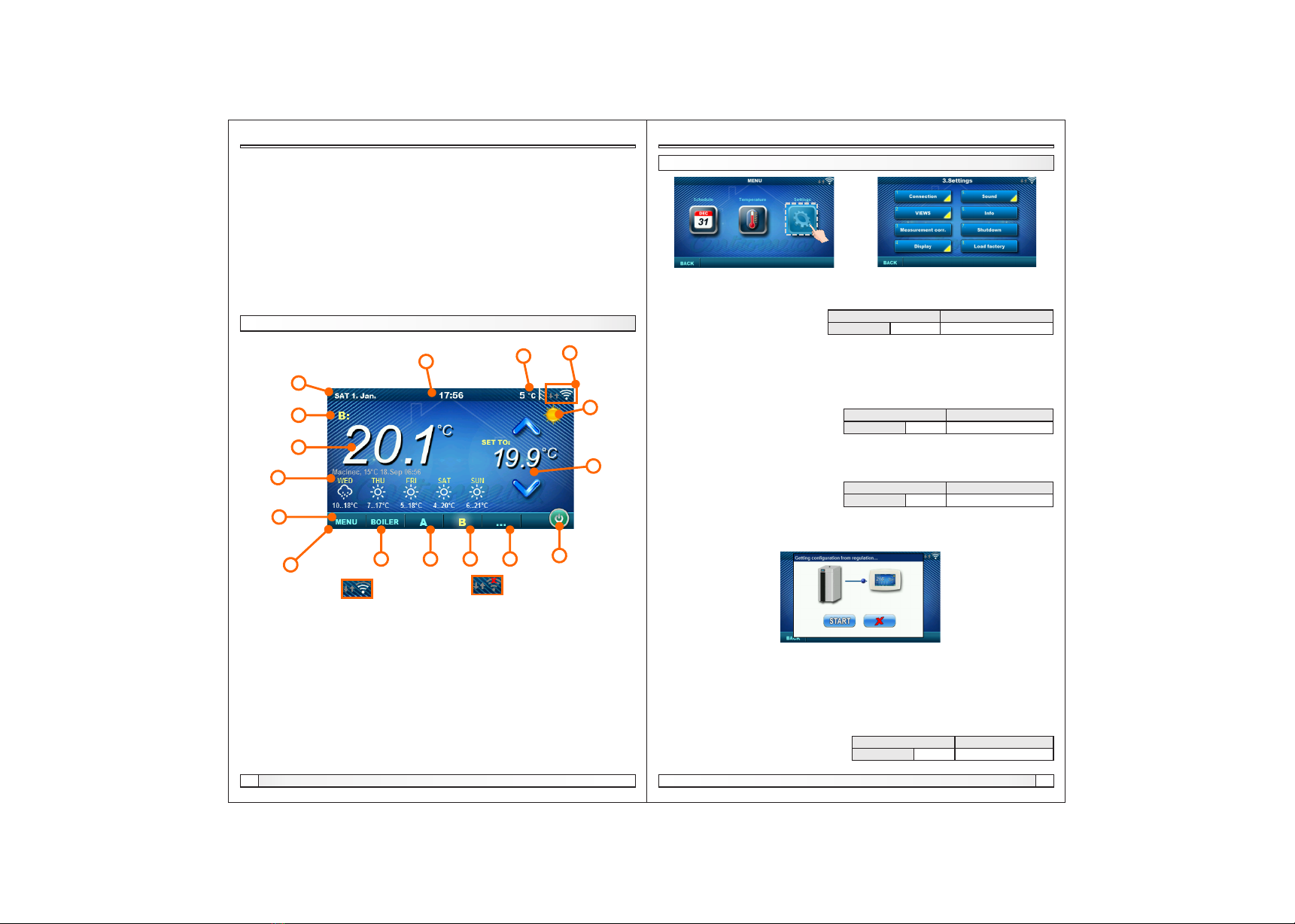

First turning on, main display

1

2

5

6

7

8

9

10

12 13 14 15 16

3

CSK-Touch is connected

with a boiler

CSK-Touch is not connected

with a boiler

11

Depending on the view selected (heating circuit), the current measured room temperature can be

displayed on the screen, you can set the desired room temperature (correction of the set

temperature on the boiler control) or switch off the heating circuit and see the weather forecast for

several days in advance (if the boiler is connected to the Internet via the CM-WiFi box).

1. Date

2. Hour

3. Outside temperature

(if there is an outdoor temp. sensor)

4. WiFi signal / data transfer

5. Name of heating view / circuit

6. Room temperature (depending on the selected

view and the heating circuit, measured either on

the current room corrector or other corrector.

