Century C-VFF30 User manual

Page 1 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

Important: Any maintenance,

service or repair should be

performed by trained and

experienced service technicians.

Proper tools and equipment

should be used to prevent injury

to the servicing technician,

property or system components.

Service repairs should always be

performed in a safe environment

and the technician should always

wear protective clothing to

prevent injury.

The Form 103-2 repair kit

instructions will provide the

technician information to

successfully repair the VFF30

Lockoff. Always inspect the

major casting pieces for damage,

corrosion or cracks before

attempting a service repair. Be

sure the repair kit part number

you are using is correct for

the Lockoff being serviced.

Diaphragms are color coded

and have different performance

characteristics.

YELLOW: Silicone diaphragm

material is the optional upgrade

material that provides excellent

exibility in cold weather climates

and is more resistant to chemical

contamination.

BLUE: diaphragm material

provides excellent high and

low temperature durability with

increased chemical resistance.

This material is recommended

for turbo applications.

Do not use Teon tape to seal any

fuel ttings. Failure to follow this

warning may cause internal leaks

resulting in serious injury and/or

property damage.

REPAIR KIT PART NUMBERS

C-RK-VFF30 Repair Kit, C-VFF30 (Standard Hydrin Diaphragm)

Part # Description

C-RK-VFF30-958 Repair Kit, C-VFF30 Blue Diaphragm, Hyster

C-RK-VFF30-2 Repair Kit, C-VFF30 (Silicone Diaphragm)

C-RK-VFF30-3 Repair Kit, C-VFF30 (Blue Diaphragm)

