16 17

2.1 Detection Principle

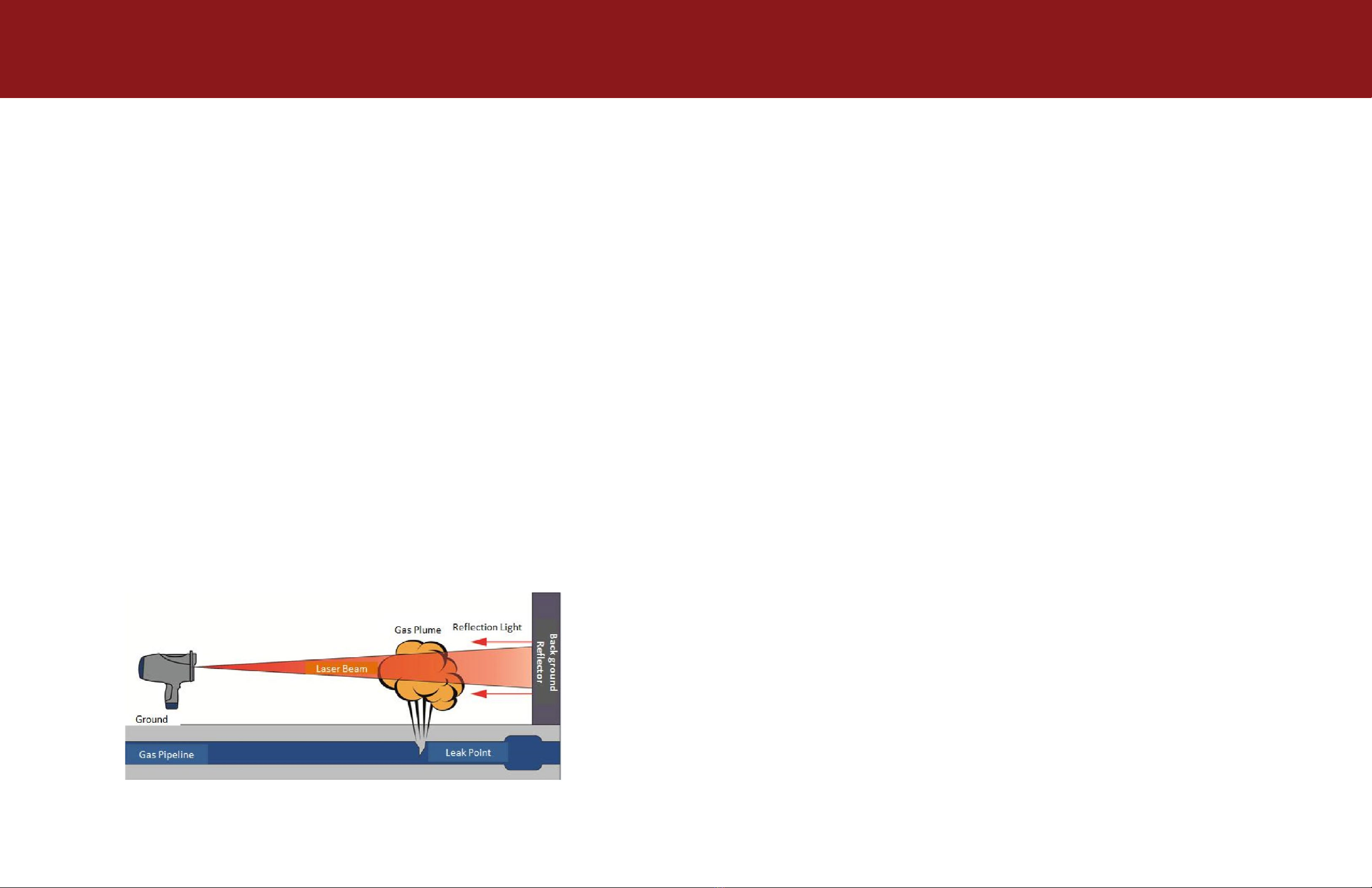

The TDL 300 adopts advanced tunable diode laser absorption

spectroscopy (TDLAS) technology combined with DSP digital signal

processing techniques. This detection method uses wavelength

scanning and tuning characteristics of semiconductor laser diodes

as well as the absorption characteristics of Methane to eliminate

cross interference. DSP allows digital circuits for signal generation,

analysis, and processing to assist the anti-interference capability,

improve stability, and produce repeatable results.

When the laser of the TDL 300 is aimed at the target gas pipeline,

part of the laser beam is absorbed by leaking Methane. The laser

beam returns after being scattered or hitting a barrier behind the

gas. Returning light is collected by an optical lens, and received by

a highly sensitive InGaAs detector. After the signal is processed, gas

concentrations are displayed on the LCD screen.

Thus, the Methane detector is suitable for areas that are difficult to

access such as expressways, bridge pipelines, or other places that

cannot be reached. Direct access to these areas is not mandatory as

an operator will know if there is a gas leak, and its concentration, if

they follow the procedures laid out in this manual.