7. Day / night heating mode

8. Desired / set room temperature

9. Weather forecast (internet connection required)

10. Menu

11. Menu bar

12. Boiler menu - data from boiler control

13. A - overview of the selected heating circuit

14. B - overview of the selected heating circuit

15. Button for other views if set

16. Turn OFF / turn ON of the selected heating circuit

In the menu 3.2. Views it is necessary to assign each view of the corrector to a specific heating

circuit and add a name to it as desired. If there is only one room corrector in the heating system,

number 1 is selected in the menu 3.2.1Number of views. If there are more room correctors (digital

or analog) to be monitored on this corrector, the number of all correctors to be monitored should be

selected in this menu. Depending on the number of views selected, the same number of buttons for

editing the views (eg 3 views, View A, View B and View C buttons) appear in the menu 3.2 Views.

In the menu 3.2.2. View A you can change the name of that view (factory A) to eg Floor 1 or Zone 1

or Circle 1 or Living Room ... (max. 30 characters) and a heating circuit must be selected to be

joined by this corrector, 3.2.2.2. Heating circuit.

After the corrector connects to the boiler / CM2K (WiFi signal strength is white), it is necessary to

download the data from the boiler control by pressing the START button in the menu 3.1.5. Get data

After adjusting these parameters, the corrector is ready for use..

MAIN DISPLAY

4

3. SETTINGS

Settings

3.1. Connection

3.1.1. Connection type

Choose how to connect the room corrector to the boiler / CM2K. Currently enabled: Only connect

via WiFi Tree.

3.1.2. WiFi ID

It is mandatory to enter the WiFi ID (unique number of the CM-WiFi box) - the number is displayed

on the boiler control in the Information menu after connecting the CM WiFi box to the boiler.

3.1.3. Corrector address

The address selected on the boiler control must be the same as the one selected here. If there is

one digital corrector the address does not have to be defined (but it can), if there is more than one

digital corrector the address of each must be defined and the address of each digital corrector must

be different.

3.1.4. Destination address

One digital corrector must always be connected directly to the WiFi box (WiFi box destination

address selected). If we have more than one digital corrector, other correctors can be connected to

each other (eg when the signal from the WiFi box is too weak or missing) by selecting the

destination address of the nearest neighboring digital corrector (destination address ADR1 / 2 ...).

3.1.5. Get data

After configuring the room corrector or afterwards changing the language, it is necessary to

download the configuration / error / setpoint data from the boiler controller in order to print the

correct information on the digital corrector.

3.1.6. Language selection

When connecting a digital corrector for the first time, the digital corrector asks you to choose a

language that will display information on the screen. After selecting the language for the first time,

the language selection menu automatically shuts off. If you wish to change the language of the

corrector later, you need to activate the language selection in the menu 3.1.6. Language selection,

turn off the corrector 3.7. Shutdown and the language selection will appear on restart (long press

on the screen). After selecting a new language, it is necessary to retrieve the data from the boiler

control unit 3.1.5. Get data.

Corrector address Not defined

Factory: setting

Not defined / ADR 1/2/3/4/5/6/7/8

Language selection ON

Factory: setting

OFF / ON

Connection type WIFI BOX Tree

Factory: setting

WIFI BOX Tree / Wired / Home router

Destination address WIFI BOX

Factory: setting

WIFI BOX / >>>ADR 1/2/3/4/5/6/7/8

Technical instructions CSK-Touch 11

Technical instructions CSK-Touch

10

Temperature

2.x. DHW

2.x.1 DHW temp.

The default temperature of the

DHW tank.

DHW temp. 50

Factory: min./max.

40 / 80 °C

2.x.2 Differential of DHW

The default differential for starting the DHW

tank to warm up (Tdhw-dTdhw).

2.x. Buffer tank

2.x.1. Buffer tank temp.

Default buffer tank temperature (measured on the upper sensor).

2.x.2. Min buf. tank temp.

Default minimum buffer tank temperature (measured on the upper sensor) - when reached, the

heating pumps behind the storage tank are switched off.

2.x.3. Diff. buf. tank temp.

Default differential to start warming up the buffer

tank (measured on the upper sensor)

(Tbuff-dTbuff).

2.x.4. Diff. stop buff. tank

Default differential to turn OFF warming up the

AKU. tank (measured on the lower sensor)

(Tbuff-dTbuff off).

Buffer tank temp. 80

Factory: min./max.

40 / 85 °C

Min buf. tank temp. 20 5 / 66 °C

Diff. buf. tank temp 10 5 / 30 °C

Dif. stop buff. tank 5 3 / 30 °C

2.x.1. Crossover temp.