MODEL C-VFF30 LOCKOFF/FILTER

REPAIR KIT INSTRUCTIONS

Page 2 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

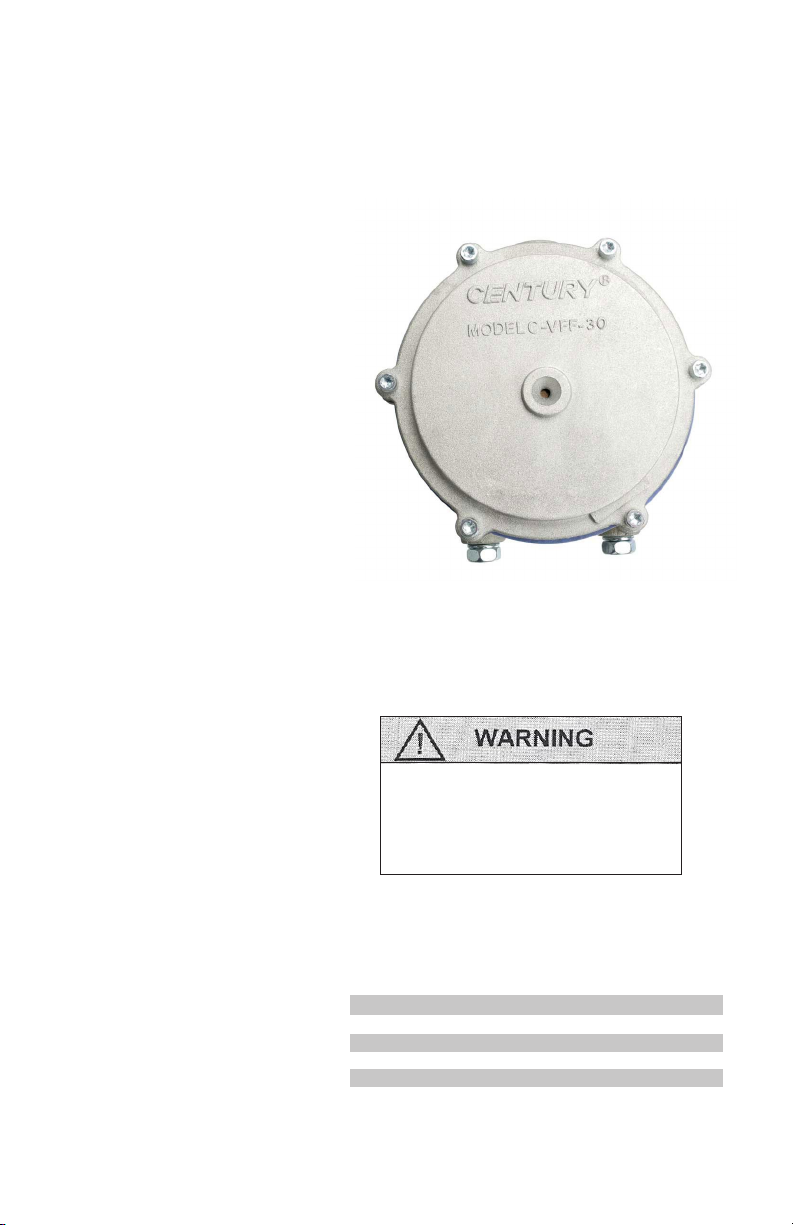

MODEL C-VFF30 LOCKOFF/FILTER COMPONENTS

ITEM# PART# DESCRIPTION

1* C-S1-15265-001 Screw, 8-32 Taptite (6)

2 C-C1-37 Diaphragm cover,

(std., C-VFF30 only)

3* C-BD1-26 Diaphragm Assy,

Standard (C-RK-VFF30)

C-BD1-27 Diaphragm Assy, Silicone

(C-RK-VFF30-2)

C-BD1-27-5 Diaphragm Assy,

Blue

(C-RK-VFF30-3)

4* C-S1-15265-002 Screw, 8-32 Taptite (3)

5 C-F3-2 Fulcrum

6 C-L1-39 Valve operating lever

7 C-AB1-30149 Body ass’y

8 C-S1-15 Screw, 1/4-20 x 5/8”

SEMS (2)

9* C-S3-116 Seal, Lip Pin

10* C-P1-15 Valve, operating pin

11 C-S2-40 Valve, spring

12* C-S7-3 Screen, back-up lter

13* C-F1-10 Filter

14* C-AF1-10 Filter ass’y

15* C-G1-89 Filter cover gasket

16 C-C1-38 Filter cover

17 *C-S1-15266-001 Screw, 12-24 Taptite (10)

18 C-AF4-66 Fitting, ball check,

assy (not shown)

19 C-S4-18 Seat, C-VFF30

20* C-W1-42 Washer, Seal Retaining

NSS = Not Serviced Separately

* Repair Kit Components. Note that extra

screws (both slotted and torx) are included

in the repair kits to replace any that may be

damaged. When replacing screws, be sure

to properly match thread type (self-tapping

or machined) as the two types are not

interchangeable.

