System User Manual

2007-2016 Cervis, Inc.

Table of Contents

List of Figures .............................................................................................................................. ii

List of Tables................................................................................................................................ ii

Welcome to Cervis....................................................................................................................... 1

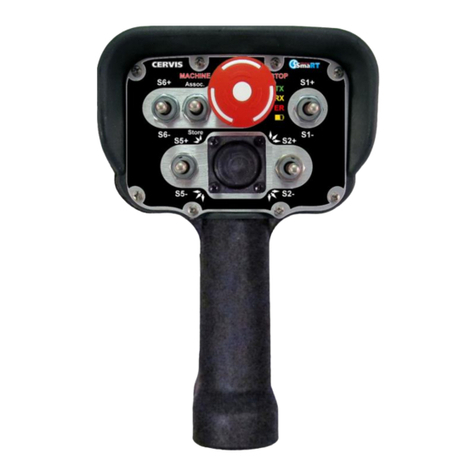

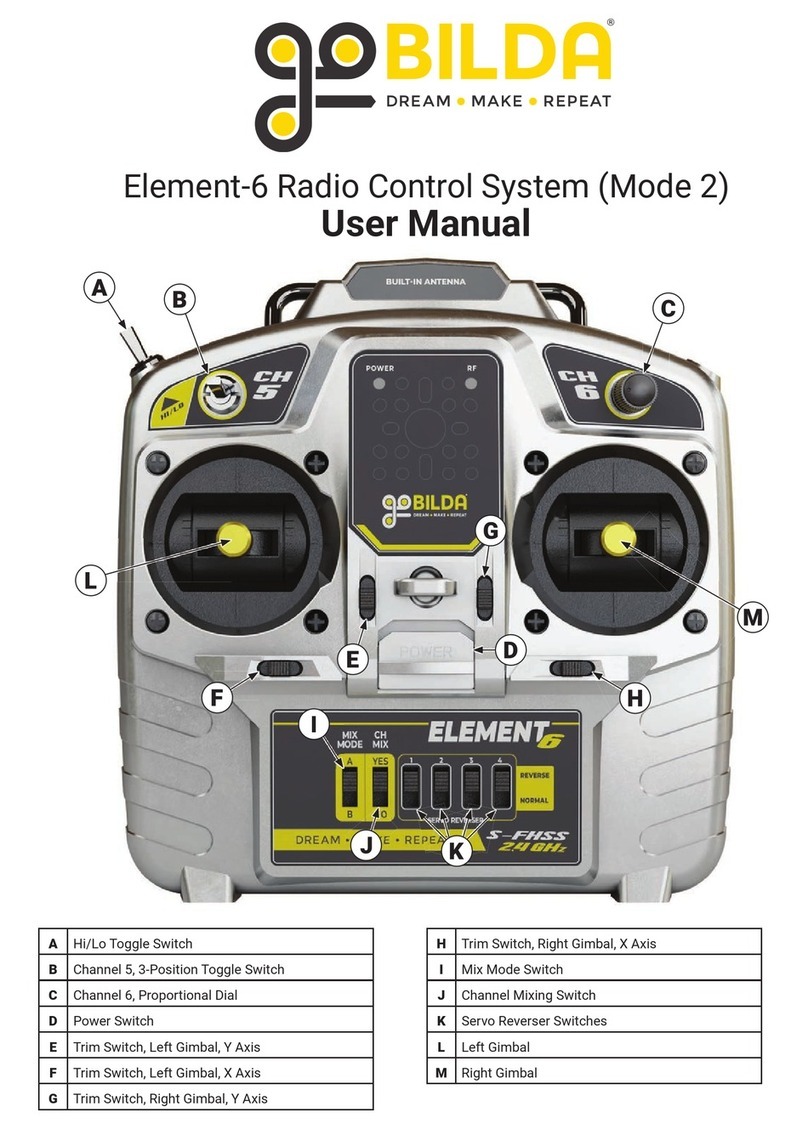

1.0 TM70 System Description ................................................................................................... 2

2.0 Safety Instructions............................................................................................................... 5

2.1 What You MUST Do .......................................................................................................... 5

2.2 What You MUST NOT Do.................................................................................................. 5

3.0 System Component Installation ......................................................................................... 7

3.1 Transmitter Battery........................................................................................................... 7

3.2 CB70 Battery Charger ...................................................................................................... 9

3.2.1 Charging Tips............................................................................................................. 10

3.3 Receiver Installation....................................................................................................... 10

3.4 Starting Up....................................................................................................................... 13

4.0 Using the System............................................................................................................... 15

4.1 General Instructions....................................................................................................... 15

4.2 Battery Level Monitor..................................................................................................... 15