Hydraulic crossover temperature setpoint. Crossover temp. 80

Factory: min./max.

75 / 85 °C

Differential of DHW 5

Factory: min./max.

4 / 40 °C

2.1.4. Heating curve

Adjustment of the coefficient (slope) of the heating curve of the selected heating circuit

(dependence of the flow temperature on the outside temperature). Depending on the type of

heating installed and the thermal insulation of the building, the slope of the heating curve must be

adjusted - it is usually recommended for radiator heating curves from 1.0 to 4.0 and for underfloor

heating from 0.1 to 0.9.

2.1.5. Correction coeff.

Determination of the coefficient of influence of the room corrector on the flow temperature. The

higher this coefficient, the room corrector will have a greater influence on the calculated required

flow temperature of the selected heating circuit.

2.1.2. Day room temp.

Selects the default daily room temperature.

2.1.3. Night room temp.

Selects the default night room temperature.

Day room temp. 20

Factory: min./max.

5 / 30 °C

Night room temp. 20 5 / 30 °C

Heating curve 1.0 0,1 / 4.0

Correction coeff 1.0 0.1 / 5.0

Technical instructions CSK-Touch 7

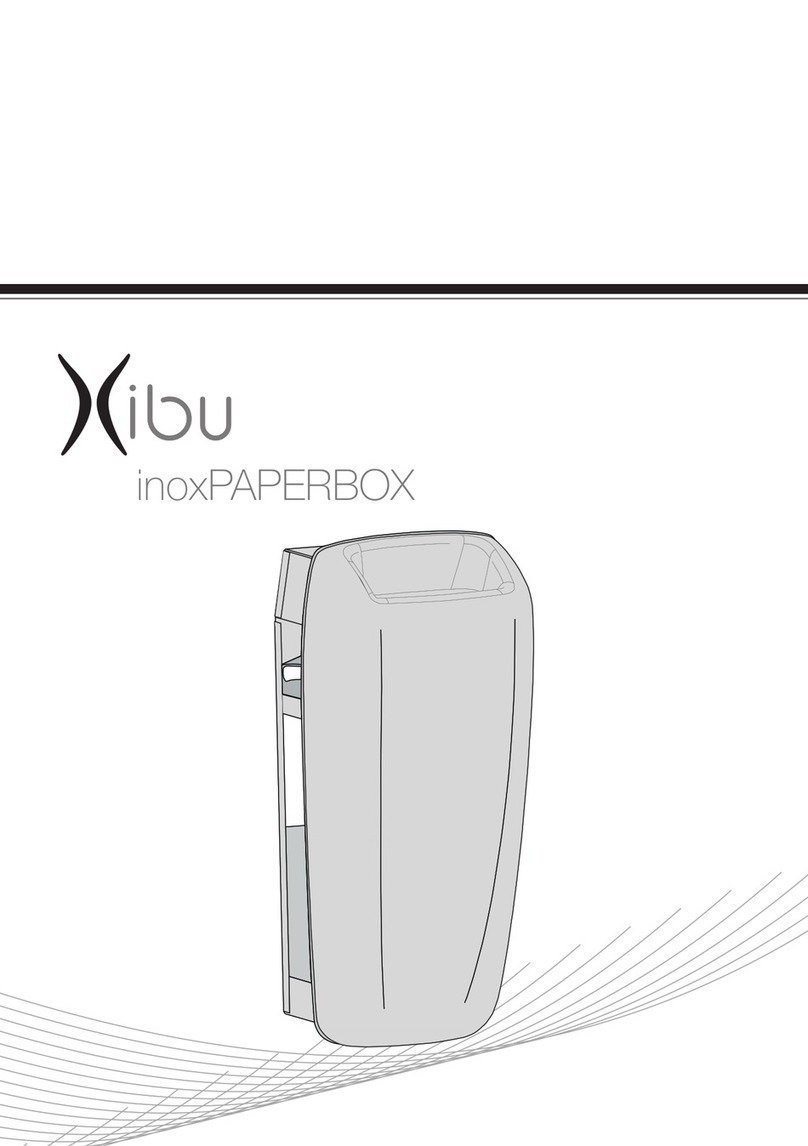

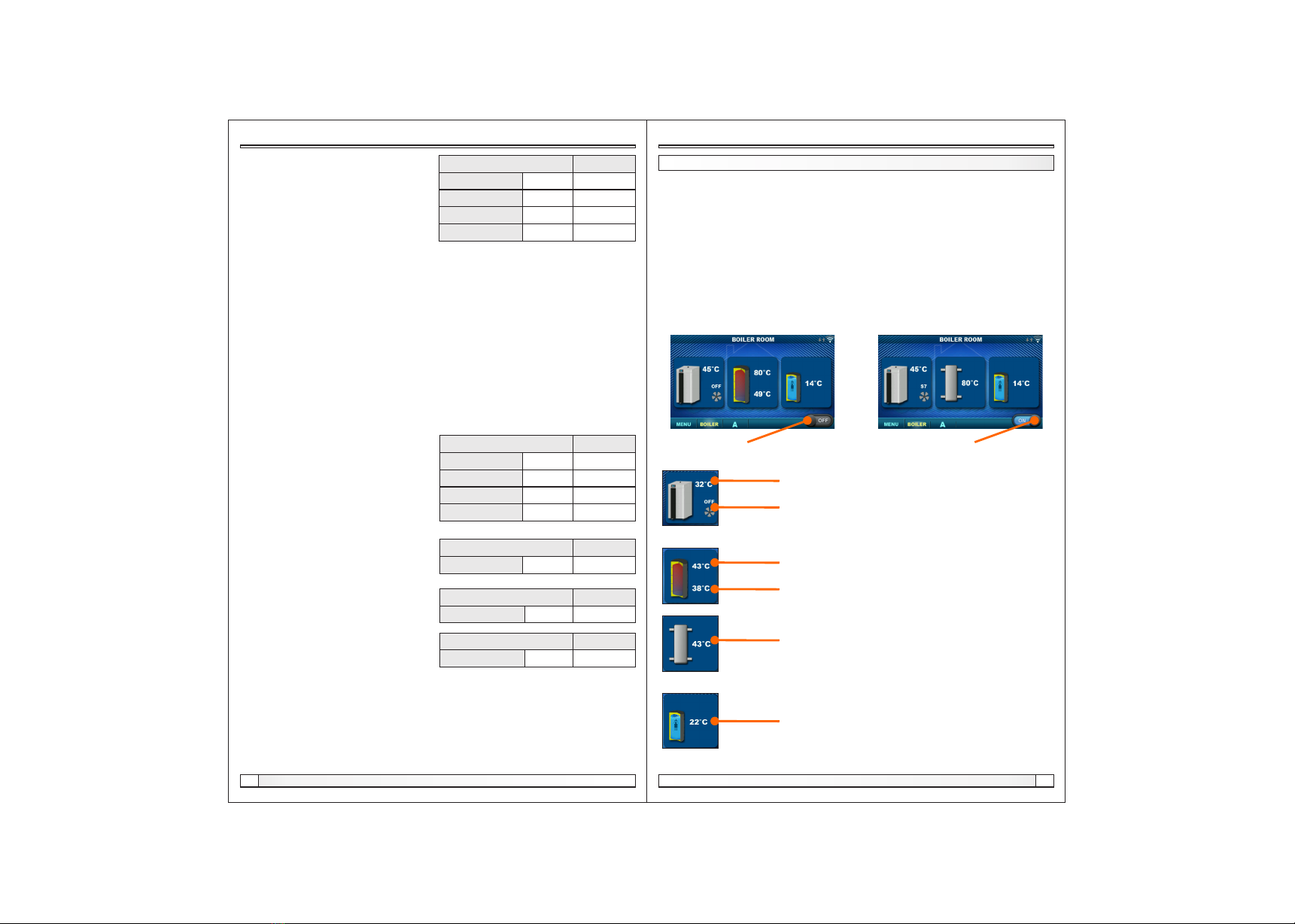

BOILER MENU

Boiler menu

In the Boiler menu it is possible to monitor the operation of the boiler and the temperature of the

existing configuration, start and stop the boiler and check all faults / warnings that have occurred on

the boiler control. The display shows the current phase of operation of the boiler with the symbols of

flame and fan operation as well as the boiler temperature and, depending on the existing

configuration, the current temperature in the accumulation tank or hydraulic crossover and DHW

tank (if any). By pressing the ON / OFF button, the boiler can be switched on / off.

If a warning or an error occurs on the boiler control, a warning / error message is also displayed on

the corrector screen. Pressing the OK button on the error / warning screen of the corrector will

reduce the error / warning and remain recorded through the (Boiler) menu and the error / warning

menu can be read again.