Page 3 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

REBUILD INSTRUCTIONS

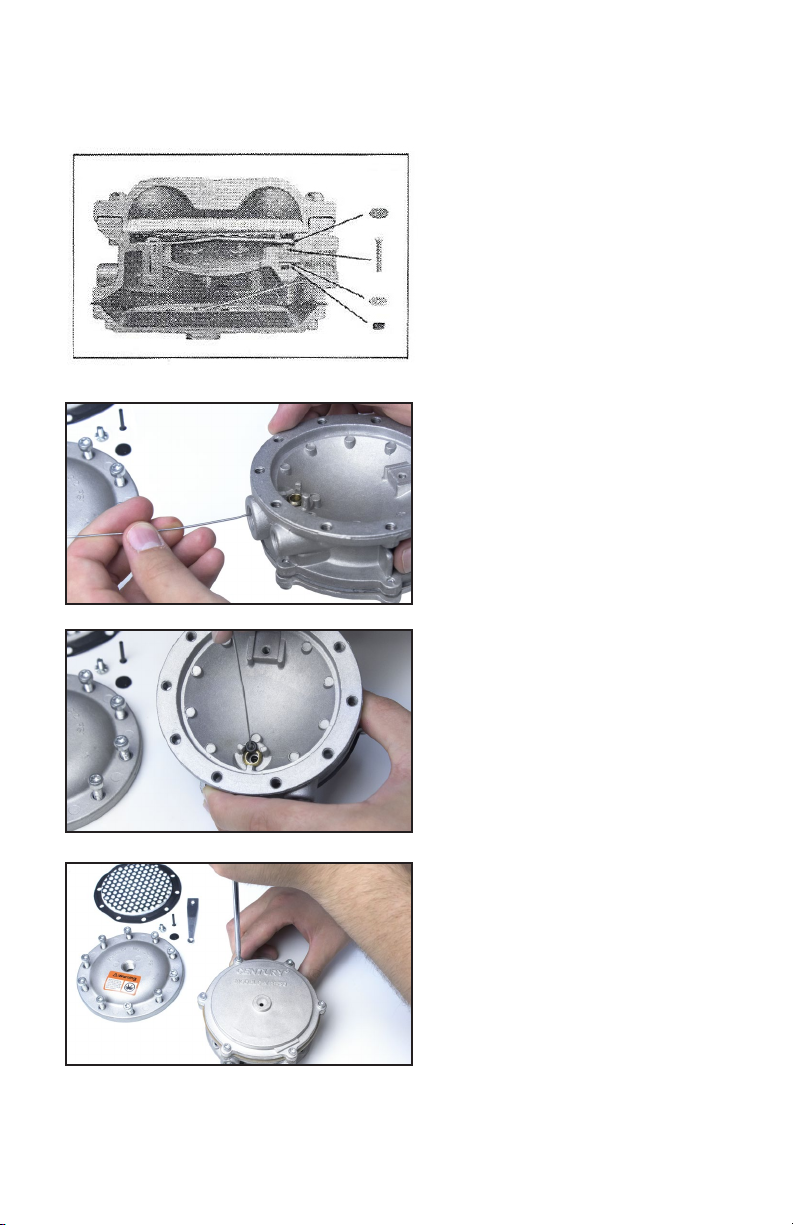

Disassembly

1. Remove 10 screws from “Fuel In”

cover.

2. Remove cover and C-GI-89

gasket.

3. Remove C-F1-10 lter and screen

C-S7-3.

4. Remove C-S1-15265-002 screw

retaining valve spring.

Page 4 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

5. Remove valve spring.

6. Using a small at head

screwdriver, remove C-S4-18 valve

seat.

7. Gently lift up and remove the

C-P1-15 valve operating pin.

8.With paper clip or wire, fashion a

hook as shown.

