6

FOREWORD

e programmable “Immergas” “System Manager Kit”

was designed to guarantee ideal temperature conditions

at any time of day and night, for every single day of the

week, using the most economically advantageous source

of energy based on the characteristics of the installed

components and environmental conditions.

e control possibilities are:

1. Direct system without mixed valves and without

dehumidiers with integration either through resist-

ances or boilers, and management of the solar system

with a layer.

2. System for up to 3 zones, with 3-point mixer, and

management of a high temperature zone with boiler

integration.

3. System with 2 mixed zones with 3-point mixer

including the aforementioned characteristics and 1

xed.

4. As in the aforementioned cases but with the pos-

sibility of managing the solar part on two layers and

a high temperature zone.

5. As in the aforementioned cases but with the possibil-

ity of managing a puer for the solar integration of

CH.

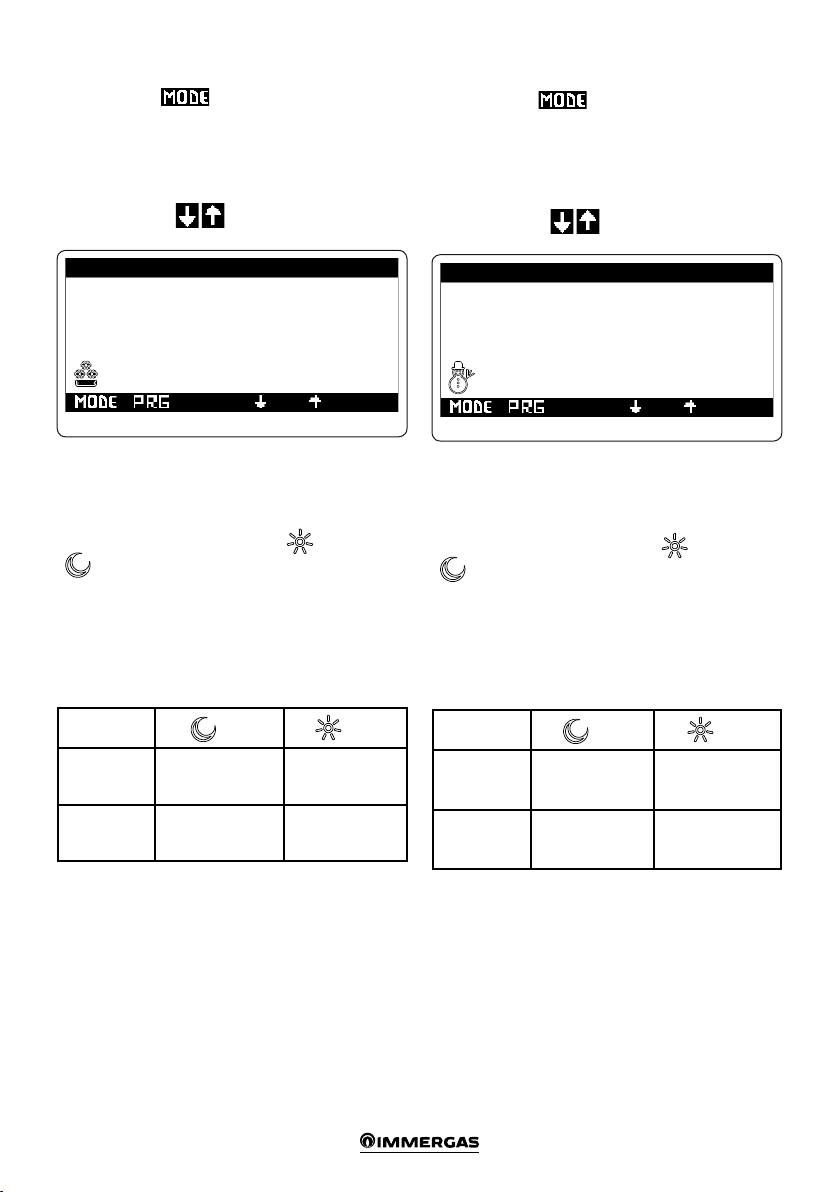

e customer can change the basic program according

to their requirements.

