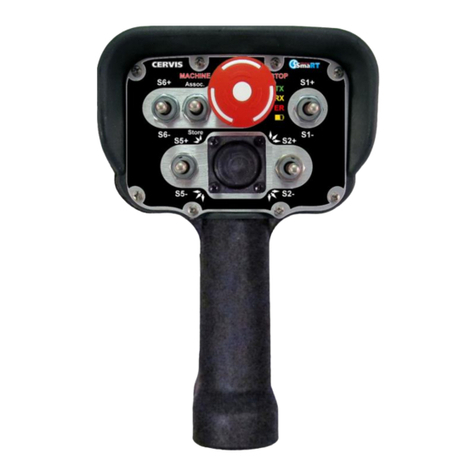

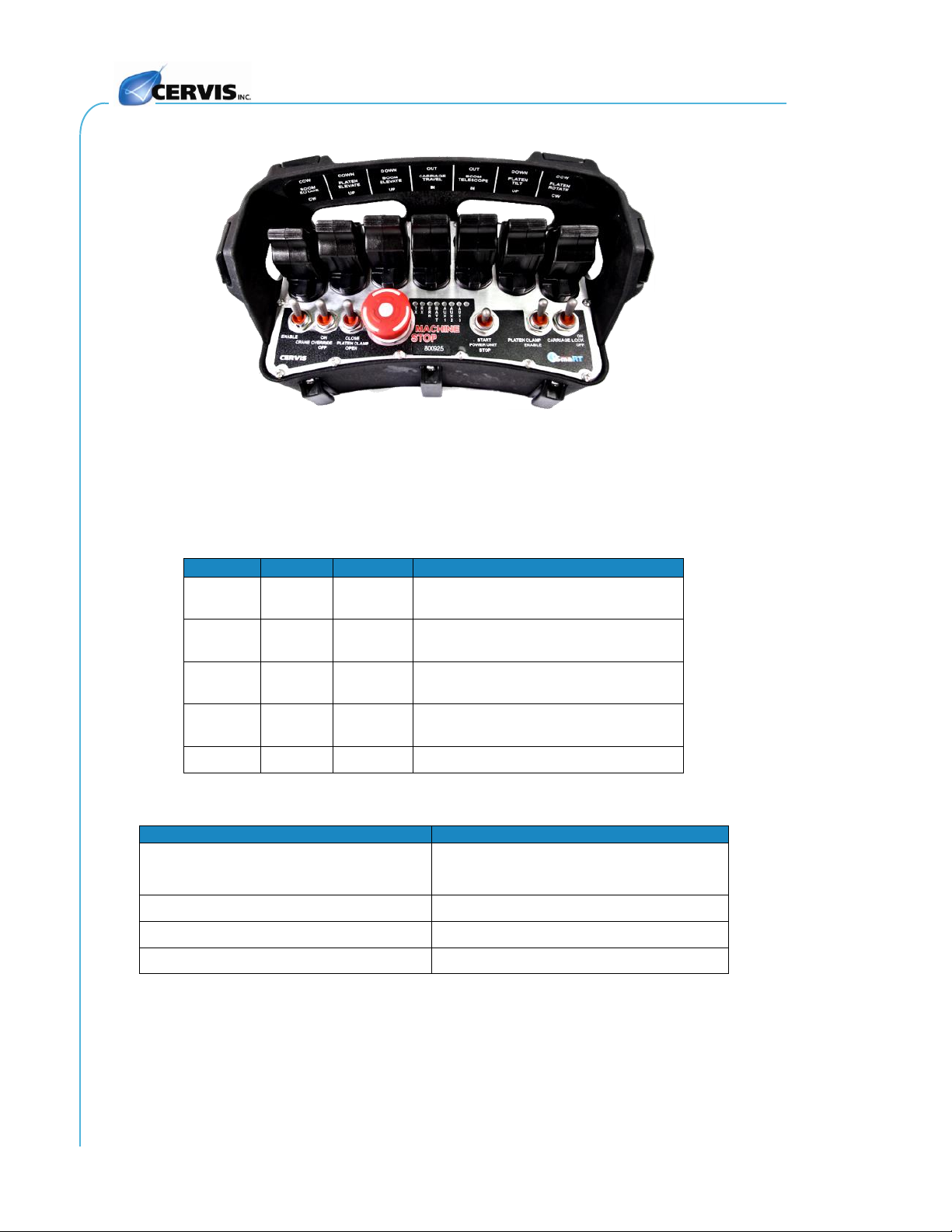

SmaRT Console Box Remote

Cervis, Inc. Safety Precautions

✓Read and follow all instructions.

✓Failure to abide by Safety Precautions may cause equipment failure, loss of authority

to operate the equipment, and personal injury.

✓Use and maintain proper wiring. Follow equipment manufacturer instructions.

Improper, loose, and frayed wiring can cause system failure, equipment damage, and

intermittent operation.

✓Changes or modifications made to equipment not expressly approved by the

manufacturer will void the warranty.

✓Equipment owner/operators must abide by all applicable Federal, State, and Local

laws concerning proper equipment installation and operation. Failure to comply could

result in penalties and could void user authority to operate the equipment.

✓Make sure that the machinery and surrounding area is clear before operating. Do not

activate the remote control system until certain that it is safe to do so.

✓Turn off the handheld remote and remove power from the base unit before attempting

any maintenance. This will prevent accidental operation of the controlled machinery.

✓Remove power from the base unit either by detaching the 12-pin cables from the

enclosure or by removing the source power from the base unit circuit.

✓Use a damp cloth to keep units clean. Remove mud, concrete, dirt, etc. after use to

prevent obstructing or clogging the buttons, levers, joysticks, wiring, and switches.

✓Do not allow liquid to enter the handheld or base unit enclosures. Do not use high-

pressure equipment to clean the handheld remote or base unit.

✓Disconnect the radio base unit before welding on the machine. Failure to disconnect

the base unit may cause destruction of or damage to the base unit.

✓Operate and store units only within the specified operation and storage temperatures

defined in this document’s specifications.

✓Keep high-energy radio frequency (RF) devices away from handheld remotes.

Activating high-power communication radios, for instance, in close proximity to

handheld remotes can cause interference and “false” circuit activation.

✓Do not key two-way radios while using the console box remote.

✓

Note: A SmaRT handheld remote’s operating frequency is in either the 2.4 GHz or 900 MHz

range. The first number in the system or device name indicates the operating frequency. For

instance, a SmaRT CB-xH (console box) handheld remote in this document may either be

CB-2H12LV or CB-9H12JS (or some variation of levers [LV] and joysticks [JS]), where “2”

indicates 2.4 GHz and “9”indicates 900 MHz operating frequency. As such, references to the

handheld remote, base unit, or system in this manual may use “x”rather than “2”or “9”in the

name to indicate the operating frequency.