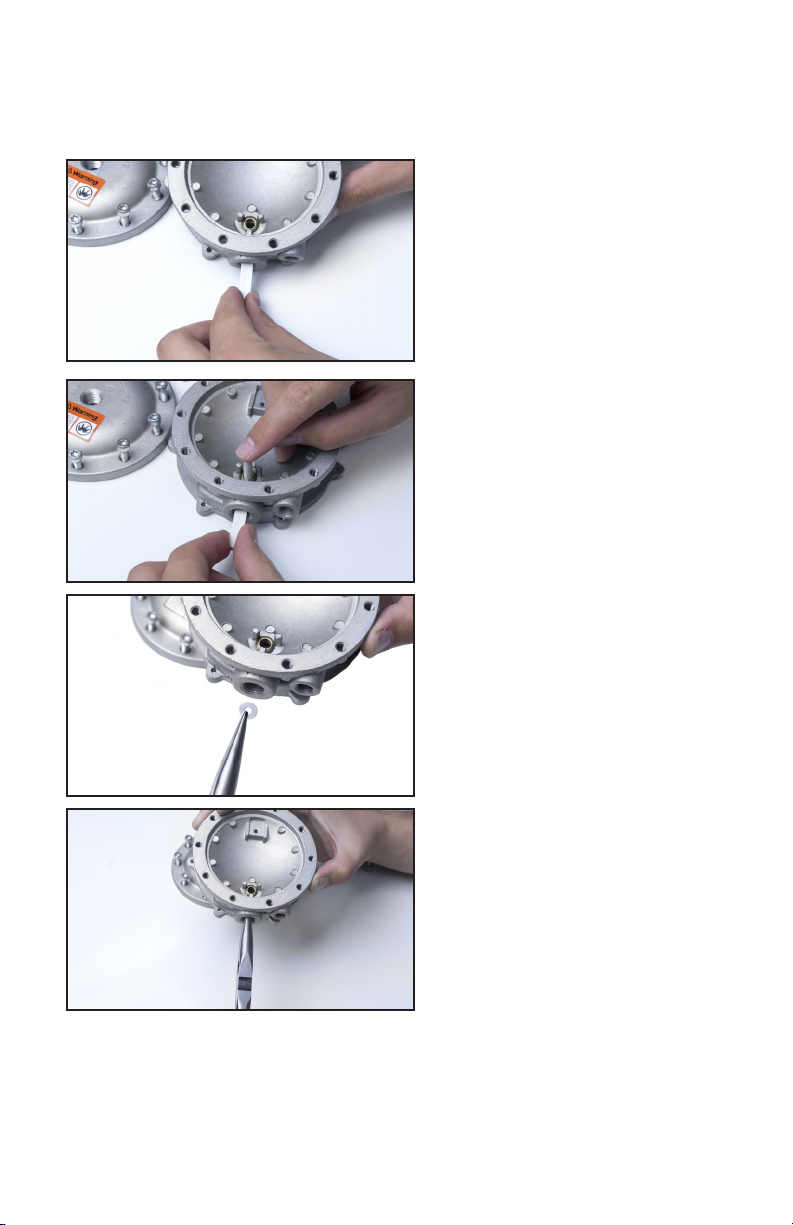

Page 5 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

9. Cutaway show assembly of valve

spring, valve seat, valve operating

pin, seal retaining washer and pin lip

seal. Note that removal of valve pin

allows retaining washer to be removed

through the 1/4” NPT opening labeled

“Out”.

10. Insert paper-clip hook in center

hole of C-W1-42 seal retaining washer

and remove.

11. Using the same hook, remove the

pin seal C-S3-116 through valve jet.