Boiler ON/OFF

(position when boiler is switched off)

Boiler ON/OFF

(position when boiler is on)

Boiler + Buffer tank + DHW Boiler + Crossover + DHW

Boiler temperature

Boiler operating phase / has / no flame / boiler fan operation

Buffer tank temperature (up)

If an buffer tank is selected in the boiler configuration

Buffer tank temperature (down)

If an buffer tank is selected in the boiler configuration

If the DHW tank does not exist in the boiler control system,

the DHW tank image will not be displayed

Crossover temperature

If a hydraulic crossover is selected in the boiler configuration

Configuration:

Technical instructions CSK-Touch

8Technical instructions CSK-Touch 9

Menu, schedule Schedule, temperature

MENU

In this menu it is possible to set time schedule of all selected boiler heating and DHW circuits (if

any), adjust the temperatures of the selected heating circuits as well as any temperatures that can

be adjusted on the boiler control and adjust the room corrector settings.

1. SCHEDULE

In this menu it is possible to set the time schedule for each selected view (heating circuit), boiler

and, if any, heating of the DHW tank. The time schedule can be switched off or selected from one of

the tables with set time intervals of active and inactive function. Views and settings of existing time

schedules vary depending on the configuration.

1.X. Boiler

1.x.x. Schedule

Choose when the boiler is active or not active

on a particular day of the week - time schedules can be switched off or select one of 3 tables

where boiler activity times can be set. Only one table can be active at a time.

Schedule OFF

Factory: setting

OFF / Table 1/2/3

1.x.x. Table 1/2/3

Table for selecting the time when the boiler is active and when not. Green at the left edge of the

table indicates the start of time from when the boiler is active for heating, and red at the edge of the

Table indicates the start of time when the boiler is not active for heating. On each day of the week it

is possible to select 3 times the active state of the boiler and 3 times the time when the boiler is not

active for heating. The factory settings of the tables are: every day from Monday to Sunday from

06:00 hours the boiler is active for heating until 22:00 from when the boiler starts to be inactive until

the next day at 06:00. On the right side of the screen there are buttons to copy the desired day and

paste it to another selected day (copy / paste).

1.1. View A

1. 1. 1. Day/Night Temp.

Selecting the set room temperature mode -

Day temperature, Night temperature or Table selection.If the temperature mode is selected

according to the Table, the times in the following Tables must be set (switching the temperature

mode according to the specified time in each day). Only one Table can be active at the same time.

Day/Night Temp. Day/Night Temp.

Factory: setting

Day / Night / Table 1/2

1.1.x. Table 1/2

Time table for day / night room temperatures. Green at the left edge of the table indicates the start of

daytime temperature, red at the edge of the table indicates the start of nighttime temperature. It is

possible to choose 3 times daily and 3 times night temperatures on any day of the week. The factory

settings of the tables are: Every day from Monday to Sunday at 06:00 hours the daily temperature

of the room starts and lasts until 22:00 when the night temperature begins, which lasts until the next

day at 06:00. On the right side of the screen there are buttons to copy the desired day and paste it to

another selected day (copy / paste).

Depending on the configuration selected on the boiler, certain menus appear in the menu

2.Temperature in which the set temperatures and differentiations (seen on the boiler control) can

be changed:

Day / Night Temp. / Daily room temp. / Night room temp. / Heating curve / Correction coeff. / Buffer

tank temp. / Min. buf. tank temp. / Diff. buf. tank temp. / Diff. stop buff. tank / Crossover temp. / DHW

temp. / Differential of DHW

2.1.1. Day/Night Temp.

Day Temperature: maintaining a set daily temperature all the time

Night temperature: maintaining a set night temperature all the time

Table 1/2: Maintain day / night temperature by set times for each day of the week of the selected

table

2.1. View A (see point 3.2.)

1.x.x. Table

Table for selecting the time when DHW heating is active and when not.

Table for selecting the time when DHW heating is

active and when not. The green color on the left

edge of the table indicates the start of time since

DHW heating is active, and the red color on the

edge of the table indicates the start of time when

DHW heating is not active. On each day of the week

it is possible to select 3 times the active DHW

heating status and 3 times the time when the DHW

heating is not active. The factory default settings for

the table are: every day from Monday to Sunday

from 06:00 hours DHW heating is active until 22:00

from when DHW heating starts to be inactive, until

the next day at 06:00. On the right side of the screen

there are buttons to copy the desired day and paste

it to another selected day (copy / paste).

Factory: setting

Table 1 06:00-22:00 mon/tue/wed/thu/fri/sat/sun

Day/Night Temp Day Temp.

Factory: setting

Day Temp. / Night / Table 1/2

1.X. DHW

1.x.x. DHW schedule

Selecting a time when DHW is active on a particular day of the week - time schedules can be

switched off or on, and when switched on, the DHW heating activity times in the table must be set.

DHW schedule OFF

Factory: setting

OFF / ON

2. TEMPERATURE

Other manuals for CSK-Touch

1

Table of contents

Other Centrometal Household Appliance manuals