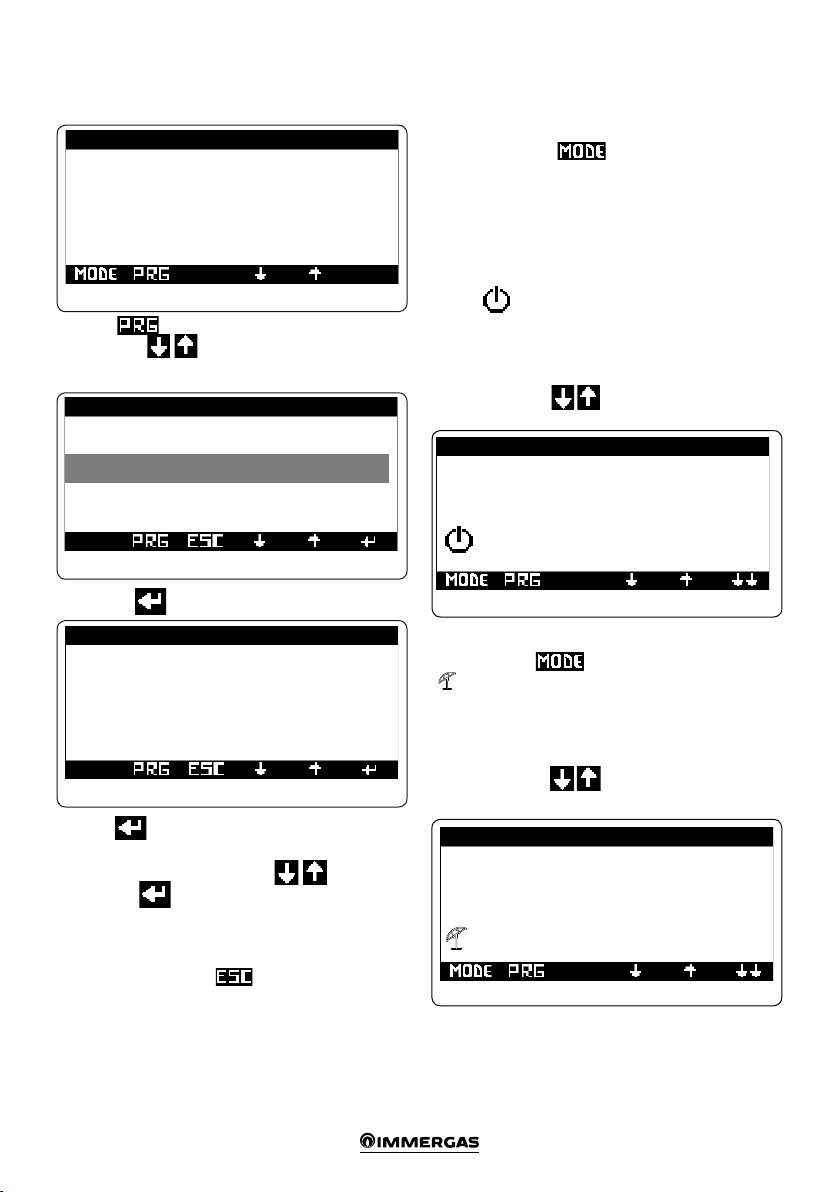

Programming the “System Manager Kit” is extremely

easy and a wide display screen allows you to constantly

control all set values.

GENERAL RECOMMENDATIONS

• Carefully read the warnings contained in this docu-

ment as they are required to indicate how to use the

“System Manager Kit” envisioned by the design, techni-

cal features, programming, adjustment and use.

• e system must be compliant with applicable IEC

Standards.

• e instruction manual must be considered a part of

the “System Manager Kit” and must be “kept for future

reference”.

• e “System Manager Kit” is intended only for the use

for which it has been expressly designed. Any other use

must be considered improper and therefore dangerous.

• Our products are produced in compliance with the

Safety Standards in force, it is therefore recommended

to use all devices or attentions in such a way that injury/

damage is not caused to persons or objects.

• Do not remove parts of the “System Manager Kit” when

it is operating.

• Do not use the “System Manager Kit” exposed to

sources of heat or under the scorching sun.

• In case the manager is switched-o, it is necessary to

also switch-o all devices connected to it (e.g. Heat

pump, expansions etc.).

• e manufacturer will not be held responsible in the

following cases:

a) Incorrect installation.

b) Malfunctions of the equipment to which the “System

manager kit” is applied.

c) Unauthorised changes or tampering.

d) Total or partial failure to comply with instructions.

e) Exceptional events etc.

N.B.: If an anomaly is detected on the external probe, the

system uses a xed temperature value of 6°C.

N.B.: All Room ermostat inputs, if they are not be-

ing used to request heating or cooling, can be used to

deactivate the zone of reference.

N.B.: When conguration is complete, restart the con-

trol zone by shutting o and turning the electric power

supply back on.

N.B.: Hook the heat pump up to the power supply only

once all necessary settings have been made.

CASE CLEANING

To clean the case of “System Manager Kit” use damp

cloths. Never use abrasive or powder detergents.

WARNING

Immergas reserves the right to make improvements and

changes to details and accessories, excepting the essential

features of the model described and illustrated herein.