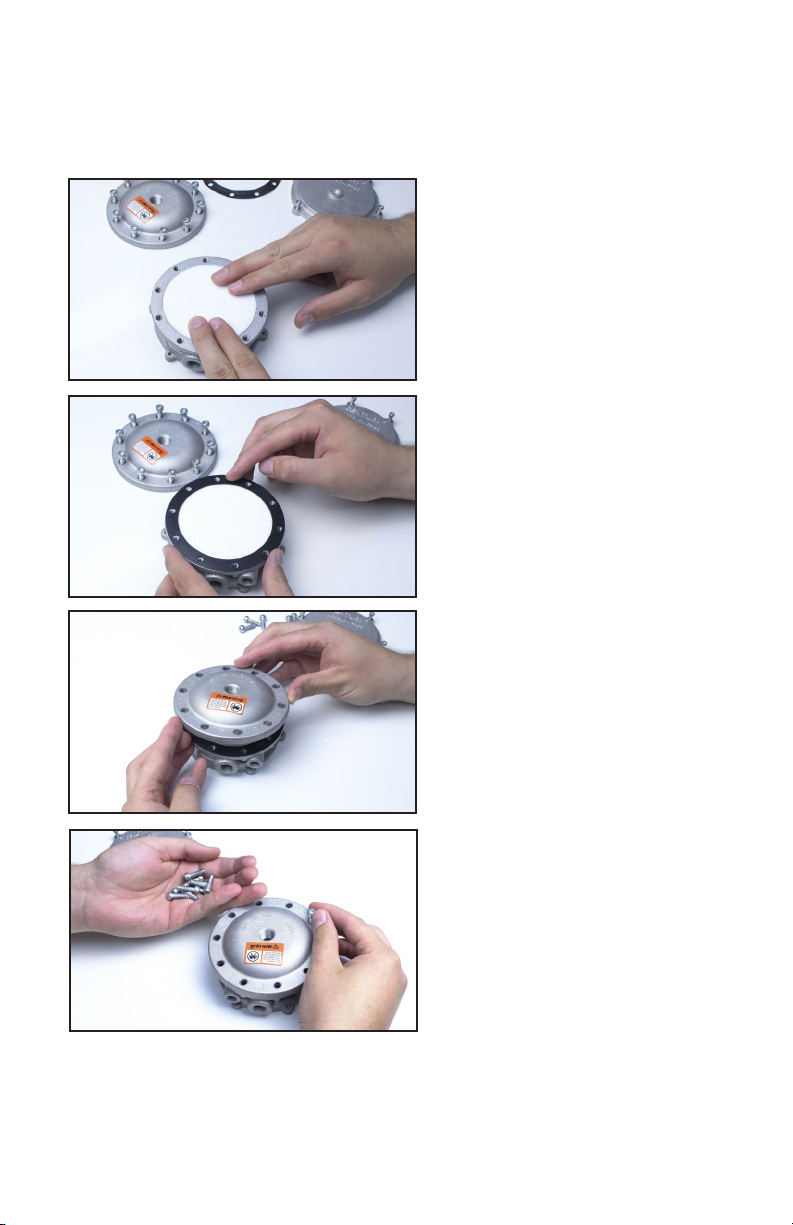

12. Remove 6 screws on diaphragm

cover side.

Page 6 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

13. Remove cover and diaphragm

assy. Clean covers, body and metal

parts as necessary with a safety

solvent and dry prior to reassembly.

Do not use harsh solvents such as

brake or carburetor cleaner on any

of the non-metallic components as

they will damage this material.

Page 7 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

14.

1

1

1

1

2

2

1

1

1

1

1

1

1

2

2

1

*Standard diaphragm. See table on page 2 for

optional diaphragms.

15. Lubricate the Lip Pin Seal C-S3-

116 with petroleum jelly or Vaseline

and insert into the Holder C-H1-

14236 groove side up, as shown

in the illustration. Note that the

C-H1-14236 Seal Holder passage is

tapered and the wide opening of the

seal holder should be facing up.

16. Place the C-VFF30 body with the

lter side up, as shown in the photo,

on a at surface. Ensure that the

groove in the seal is visible from the

top of the taper of the seal holder.

Reassembly

C-GI-89 Gasket

C-RK-VFF30 Kit Includes:

C-F1-10 Filter

C-S7-3 Screen

C-BD1-27* Diaphragm Assy

C-S1-59 Screw, 8-32 x 5/8”

C-S1-100 Screw, 12-24 x 5/8”

C-S4-18 Seat (Viton Bonded to Aluminum)

