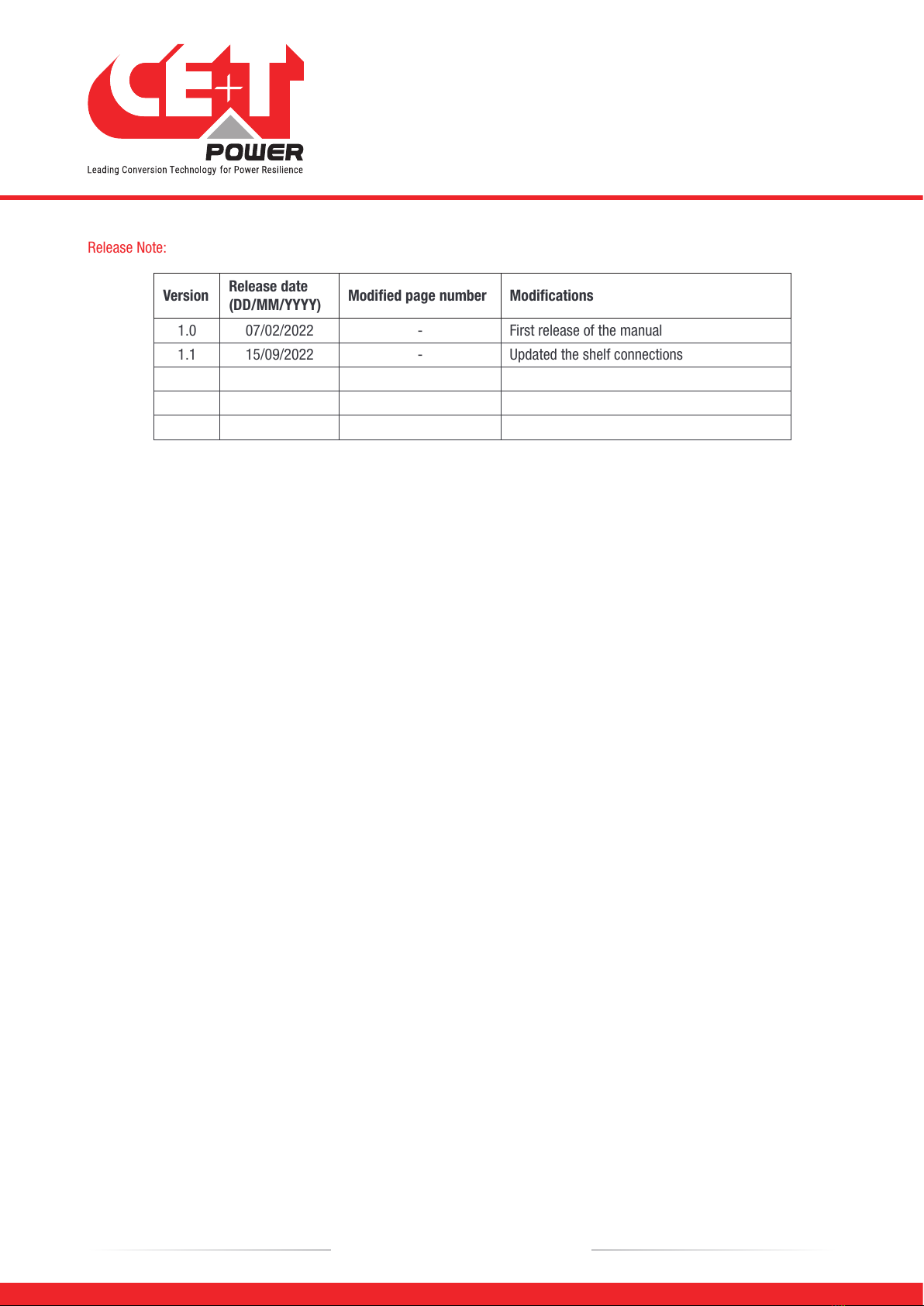

2 – Sierra 10 - 48/120 VAC – User Manual – v1.1

Table of Contents

1. Introduction to CE+T.............................................................................................................................. 6

2. Abbreviations......................................................................................................................................... 7

3. Warranty and Safety Conditions ............................................................................................................. 8

3.1 Disclaimer................................................................................................................................... 8

3.2 Technical care............................................................................................................................. 8

3.3 Installation .................................................................................................................................. 9

3.3.1 Handling......................................................................................................................... 9

3.3.2 Surge and transients ...................................................................................................... 10

3.3.3 Other.............................................................................................................................. 10

3.4 Maintenance .............................................................................................................................. 10

3.5 Replacement and Dismantling..................................................................................................... 10

4. ECI Technology....................................................................................................................................... 11

4.1 EPC mode ................................................................................................................................... 12

4.2 Back up mode............................................................................................................................. 12

5. Building Blocks ...................................................................................................................................... 13

5.1 Sierra 10 - 48/120 ...................................................................................................................... 13

5.1.1 Specifications................................................................................................................. 13

5.2 Sub-rack..................................................................................................................................... 15

5.3 Controller Unit ............................................................................................................................. 15

5.3.1 Inview Slot ..................................................................................................................... 15

5.4 Inview S ...................................................................................................................................... 17

5.4.1 Inview S - Connections................................................................................................... 17

5.5 Measure Box Battery (MBB)......................................................................................................... 18

6. System Installation................................................................................................................................. 19

6.1 Transformer and Generator Sizing ............................................................................................... 19

6.2 Mounting kit for Sierra 10 shelf ................................................................................................... 20

6.3 Cable Routing and Fixation .......................................................................................................... 21

6.3.1 Grounding ...................................................................................................................... 21

6.4 Electrical Installation for Sierra 10 shelf....................................................................................... 22

6.4.1 Pre requisites ................................................................................................................. 22

6.4.2 Terminations .................................................................................................................. 22

6.4.3 Single phase configuration - 120 Vac ............................................................................. 23

6.4.4 Split phase or Single phase configuration - 240 Vac ....................................................... 24

6.4.5 Three Phase Configuration - 208 Vac.............................................................................. 25

6.4.6 AC Input and Output ....................................................................................................... 26

6.4.7 DC.................................................................................................................................. 27

6.4.8 Sierra 10 System with Inview S - Connections................................................................ 28

6.4.9 Signalling ....................................................................................................................... 28

7. Interface ................................................................................................................................................ 30

7.1 Inverter module........................................................................................................................... 30