2.2 Glossary & Definitions

Detecting Laser: the laser beam sent by the handheld detector to

detect gas leaks;

Spotter Laser: the visible laser beam sent by the handheld detector

to assist the operator in aiming at a targeted area;

Scanning Distance: the longest working distance of the detector;

Reflection Light Fault: a fault caused when the handheld detector

cannot get enough returned light because the reflective rate is low,

the scanning distance it too long, or the ambient environment is not

conducive to scanning, etc.

Tunable Diode Laser Absorption Spectroscopy (TDLAS): an

advanced technique used for gas detection which adopts laser

wavelengths and tuning characteristics;

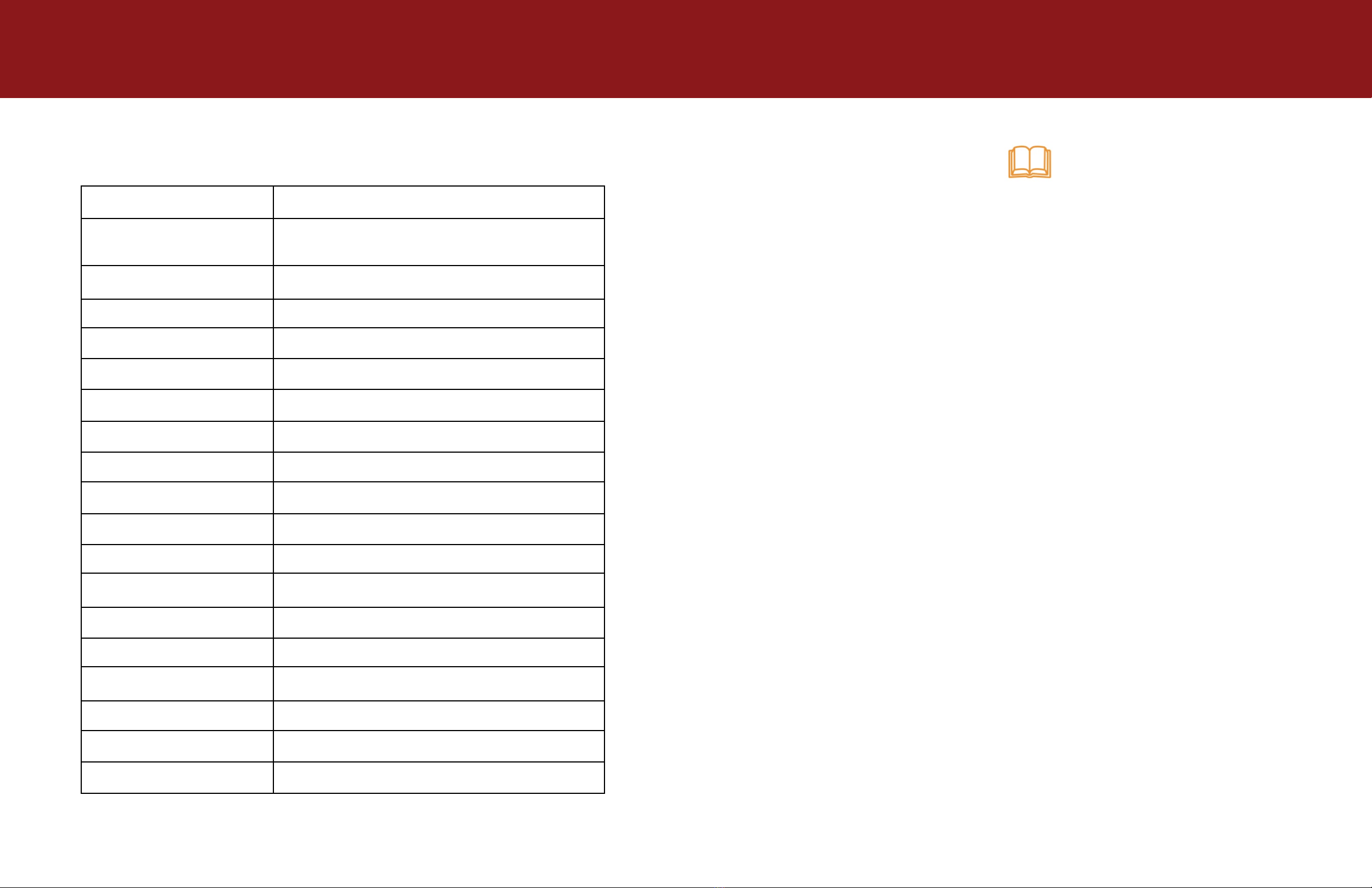

Integral Concentration: the traditional measurement of gas

detectors is the average indoor/outdoor gas concentration, the unit

is ppm or %LEL. The TDL 300 measures the gas concentration along

the “effective path of light transmission“ between the detector and

the target reflector. Normally, the effect of high gas concentrations

in small ranges is equal to low gas concentrations at a larger range.

The unit is measured as a gas average concentration, i.e. PPM*m or

ppm.m.

Diagram 2-2 (next page) shows two gas plumes: one at 5 m with a

concentration of 100 ppm and a second gas plume at 2 m with 250

ppm. These plumes appear in the path between the detector and the

background reflector and is equal to that of 100 ppm * 5 m * 2 =

250 ppm * 2 m * 1000 ppm.m.

2. Principle Instruction

Diagram 2-1 Unit Calculation Principle Diagram