C-S3-116 Seal, Lip Pin

C-PI-15 Pin, Valve Operating

C-W1-42 Retainer Washer 1

C-H1-14236 Seal Holder Insertion Tool

C-P1-14235 Pin Insertion Tool

Form 103-2 Instructions

C-S1-15265-001 Screw, 8-32 17/32” Taptite Torx

C-S1-15266-001 Screw, 12-24 x 11/16 Torxl

C-S1-15265-002 Screw, 8-32” 3/8” Taptite Torx

Page 8 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

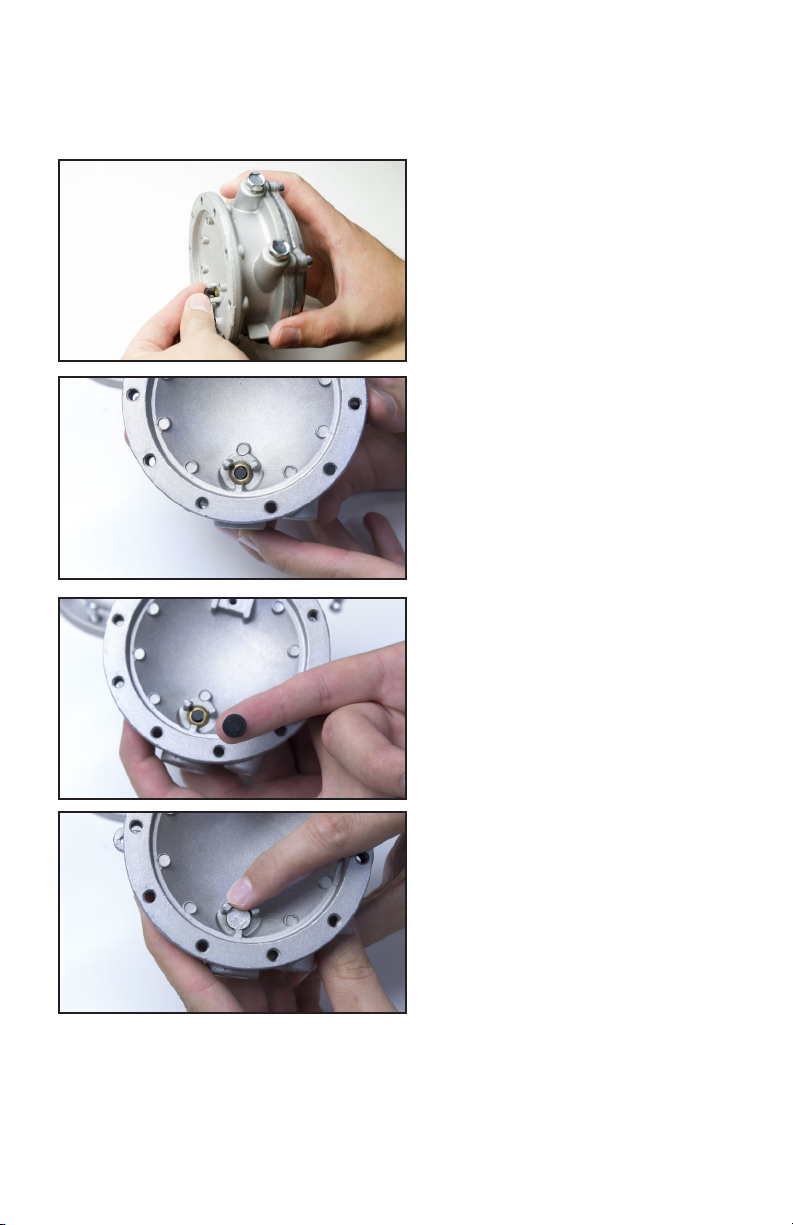

17. Place the holder in the up

position and slide the holder into the

seal into the body of the C-VFF30.

Looking through the fuel port,

position the seal above the cavity of

the seal recess.

18. Coat the installation pin C-P1-

14235 with petroleum jelly and push

the seal through the holder and into

the seal recess of the C-VFF30 body.

Look through the fuel port to ensure

the seal is seated in the seal recess

and that the groove in the seal is

visible.

19. Use needle nose pliers to hold

C-W1-42 seal retainer washer.

20. Insert seal retainer washer in

slot to hold the lip seal in place.

Page 9 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

21. Lubricate pin with petroleum jelly

and insert through hole in retainer

washer and pin lip seal. Again rotate

head of pin gently in a circular motion

to ease pin into place through washer,

lip seal and body housing.

22. Pin C-P1-15 is properly placed in

valve jet.

23. Valve seat shown with aluminum

side up ready to be placed on jet.

24. Place the seat with the viton (black

rubber) side down, in position on jet.

Page 10 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

25. C-S2-40 spring ready to be

fastened in place. Be sure the arc

in the center faces upward (see

illustration in step 26 below).

26. Replace spring and fasten in

place by C-S1-15265-002 screw

(8-32). Align the tip of spring (over

valve) and center between the 3

guide ns as shown in illustration.

Tighten screw to 30 +/-3 in-lbs.

27. When spring is in place, lift

slightly to ensure it can move freely.