4.2.1 LCD Option Power Level Display............................................................................... 16

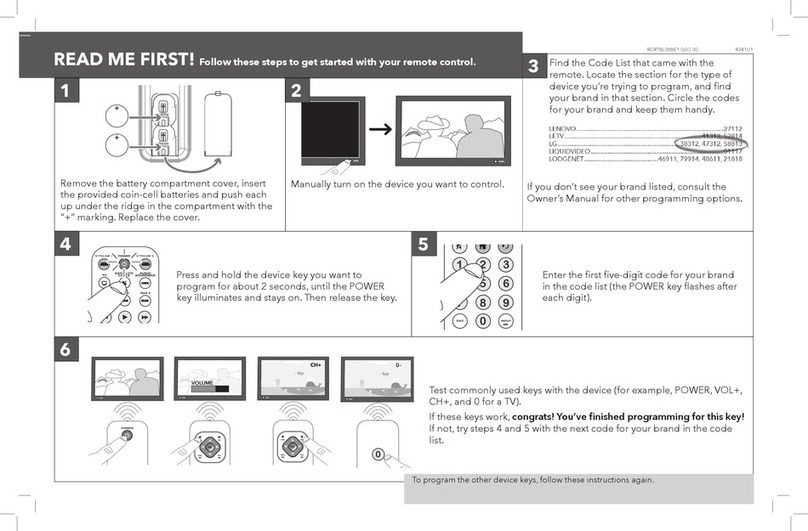

4.3 Programming a Spare Transmitter ............................................................................... 16

4.3.1 Transfer EP70 From Transmitter to Spare Transmitter ............................................. 16

4.3.2 Copy Receiver EP70 to Transmitter EP70................................................................. 17

4.4 Programming the Machine Identification in LCD Transmitters ................................. 19

4.5 LCD Display Analog Feedback Calibration.................................................................. 20

4.5.1 Calibrating Analog Feedback..................................................................................... 20

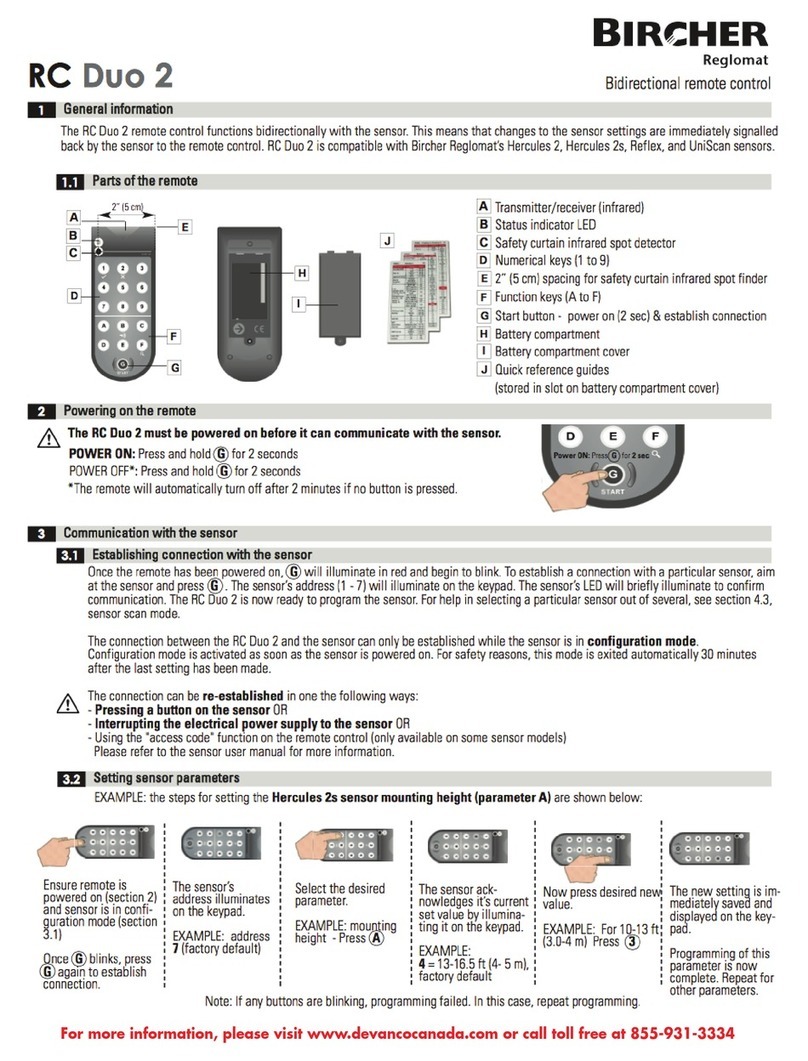

4.6Range Limiter.................................................................................................................. 21

4.6.1 Infrared Sensor........................................................................................................... 22

4.6.2 Infrared Transmitter.................................................................................................... 23

4.6.3 Installation .................................................................................................................. 23

4.6.4 Technical Characteristics of the LA70........................................................................ 24

5.0 Maintenance ....................................................................................................................... 25

5.1 Precautions ..................................................................................................................... 25

5.2 Fault Identification.......................................................................................................... 25

5.2.1 Transmitter................................................................................................................. 25

5.2.2 Receiver ..................................................................................................................... 25

5.3 Returning Equipment for Repair ................................................................................... 26

5.4 Spare Parts...................................................................................................................... 27

5.5 Common Spare Parts Identification (limited)............................................................... 29

6.0 Warranty.............................................................................................................................. 32