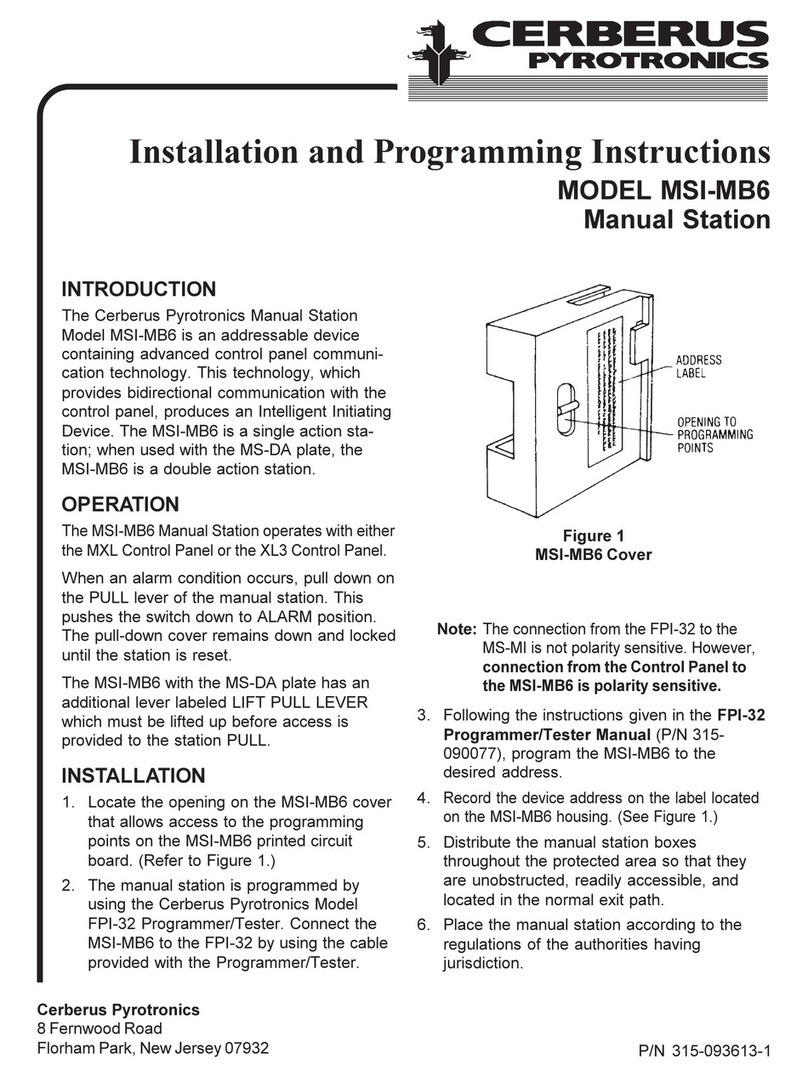

Figure 1

Installation and

Wiring Diagram

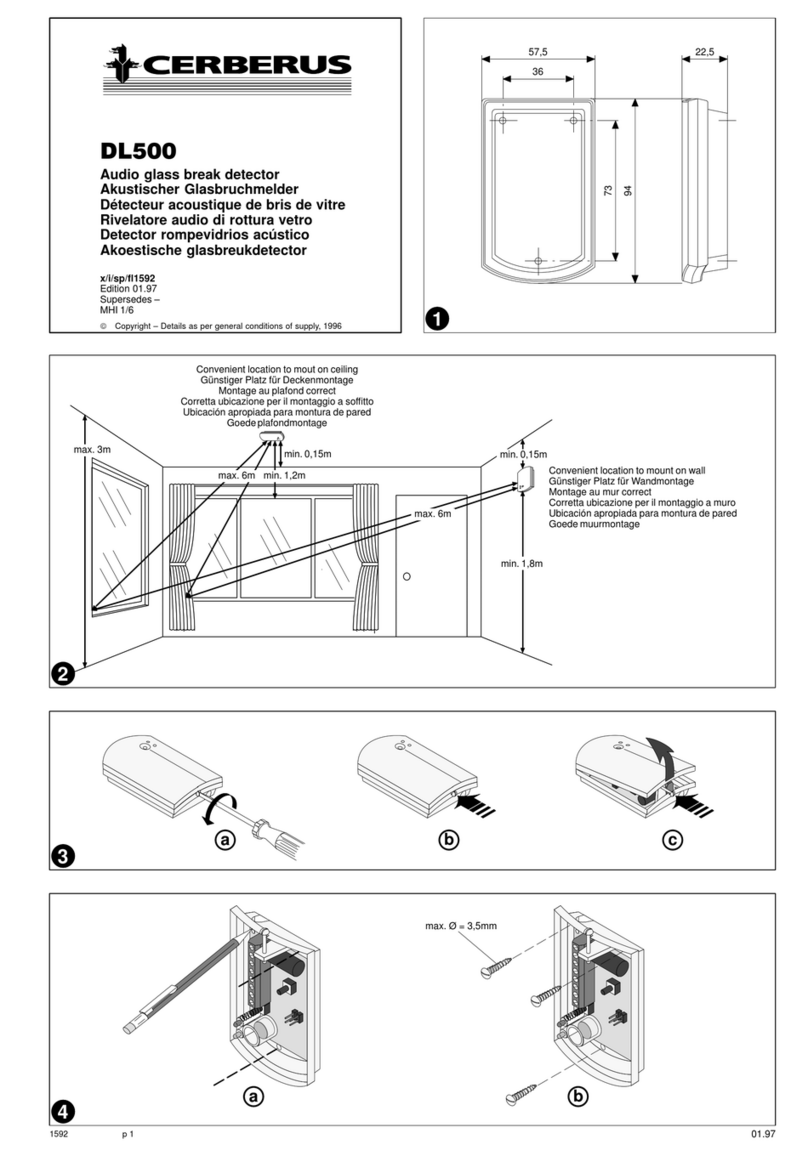

2

each smoke detector. This is why it is mandatory to

closely follow the installation drawings. In all installations

place the detector on the ceiling, a minimum of 6 inches

from a side wall, or on a wall, 6 inches from the ceiling.

If you have any questions regarding detector placement,

follow the drawings provided or approved by Cerberus

Pyrotronics or by its authorized distributors. This is

extremely important! The detector placements shown on

these drawings were chosen after a careful evaluation

of the area that is protected. Factors such as air currents,

temperature, humidity, pressure, and the nature of the

load were carefully considered. Especially noted were

the room or area configuration and the type of ceiling

(sloped or flat, smooth or beamed). Cerberus Pyrotron-

ics extensive experience in the design of the system

assures the best detector placement. Sound engineer-

ing judgment by qualified personnel must be followed.

DB-3S DB-X3RS DB-3S DB-X3RS

To avoid nuisance alarms:

Do not locate the detector next to an oil burner,

electric heaters, kitchens, or garages where exhaust

smoke can trigger an alarm. Other causes of false

alarms are dust accumulation, heavy concentrations

of steam, heavy pipe or cigar smoking, high relative

humidity or other humid areas where condensa-

tion may occur, and concentrated aerosol sprays.

AIR CURRENTS

Before a detector can sense a fire, the products of com-

bustion or smoke must travel from the fire to the detector.

This travel is especially influenced by air currents;

therefore, consider air movement when designing the

system. While combustion products tend to rise, drafts

from hallways, air diffusers, fans, etc., may help or hinder

the travel of combustion products to the detector. When

positioning a detector at a particular location, give

3