28. Insert C-S7-3 screen and lter

C-F1-10 into recess.

Page 11 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

29. Press C-F1-10 lter so that it is

properly seated in recess.

30. Place C-G1-89 gasket in place

and align with screw holes.

31. Insert screws opposite each

other in the “Fuel In” cover and

place on gasket. Thread the two

screw C-S1-15266-001 through the

gasket and into the body.

32. Insert remaining 8 screw in their

openings.

Page 12 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

33. Tighten screws, alternating from

side to side on opposite sides of the

cover until all screws are solidly set.

Torque to 65+/-5 in-lbs.

34. Lift lever C-L1-39 to ensure it

moves properly and verify that the

C-P1-15 lever control pin follows lever

travel.

35. Turn diaphragm so the raised lip

is downward (see illustration on page

2) place on the Lockoff and rotate to

position so the screw hole pattern

aligns with the holes in the body

(there is only one position in which

the holes will line up).

36. Place cover in correct position and

insert screws C-S1-15265-001.

Page 13 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

37. Tighten screws alternatively

from side to side across cover until

all are solidly fastened. Torque to

30 +/-3 in-lbs.

38. Pressurize the “Fuel In”

opening with approximately 100

psi of air pressure. Draw a soap

bubble across the Lockoff outlet

and vacuum port (labeled “VAC”) to

verify that no air is owing through

either opening. If air escapes, the

rebuild has failed and the Lockoff

must be replaced. Apply a small

amount of vacuum to the port

labeled “VAC” to verify the air ows

freely through the outlet. Use soap and/or a commercial leak detector solution

to inspect the gasket seals around the perimeter of the Lockoff for leaks. If leaks

are found, the Lockoff must be replaced. If no leaks are found, the Lockoff can be

reinstalled and returned to service.

Page 14 of 14 C-VFF30 Repair Kit Instructions (Form 103-2)

SERVICE TECHNICIANS AND USERS

SHOULD CAREFULLY READ AND ABIDE BY THE PROVISIONS SET FORTH IN

NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #37 FOR STATIONARY

ENGINES, #52 FOR CNG VECHICULAR FUEL SYSTEMS OR #58 FOR LPG

SYSTEMS.

IN CANADA

REFER TO CAN/CGA PROPANE INSTALLATION CODES

CNG INSTALLATIONS IN THE UNITED STATES

MUST BE DONE IN ACCORDANCE WITH FEDERAL STATE OR LOCAL LAW AND

NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #52, COMPRESSED

NATURAL GAS (CNG) VEHICULAR FUEL SYSTEMS TO THE EXTENT THESE

STANDARDS ARE NOT IN VIOLATION WITH FEDERAL, STATE OR LOCAL LAW.

IN CANADA

REFER TO CAN/CGA CNG INSTALLATION CODES.

LPG AND/OR NATURAL GAS INSTALLATIONS ON STATIONARY

ENGINES

MUST BE DONE IN ACCORDANCE WITH FEDERAL, STATE OR LOCAL LAW AND

NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #37, STATIONARY

COMBUSTION ENGINES AND GAS TURBINE ENGINES, TO THE EXTENT THESE

STANDARDS ARE NOT IN VIOLATION WITH FEDERAL, STATE OR LOCAL LAW.

FAILURE TO ABIDE BY THE ABOVE WILL VOID ANY IMPCO WARRANTY ON THE

PRODUCTS AND MAY CAUSE SERIOUS INJURY OR PROPERTY DAMAGE.

DUE TO THE INHERENT DANGER OF GASEOUS FUELS THE CENTURY PRODUCTS

SHOULD NOT BE INSTALLED OR USED BY PERSONS NOT KNOWLEDGEABLE

OF THE HAZARDS ASSOCIATED WITH THE USE OF GASEOUS FUELS.

WARNING:

IMPROPER INSTALLATION OR USE OF THIS PRODUCT MAY

CAUSE SERIOUS INJURY AND/OR PROPERTY DAMAGE.